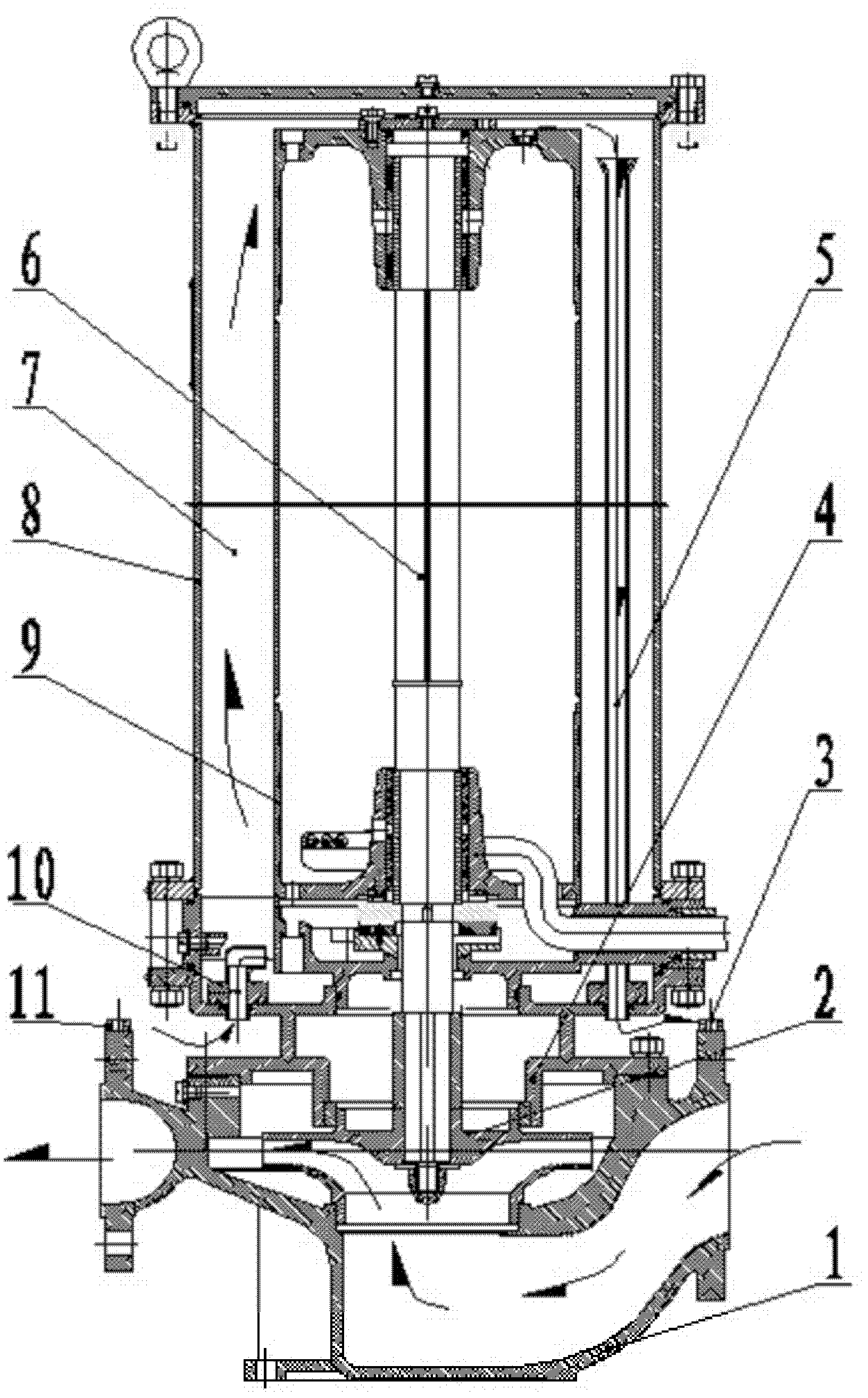

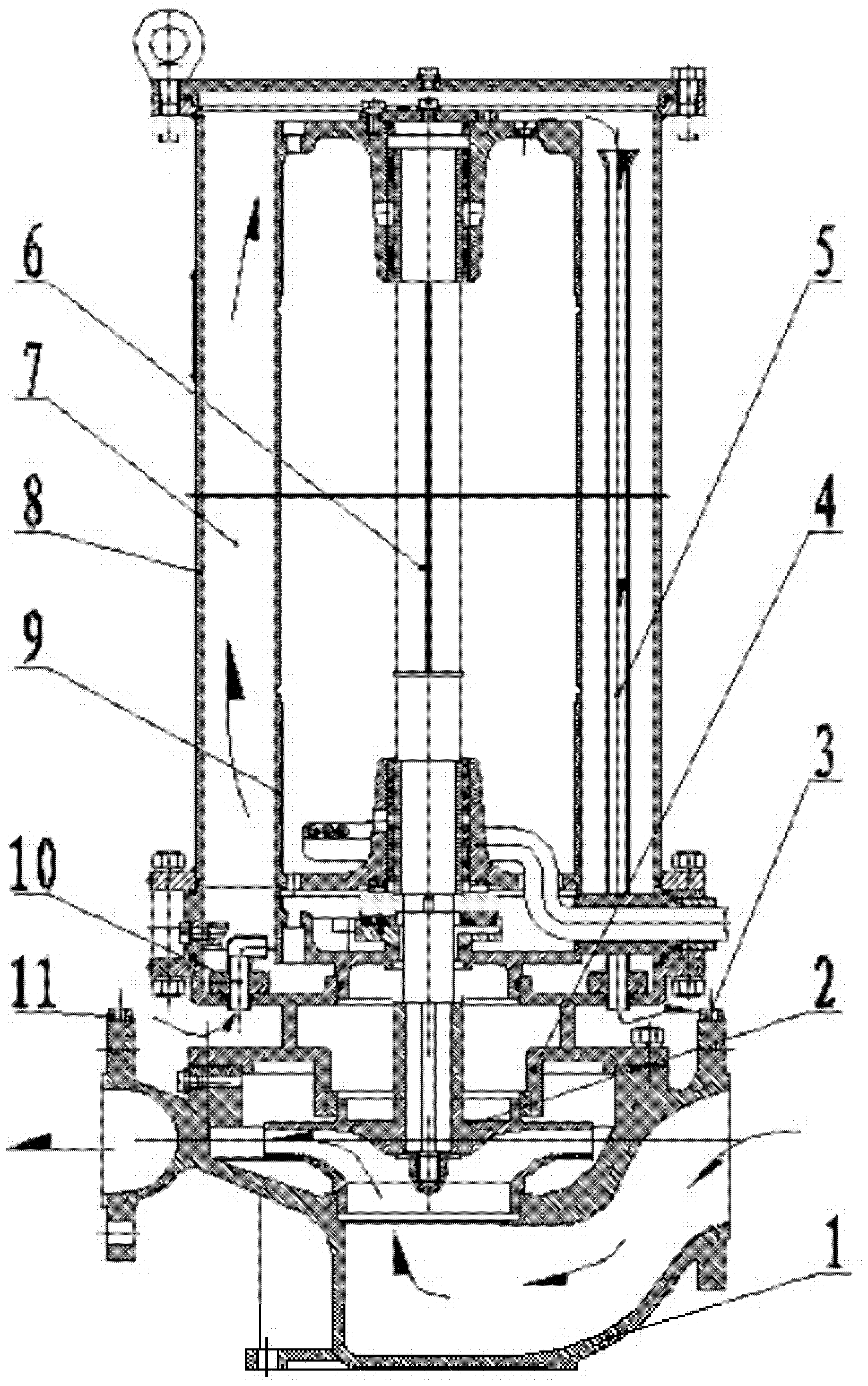

An amphibious vertical centrifugal pump unit

An amphibious and centrifugal pump technology, used in non-variable-capacity pumps, pumps, pump devices, etc., can solve the problems of strict operating environment restrictions, inability to use water cooling, and inability to use centrifugal pumps, achieving low noise and reducing pouring. Difficulty, small vibration effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] In order to make the above objects, features and advantages of the present invention more comprehensible, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0015] The invention is an amphibious vertical centrifugal pump unit. The centrifugal pump adopts a new submersible motor as the power equipment of the centrifugal pump. The cooling method is changed from air cooling to water cooling. Amphibious operations can replace IS and S-type water pumps in engineering applications, and are widely used in pumping stations such as agriculture, industry, water supply, and drainage. It has unique advantages in terms of environment, and it can also greatly reduce civil engineering investment and construction difficulty, reduce operation and maintenance costs, and exert significant comprehensive benefits.

[0016] The motor of the amphibious vertical centrifugal pump unit adopts the water-cooling...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com