A multi-ridge diamond composite sheet

一种金刚石复合片、金刚石的技术,应用在多脊金刚石复合片领域,能够解决钻进效率低、钻头扭矩大、钻进切削阻力大等问题,达到提升机械钻速、提高机械钻速、降低切削阻力的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

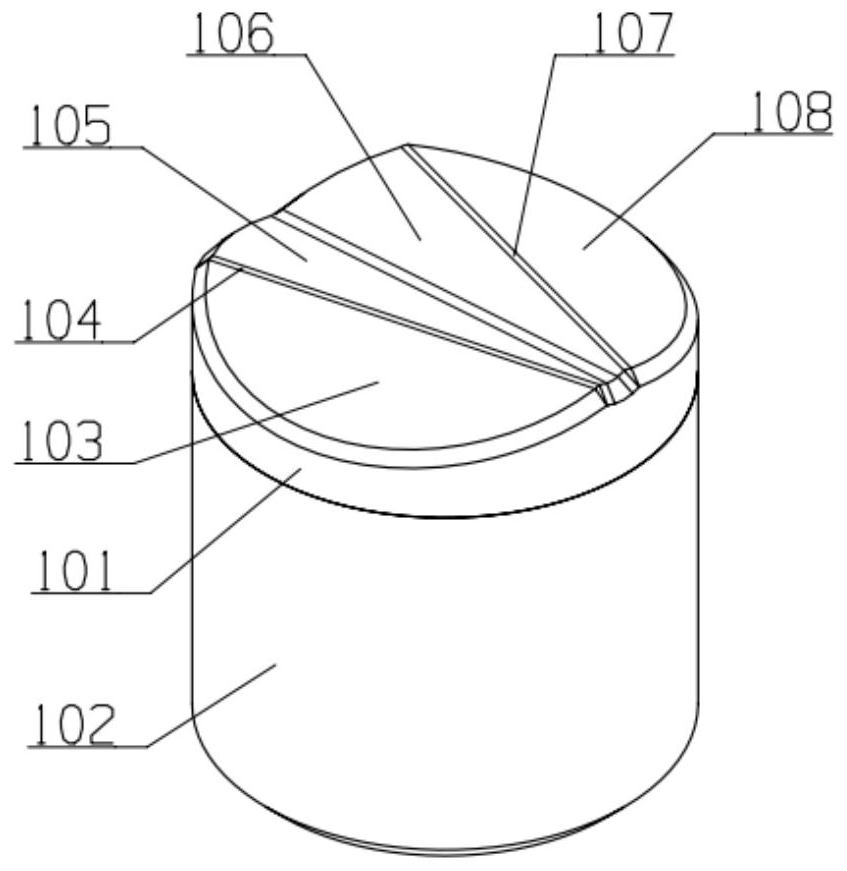

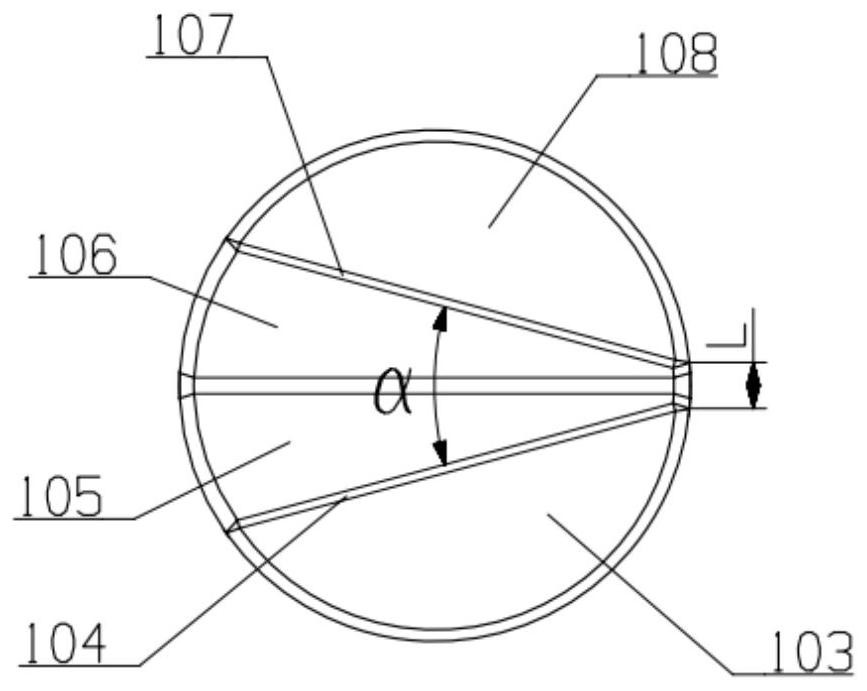

[0031] Example as figure 1 , figure 2 As shown, including a columnar diamond composite layer 101 and a columnar cemented carbide substrate 102, the end face of the diamond composite layer is provided with two ridges (104, 107) at a certain angle, and the contraction ends of the two ridges (104, 107) The extension meets the edge of the diamond composite layer, and the expansion end also extends and meets the edge of the diamond composite layer. The edge of the diamond composite layer is chamfered, so that the edge of the diamond composite layer forms a contracted cone surface, and the intersection of the contracted cone surface and the contracted end of each convex ridge forms a cutting edge. The convex ridge 104 is formed by the intersection of two slopes 103 and 105 , the convex ridge 107 is formed by the intersection of two slopes ( 106 , 108 ), and grooves are provided between adjacent slopes ( 105 , 106 ). In the present embodiment, the radius of the curved surface of t...

