A screw safety assembly equipment capable of automatic feeding and synchronous loading and unloading of workpieces

A technology for assembling equipment and loading and unloading workers, applied in metal processing equipment, metal processing, manufacturing tools, etc., can solve the problems of large human factors, long production cycle, low efficiency, etc., achieve a wide range of applications, reduce labor intensity, reduce The effect of labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The technical solutions of the present invention will be further elaborated below in conjunction with the accompanying drawings and embodiments.

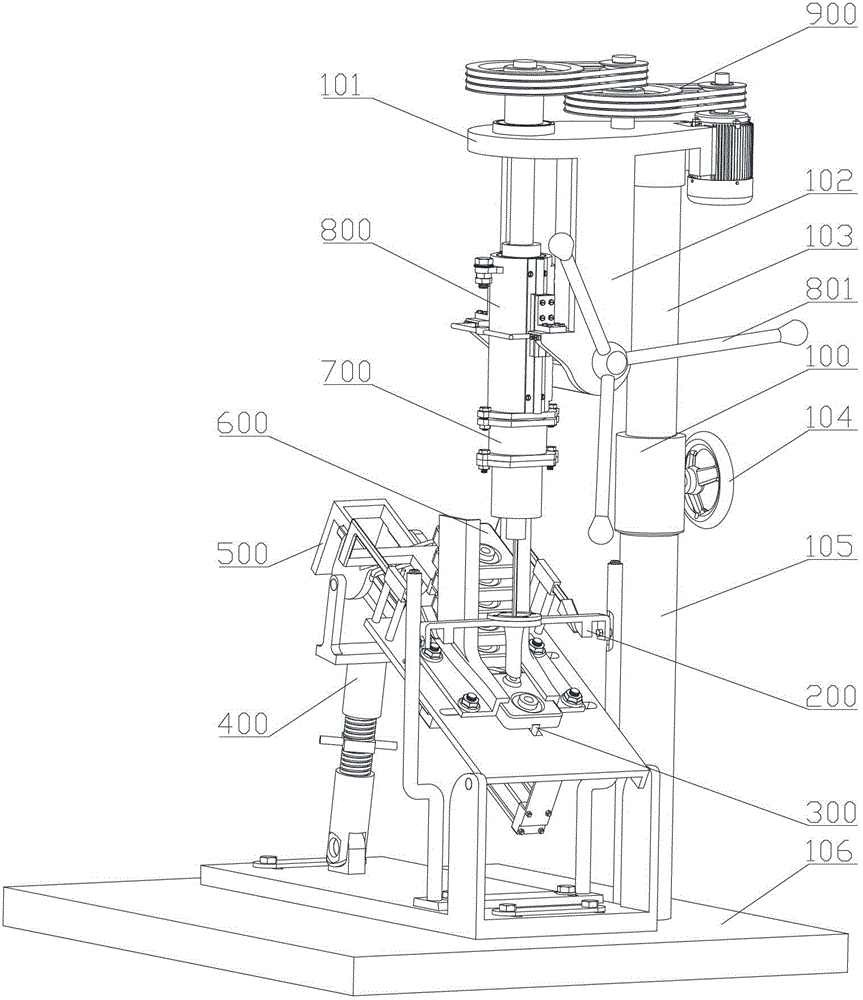

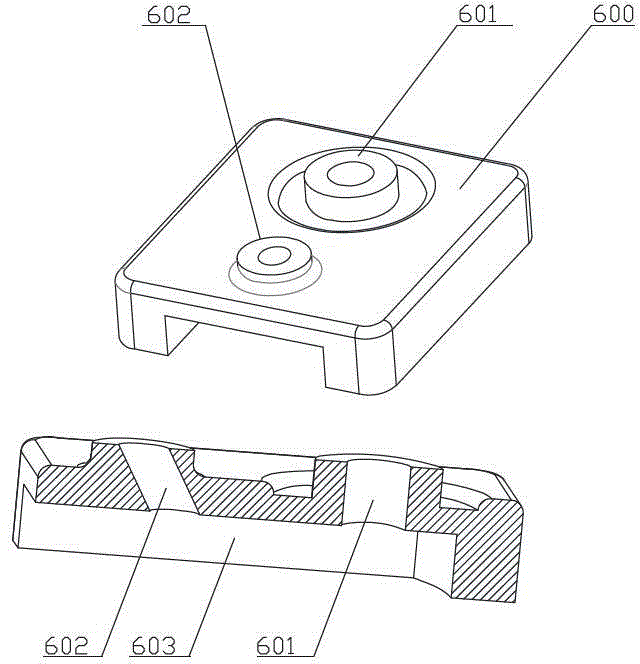

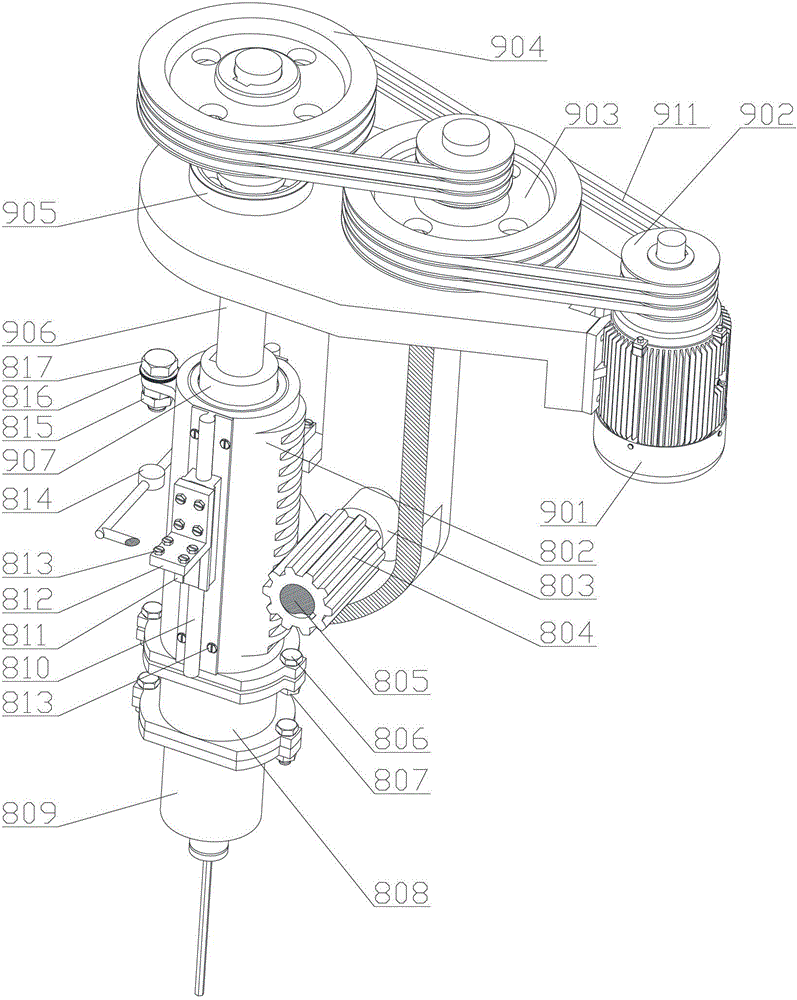

[0033] control figure 1 , a screw safety assembly equipment that can automatically feed and synchronously load and unload workpieces. It consists of a frame 100, a power device 900, a screw feed device 800, a screw clutch mechanism 700, a set screw guide device 200, and an adjustable working angle. Table 400, base automatic feeding device 500 and base synchronous loading and unloading device 300.

[0034] control figure 1, the frame 100 is composed of a machine base 106, a fixed column 105, an adjustable column 103, a compression hand wheel 104, an upper support plate 101 and a lower support plate 102, the lower support plate 102 is welded to the upper support plate 101, and the upper support plate The plate 101 is fixed on the adjustable column 103, the axial surface of the adjustable column 103 is matched with the hole su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com