Patents

Literature

36results about How to "Guaranteed bending strength" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Carbon ceramic braking pad for high-speed train and preparation method of carbon ceramic braking pad

ActiveCN103511525ALess impact on friction and wear propertiesHigh and stable coefficient of frictionFriction liningFiberCeramic composite

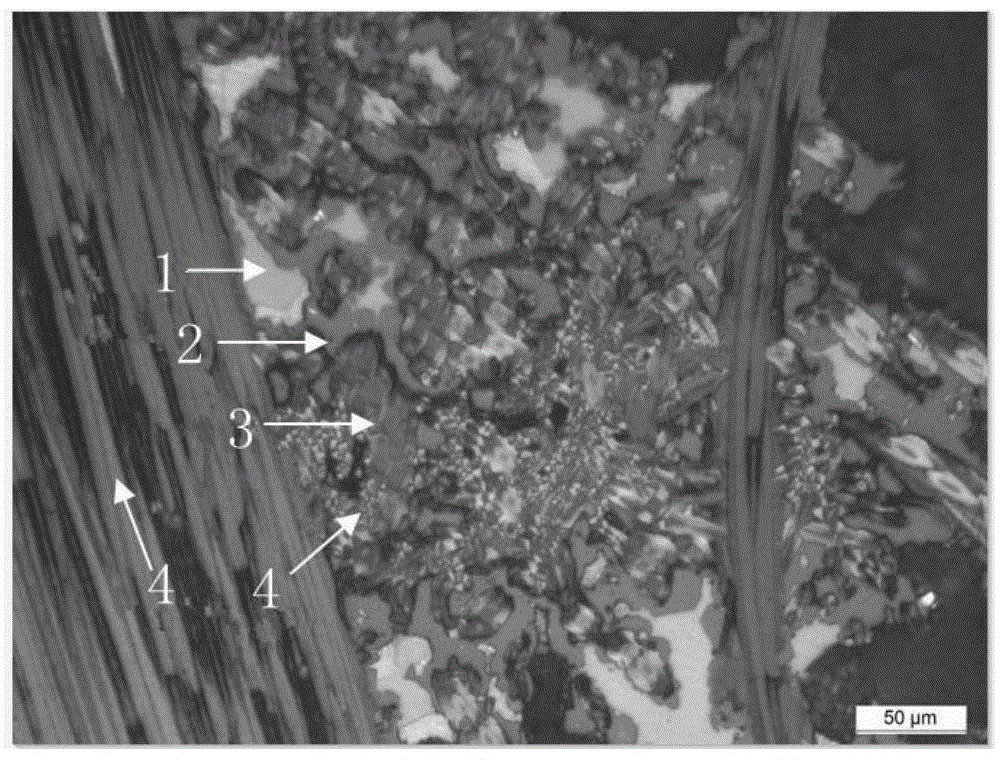

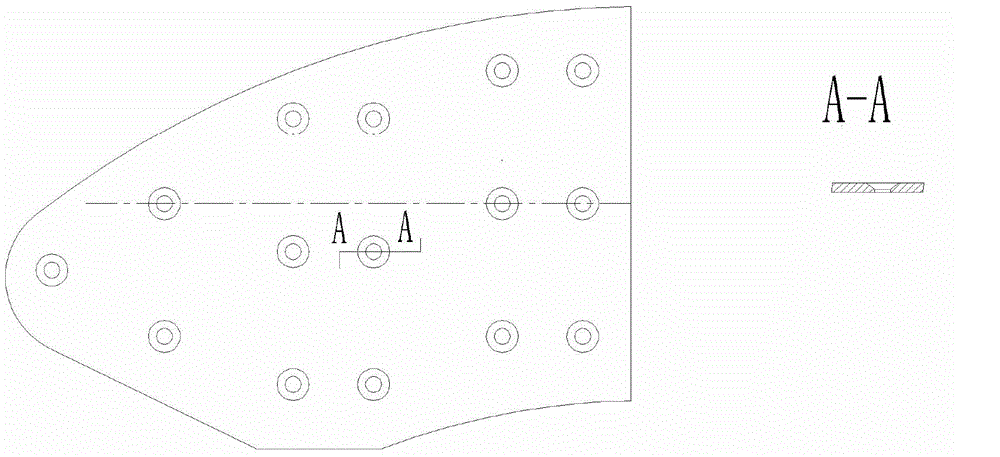

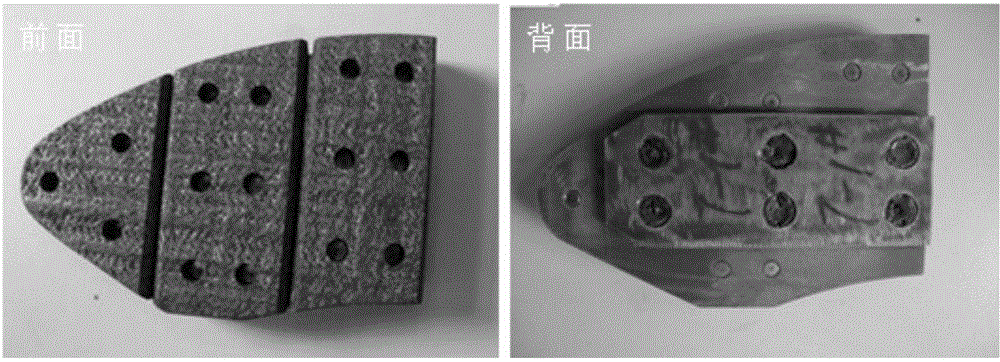

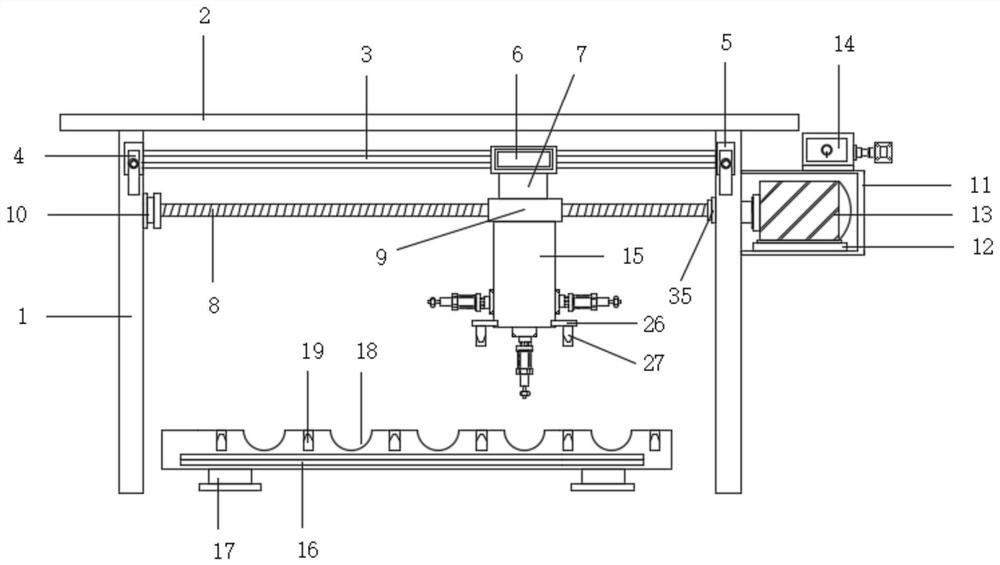

The invention relates to a carbon ceramic braking pad for a high-speed train and a preparation method of the carbon ceramic braking pad. The carbon ceramic braking pad is made of carbon ceramic composite material; the carbon ceramic composite material comprises the following components in percentage by mass: 16-30 percent of carbon fibers, 20-36 percent of pyrolytic carbon, 28-46 percent of silicon carbide, 6-12 percent of molybdenum disilicide and 2-6 percent of simple substance silicon; the density of the carbon ceramic composite material is 1.8-2.4g / cm<3>; the carbon fibers are uniformly distributed in the carbon ceramic composite material in a three-dimensional network structure. According to the invention, after the high-temperature heat treatment is performed on a carbon fiber felt with the density of 0.20-0.65g / cm<3>, the pyrolytic carbon is generated in the carbon fiber felt through the thermal-gradient chemical vapor deposition carburizing treatment, then the catalytic graphitization treatment, non-immersion type melting infiltration and assembly are performed, so that the carbon ceramic braking pad for the high-speed train is obtained.The carbon ceramic braking pad is simple in preparation technology, moderate in friction coefficient, good in abrasion performance, stable in braking and strong in environmental suitability and can meet braking requirements of the high-speed train with the speed of 200Km / h.

