Combined bit

A composite drill bit and cutter head technology, applied in drill bits, drilling equipment, earthwork drilling and other directions, can solve problems such as affecting the construction quality of underground diaphragm walls, unstable drilling quality, blade wear and tear, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

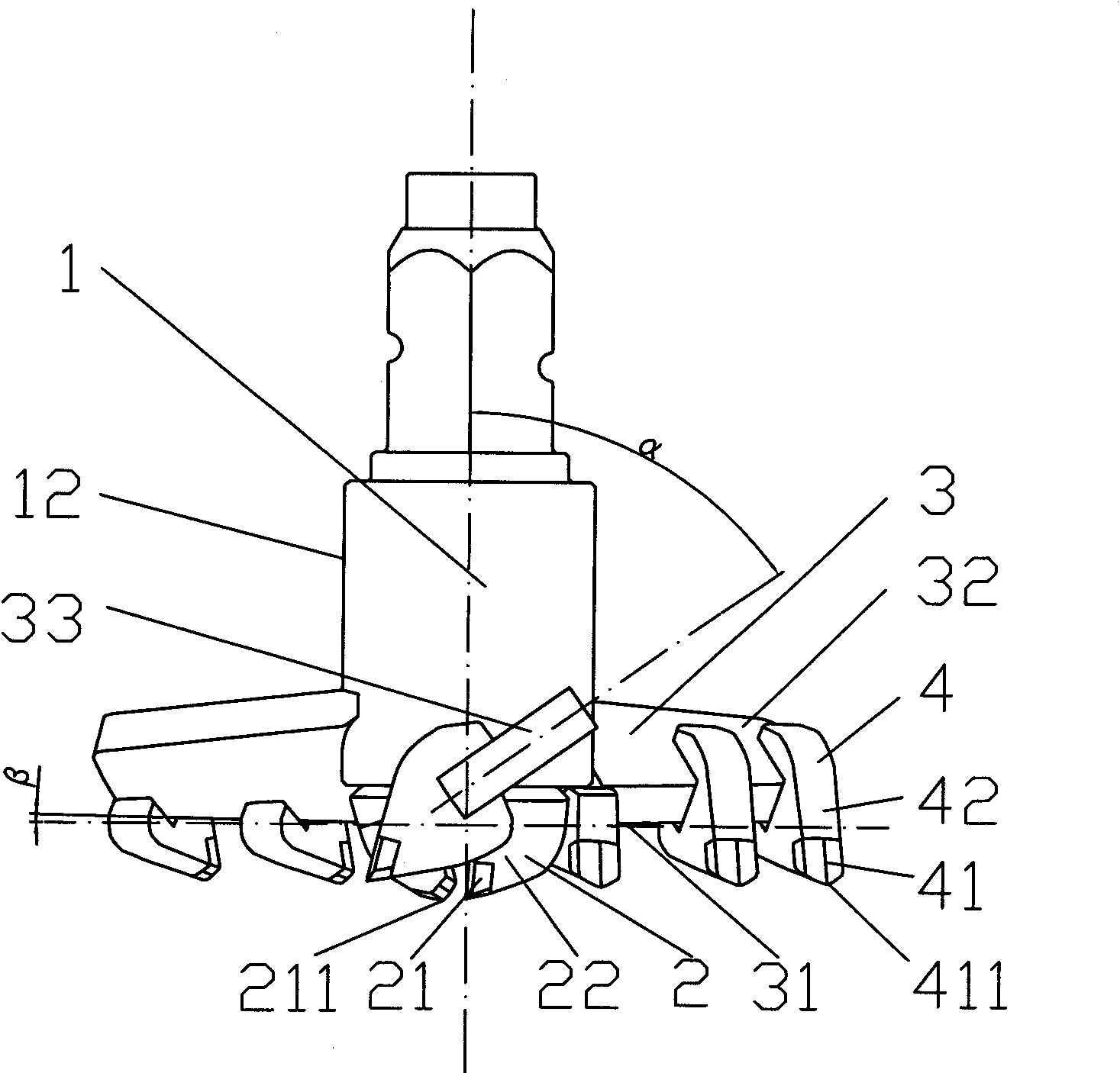

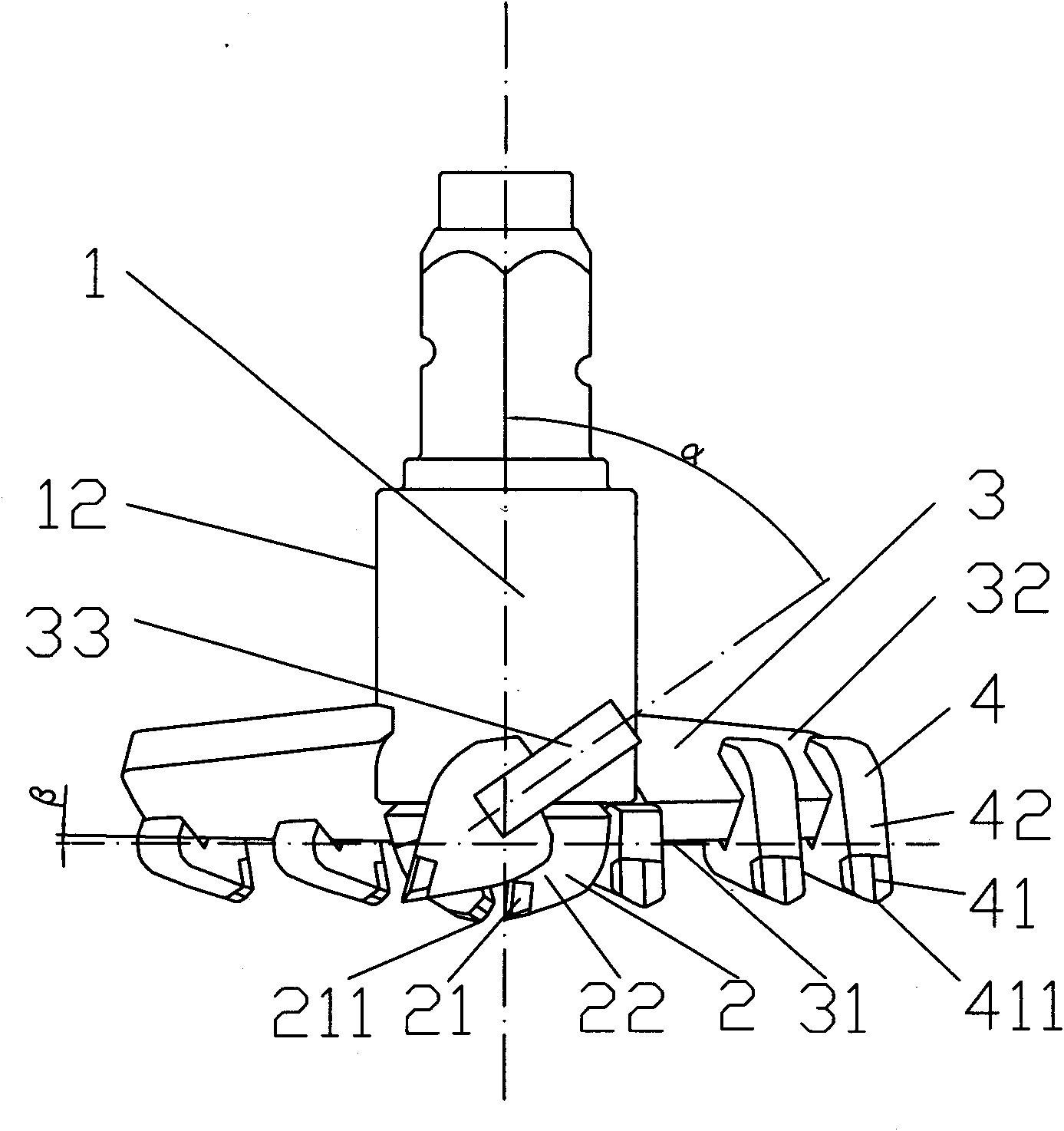

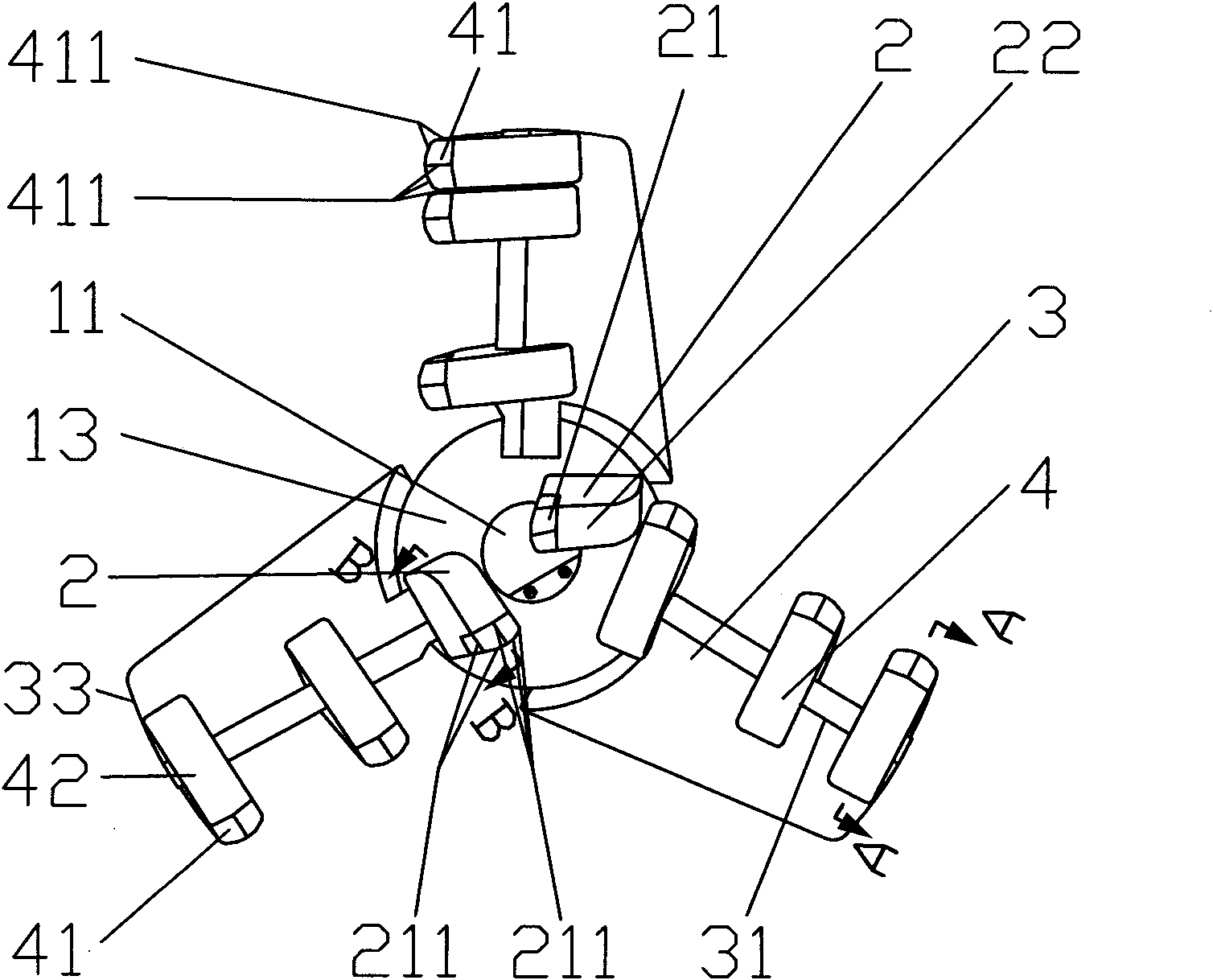

[0019] As shown in Fig. 1, Fig. 2, Fig. 3 and Fig. 4, a kind of compound drill bit, comprises rod body 1, the inner cutter body 2 that is made up of inner cutter head 21 and inner cutter handle 22, fin 3, consists of outer cutter head 41 and An outer cutter body 4 composed of an outer cutter handle 42; wherein, a grouting channel 11 is provided in the middle of the rod body 1 for pouring cement slurry; an inner cutter body 2 is fixed on the lower end of the rod body 1, and there are 2-4 inner cutter bodies 2, The lower end of the rod body 1 is provided with a flange 13, and the inner cutter body 2 is fixed on the lower surface of the flange 11 of the rod body 1 by radially symmetrical welding of the inner knife handle 22; The axial centerline direction of the rod body 1 is uniformly fixed on the outer peripheral surface of the rod body 1 bottom, and the outer cutter body 4 is fixed on the fins 3; The included angle α=50-70° of the axial center line; the included angle β=0-15° ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com