Polishing device for automobile parts

A technology for auto parts and bevel gears, which is applied in the direction of grinding drive devices, grinding/polishing safety devices, grinding machines, etc. It can solve the problem of reducing the service life of mounting parts, easily hurting the hands of installers, and increasing wear of mounting parts, etc. problem, to achieve the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

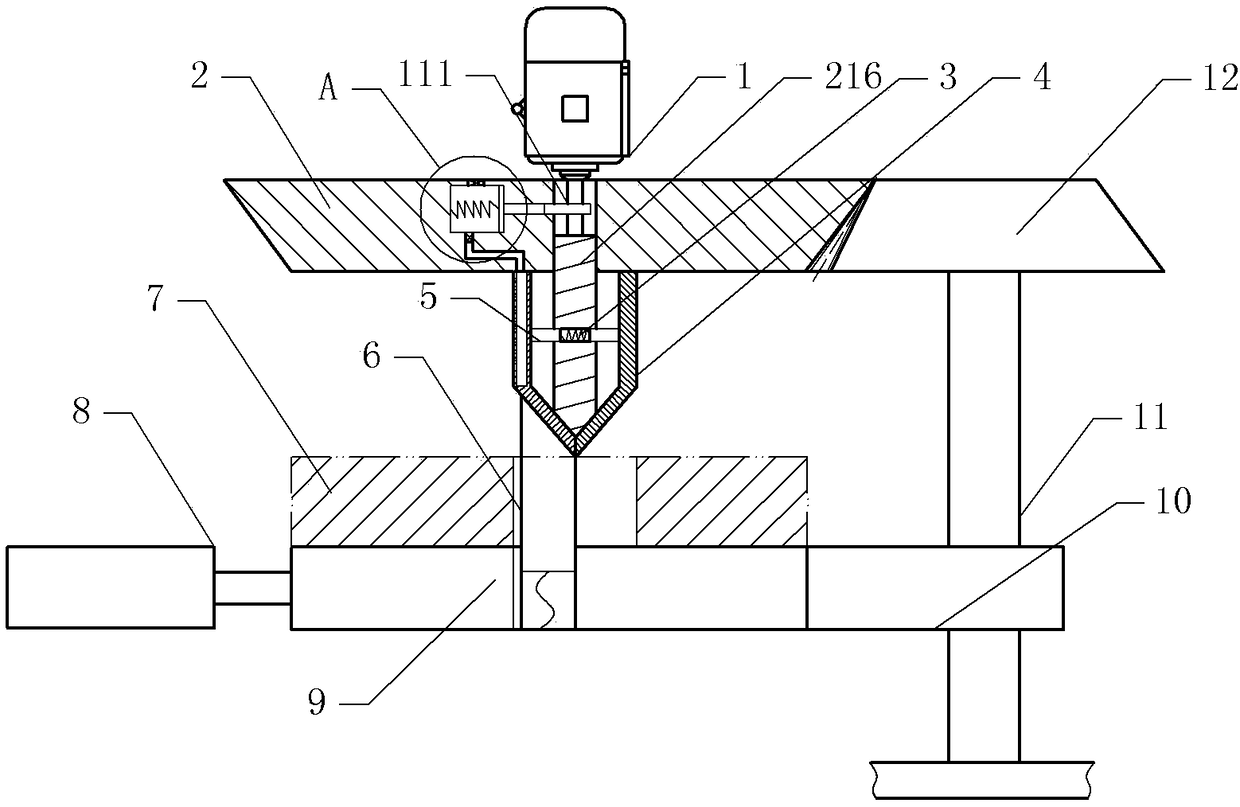

[0023] as attached figure 1 And attached figure 2 As shown, a grinding device for auto parts includes a frame and a motor 1, the motor 1 is fixed on the frame and the output shaft of the motor 1 faces downward, the output shaft of the motor 1 is fixed with a main bevel gear 2 and is located at the main bevel Cam 111 in gear 2.