Owner:HUNAN SHIXIN NEW MATERIALS CO LTD

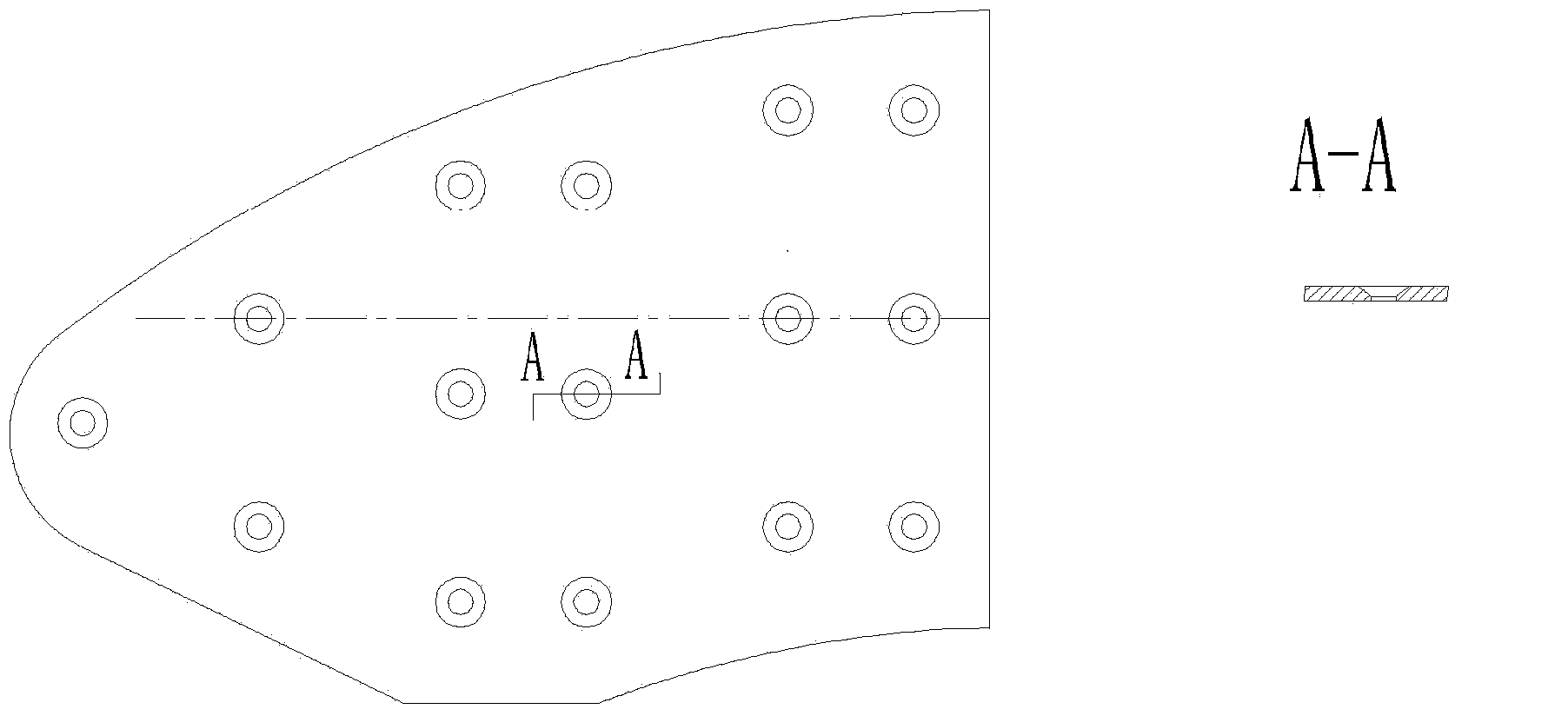

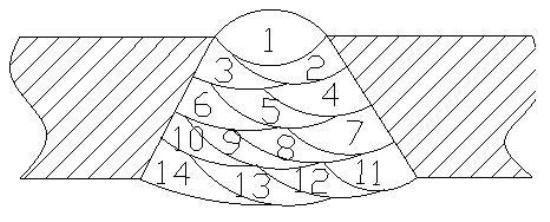

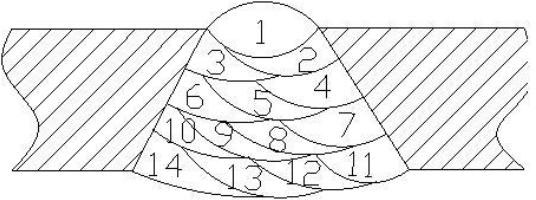

Method for welding butt-jointed seam of upward plate through manual arc welding

The invention relates to a method for welding a butt-jointed seam of an upward plate through manual arc welding, which comprises the following steps of: (1) burnishing the groove and 10-15 mm range of the surface of a test piece to have metallic luster, assembling and pairing the test piece, wherein the included angle between the groove face and the central vertical face is 30-35 DEG, the length of a root gap is 3.0-4.0 mm, the length of the truncated edge is 1.5-2.0 mm, and the unfitness of butt joint is less than 0.5 mm; (2) performing positioned welding on both ends of the test piece, wherein the length of the welding spot is 10-15 mm; and (3) adopting a layered lane welding process for the welding sequence. In the method, a linear or lateral small swing electrode manipulation manner is adopted for welding, therefore, the operation is simple and easy to master; welding joints are reduced, and the defects of porosity, slag inclusion, incomplete fusion and the like at the joints are prevented; the temperature of the molten bath is effectively controlled, and weld beading formed by the burnthrough of the root layer is prevented; the heat input of the weld seam is reduced, and the plasticity and the tenacity of the weld seam are effectively increased.

Owner:CHINA ENERGY ENG GRP TIANJIN ELECTRIC POWER CONSTR CO LTD

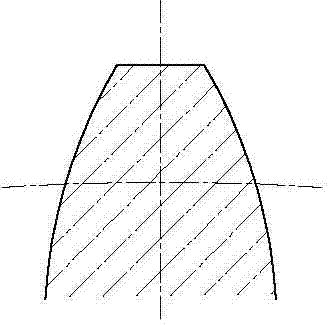

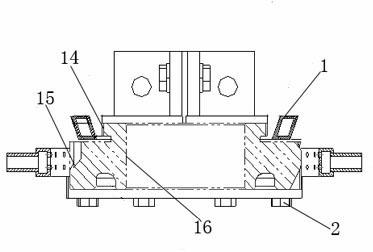

Crowned tooth gear, processing method and processing milling cutter

InactiveCN102506149ASimple structureEasy to processPortable liftingGear teeth manufacturing toolsMilling cutterCoupling

The invention discloses a crowned tooth gear. The teeth of the gear are in the form of a gradual tooth profile angle. The gear is characterized in that: the teeth (14) of the crowned tooth gear are in the form of a gradual tooth profile angle; the tooth length direction of the teeth (14) is crowned; the tooth forms of the radial section of the teeth (14) are