Flotation machine hollow shaft dredger

A dredge and flotation machine technology, applied in the field of flotation machines, can solve problems such as affecting the stable production of workshops and affecting the operation rate of equipment, and achieve the effects of improving dredging efficiency, improving dredging effect, and increasing dredging range.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

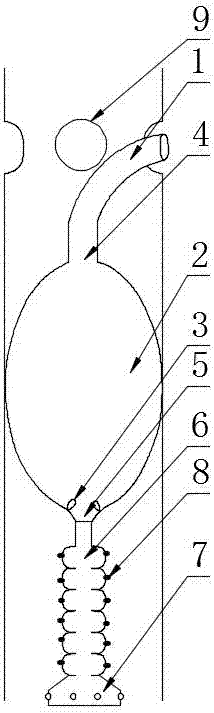

[0023] A hollow shaft dredge of a flotation machine includes a rubber hose 1, an expansion rubber bag 2, a rubber valve 3, and a flushing mechanism. The expansion rubber bag 2 is provided with a fluid inlet 4 and a fluid outlet 5 respectively, and the rubber hose 1 Connected to the fluid inlet 4, the flushing mechanism is connected to the fluid outlet 5. The inner diameter of the expanded rubber bladder 2 when it is not inflated is preferably the same as the inner diameter of the rubber hose 1, so that it can be quickly inserted into the hollow shaft 9; the rubber valve 3 It is arranged in the expanded rubber bladder 2 and the rubber valve 3 is located above the fluid outlet 5. The scouring mechanism includes a scouring tube 6 and a spray head 7. The scouring tube 6 is provided with a plurality of spray holes 8. One end of the scouring tube 6 is connected to the fluid outlet 5, and the other end is connected to the spray head 7. Further, the scouring tube 6 is a telescopic tele...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com