The method of making up the raw material of titanium steel clad plate

A composite plate and steel plate technology, which is applied in the direction of metal rolling, metal processing equipment, auxiliary arrangement, etc., can solve the problem of good bonding of the bonding surface, and cannot guarantee the cladding titanium plate and the base steel plate, etc., to achieve the bonding state good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

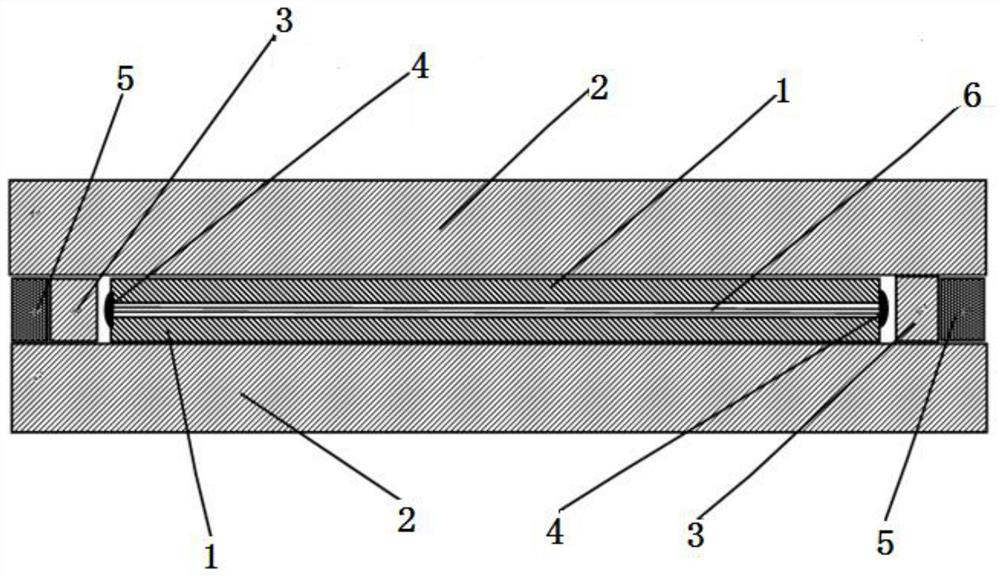

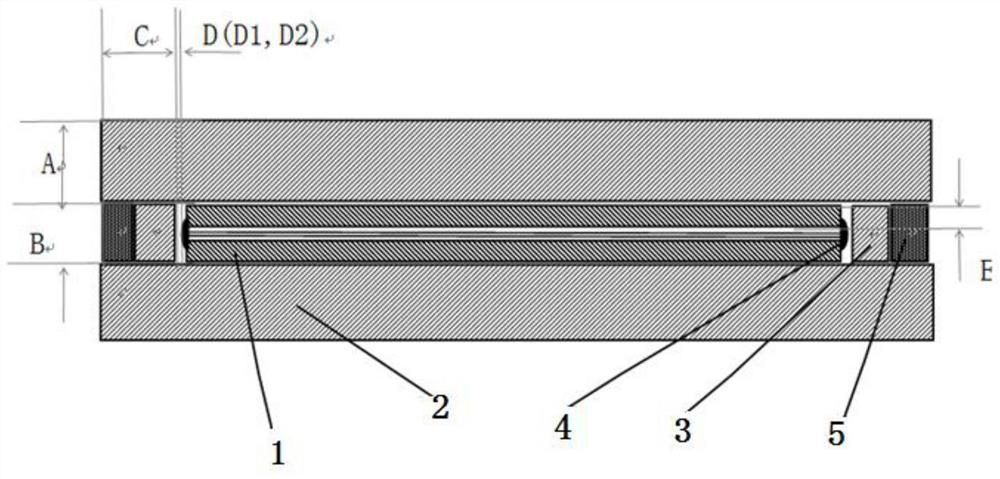

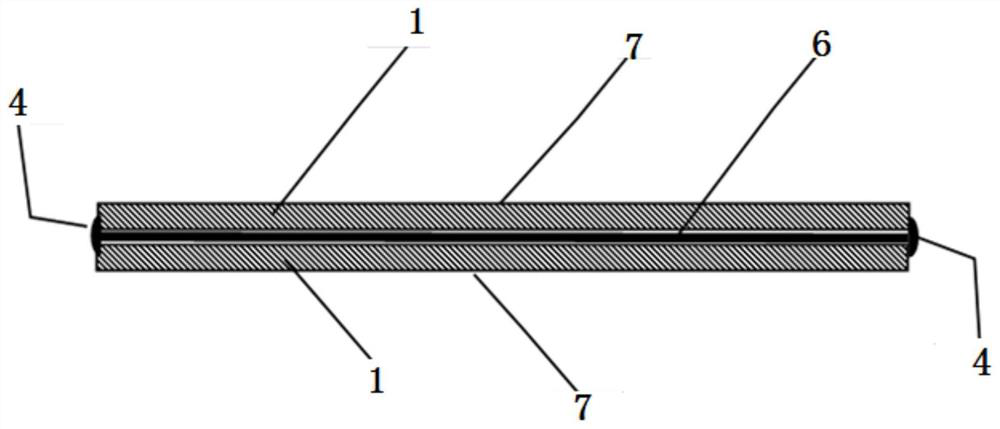

Method used

Image

Examples

Embodiment 1

[0048] Example 1: A raw material billet with a finished product thickness of 5.0 mm titanium-steel composite plate (the thickness of the clad titanium plate is 1.5 mm, and the thickness of the base steel plate is 3.5 mm).

[0049] Step 1: Raw material preparation.

[0050] See Example 1 in Table 1, the plugging steel plate contains 0.10% carbon and 0.50% manganese, which are higher than the 0.08% carbon and 0.40% manganese content of the base steel plate 2, and TA0 is used as the raw material of the cladding titanium plate.

[0051] According to the thickness of the finished titanium-steel clad plate is 5.0mm, the thickness of the cladding titanium plate is 1.5mm, and the thickness of the base steel plate is 3.5mm, and the compression ratio is 15, the thickness of the cladding titanium plate raw material TA0 is calculated to be 22.5mm, and the base plate thickness is 22.5mm. The thickness of the raw material of the steel plate 2 is 52.5 mm, see Example 1 in Table 2.

[0052] ...

Embodiment 2

[0081] Example 2: a raw material group blank with a finished product thickness of 8.0 mm titanium-steel composite plate (the thickness of the clad titanium plate is 1.5 mm, and the thickness is 6.5 mm).

