Fabricated longspan concrete double-slope net shell roof framework and manufacturing method thereof

A concrete and long-span technology, applied to roofs, building components, building structures, etc., to achieve the effects of ensuring construction quality, reducing the impact of thrust, and reducing maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, but not as any limitation to the present invention.

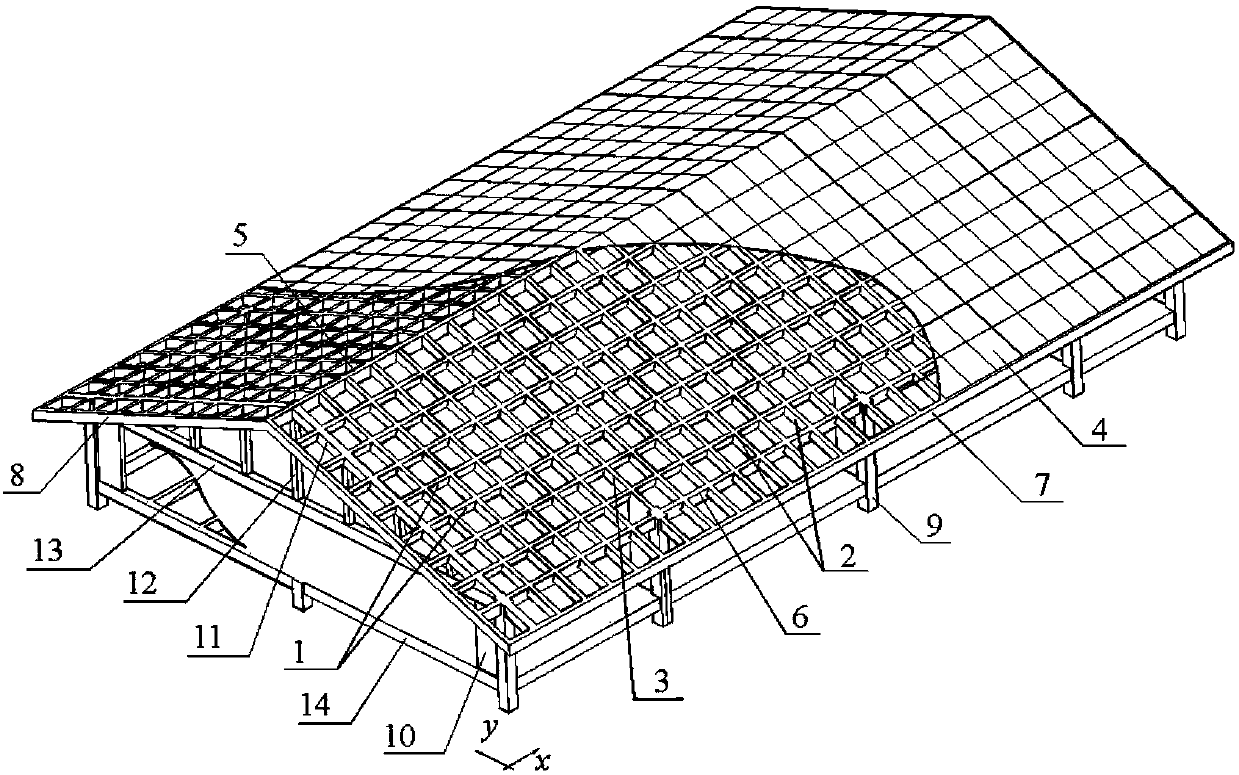

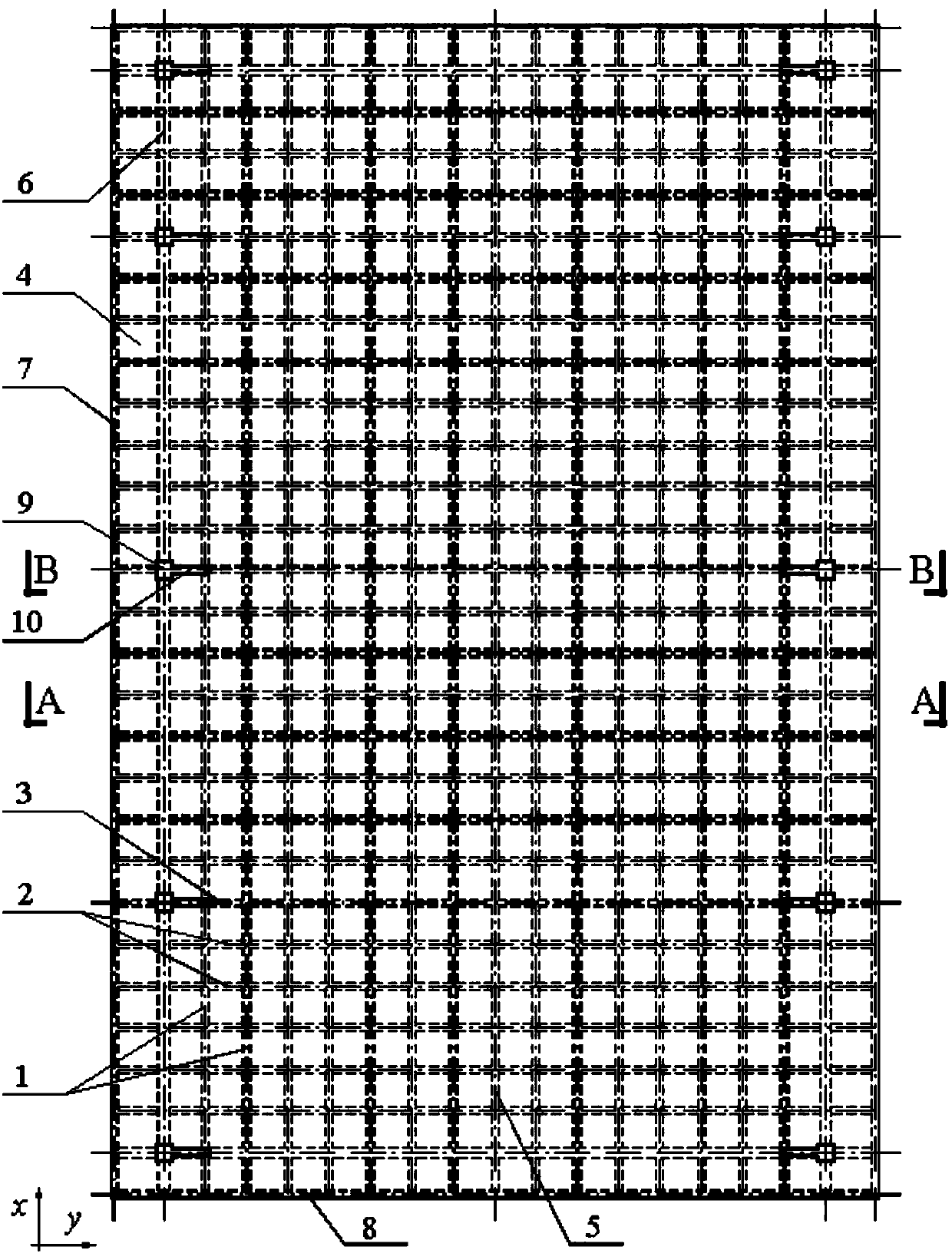

[0029] refer to figure 1 and figure 2 , a prefabricated double-slope reticulated shell roof structure is composed of obliquely placed densely ribbed slabs, roof beams 5, gable end partitions, longitudinal