Transversely-widening splicing structure of three-dimensional prestress concrete continuous box girder bridge

A three-way prestressing and concrete technology, which is applied to bridges, bridge parts, bridge maintenance, etc., can solve the problems of less planting bars, increase the difficulty and workload of construction, and implement difficulties, so as to reduce the amount of engineering and the difficulty of pouring , Avoid cross-section reinforcement construction, and avoid the effect of difficulty in horizontal reinforcement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

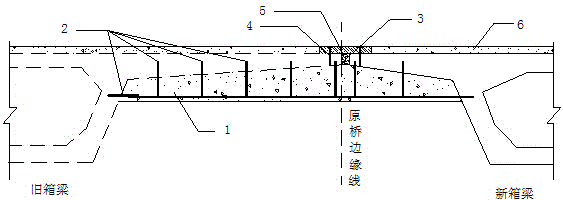

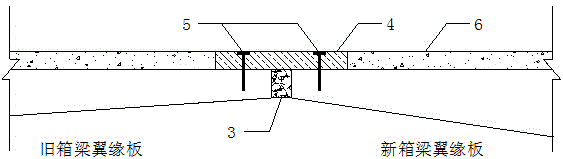

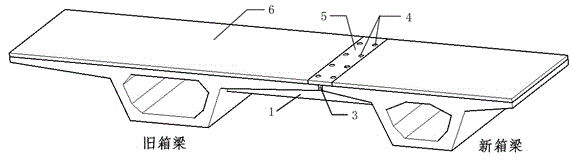

[0026] The lateral widening splicing structure of the three-way prestressed concrete continuous box girder bridge of the present invention comprises: the old box girder, the new box girder, the transverse splicing stiffeners 1 arranged at intervals along the longitudinal direction of the bridge on the web of the old and new box girders, and the built-in stiffeners Reinforcing bar 2, the longitudinal seam 3 reserved between the old and new box girder flange plates, and the plate rubber belt 5, anchor bolts 4 and bridge deck pavement layer 6 on it.

[0027] The implementation technique of splicing structure of the present invention is:

[0028] 1) At the position where transverse splicing stiffeners need to be arranged, implant transverse connecting reinforcement at the lower edge of the cantilever flange plate of the old bridge box girder and the corresponding position on the side of the web;

[0029] 2) Prefabricate and widen the box girder and maintain it. Set the reserved co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com