[0082]Step 1: Raw material preparation.

[0083] See Example 2 in Table 1, the plugging steel plate contains 0.16% carbon and 1.00% manganese, which are higher than the 0.12% carbon and 0.8% manganese content of the base steel plate 2, and TA2 is used as the raw material of the cladding titanium plate.

[0084] According to the thickness of the finished titanium-steel clad plate is 8.0mm, the thickness of the cladding titanium plate is 1.5mm, and the thickness is 6.5mm, and the compression ratio is 5, the thickness of the cladding titanium plate raw material TA2 is calculated to be 7.5mm, and the base steel plate is 2 The thickness of the raw material is 32.5 mm, see Example 2 in Table 2.

[0085] Length and width of the raw material of the cladding titanium plate TA2: First...

Embodiment 3

[0114] Example 3: A raw material blank with a finished product thickness of 10.0 mm titanium-steel composite plate (the thickness of the clad titanium plate is 2.0 mm, and the thickness is 8.0 mm).

[0115] Step 1: Raw material preparation.

[0116] See Example 3 in Table 1, the plugging steel plate contains 0.16% carbon and 1.00% manganese, which are higher than the 0.16% carbon and 1.00% manganese content of the base steel plate 2, and TA1 is used as the raw material of the cladding titanium plate.

[0117] According to the thickness of the finished titanium-steel clad plate is 10.0mm, the thickness of the cladding titanium plate is 2.0mm, and the thickness is 8.0mm, and the compression ratio is 10, the thickness of the cladding titanium plate raw material TA2 is calculated to be 20.0mm, and the base steel plate is 2 The thickness of the raw material is 80.0 mm, see Example 3 in Table 2.

[0118] Length and width of the raw material of the cladding titanium plate TA1: First...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com