consistent; and the tooth roots are fully arcs. A processing method of the crowned tooth gear comprises a step of processing the tooth forms by a forming process. The teeth are processed one by one on a numerically controlled milling machine. A used milling cutter comprises a cutter body (8) and a cutter head (9). The shape of a cutting blade of the cutter head (9) is the same as that of tooth slots (13) on the biggest part of the crowned tooth gear in size. The cutting blade comprises an involute section (10) and an arc section (12). The top end of the cutting blade is in full arc smooth connection. The crowned tooth gear is simple in structure, is convenient to process, is applied to a gear coupler, can ensure good linear contact between the crowned tooth gear and a gear ring and no point contact between the crowned tooth gear, ensures the bending strength of the gear roots at the same time, improves the using performance of the gear coupler and prolongs the service life of the gear coupler.

Owner:YIYANG KANGYI MACHINERY DEV

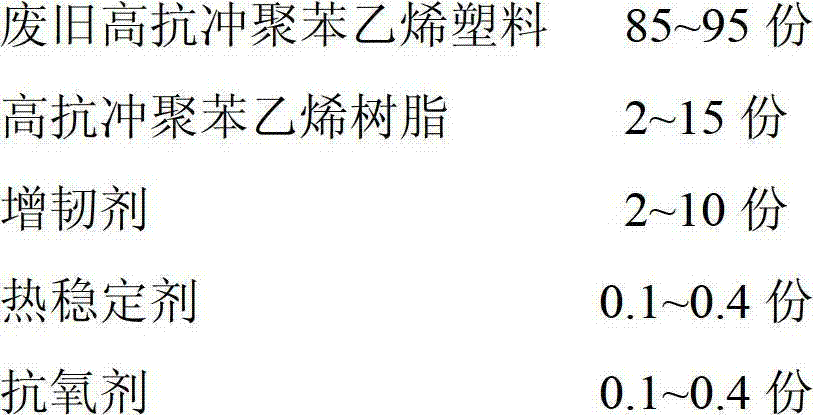

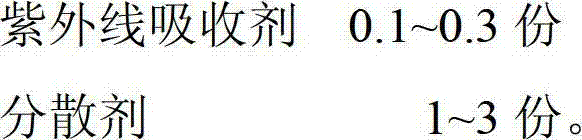

Modified high-impact polystyrene plastic

InactiveCN102786761AImprove impact strengthGuaranteed tensile strength and flexural strengthPlastic recyclingFlexural strengthAntioxidant

The invention relates to the technical field of modification treatment of waste plastics, in particular to modified high-impact polystyrene plastic. The modified high-impact polystyrene plastic comprises, by weight, 85-95 parts of waste high-impact polystyrene plastics, 2-15 parts of high-impact polystyrene resin, 2-10 parts of flexibilizers, 0.1-0.4 part of heat stabilizers, 0.1-0.4 part of antioxidants, 0.1-0.3 part of ultraviolet absorbers and 1-3 parts of dispersing agents. By adding certain quantities of novel high-impact polystyrene and plastic additives, the impact resistance of the waste HIPS (high-impact polystyrene plastic) is increased while the tensile strength and the flexure strength of the plastic are guaranteed, mechanical properties of the plastic reach standards of fresh materials, the waste HIPS plastic can be recovered effectively, and affection to environments is low.

