Ground control method of directional drilling adopting mud motor

A directional drilling and mud motor technology, which is applied in the automatic control system of drilling, drilling equipment, earthwork drilling and other directions, can solve problems such as reduction, and achieve obvious effects, improve service life, and improve correction ability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

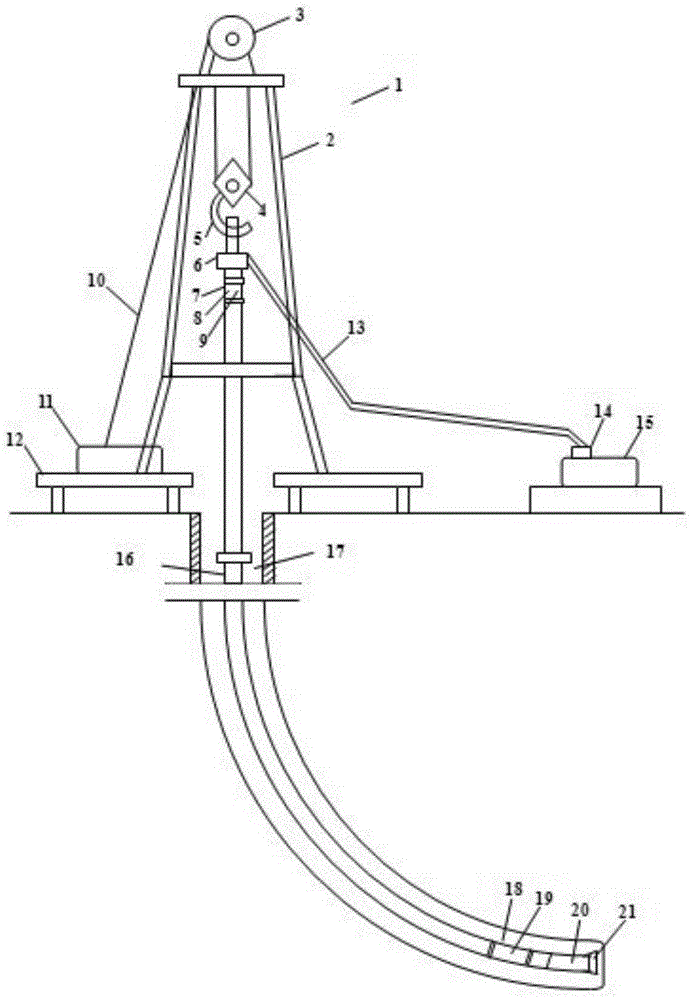

[0039] like figure 1 As shown, the system for drilling directional wells with the land top drive drilling rig of the present invention is basically the same as the prior art. Among them, 1 drilling rig; 2 derrick; 3 crown block; 4 travel block; 5 hook; 6 top drive; 7 top drive instrument joint; 8 drill pipe torque sensor; 9: drill pipe direction or angular displacement sensor; 10 winch drum wire rope ;11 drawworks; 12 drill floor; 13 mud hose; 14 pump pressure or standpipe pressure sensor; 15 mud pump; 16 drill string; 17 wellbore; 18 bottom hole assembly; ; 20 mud motor; 21 drill bit.

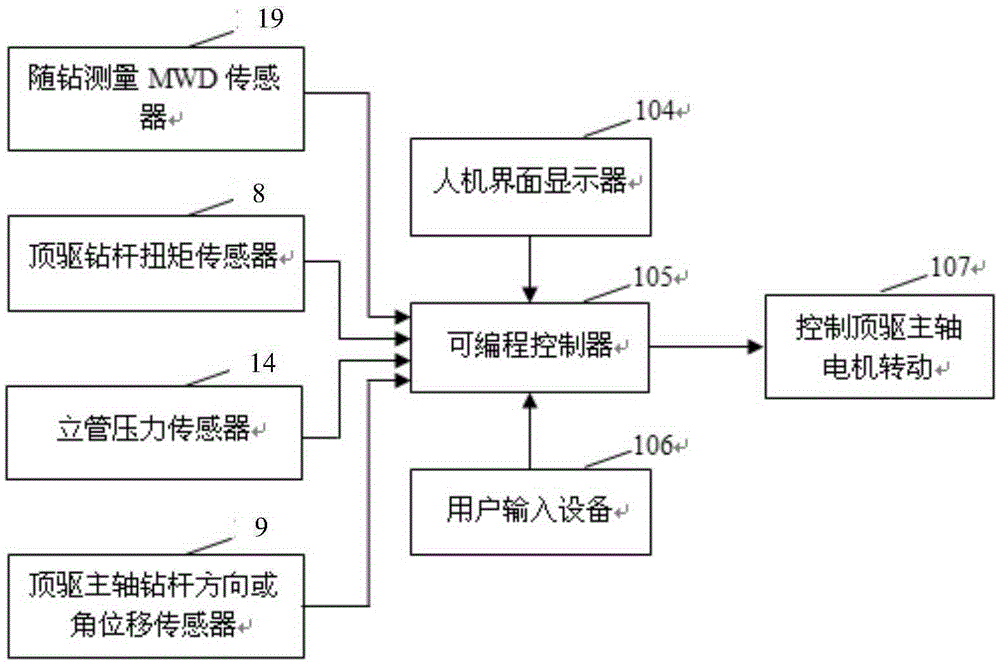

[0040] like figure 2 As shown, the measurement while drilling MWD tool face angle sensor 19, the top drive drill pipe torque sensor 8, the pump pressure or standpipe pressure sensor 14 and the top drive spindle drill pipe direction or angular displacement se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com