Lightweight warping-resistant continuous glass fiber enhanced polypropylene composite material, and preparation method thereof

A continuous glass fiber and composite material technology is applied in the field of filling glass fiber reinforced polypropylene composite materials with hollow glass microspheres and the field of preparation, and can solve the problems of high density, high use cost, hollow glass microspheres, and high density of glass fiber reinforced polypropylene composite materials. Easy to break and other problems, to achieve the effect of excellent material performance and high density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

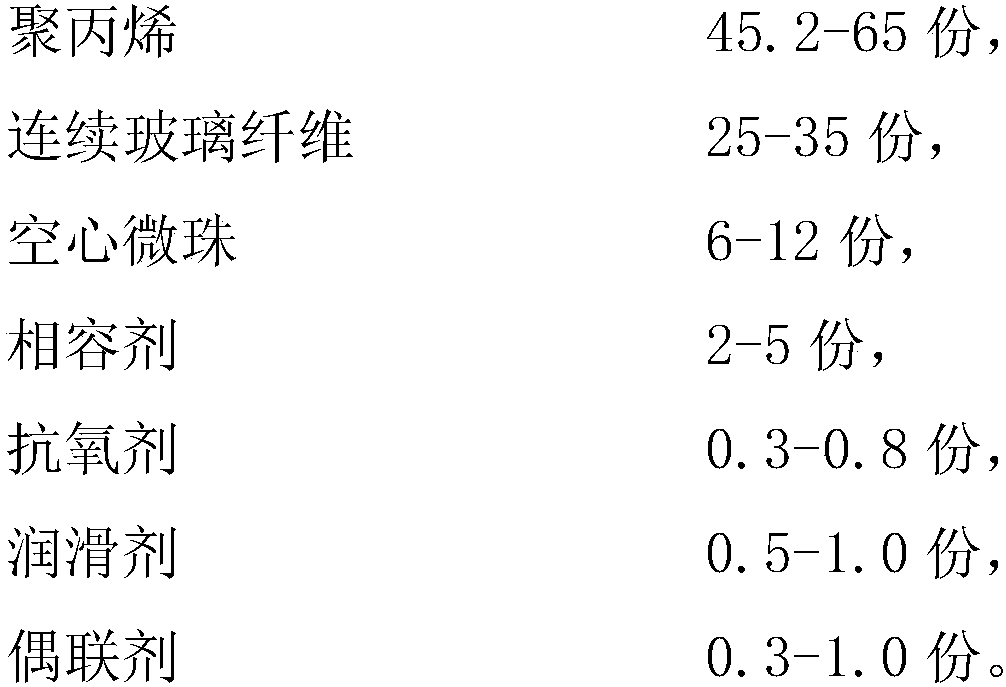

[0034]

[0035] Dosing according to the above ratio, mix polypropylene, compatibilizer, antioxidant, lubricant, coupling agent evenly in a high-speed mixer, then feed the mixture into the extruder from the main feed port, and continuously The glass fiber is fed into the extruder from the long glass fiber feed port, and the hollow microspheres are fed into the extruder from the side feed port; the speed of the main engine is controlled at 300-420 rpm, and the temperature of the barrel is controlled at 180-220°C .