Owner:四川长虹格润环保科技股份有限公司

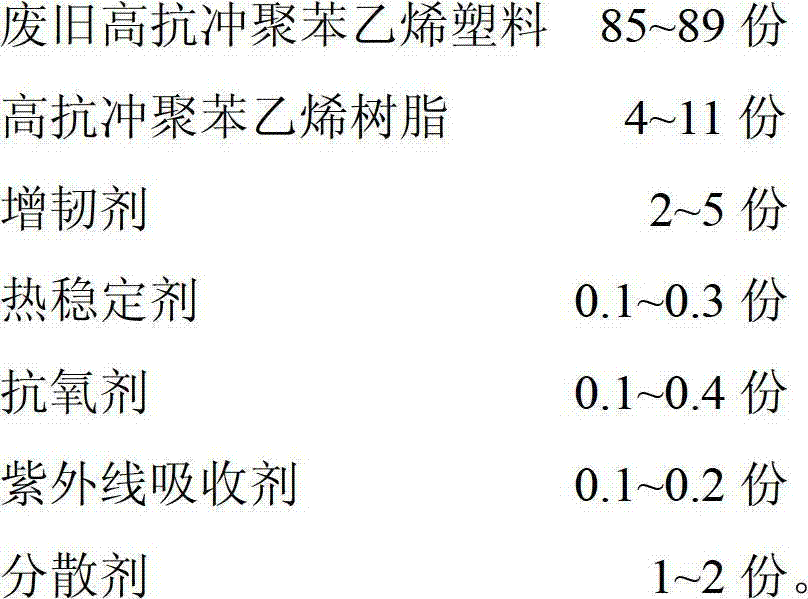

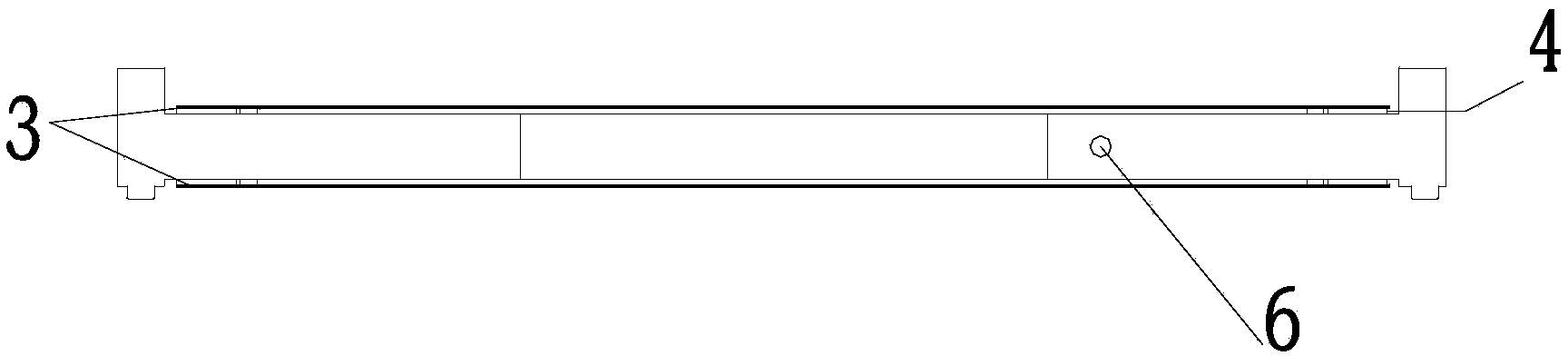

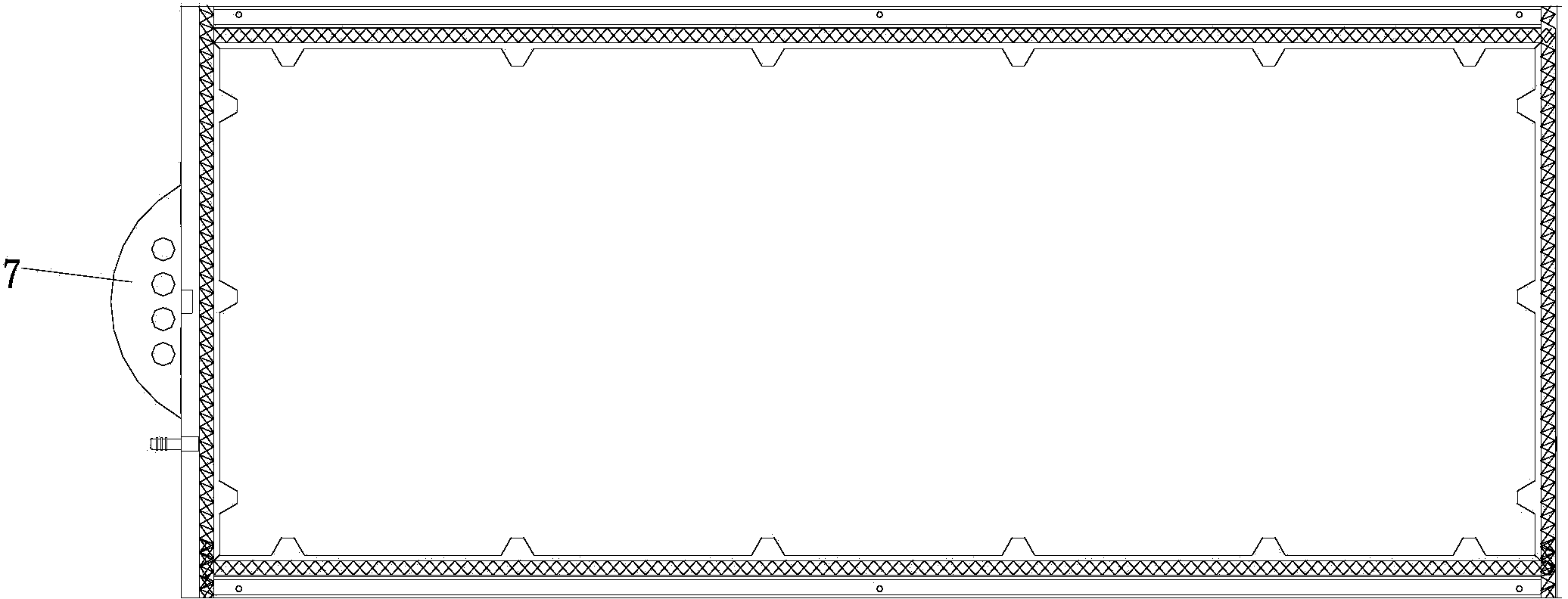

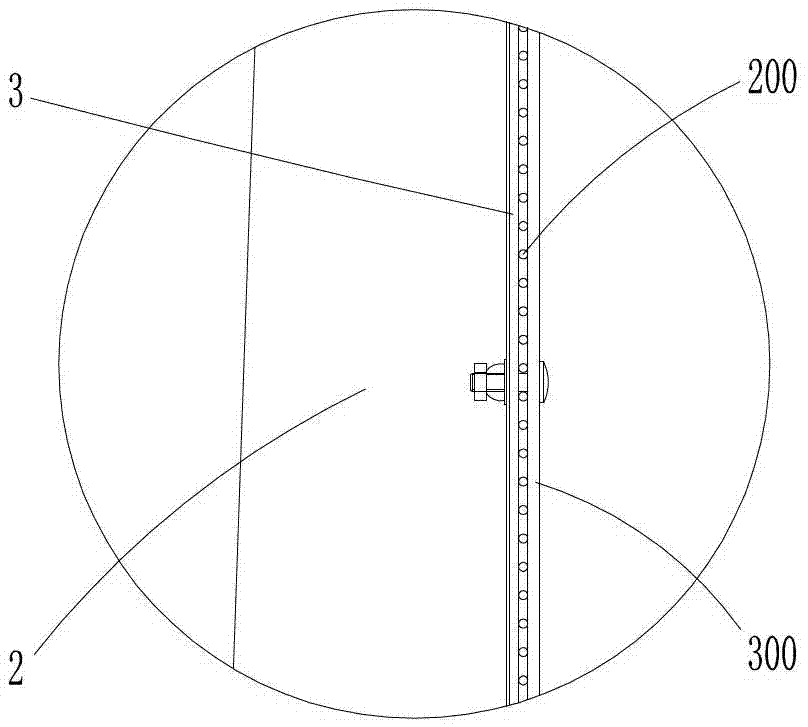

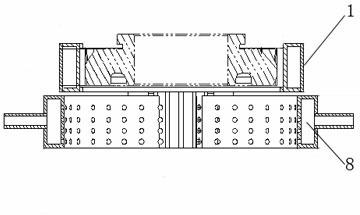

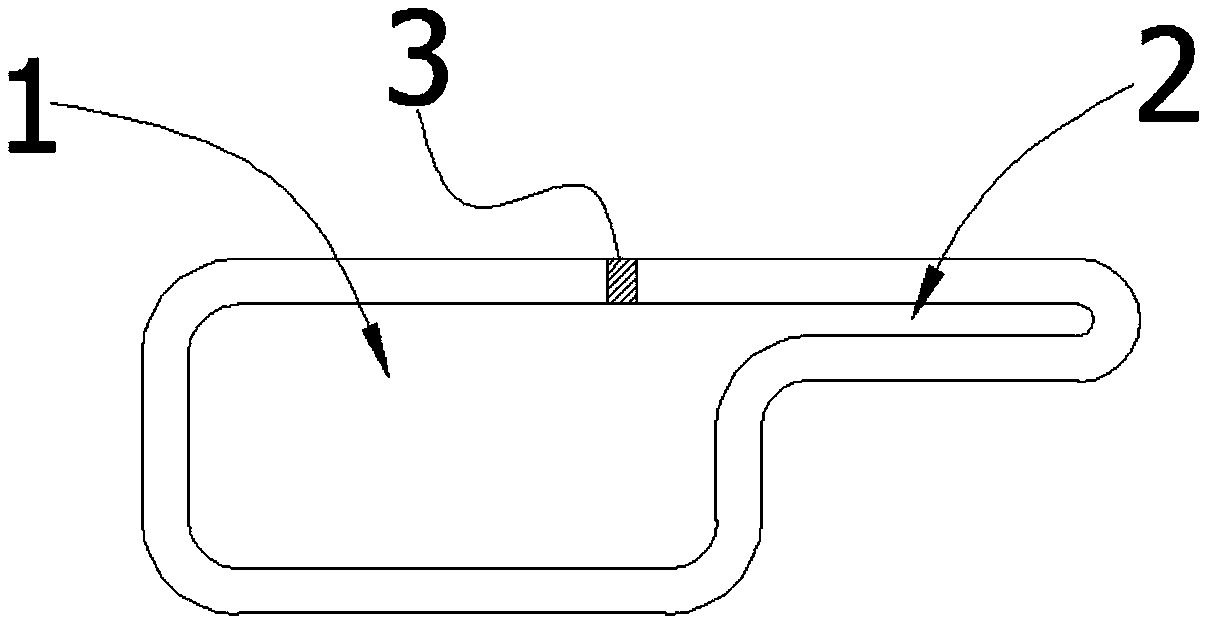

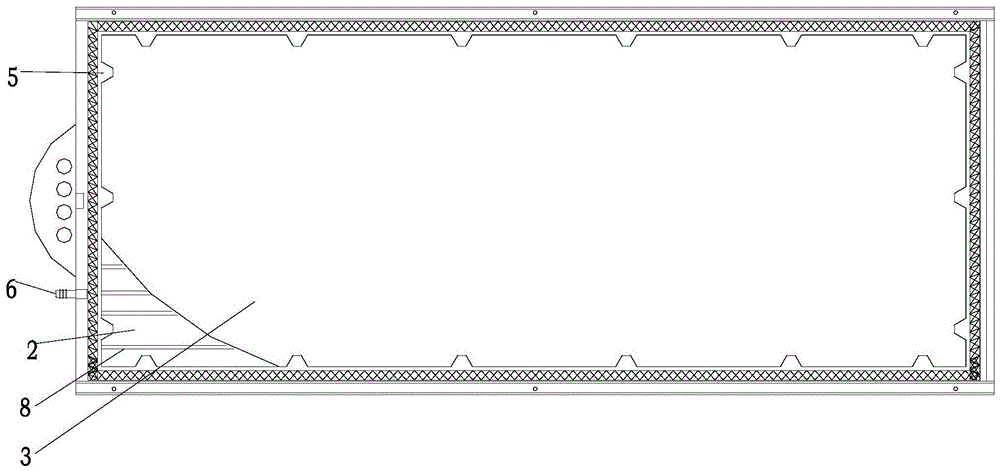

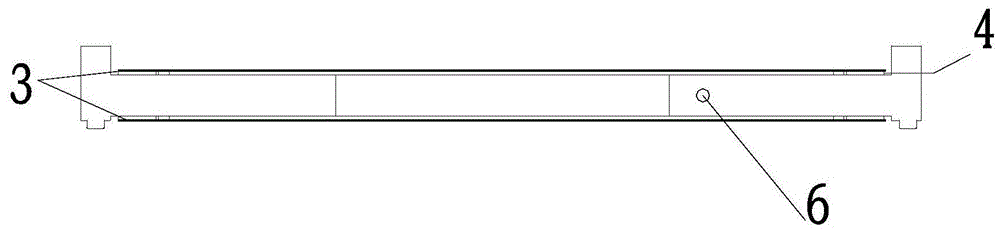

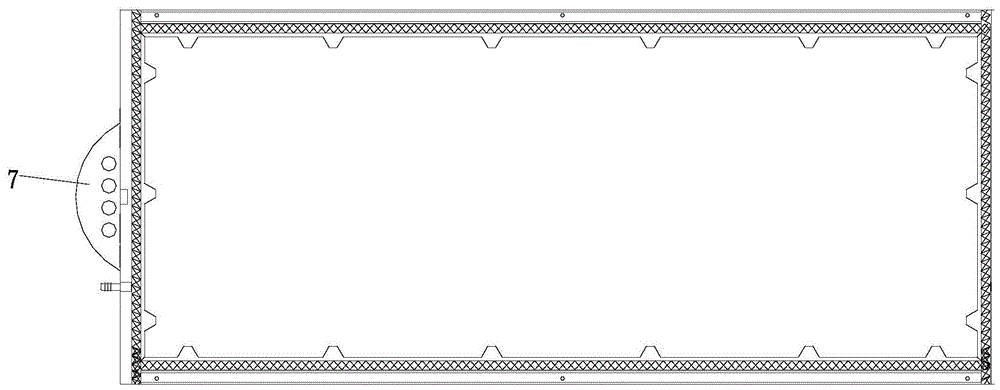

Split type flat membrane

ActiveCN104226119ARealize secondary valueLow costSemi-permeable membranesSustainable biological treatmentHollow fibre membraneFiltration membrane

The invention discloses a split type flat membrane. The split type flat membrane comprises a plurality of flat membrane units which can be stacked up and down, wherein each flat membrane unit comprises an edge strip framework, a support body and filtration membranes; the edge strip frameworks are formed by a plurality of edge strips; corresponding welding line strips and a plurality of riveting buttons are arranged on the inner side of the edge strip framework; the support body is mounted on the edge strip framework by virtue of the welding line strips; a water discharging channel connected with a water collecting runner is formed at the edge of the outer side of the edge strip framework; a plurality of runners and clamping openings are formed in the support body; the filtration membranes are paved on the upper side and the lower side of the support body; the riveting buttons are adapted with the clamping openings and can be directly clamped into the clamping openings; and the edge strips are in seamless butt joint with the support body. According to the split type flat membrane, the edge strips and the support body are combined for use and can be in seamless butt joint with each other to form an integrated support plate; the manufacturing cost of the flat membrane can be reduced; the problem that the flat membrane is difficult to be applied in a large scale can be solved; the investment cost of the flat membrane is equivalent to that of a hollow fiber membrane; the support body can be repeatedly used after the edge strips are demounted; and the secondary value of the support body is realized.

