Cloth shaping method and machine with energy-saving heat source

A sizing machine, energy-saving technology, applied in the direction of heating/cooling fabrics, textiles and papermaking, fabric surface trimming, etc., can solve the problems of not reaching the preset temperature, consumption, multiple heat sources, etc., to meet the needs of fabric sizing and reduce consumption energy and cost savings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

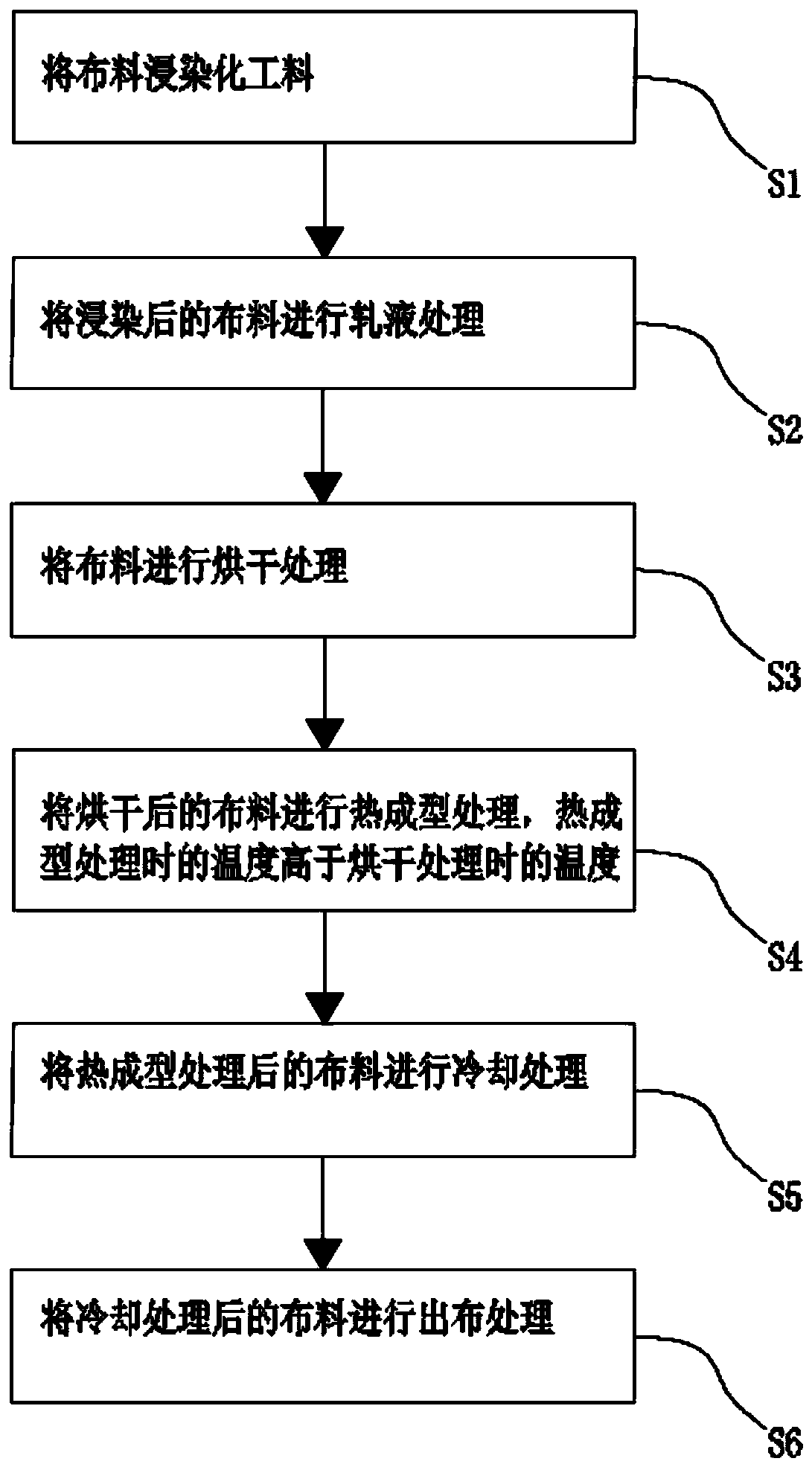

[0034] Such as figure 1 As shown, this embodiment provides a heat source energy-saving cloth shaping method, comprising the following steps:

[0035] S1: Soak the cloth with chemical materials; it should be noted that in this embodiment, the cloth enters the feeding device 2 through the cloth feeding device 1, and then dips the chemical materials in the feeding device 2, and the dipping of the chemical materials can increase the humidity of the cloth The role of the fabric so that the overall relaxation and shrinkage of the fabric, thereby enhancing the plasticity of the fabric.

