Rotary drilling rig bit capable of impact drilling

A technology for rotary drilling rigs and drill bits, which is applied in the direction of drill bits, drill pipes, drill pipes, etc., and can solve the problems of single function, low operating efficiency, and poor applicability of DTH hammers, and achieve simple structure, improved operating efficiency, and improved efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described in detail below in conjunction with specific embodiments, which are explanations of the present invention rather than limitations.

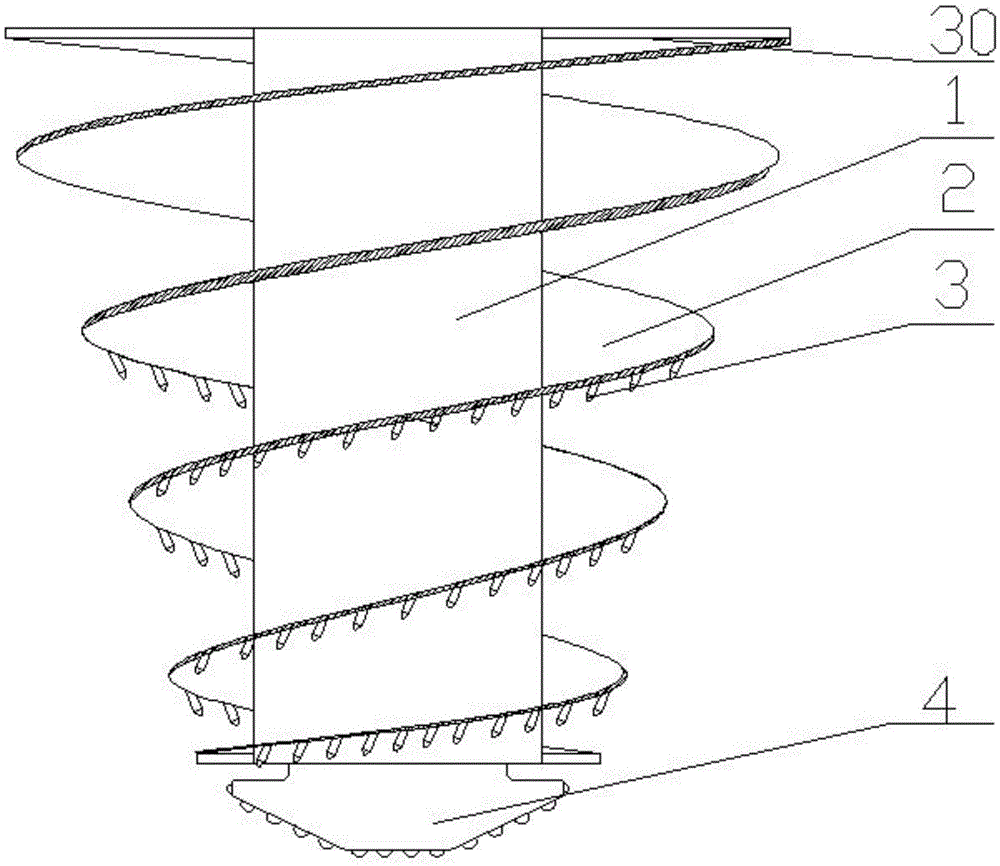

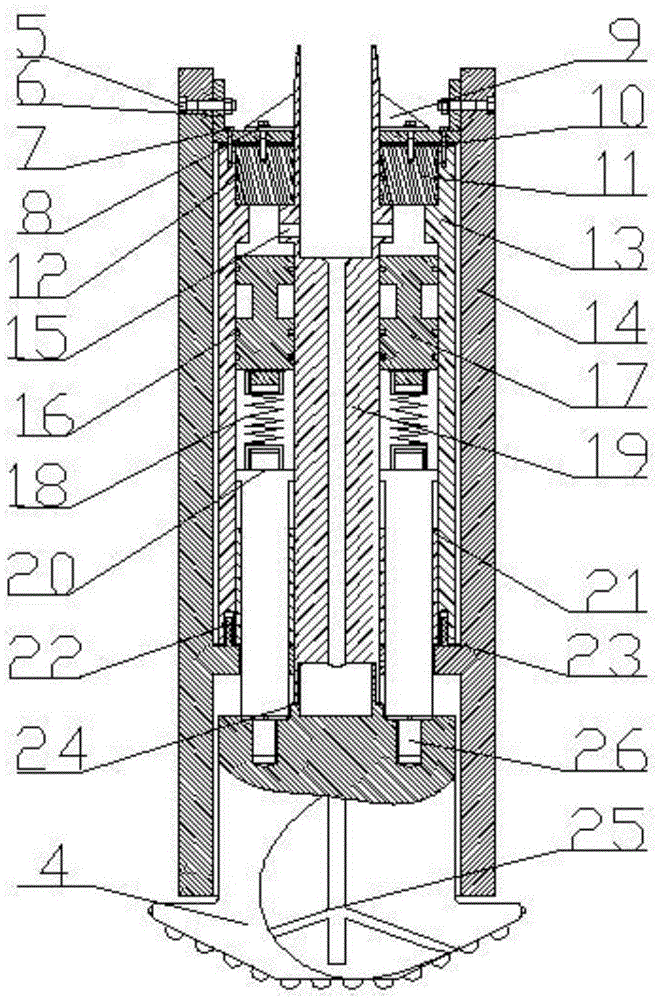

[0024] A kind of impactable rotary drilling rig drill bit of the present invention, as figure 1 As shown, it includes a