Owner:南京瑞洁特膜分离科技有限公司

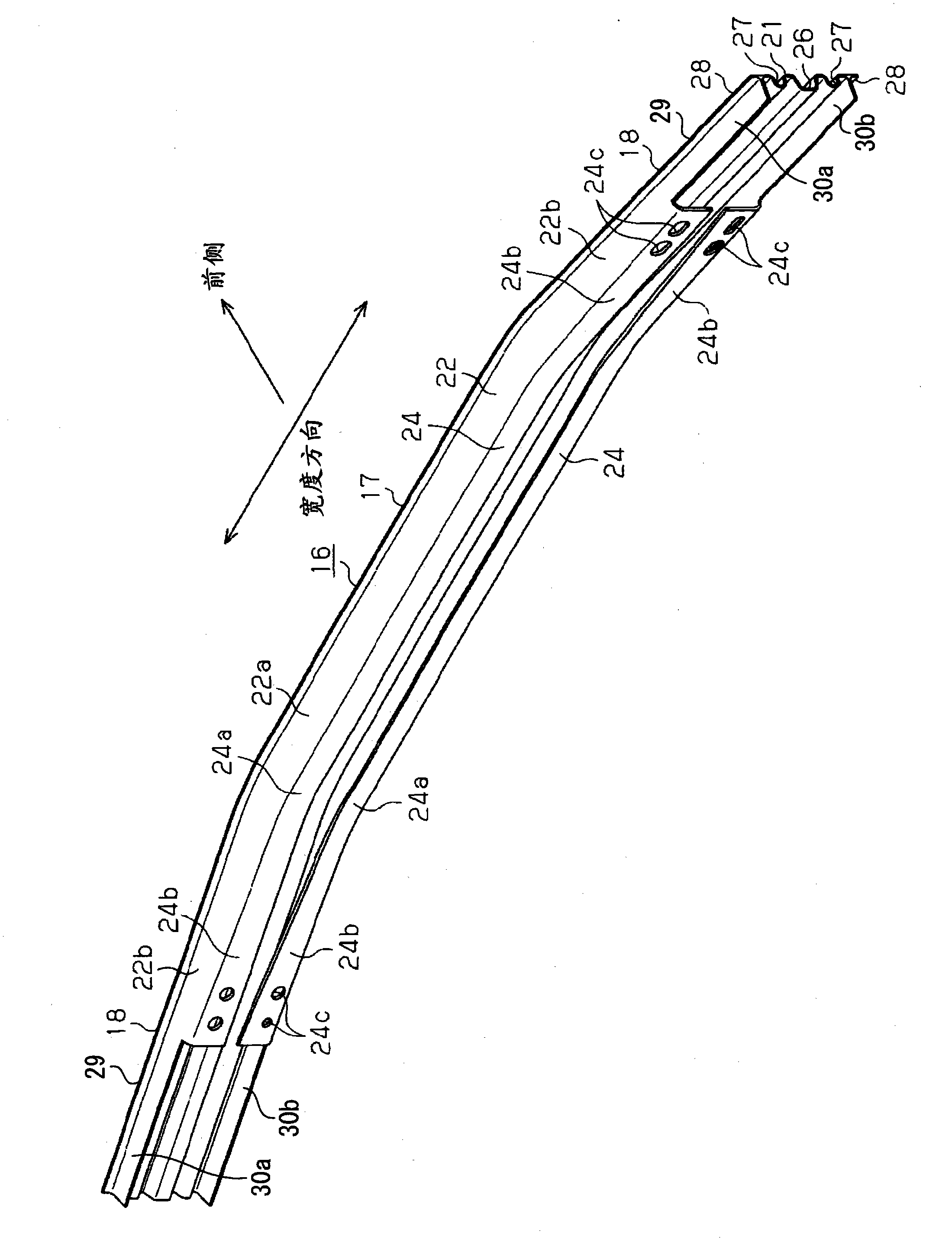

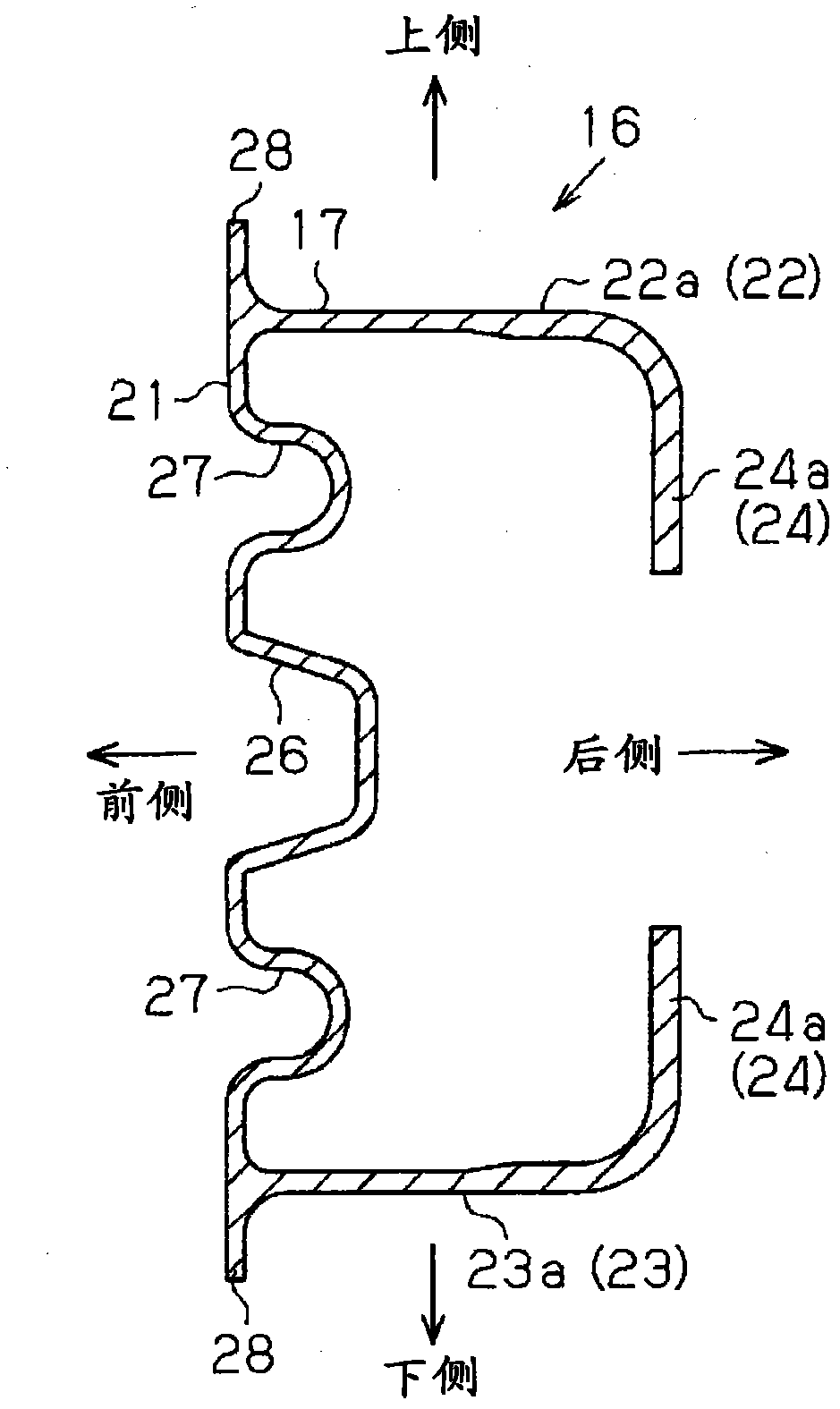