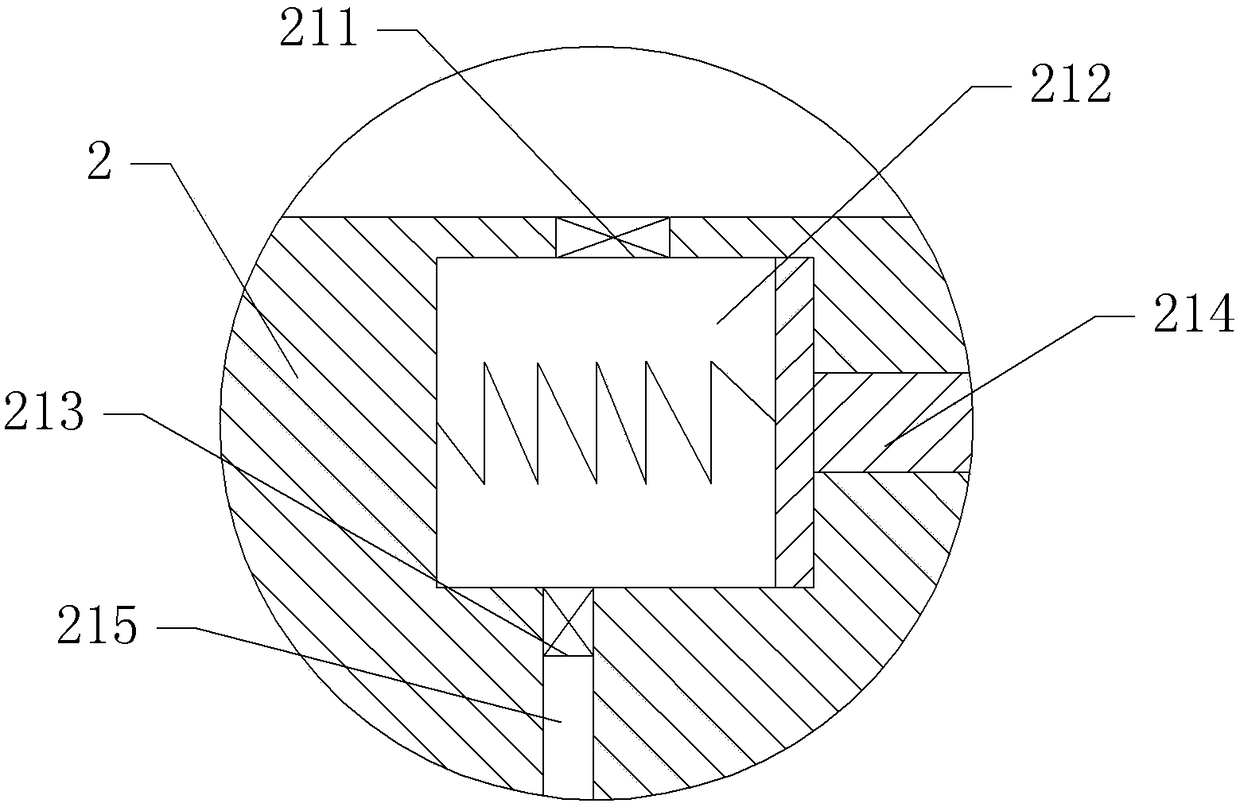

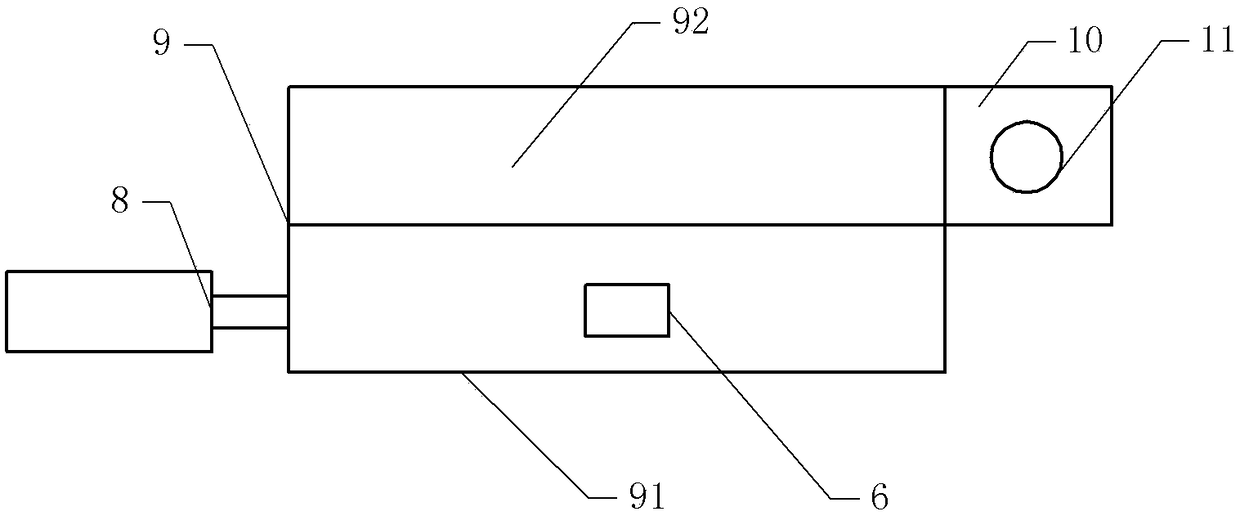

[0024] The bottom of the main bevel gear 2 is provided with a support shaft 216, and the two sides of the support shaft 216 are provided with friction plates 4 slidingly connected with the main bevel gear 2. The two friction plates 4 are arc-shaped and form a drum. The friction plate 4 is bonded with sandpaper by glue. The support shaft 216 is provided with a slideway, and the friction plates 4 are fixed with bumps 5 located in the slideway, and a compression spring 3 is fixed between the two bumps 5 . The friction plate 4 on the left side is provided with an inner chamber, and the left side wall of the inner chamber is provided with a through hole...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com