A fully assembled prestressed frame cable system composite structure

A prestressed frame and composite structure technology, which is applied in basic structural engineering, building construction, towers, etc., can solve the problems of limited structural strength and low lateral resistance of the structure, and achieve easy construction quality, light weight and high strength assembly, fast The effect of efficient assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] The present invention will be further described in detail below through specific embodiments and in conjunction with the accompanying drawings.

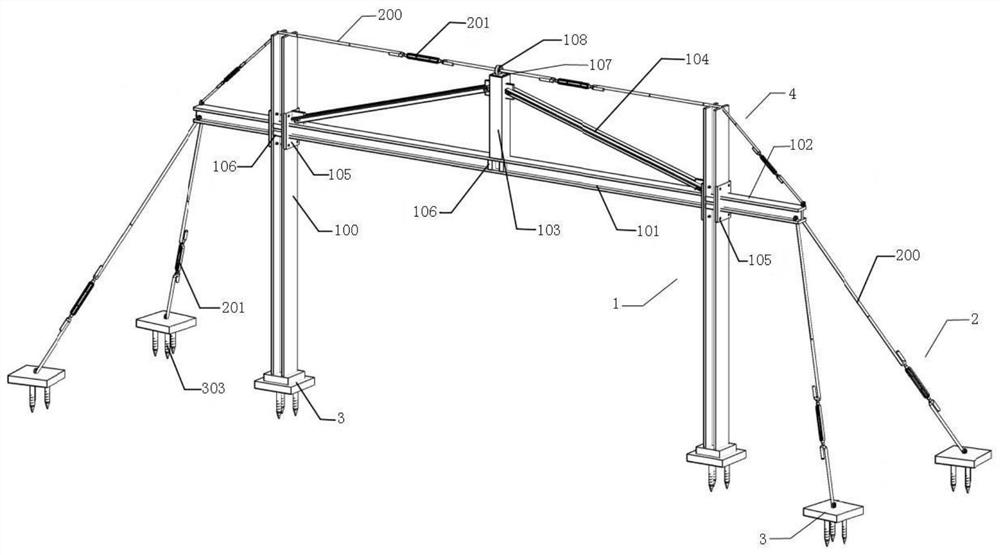

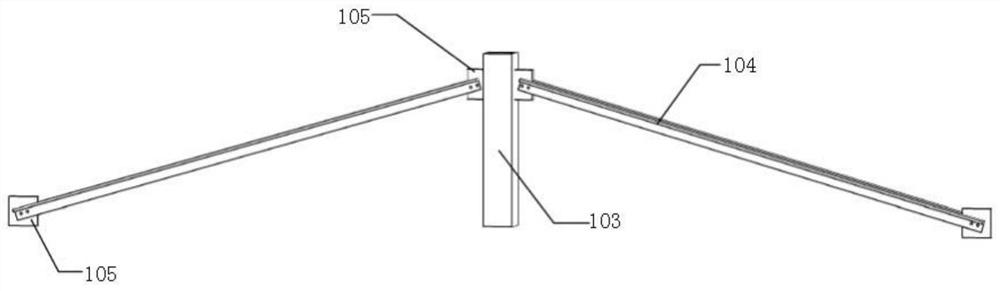

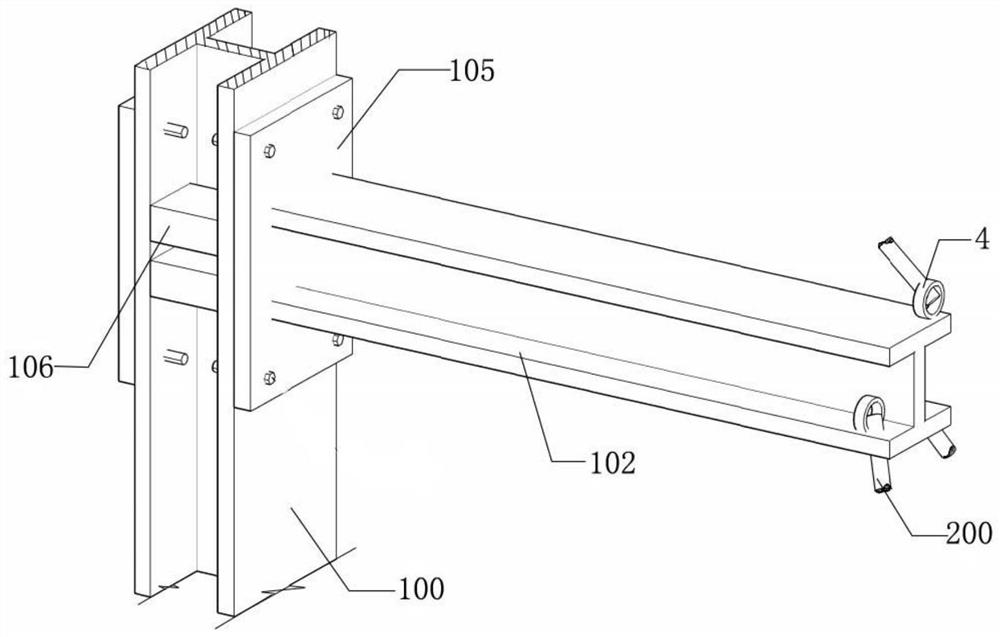

[0051] like figure 1 , Figure 4 to Figure 11 As shown, a fully assembled prestressed frame cable system composite structure provided by the present invention includes a light steel frame structure 1 and a plurality of stay cable assemblies 2. After the light steel frame structure 1 is installed, it passes through a plurality of inclined The cable assembly 2 jointly applies prestress to the light steel frame structure 1, which ensures the stability of the light steel frame structure 1 while reducing the automatic movement of the light steel frame structure 1, improves the lateral stiffness of the light steel frame structure 1, and prevents the light steel frame structure 1. The frame structure 1 is deformed after being stressed, so as to improve the spatial rigidity of the entire structure, thereby realizing the efficient pos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com