Structural design method for load-bearing section of miniature anti-slip compound pile

A technology for structural design and combination piles, which is used in foundation structure engineering, excavation, sheet pile walls, etc., to ensure the bending and shear strength, accurate results, and improve bending stiffness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

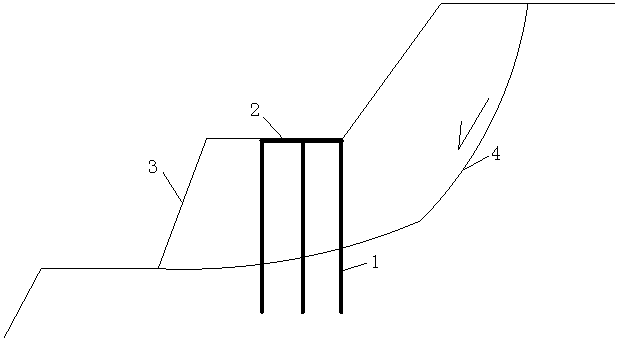

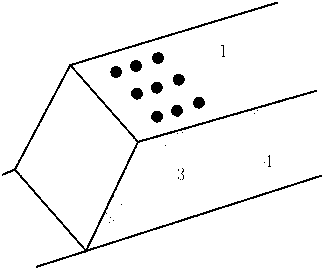

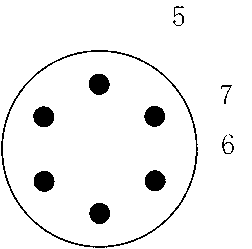

[0035] Example 1: According to attached figure 1 And attached figure 2 For the slope shown, according to the sliding body 3 and sliding surface 4 of the rock and soil of the slope, a micro anti-sliding composite pile 1 is designed, including a top beam 2 and a micro pile 5, and the micro pile 5 is provided with a main reinforcement 6 and a stirrup 7. After the on-site geological survey, the mechanical properties of the rock and soil mass of the slope are determined through tests; the stability of the slope is evaluated, and the remaining sliding thrust of the slope is calculated Q .

[0036] Consider the adjustment and distribution of the remaining sliding thrust of the slope between the piles, and determine the distribution ratio of the remaining sliding thrust of each pile; Figure 4 The calculation model diagram of the miniature anti-sliding composite pile is shown, and the sliding thrust acting on the rear, middle and front piles is calculated as q 1 , q 2 , q ...

Embodiment 2

[0058] Example 2: The total length of K38+560~K38+680 side slope of Tongping Expressway is 120m. From top to bottom, the slope engineering strata are 15-30m strongly weathered sandy slate, 4.0m strongly weathered carbonaceous shale, and 14.4-14.8m moderately weathered sandy slate. Carbonaceous shale is exposed on the 1st and 2nd grade slopes. The physical parameters of slope rock and soil are shown in Table 1. The initial design maximum excavation height of the slope was 34.8m. When the slope was excavated to the first-level platform, a landslide occurred after heavy rainfall. After the landslide, the slope was trimmed, and the maximum excavation height after the trimming was 53.8m.

[0059] Table 1 Physical and mechanical parameters of slope rock and soil

[0060]

[0061] Design miniature anti-sliding tissue pile with the method of the present invention, as attached Figure 9 Shown, comprise front pile 8 and back pile 9. Calculate the maximum remain...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Pile diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com