Main shaft assembly and photovoltaic tracking support adopting same

A component and spindle technology, applied in the field of solar energy facilities, can solve the problems of increased material and manual installation costs, increased hoop cost, weak structural strength, etc., and achieves the effect of safe and reliable structural design, simplified structure, and light overall weight.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] In order to make the technical problems, technical solutions and beneficial effects solved by the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

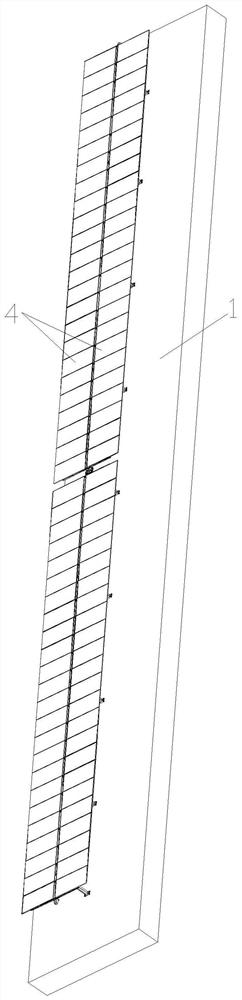

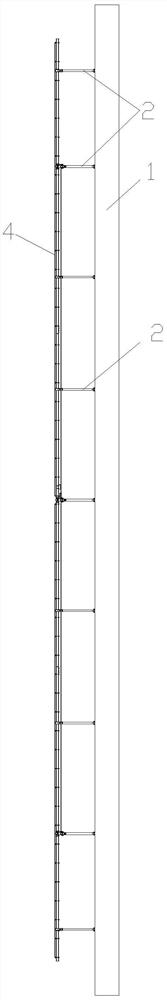

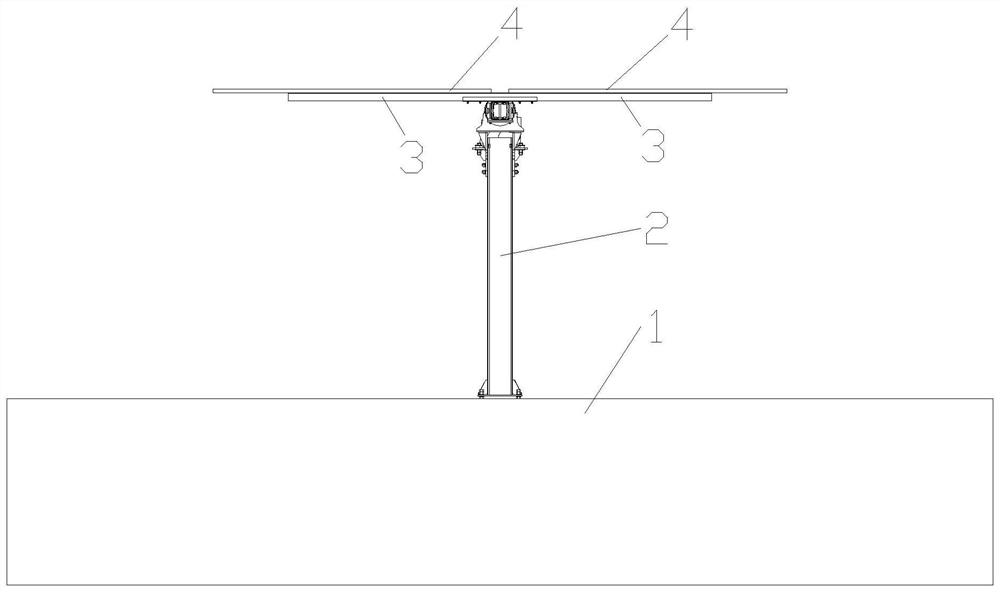

[0040] See Figure 1-19 , a spindle assembly of the present invention has several large rounded square tubes 18, each large rounded square tube 18 includes a straight tube section 181 and a shrink tube section 182 integrally formed at one end of the straight tube section 181, two adjacent large rounded square tubes The pipes 18 are inserted into the straight pipe section 181 of another large rounded square pipe 18 through the shrinkage section 182 of one of the large rounded square pipes 18, and the connection area between two adjacent large rounded square pipes 18 is op...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com