Embodiment 2

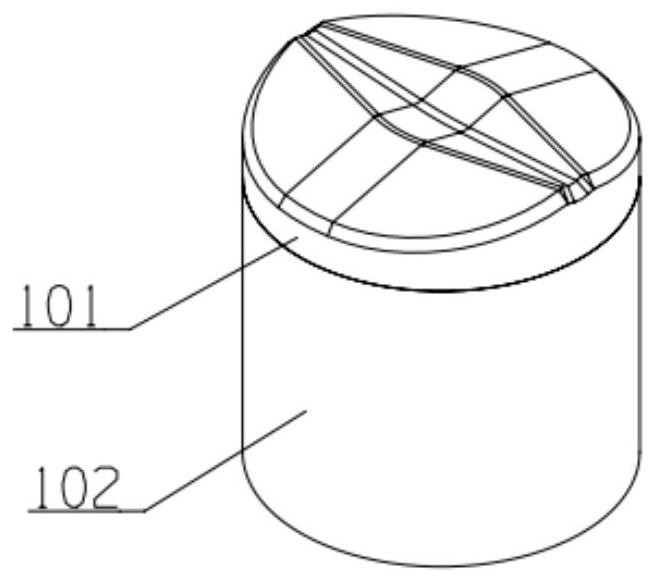

[0033] Example two such as image 3 As shown, the difference from Embodiment 1 lies in that two expanded ends of the convex ridge meet at the end surface of the diamond composite layer, and the meeting place is located at the center of the two, and meets through the transition surface. In addition, this embodiment is provided with two groups of convex ridges arranged symmetrically. Each group of convex ridges is composed of two convex ridges with a certain angle. Meet through transition faces. The constricted ends of the two groups of convex ridges meet with the edges of the diamond composite layer to form two groups of cutting edges (namely two), and the cutting edges are arranged symmetrically at 180°.

Embodiment 3

[0034] Embodiment three such as Figure 4 As shown, it differs from Embodiment 2 in that it is provided with three sets of ridges, and the three sets of ridges are evenly arranged along the circumference of the end face of the diamond composite layer to form three sets of cutting edges, which are distributed at 120°.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com