Reinforcement pin joint permanency beam formwork, concrete structural member and manufacturing method

A manufacturing method and permanent technology, applied to truss structures, bridge parts, joists, etc., to achieve simple manufacturing procedures, ensure shear strength, and high quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The specific implementation of the technical solution provided by the present invention will be further described below in conjunction with the accompanying drawings. This implementation example is an illustration of the present invention, rather than limiting the present invention.

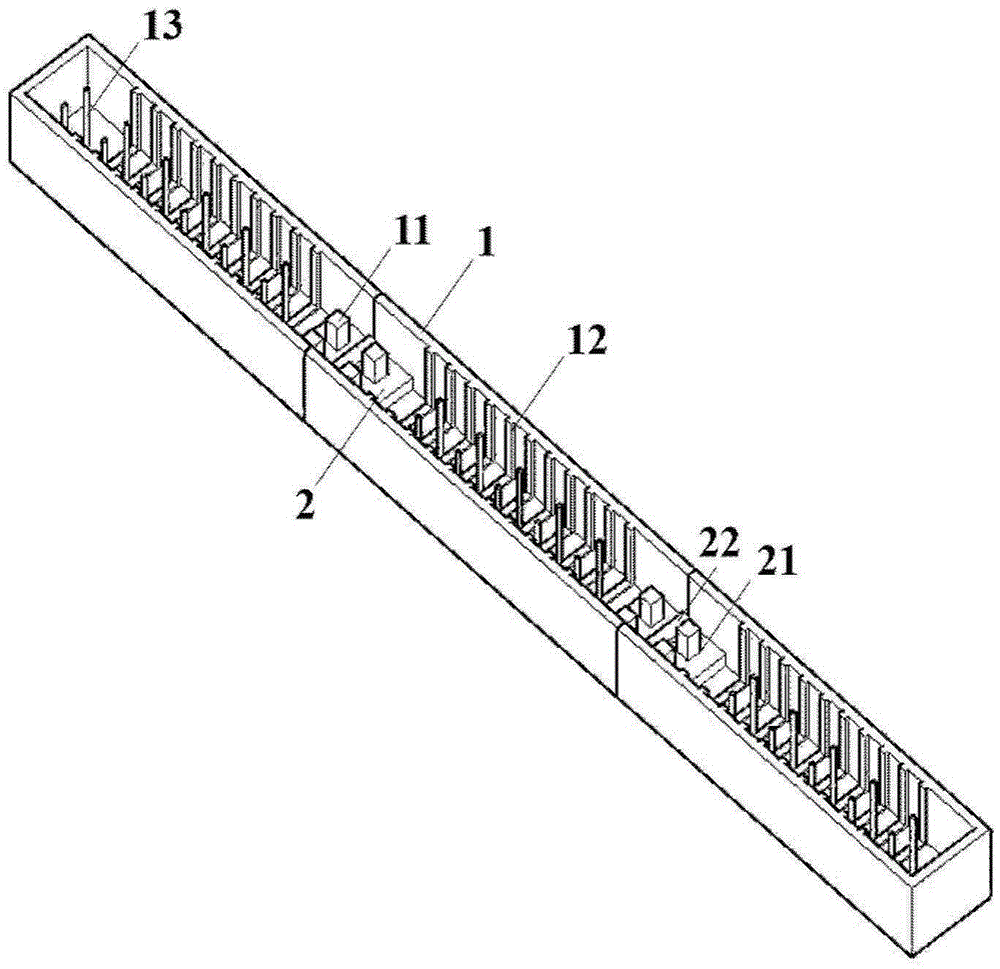

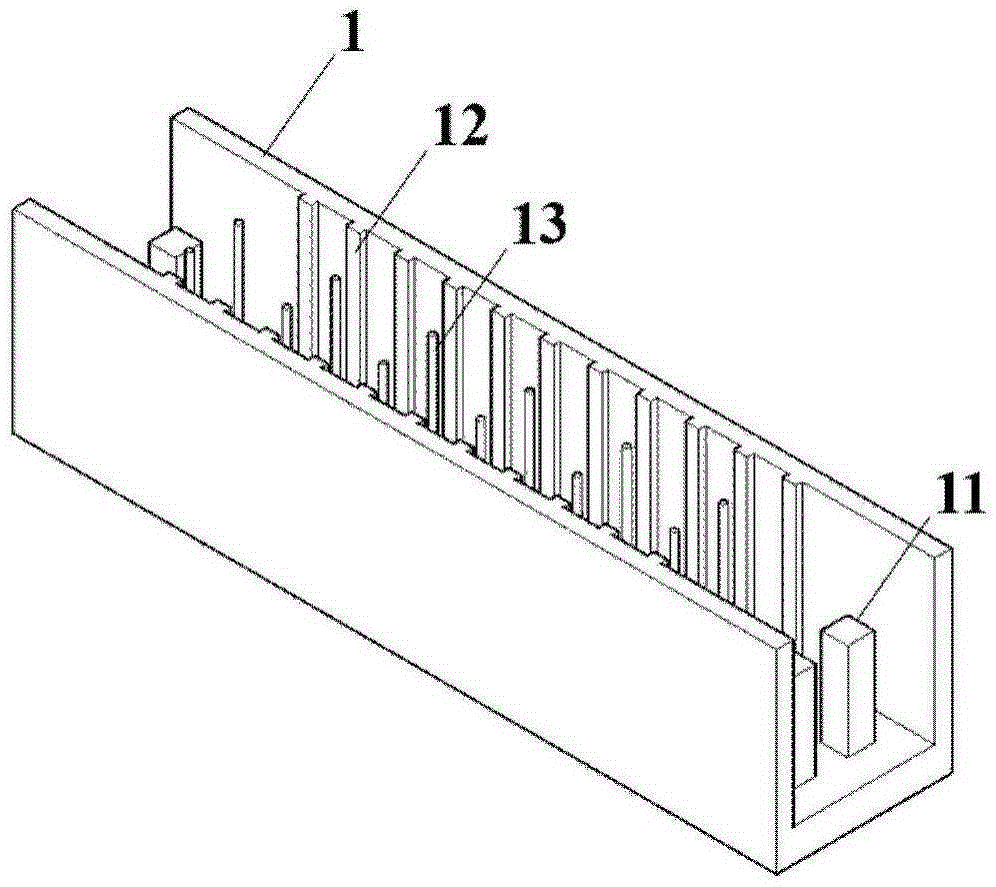

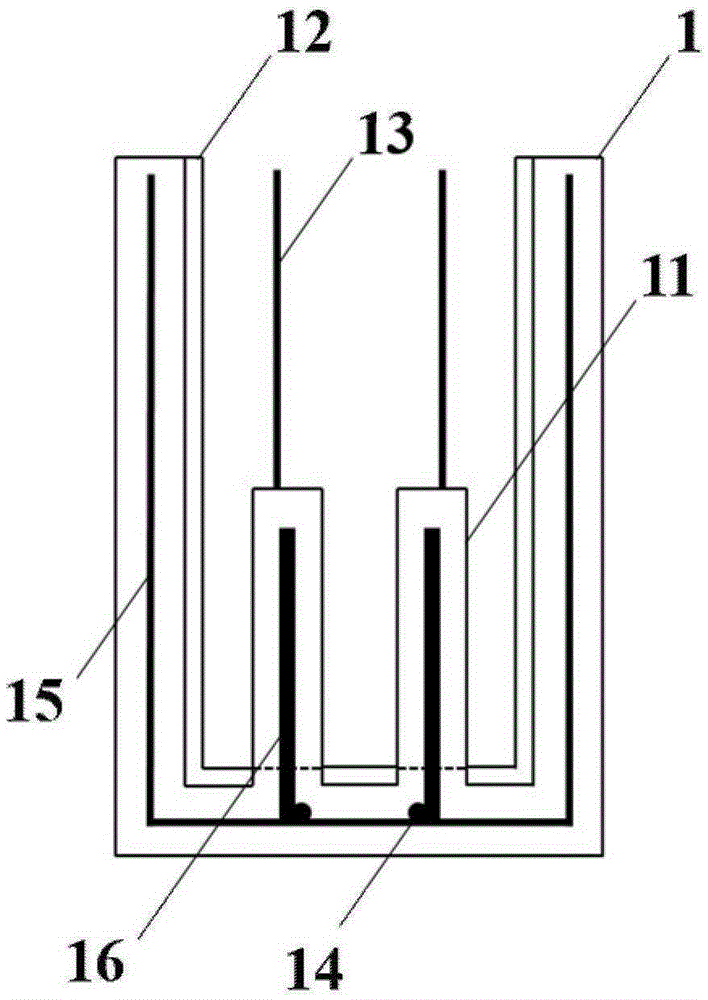

[0025] Referring to the accompanying drawings, a reinforced pinned permanent beam formwork provided by the present invention is composed of a panel 1 and a connector 2; the panel 1 has a first connection part 11, and the connector 2 has a second connection part 21, the first connection part 11 can be inserted into the second connection part 21; the pouring interface of the panel 1 is provided with a first protrusion 12, and the pouring interface of the connector 2 is provided with a third protrusion 22; The cross-section of the panel is concave; the panel and connectors are made of ultra-high toughness cement-based composite materials; the panels and connectors of the permanent formwork are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com