Axial safety positioning device for hub machining

A technology for safe positioning and wheel hubs, which is used in grinding/polishing safety devices, metal processing equipment, manufacturing tools, etc., can solve the problems of poor positioning accuracy and stability, and achieve good positioning effect, guaranteed accuracy, and good electrical conductivity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The following examples are for illustrative purposes only and are not intended to limit the scope of the invention.

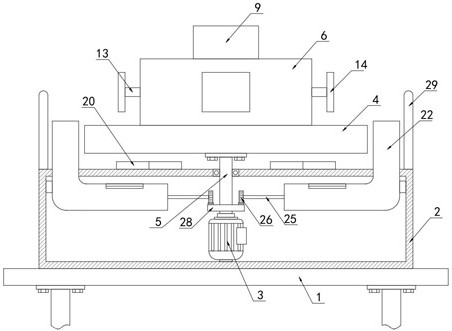

[0029] Such as Figure 1-6 As shown, a hub processing axial safety positioning device includes a workbench 1, a mount 2 is fixedly connected to the workbench 1, the mount 2 adopts a hollow structure, a motor 3 is fixedly installed in the mount 2, and a motor 3 is fixed on the mount 2. A rotating base 4 is provided, the output end of the motor 3 is connected with a rotating shaft 5 through a coupling, the upper end of the rotating shaft 5 is fixedly connected with the bottom of the rotating base 4, and the rotating base 4 is provided with a positioning mechanism for positioning the hub.

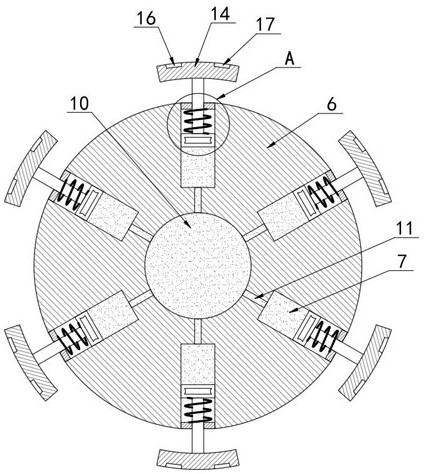

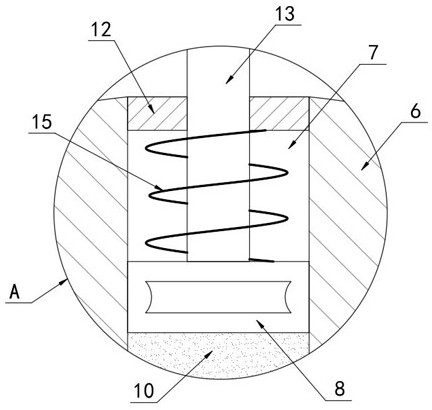

[0030] Further, the positioning mechanism includes a rotating disk 6 fixedly connected to the rotating seat 4, and a plurality of chutes 7 arranged in an annular array are opened on the peripheral side wall of the rotating disk 6, and a piston plate 8 is fitted in the ch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com