Hydraulic low-frequency-absorption vibration isolator

A vibration isolator, hydraulic technology, applied in the direction of shock absorber, shock absorber-spring combination, shock absorber, etc., can solve the problems of insufficient bearing capacity, inability to realize broadband of mechanical vibration and double vibration isolation of line spectrum, etc. Achieve the effect of easy bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

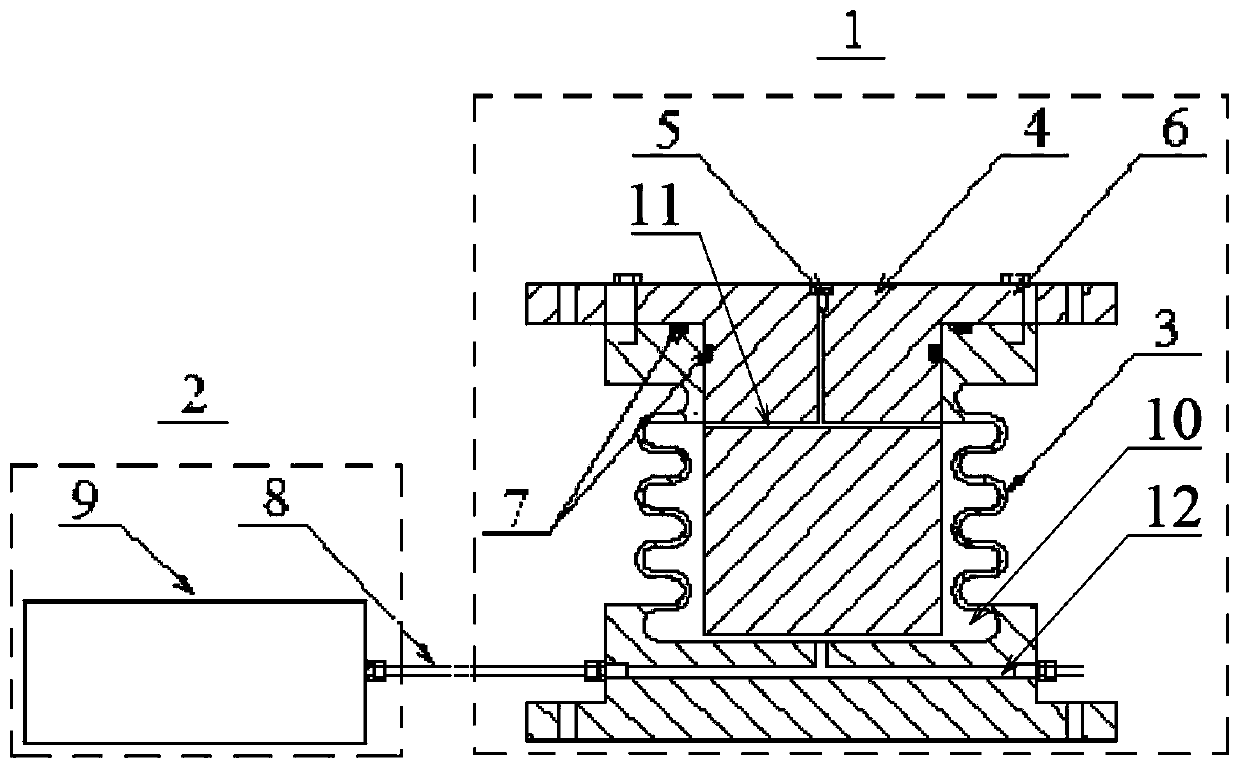

[0031] Such as figure 1 As shown, the hydraulic low-frequency vibration isolator of this embodiment includes a hydraulic vibration isolator 1 and a hydraulic vibration absorber 2 .

[0032]The hydraulic vibration isolator 1 is composed of a bellows elastic oil tank 3 and a top cover 4 . Preferably, the circumferential surface of the bellows elastic oil tank 3 in this embodiment is a three-layer metal bellows structure, which can provide better elasticity in the vertical direction. The metal bellows structure and the base enclose the oil chamber 10 . A through hole is opened in the center of the base of the bellows elastic oil tank 3 , two through holes are opened in the circumferential direction, and the three through holes are connected internally to form a three-way channel as the hydraulic oil channel 12 . Among them, one through hole in the circumferential direction of the base is used as the connection interface of the hydraulic vibration absorber 2, and the other throu...

Embodiment 2

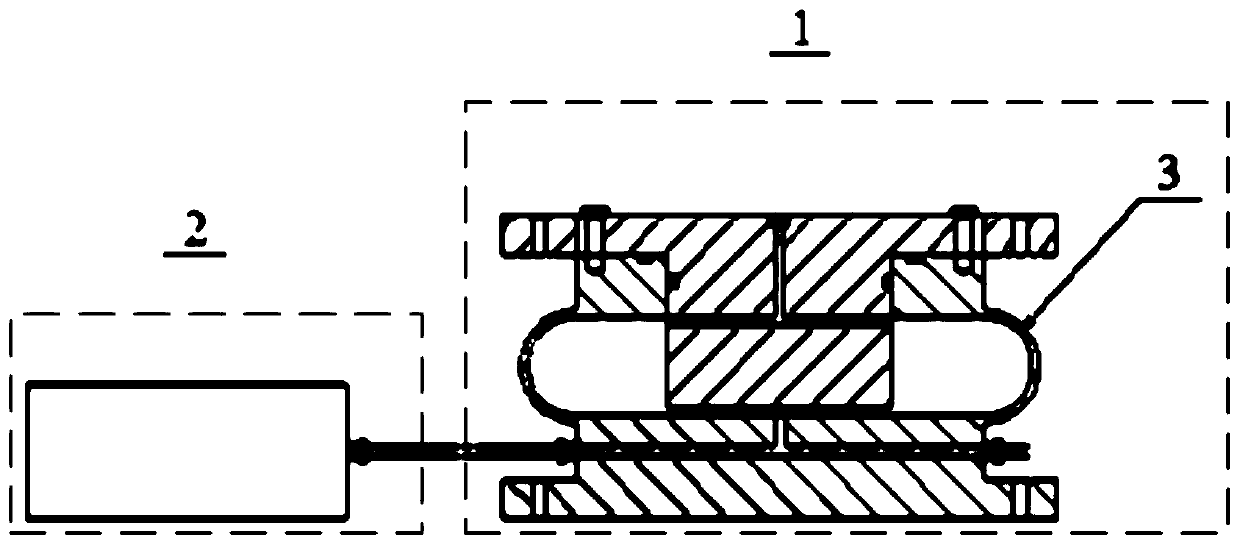

[0041] Such as figure 1 As shown, the difference between the hydraulic low-frequency vibration isolator of this embodiment and the structure described in Embodiment 1 is that the bellows elastic oil tank 3 is changed to a single bellows structure, and other structures are basically the same, and only need to be adapted. The elasticity of single bellows is not as good as that of three bellows, but the manufacturing process is relatively simple, and it is suitable for application in light-load vibration isolation scenarios.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com