Shelf for dish-washing machine and dish-washing machine

A technology for dishwashers and racks, which is applied in the field of home appliances, can solve the problems of insufficient washing force, long spray distance, and inability to achieve enhanced washing, and achieve the effect of increasing the impact force of water flow, reducing spray distance, and remarkable washing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

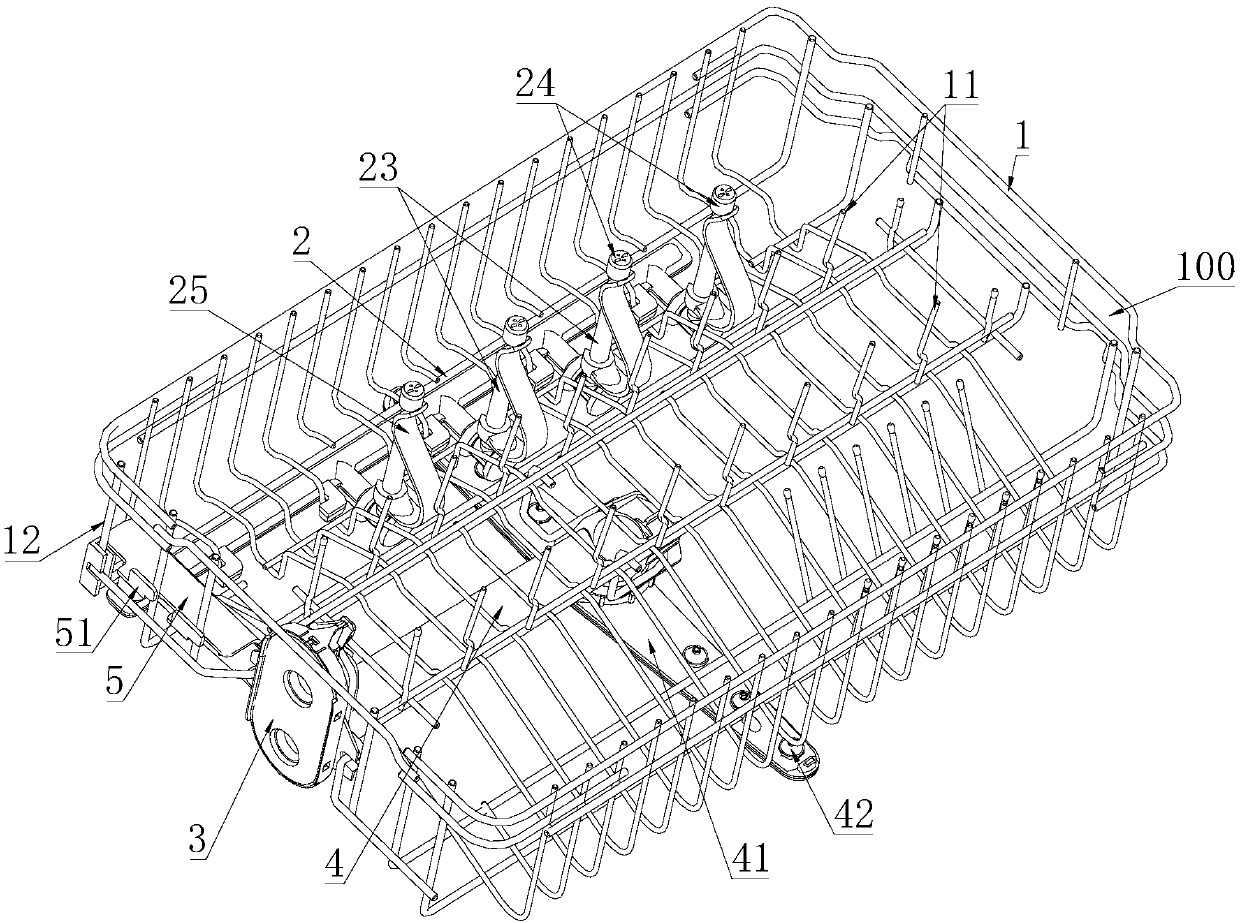

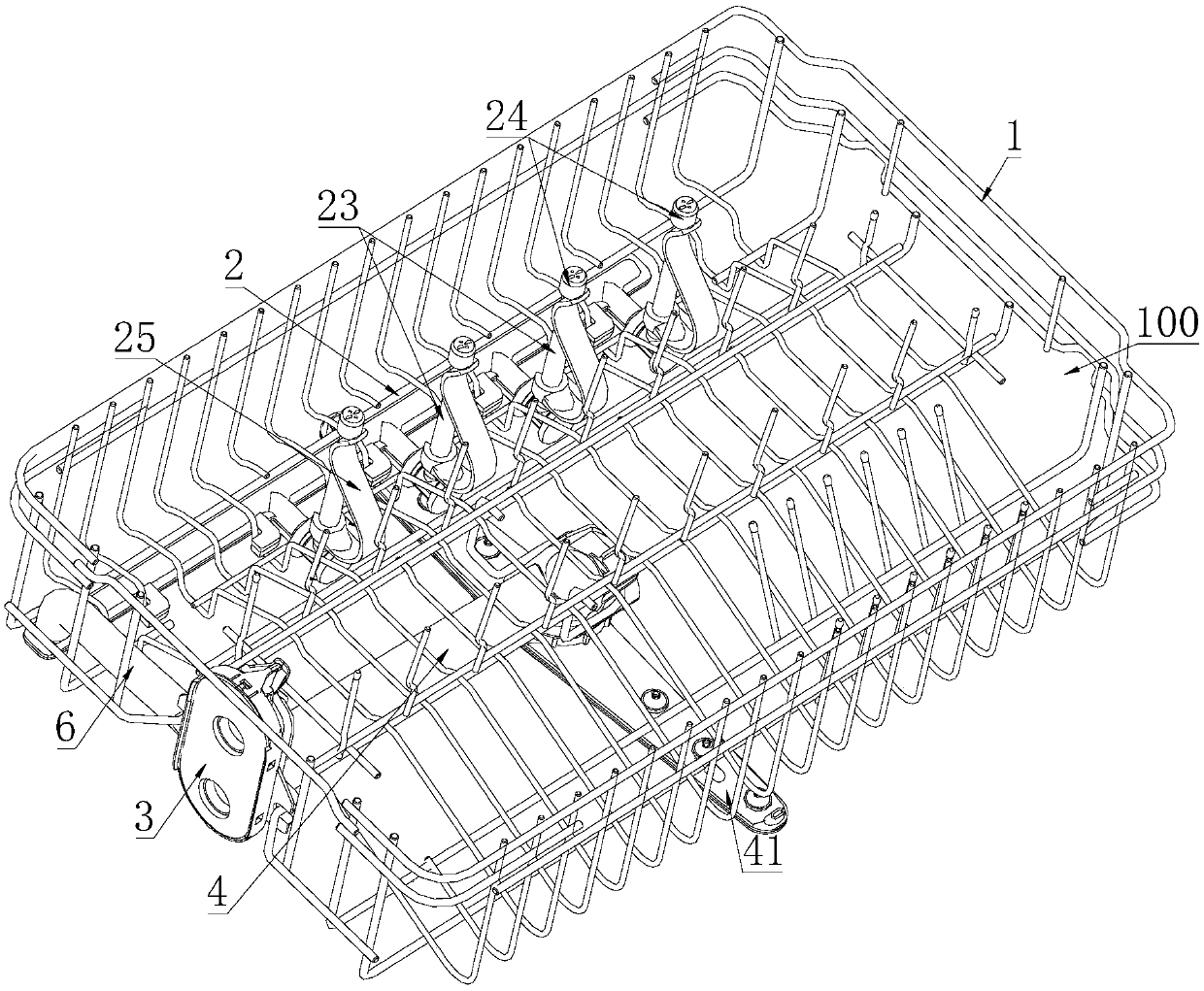

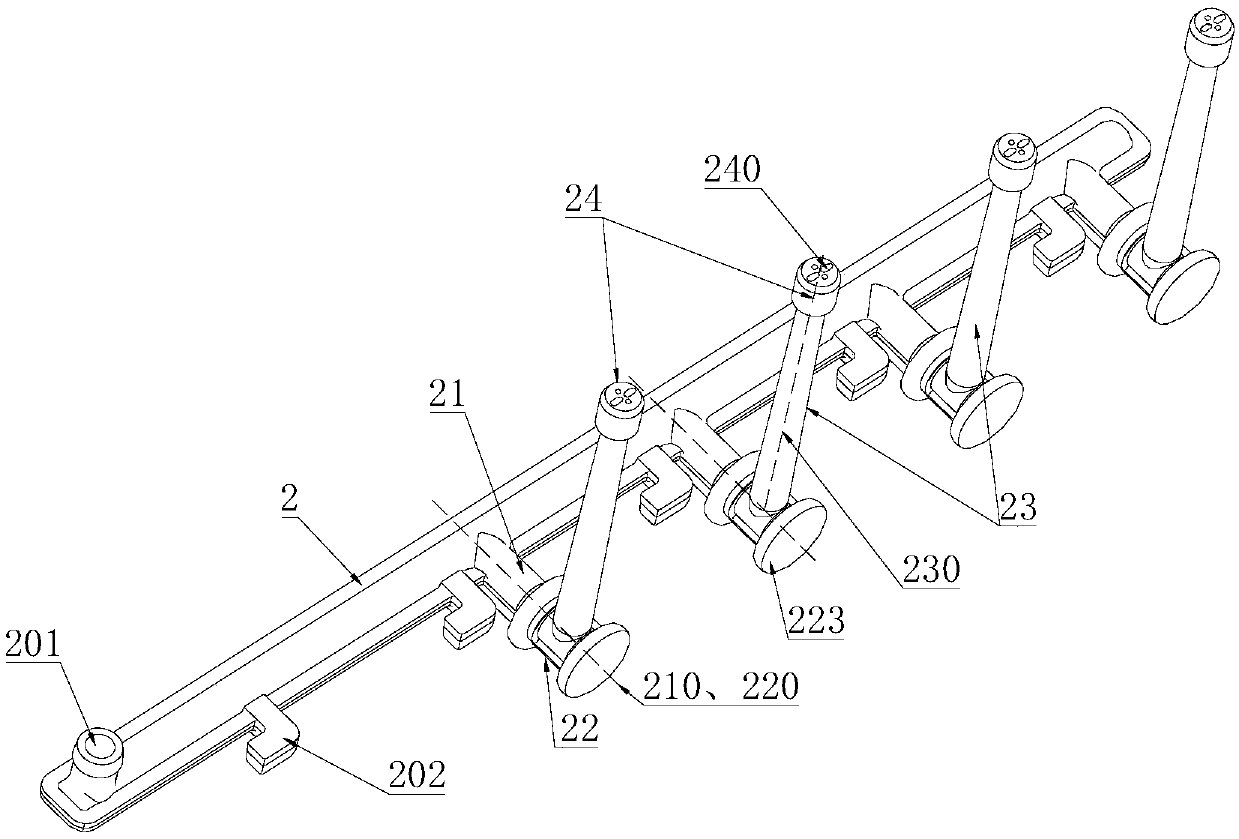

[0035] Such as Figure 1 to Figure 4 As shown, the shelf 1 described in this embodiment includes a conduit 2 for introducing washing liquid into the washing chamber 100. At least one spray pipe 23 is provided on the conduit 2, and a nozzle 24 is provided at the top of the spray pipe 23. , The nozzle 24 is provided with a plurality of spray holes 240 to spray the washing liquid to wash the tableware.

[0036]In this embodiment, the conduit 2 is provided with a joint 21, the axis of the joint 21 is perpendicular to the extension direction of the conduit 2, the connecting end 232 of the spray pipe 23 is connected to the outlet of the joint 21 through the rotating member 22, and the conduit 2 is connected to the axis of the joint. 