An airbag-filled truss for large offshore platforms

An airbag filling and offshore platform technology, which is applied to floating buildings and other directions, can solve the problems of large diameter of rigid shell, insufficient pressure bearing capacity, large stress of upper structure, etc., and achieves simple processing and manufacturing, high assembly efficiency, and large space rigidity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

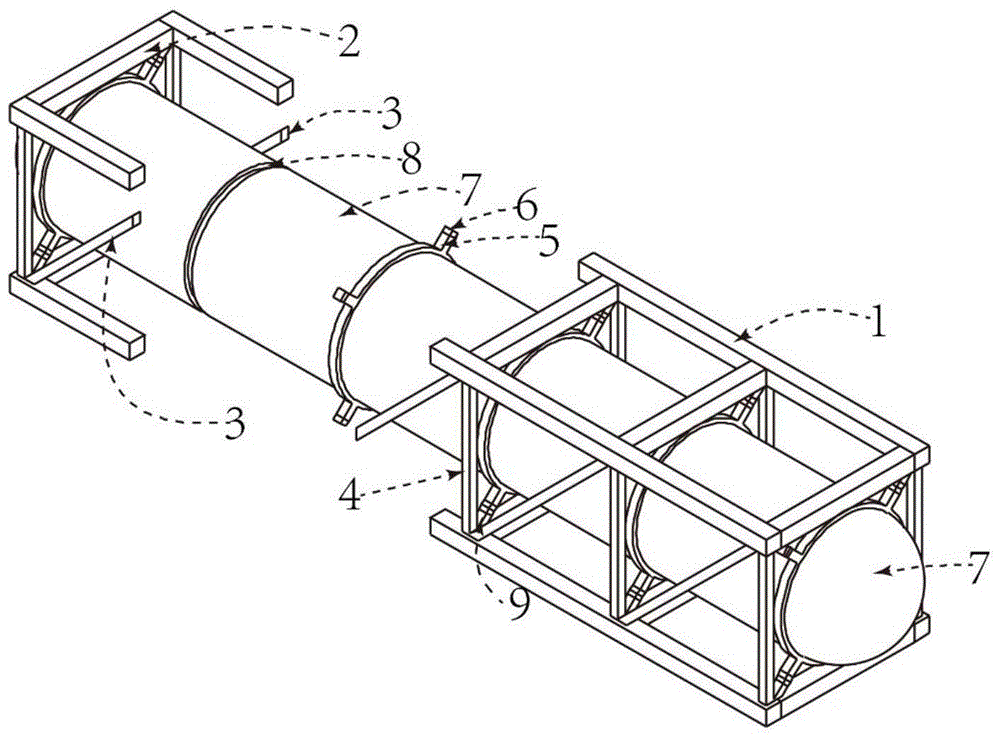

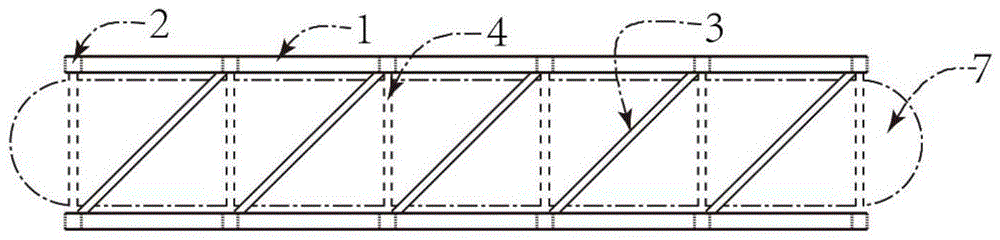

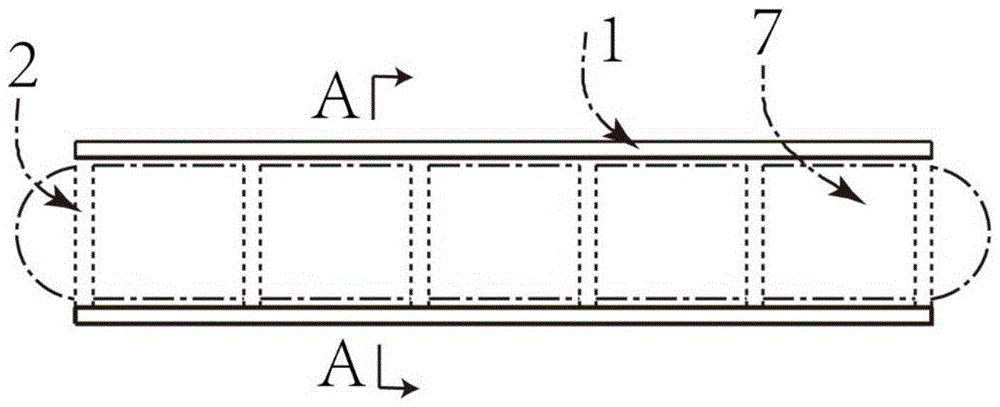

[0034] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

[0035] The invention is an airbag-filled truss for large-scale ocean platforms. The structure fully combines the advantages of light airbag structure, good buoyancy performance, internal air pressure can be manually adjusted according to the water depth, and the space truss structure is convenient for assembly and construction, and the space rigidity The great advantages are combined to form a hybrid floating structure system of airbags and trusses, which can form a large-scale offshore platform structure that meets the requirements of self-weight, buoyancy, strength, stiffness, and use of space.

[0036] Such as Figure 1a As shown, an airbag-filled truss for large offshore platforms in the present invention is a structural system formed by filling airbags 7 after the airbag support frame 5 replaces the oblique web bars in the transverse pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com