PDC drill bit

A drill bit and bit body technology, applied in the direction of drill bits, drilling equipment, earthwork drilling and mining, etc., can solve the problems of thermal wear and cutting teeth can not be satisfied at the same time, to reduce adhesion, good auxiliary damage effect, increase concentration The effect of the spray effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

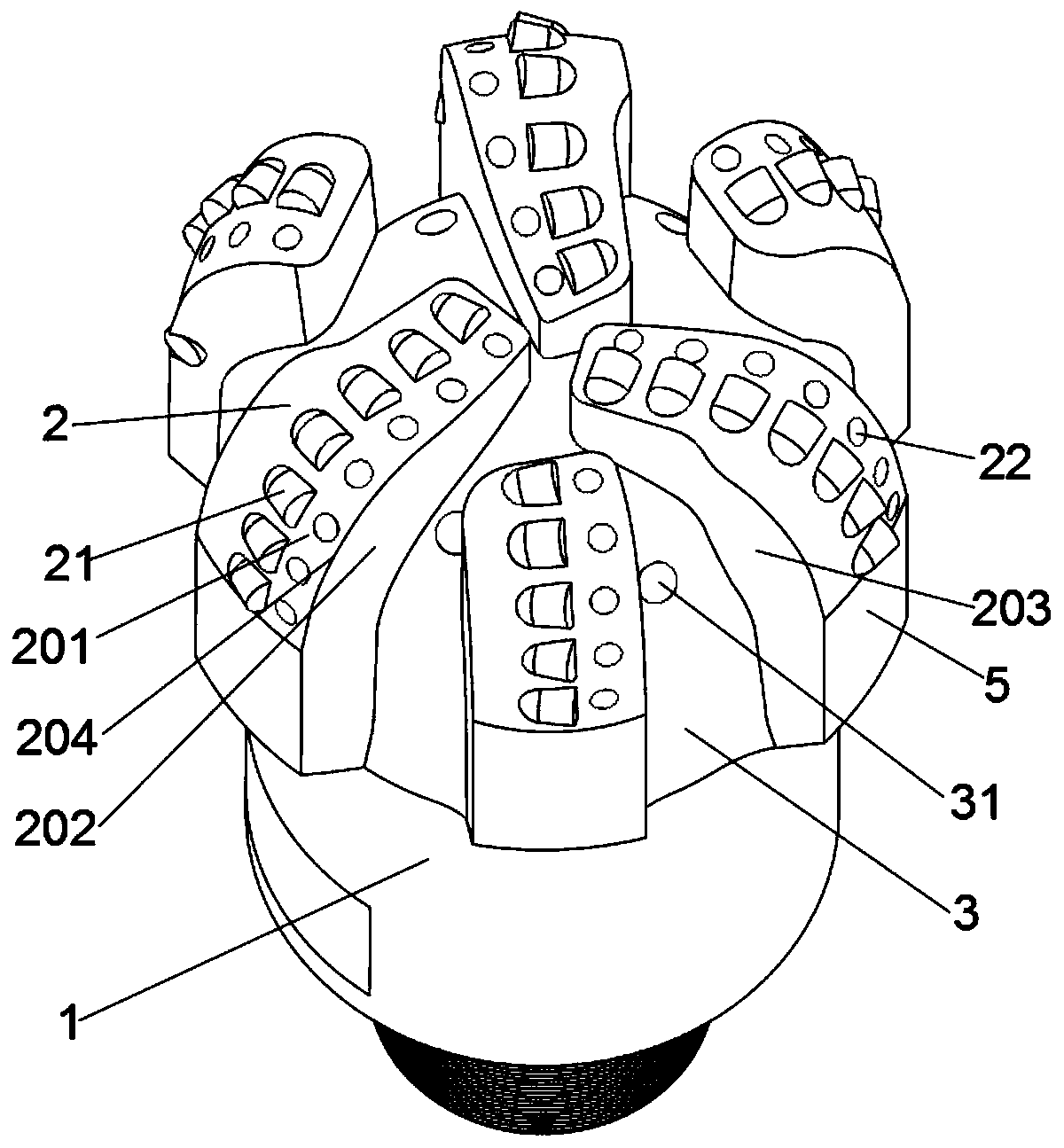

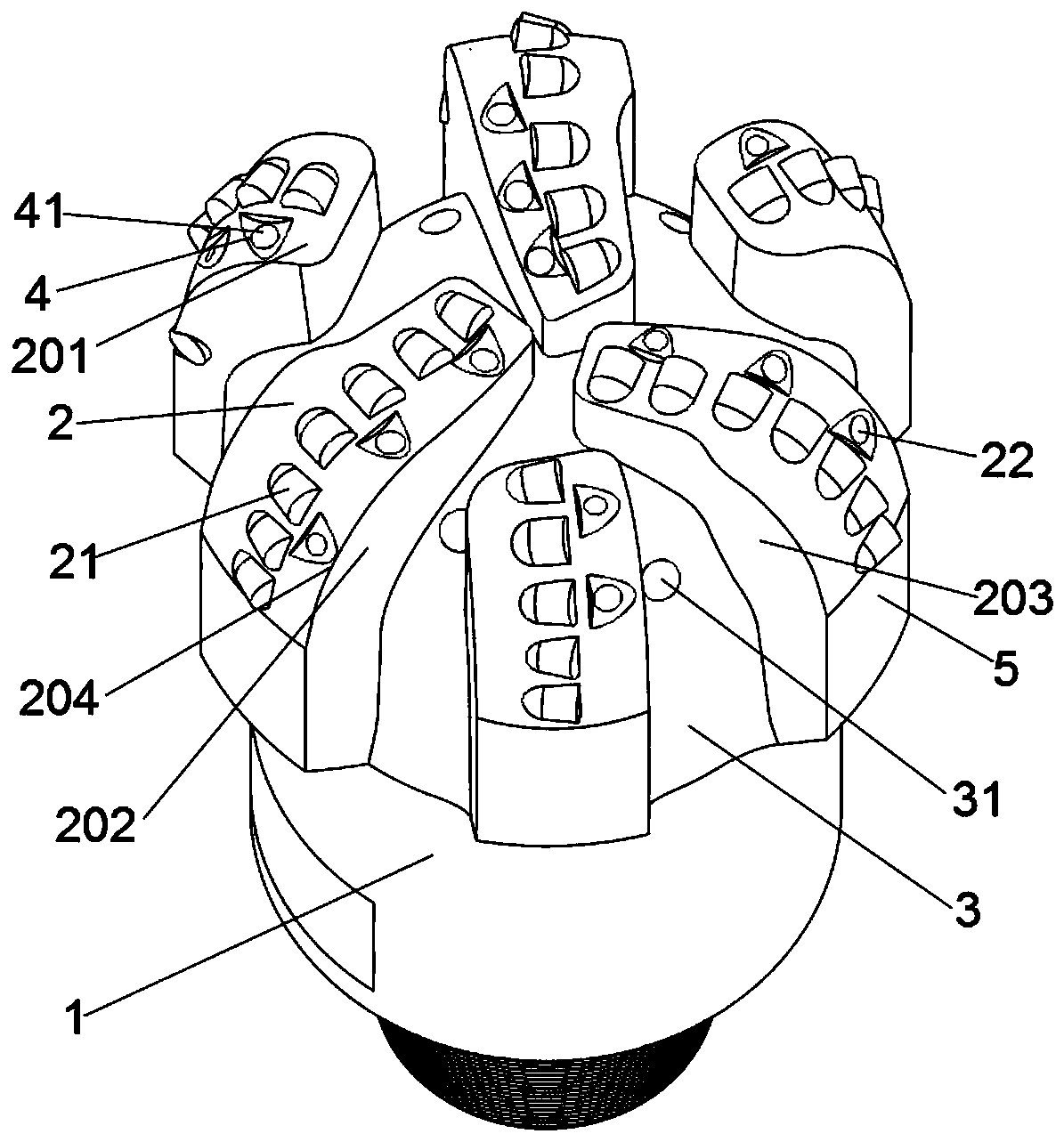

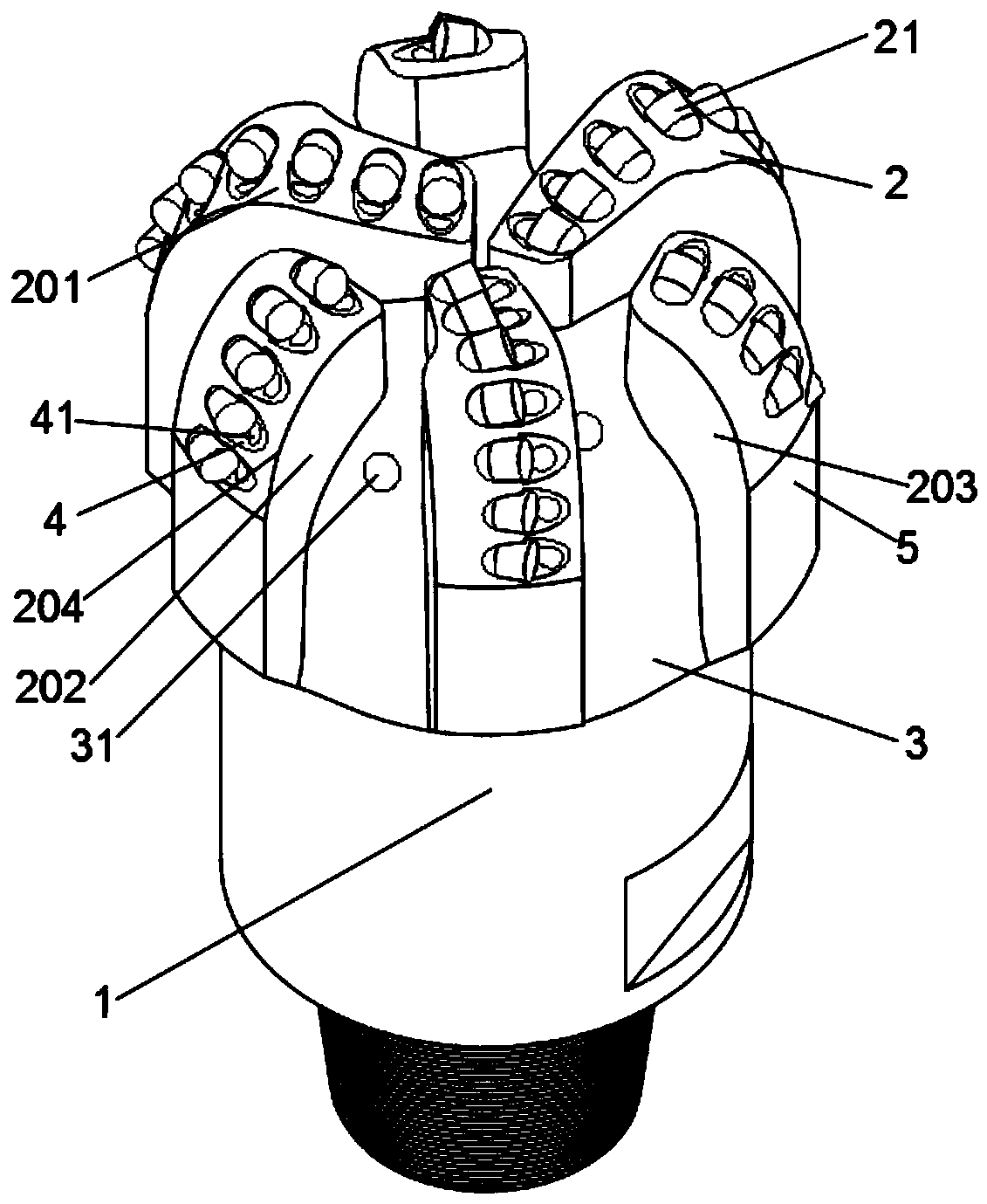

[0035] Such as figure 1 As shown, a PDC drill bit includes a drill body 1, several blades 2 extending from the drill body 1 or fixed on the drill body 1, the blades 2 are provided with cutting teeth 21, and the adjacent blades 2 Drilling fluid channel grooves 3 are formed between them; at least one blade 2 of the drill body 1 is provided with a water hole, and the outlet of at least one of the water holes is located between the leading edge 204 of the blade and the front row of cutting teeth.

[0036] Front row cutting teeth: In the direction of drill bit rotation, the front cutting teeth on the same blade are the front row cutting teeth, which are also the first teeth that the drill bit touches the rock for cutting during the working process.

[0037] Blade leading edge 204: Usually, for a blade, the intersection area between the blade tooth surface 201 of the blade 2 and the front side is called the blade leading edge 204, such as figure 1 shown. The cloth tooth surface 20...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com