Hidden beam floor constructional column structure and construction method thereof

A construction method and technology for constructing columns, which are applied in building construction, construction, and building material processing, etc., can solve problems such as inability to reach corners of binding steel cages, floor slabs drilled through and rotten, and hidden quality problems, so as to eliminate hidden quality problems. , Reduce costs and facilitate the effect of pouring construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

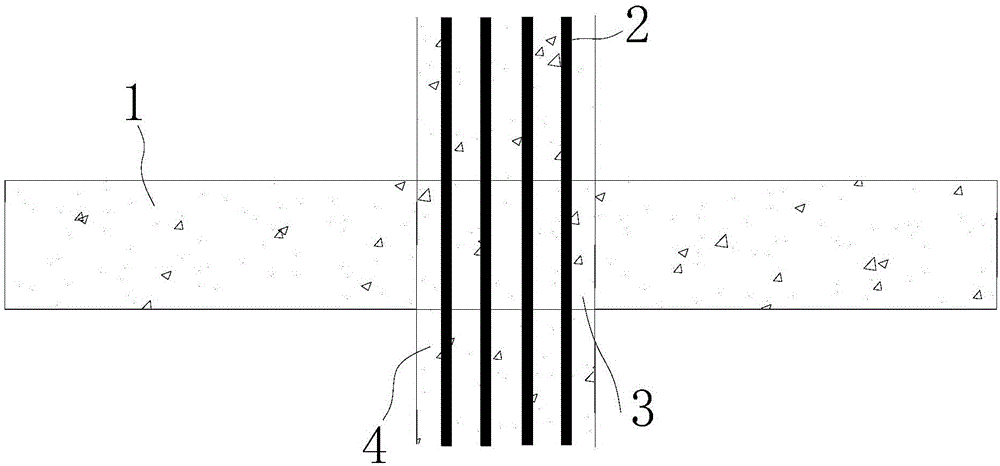

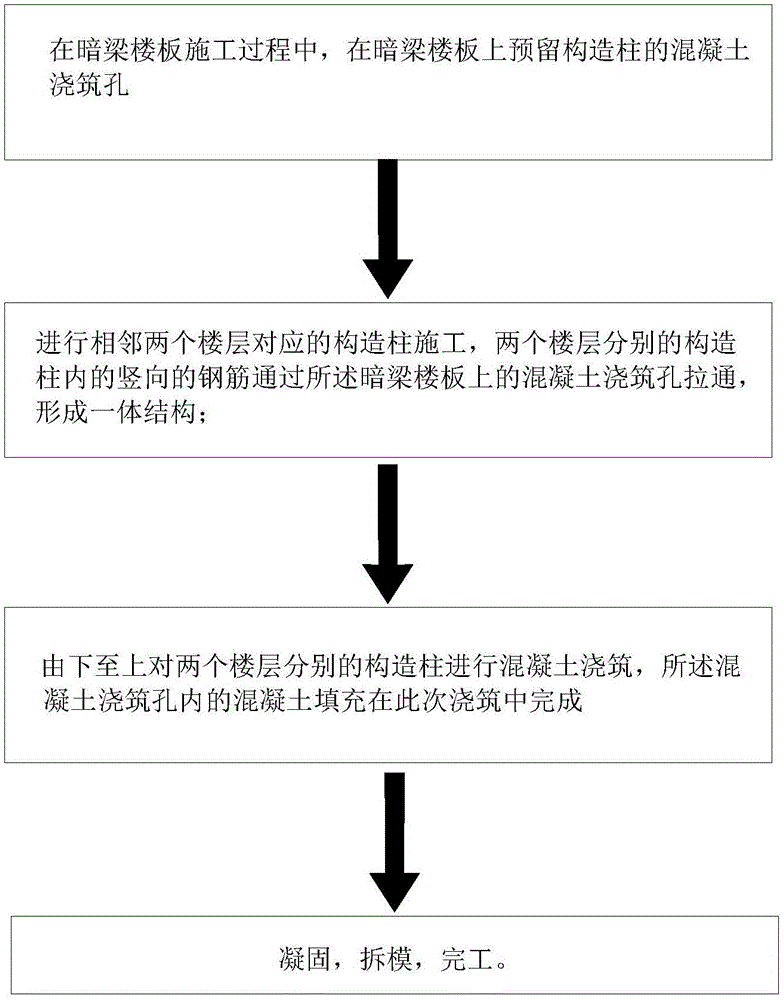

[0039] Such as figure 1 , a concealed beam floor construction column structure, which comprises:

[0040] Concealed beam floor 1 (there are walls on the floor that need beams to bear the load, or tie beams need to be installed between columns, but the beams cannot protrude from the bottom of the slab to affect the space use requirements. In this case, set reinforcement bars 2 on the slab play the role of the beam, that is, the hidden beam);

[0041] A reinforcing cage, in which a plurality of reinforcing bars 2 are vertically arranged, and the upper and lower ends of the reinforcing bars 2 are connected to the concealed beam floor 1;

[0042]A columnar structure 4, the columnar structure 4 is formed by pouring concrete, the steel bar 2 is penetrated inside the columnar structure 4, and the upper and lower ends of the columnar structure 4 are connected to the concealed beam floor 1;

[0043] The structural column runs through two adjacent floors, the steel bars 2 in the resp...

Embodiment 2

[0051] A floor construction column structure, comprising:

[0052] A reinforcing cage, in which a plurality of reinforcing bars 2 are arranged vertically, and the upper and lower ends of the reinforcing bars 2 are connected to the floor 1;

[0053] A columnar structure 4, the columnar structure 4 is formed by pouring concrete, the steel bar 2 is pierced inside the columnar structure 4, and the upper and lower ends of the columnar structure 4 are connected to the floor;

[0054] The structural column runs through two adjacent floors, the steel bars 2 in the structural columns of the two floors are connected as a whole, and the columnar structure 4 is arranged around the steel bar 2 at the intersection of the two floors.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com