Air supply throwing fog dust suppression machine

A technology for fans and racks, applied in the field of environmental protection equipment, can solve the problems of large loss of wind energy in the guide tube, small dust coverage area, and consumption of high-pressure water, etc., and achieve the effects of improving dust reduction efficiency, saving water, and reducing wind energy loss.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

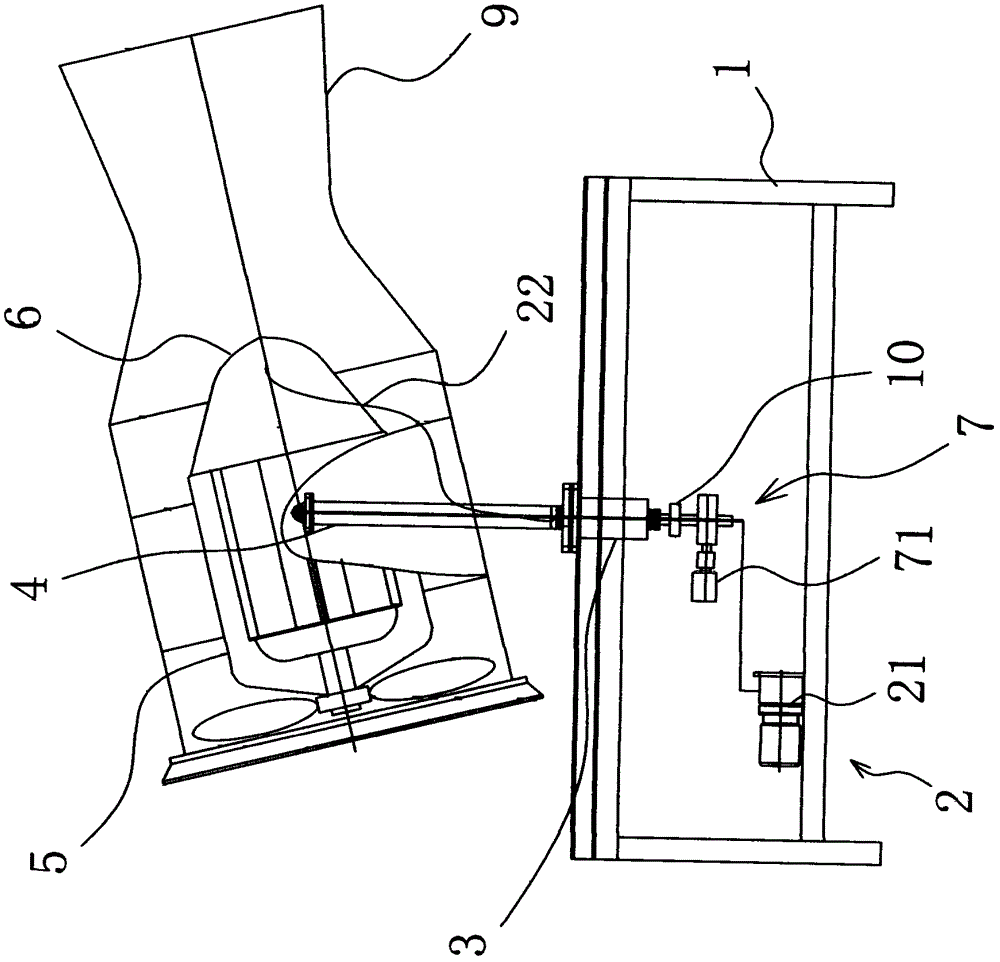

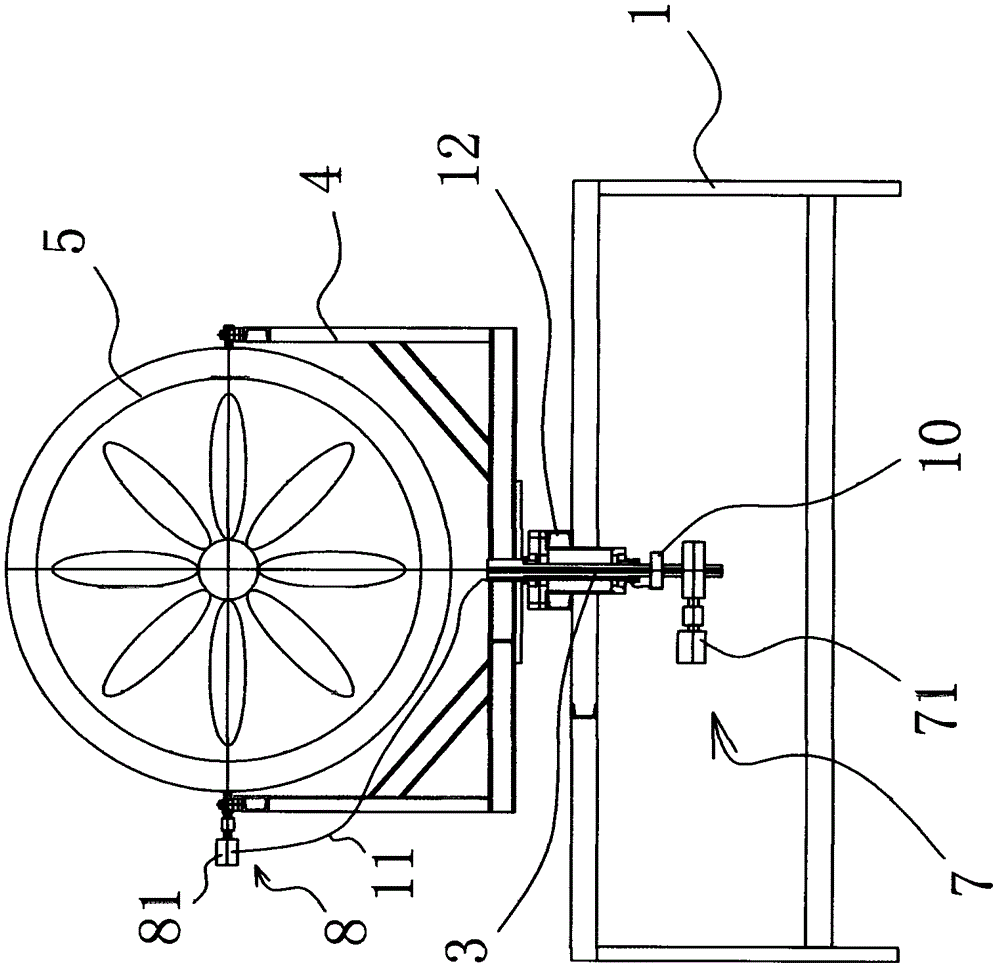

[0020] Such as Figure 1-2 As shown, the air supply, throwing, fogging and dust suppressing machine includes a frame 1, on which a water supply mechanism 2 and a hollow support shaft 3 are arranged, a support frame 4 is provided on the support shaft 3 upper end, and on the support frame 4 A fan 5 is connected, an atomizing nozzle 6 is arranged at the front end of the fan 5, the water supply mechanism 2 is connected with the atomizing nozzle 6, and the frame 1 is provided with a driving mechanism 7 capable of driving the supporting frame 4 to rotate axially along the supporting shaft 3, The support frame 4 is provided with an adjustment mechanism 8 capable of adjusting the pitch angle of the blower fan 5. At the front end of the atomizing nozzle 6, there are guide tubes 9 whose ends are gradually widened relative to the middle. The guide tube 9 and the fan 5 connect. The guide tube 9 adopts a structure with both ends gradually wider than the middle, and fully utilizes the prin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com