Embodiment 2

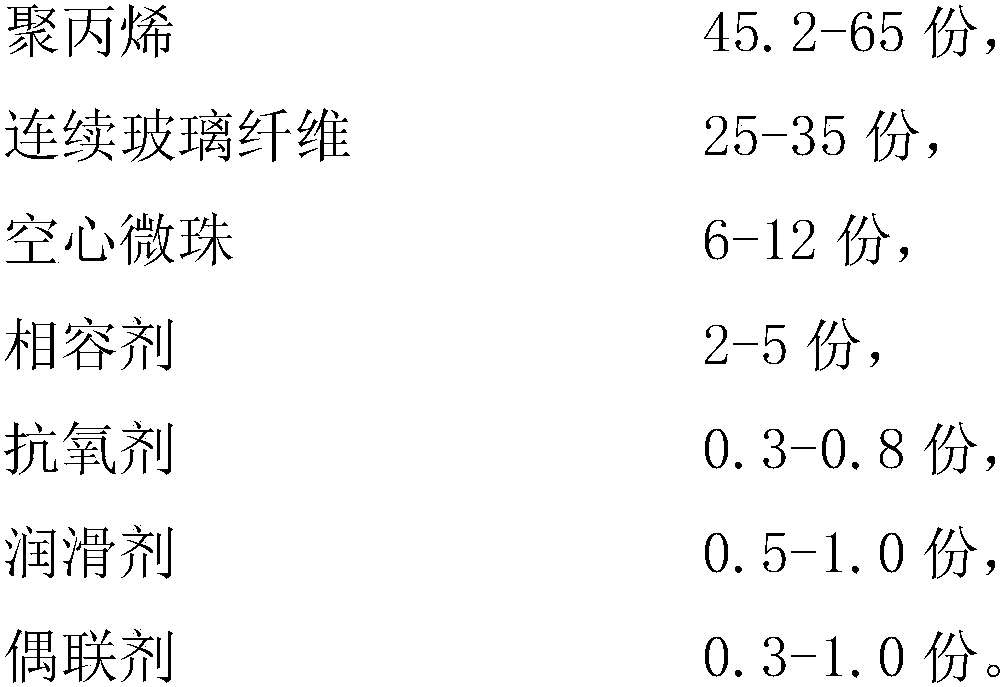

[0037]

[0038]

[0039] Dosing according to the above ratio, mix polypropylene, compatibilizer, antioxidant, lubricant, coupling agent evenly in a high-speed mixer, then feed the mixture into the extruder from the main feed port, and continuously The glass fiber is fed into the extruder from the long glass fiber feed port, and the hollow microspheres are fed into the extruder from the side feed port; the speed of the main engine is controlled at 300-420 rpm, and the temperature of the barrel is controlled at 180-220°C .

Embodiment 3

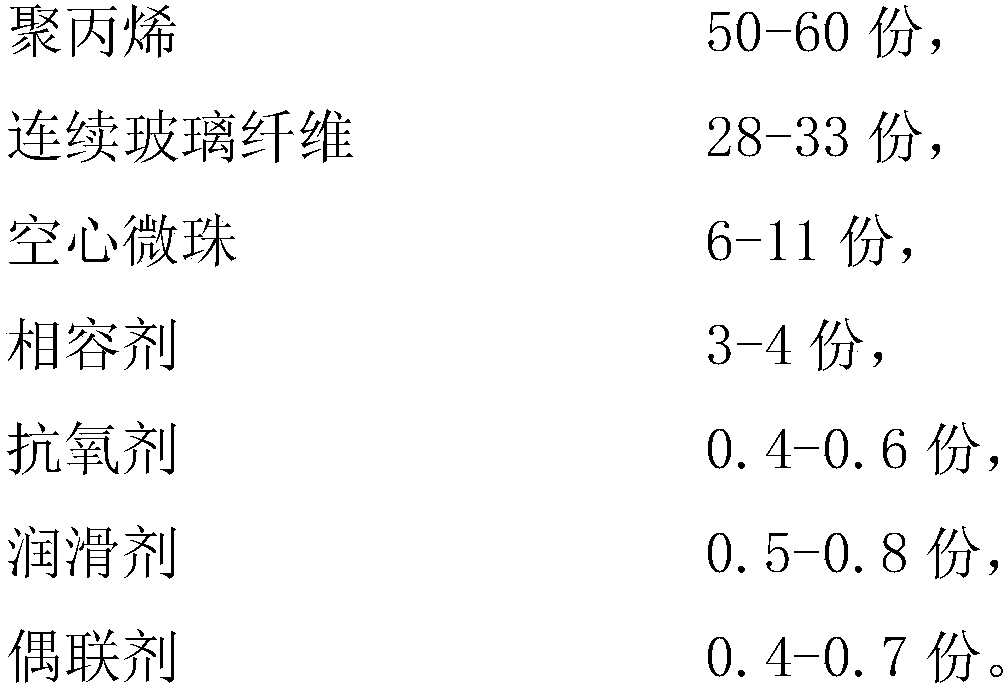

[0041]

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com