Compound cantilever excavator

A technology of cantilever roadheader and roadheader, which is applied in cutting machinery, slitting machinery, earthwork drilling and mining, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

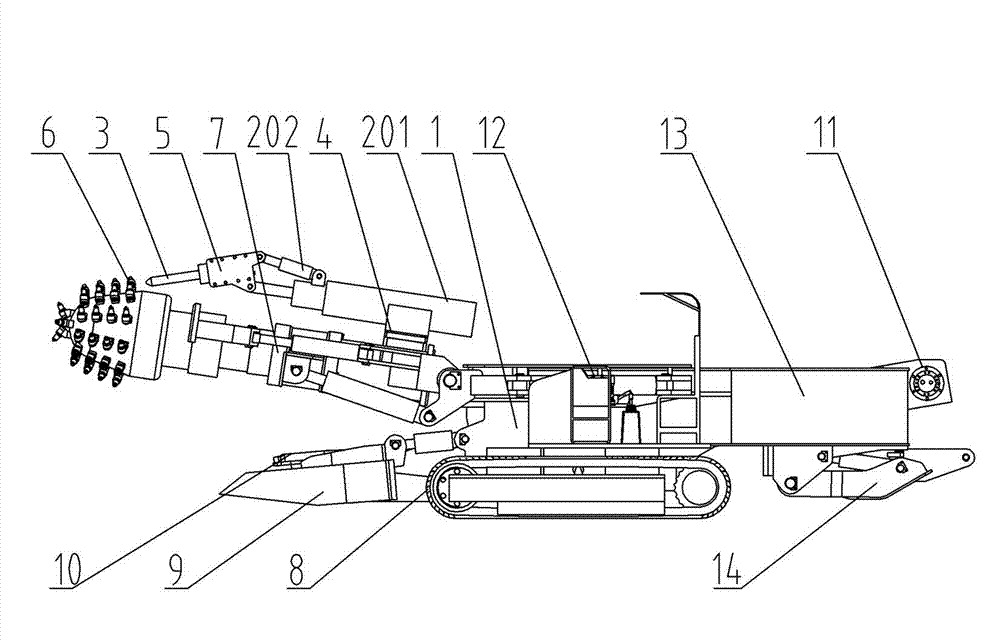

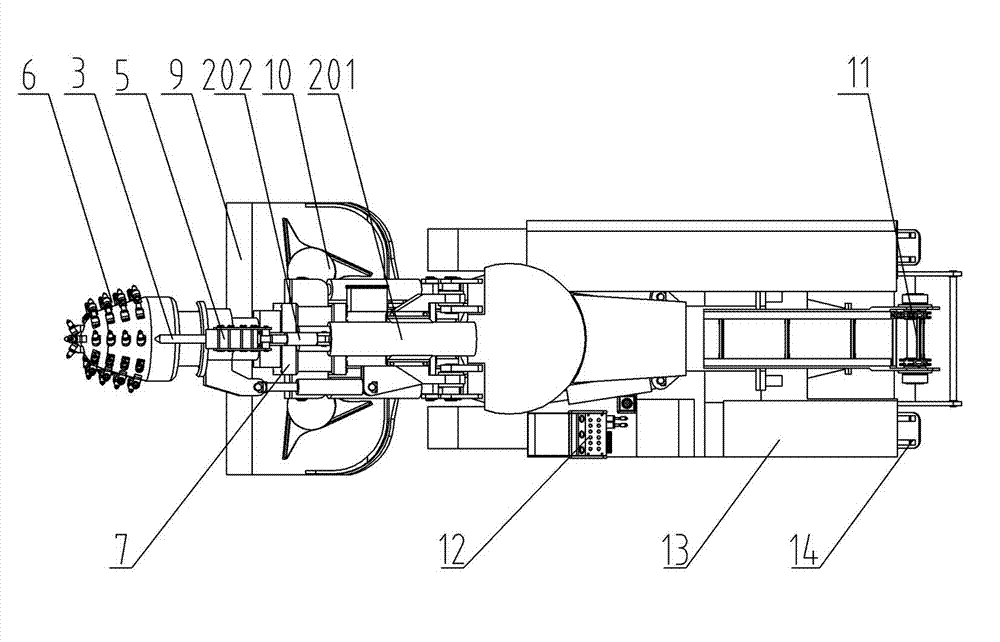

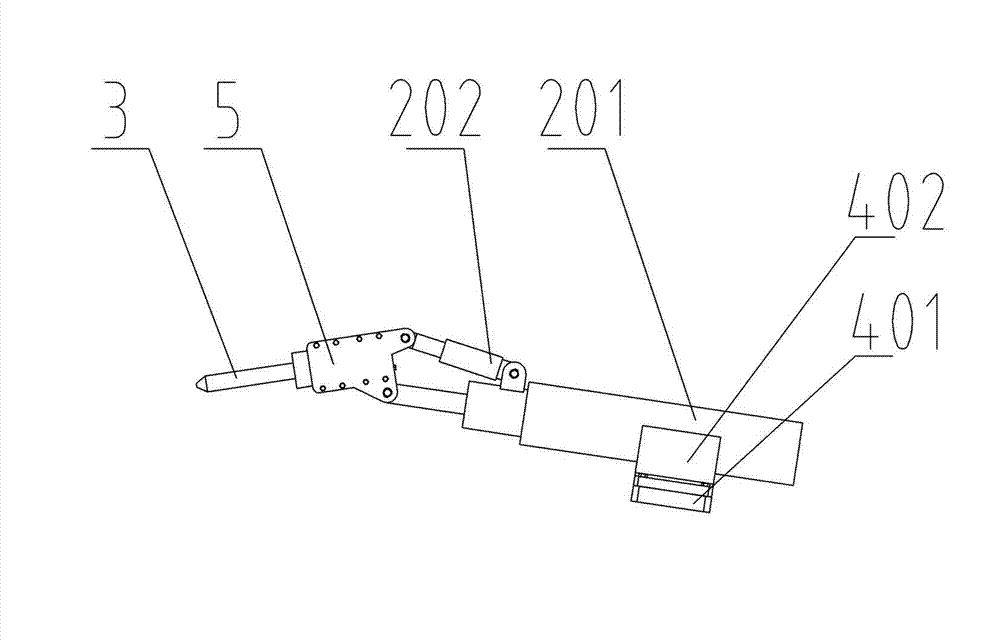

[0021] The cantilever roadheader of the present invention comprises a roadheader body 1, a tunneling mechanism, a traveling mechanism, a hydraulic system, an electrical system 13, a conveying mechanism, and a dust removal system. 7 top, the lower part of the cutting arm 7 is movably fixed on the roadheader body 1; the traveling mechanism includes a power machine and crawler belts 8 located on both sides below the roadheader body 1; The hydraulic cylinder 2, the breaker 3 located at the top of the hydraulic cylinder and the mounting frame 4 connected to the main body of the roadheader, the hydraulic cylinder includes a telescopic cylinder 201 and a swing cylinder 202, the telescopic cylinder 201 is fixed above the cutting arm 7 in parallel, and the piston at the front end of the telescopic cylinder 201 The rod is hinged at the lower end of the breaker 3 base, and hinge ears 5 are arranged around the breaker 3 base, and the swing cylinder 202 is hinged between the hinge ears 5 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com