210 all extend along the horizontal direction, and the axis 230 of the spray pipe is perpendicular to the axis 210 of the joint.

[0037] In this embodiment, the spray pipe 23 is provided with a connection end 232 and a water spray end 233, and the wate...

Embodiment 2

[0048] Such as Figure 3 to Figure 4 As shown, a rotating member 22 is provided between the conduit 2 and the shower pipe 23 in this embodiment, and the rotating member 22 can rotate relative to the spray pipe 23 and / or the conduit 2 to utilize the rotation of the rotating member 22 The communication between the shower pipe 23 and the conduit 2 is switched on and off.

[0049] In this embodiment, the conduit 2 is connected to the spray pipe 23 through the rotating part 22, so as to use the washing liquid to spray and wash the tableware; Rotate to use the rotation of the rotating member 22 to switch the connection between the spray pipe 23 and the conduit 2, so that the user can choose the number of washing spray pipes 23 according to actual needs and save water resources. The spray pipe 23 It can rotate around the axis 220 of the rotating member to perform intensive washing on different parts of the tableware.

[0050] In this embodiment, the rotating member 22 includes a gr...

Embodiment 3

[0057] Such as Figures 1 to 2 As shown, the shelf 1 described in this embodiment is composed of multiple elongated ribs 12 , and the bottom wall and side walls of the shelf 1 form a washing chamber 100 .

[0058] In this embodiment, the conduit 2 extends along the bottom wall of the shelf 1, and the spray pipe 23 extends from the bottom wall of the shelf 1 into the washing chamber 100, so as to penetrate into the deep washing tableware for washing. , can also provide support for other tableware.

[0059] In this embodiment, the shelf 1 is suitable for various dishwashers, and the shelf 1 can be the upper shelf, the lower shelf or the third shelf of the dishwasher; the bottom wall of the shelf 1 and the A side wall perpendicular to the bottom wall forms a washing chamber 100 , and tableware for washing can be placed or positioned in the washing chamber 100 of the rack 1 .

[0060] In this embodiment, the shelf 1 also includes a plurality of fixed teeth 11. During the washing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com