[0036] S2: Carry out padding treatment on the cloth after dipping; it should be noted that since the degree of dipping of chemical materials on the cloth has an important effect on the color, feel, and appearance of the cloth surface, in this embodiment, 3 pairs of padding devices are used to The cloth is treated with squeeze liquid to squeeze out the excess chemical materials, so that the chemical ...

Embodiment 2

[0044] Such as figure 1 As shown, this embodiment provides a heat source energy-saving cloth shaping method, comprising the following steps:

[0045]S1: Soak the cloth with chemical materials; it should be noted that in this embodiment, the cloth enters the feeding device 2 through the cloth feeding device 1, and then dips the chemical materials in the feeding device 2, and the dipping of the chemical materials can increase the humidity of the cloth The role of the fabric so that the overall relaxation and shrinkage of the fabric, thereby enhancing the plasticity of the fabric.

[0046] S2: Carry out padding treatment on the cloth after dipping; it should be noted that since the degree of dipping of chemical materials on the cloth has an important effect on the color, feel, and appearance of the cloth surface, in this embodiment, 3 pairs of padding devices are used to The cloth is treated with squeeze liquid to squeeze out the excess chemical materials, so that the chemical m...

Embodiment 3

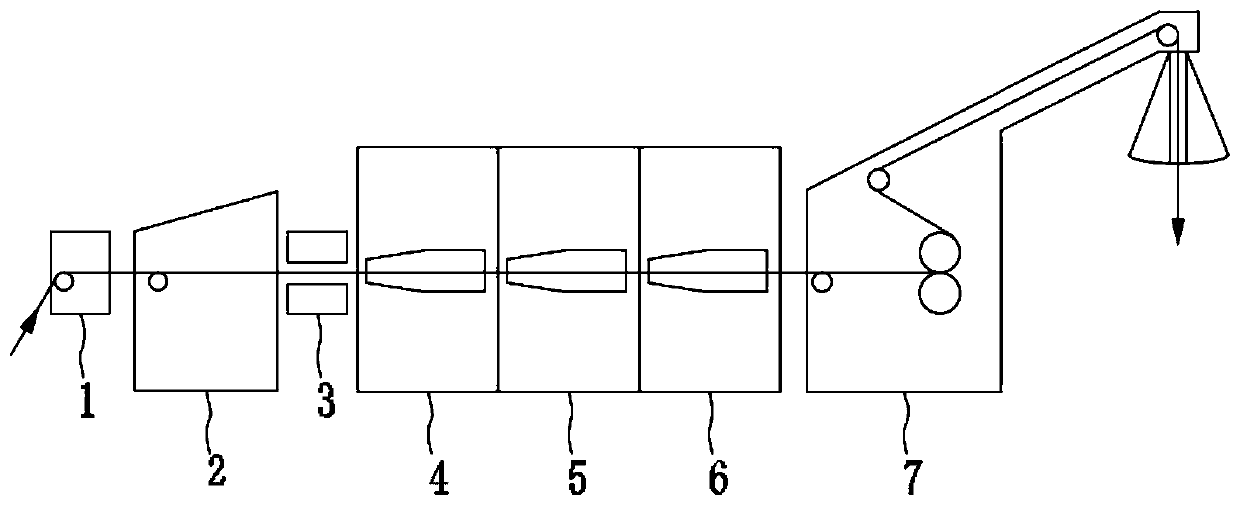

[0052] Such as figure 2 As shown, the present embodiment provides a sizing machine, comprising a cloth feeding device 1, a feeding device 2, a cloth rolling device 3, a drying machine box 4, a molding machine box 5, a cooling machine box 6 and an outlet Cloth device 7, the temperature of the forming machine box 5 is higher than the temperature of the drying machine box 4, and the arrow direction in the figure is the cloth feeding direction.

[0053] In the use process of this embodiment, the cloth is firstly fed through the cloth feeding device 1, then the cloth is impregnated with chemical materials in the material passing device 2, and then the cloth after the impregnated cloth is subjected to liquid rolling treatment through the cloth rolling device 3. After completion, the cloth is dried, thermoformed and cooled through the drying cabinet 4, the forming cabinet 5, and the cooling cabinet 6 in sequence, and finally the cloth is processed in the cloth discharging device 7, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com