Diamond compact

A diamond composite sheet and diamond technology, which is applied in the field of diamond composite sheets, can solve the problems of high drilling cutting resistance, high drill bit torque, and low drilling efficiency, so as to increase the ROP, increase the ROP, and reduce the drilling efficiency. The effect of cutting resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

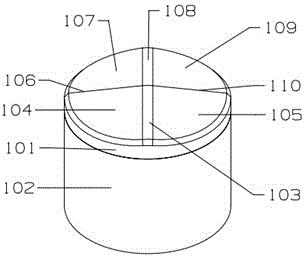

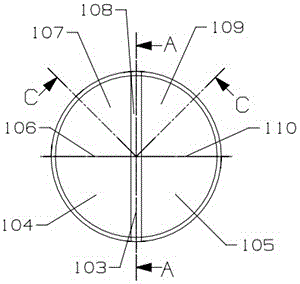

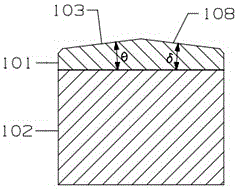

[0026] Example as Figure 1 to Figure 4 As shown, including a diamond composite layer 101 and a cemented carbide substrate 102, the end face of the diamond composite layer has 2 upwardly protruding band-shaped ribs, and each band-shaped rib extends obliquely from the edge of the composite layer and meets at the center of the end face, 2 The strip-shaped convex ribs are evenly distributed along the circumference, that is, the central angle between two adjacent strip-shaped convex ribs is 180°. One side of the end surface is composed of a strip-shaped convex rib 108 and flank surfaces 107, 109 on both sides thereof, and the other side of the end surface is composed of a strip-shaped convex rib 103 and flank surfaces 104, 105 on both sides thereof. The flank surfaces of the two intersect each other to form intersection lines 106,110. In this embodiment, the upward inclination angles of the two strip-shaped convex ribs, that is, the angles θ and δ between the vertical projection p...

Embodiment 2

[0027] Example two such as Figure 5 to Figure 8 As shown, the difference with Embodiment 1 is that: the angles θ and δ of the 2 strip-shaped ribs 203, 208 inclined upward are 4.5°, and the flank surfaces 204, 205 on both sides of the 2 strip-shaped ribs ( or 209, 207), the inclination angles α and β are not equal, the inclination angle α is 5°, and the inclination angle β is 10°, wherein the wing surface with a larger inclination angle has a larger area, and the corresponding flank surfaces on both sides intersect in pairs to form an intersection line 206 , 210.

Embodiment 3

[0028] Embodiment three such as Figure 9 to Figure 12 As shown, the end face of the diamond composite layer has three upwardly protruding band-shaped ribs 303, 306, 308, and each band-shaped rib extends obliquely from the edge of the composite layer and meets at the center of the end face. Evenly distributed in the circumferential direction, that is, the central angle between two adjacent strip-shaped convex ribs is equal, which is 120°, and the upward slope angle θ of the three strip-shaped convex ribs is the same, which is 5°. Three flank surfaces 304 , 305 , and 307 are arranged corresponding to the three strip-shaped ribs, and the inclination angles α, β, and λ of the three flank surfaces are equal. Other structures are the same as in Embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com