Piston cooling device and cylinder liner

A cooling device and cylinder liner technology, applied in the field of cylinder liners, can solve the problems of long spray distance and unfavorable cooling system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Embodiments of the present invention will now be described in more detail with reference to the accompanying drawings.

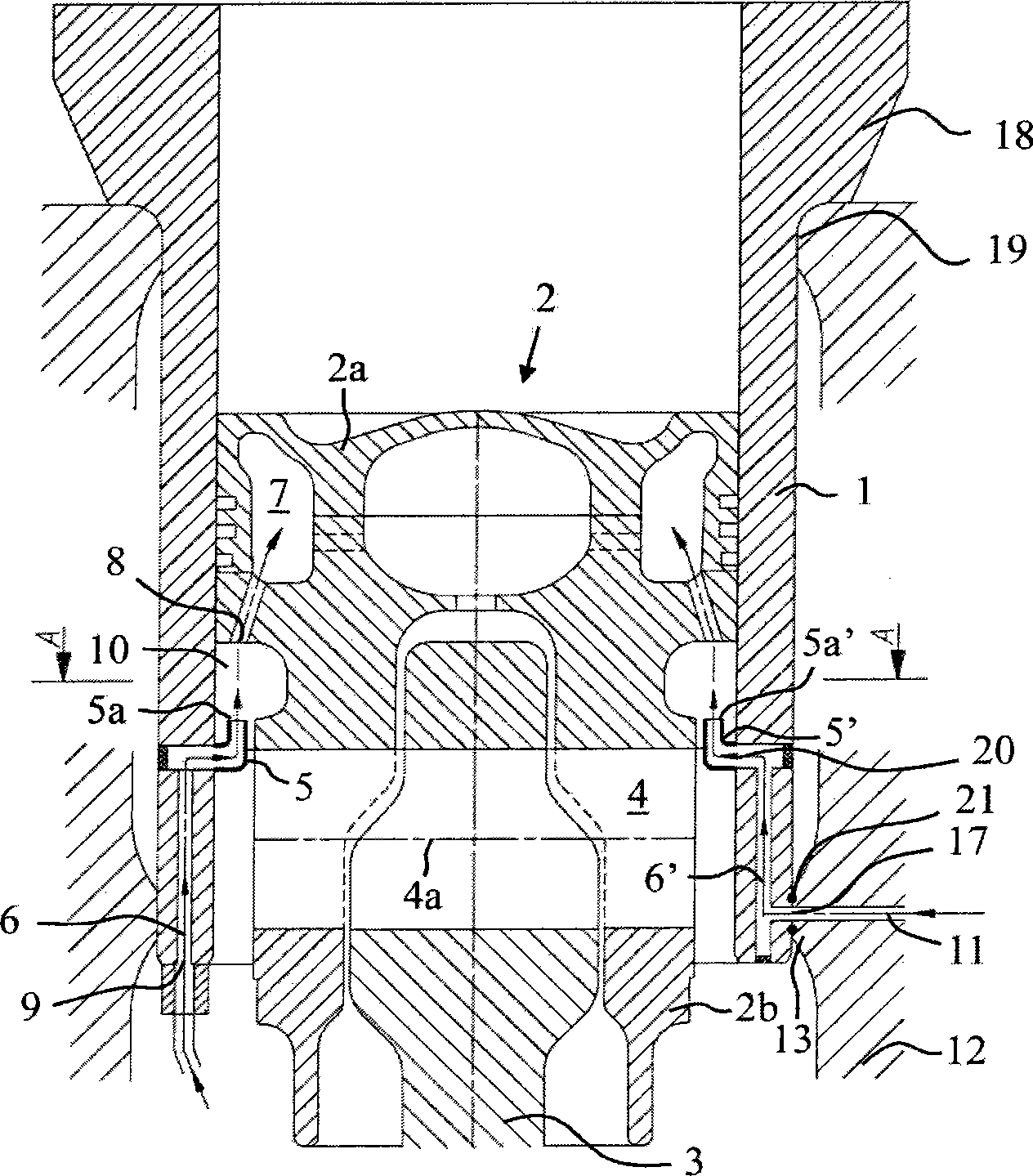

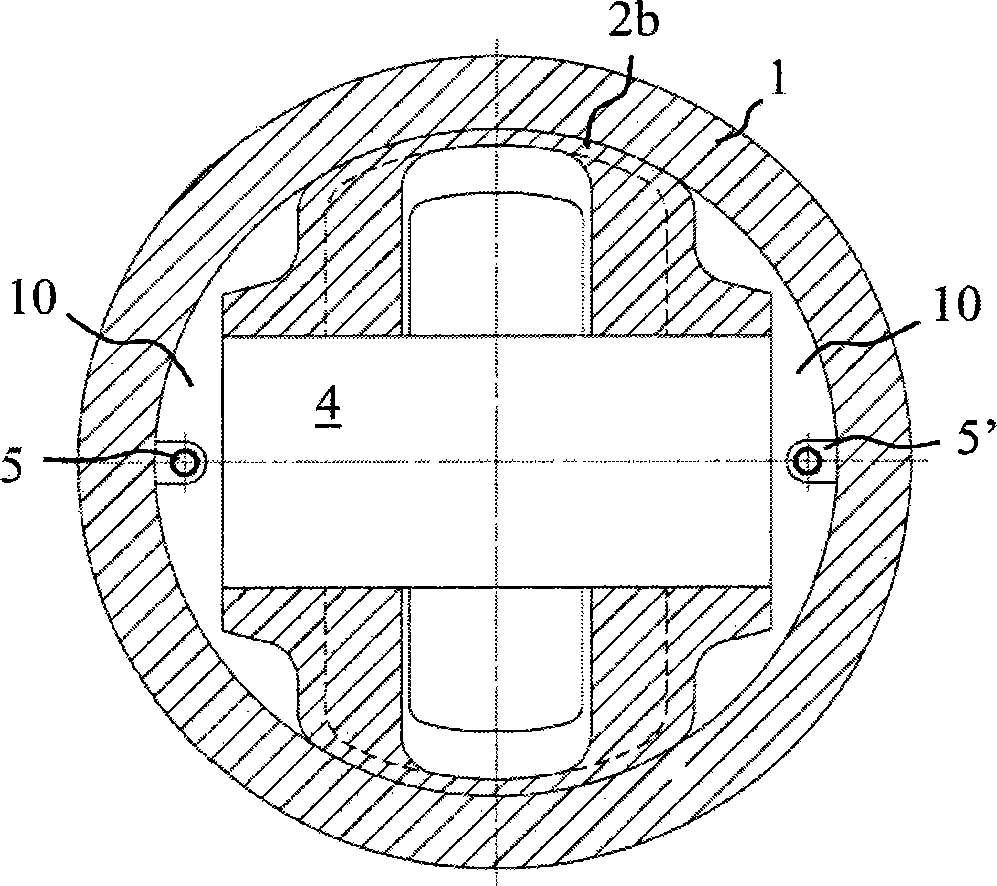

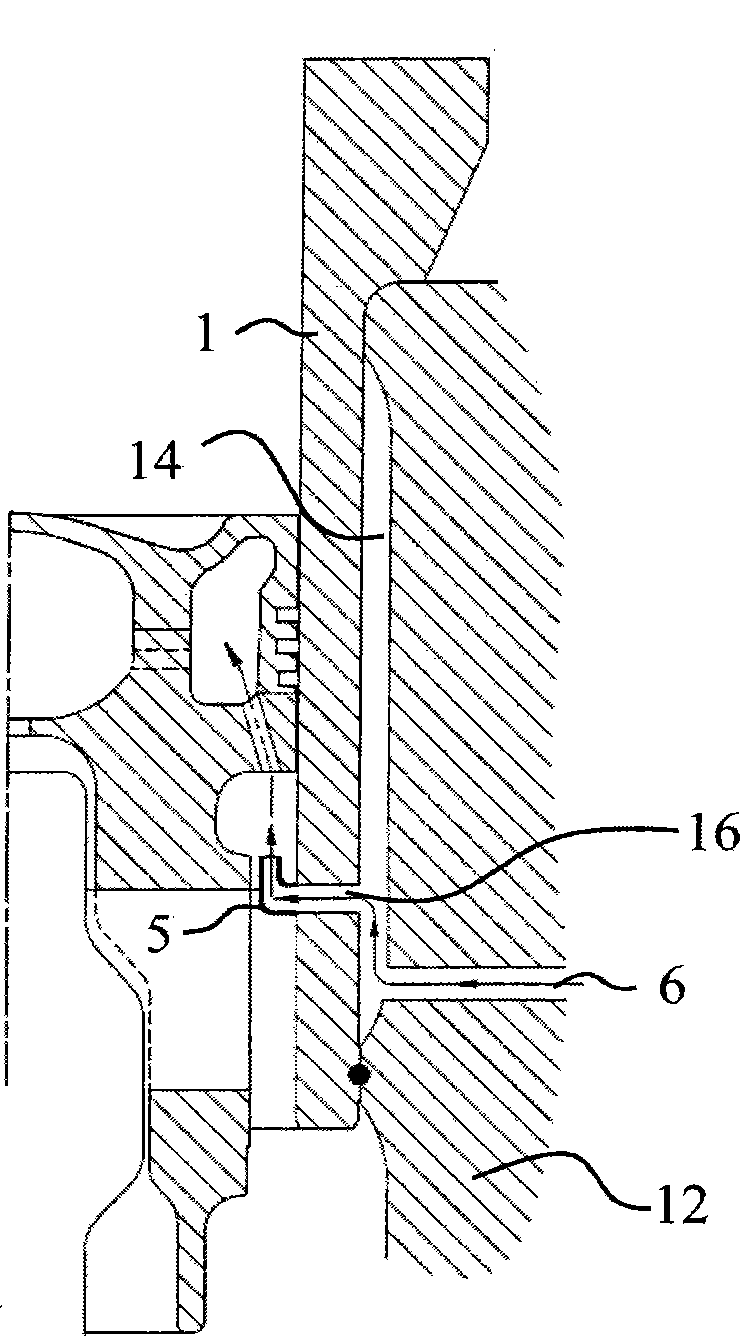

[0020] figure 1 A cooling device for a reciprocating piston 2 of an internal combustion engine according to an embodiment of the invention is shown in . figure 1 , piston 2 is at bottom dead center. Engines using piston cooling are large medium or high speed internal combustion engines. The engine can be used, for example, as the main or auxiliary engine in a boat or in a power plant for generating electric power. The engine may have any reasonable number of cylinders, which may, for example, be arranged in an inline or V configuration. Each cylinder of the engine is provided with a cylinder liner 1 . The cylinder liner 1 is arranged in an engine block 12 . The upper end of the cylinder liner 1 is provided with a collar 1 which leans against the upper surface of the engine block 12 . The engine block 12 includes a protrusion 19 extending towards...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com