side frame beams 6 and anti-thrust structures, and the densely ribbed slabs include prefabricated roof slabs 4, flat Set the secondary rib 1, the oblique secondary rib 2 and the oblique main rib 3.

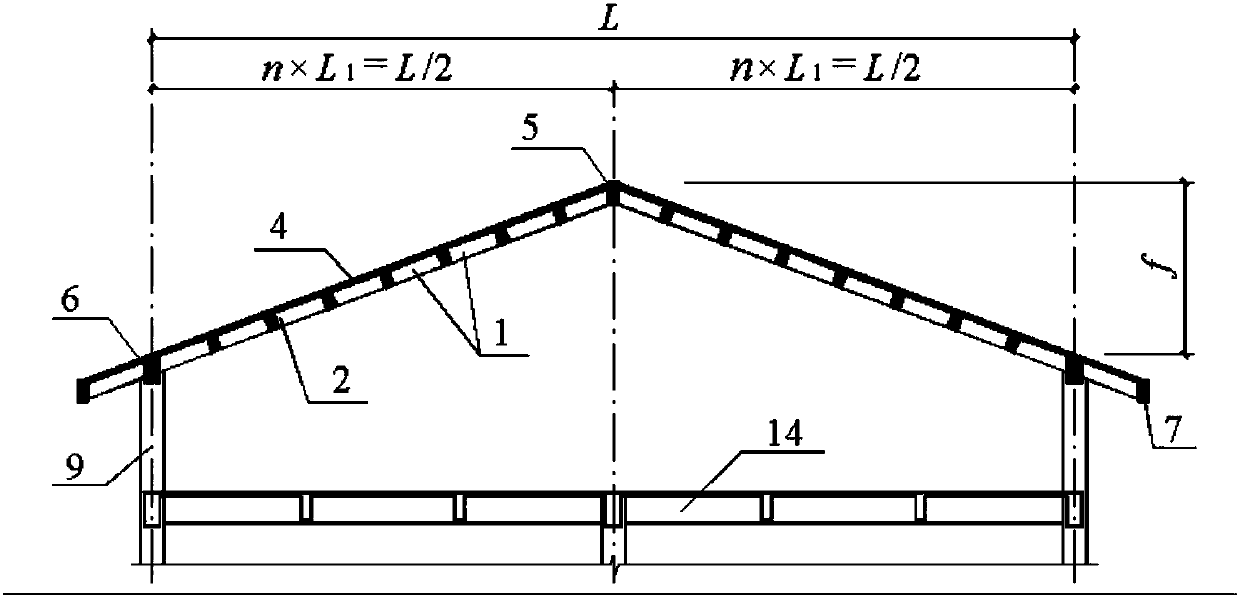

[0030] refer to image 3 and Figure 4 , the oblique main rib 2 is a constant section rib, the oblique main rib 3 is connected in-plane with the push-resistant wall 10 of the anti-thrust structure, and the root of the oblique main rib 3 needs to increase the section according to its internal force.

[0031] refer to Figure 5 , the densely ribbed plate needs to use cast-in-place connecting blocks 18...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com