flange 30 for connecting the machine body, and a drill pipe 1 arranged on the flange 30, a double helical blade 2 arranged on the outside of the drill pipe 1, and a submersible protruding from the head of the drill pipe 1. A hole hammer 4; a number of bullet picks 3 are arranged on the edge of the double helix blade 2. Preferably, the bullet pick 3 is made of cemented carbide.

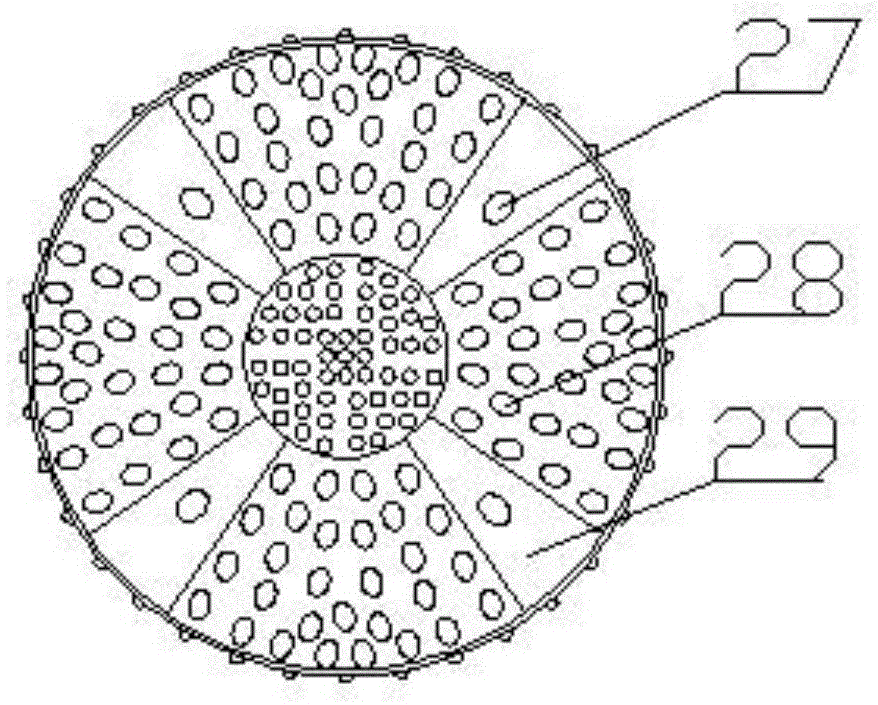

[0025] Such as image 3 As shown, a spherical hammer body 28 and a groove 29 are arranged at intervals on the end face of the hammer head of the down-the-hole hammer 4 , and an air outlet 27 is arranged in the groove 29 . Preferably, the hammer head end of the down-the-hole hammer 4 is arranged as...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com