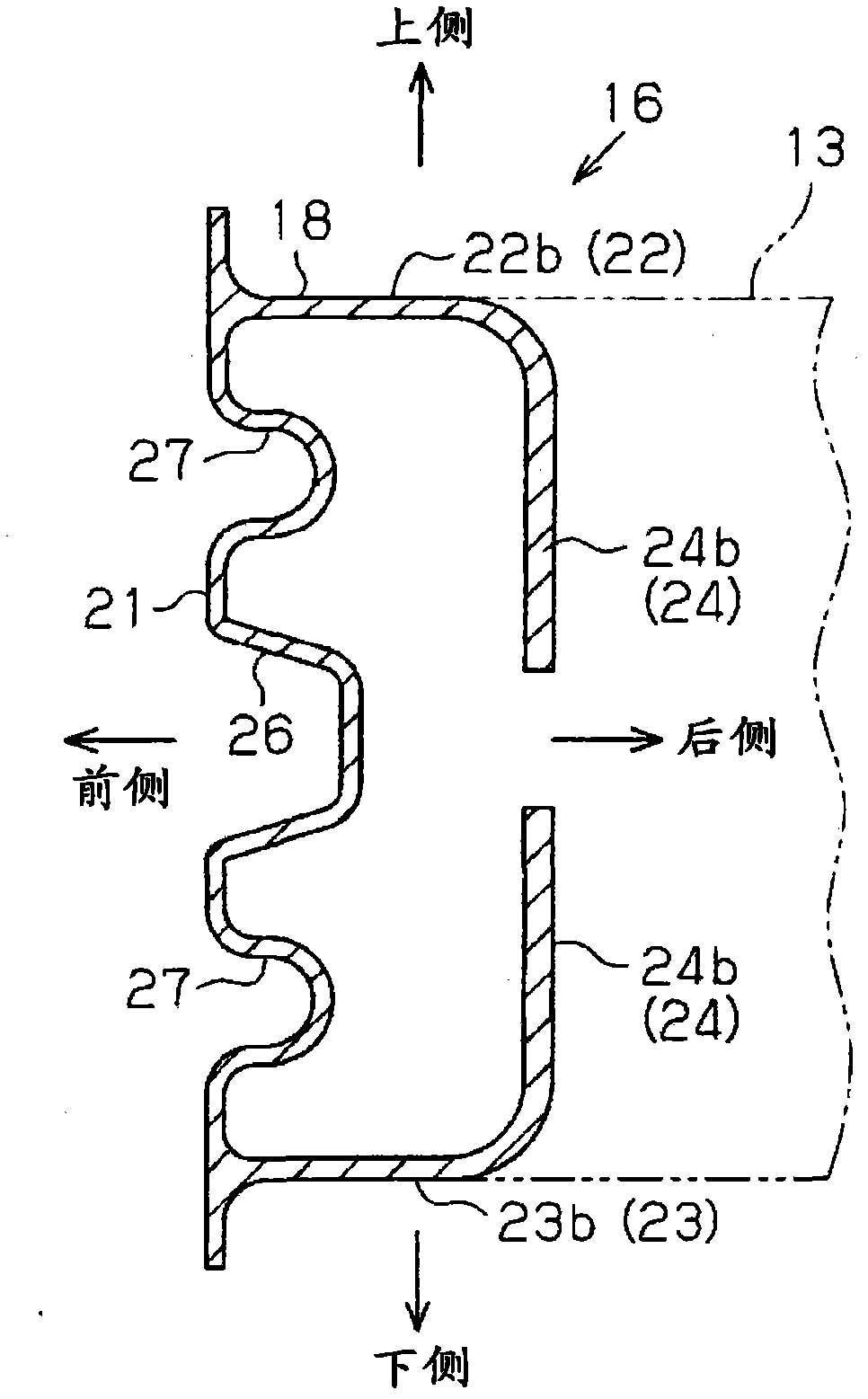

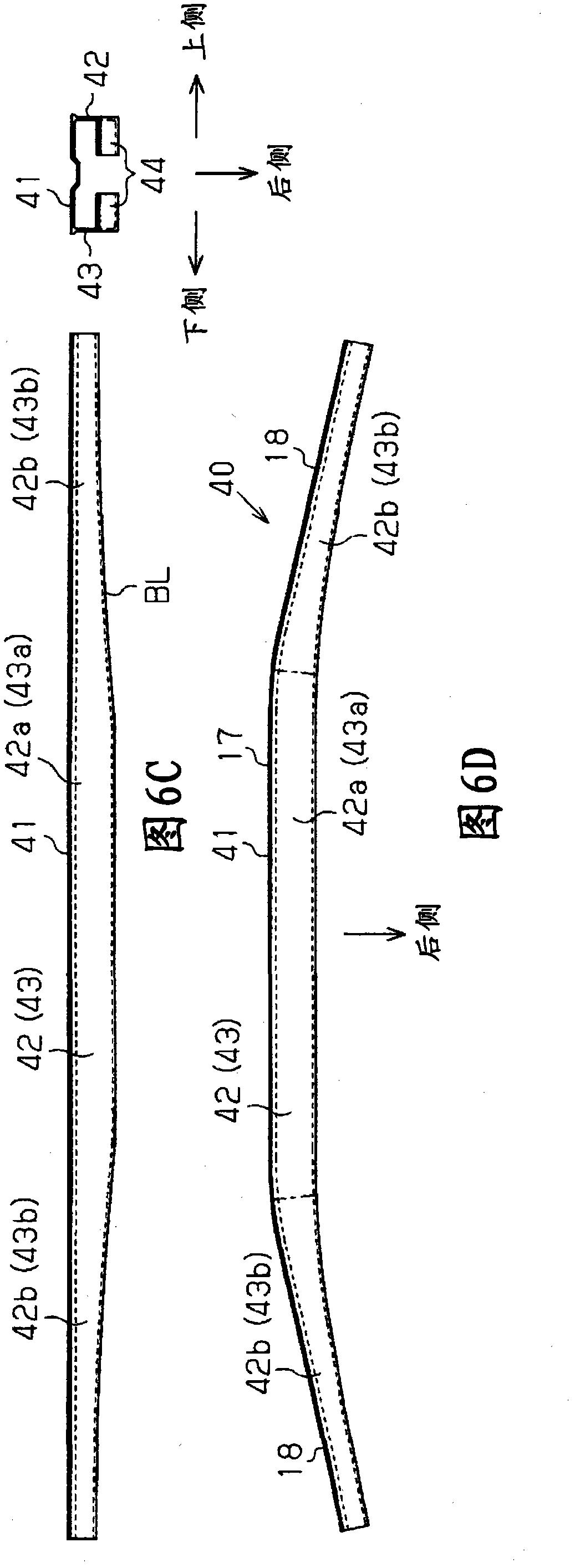

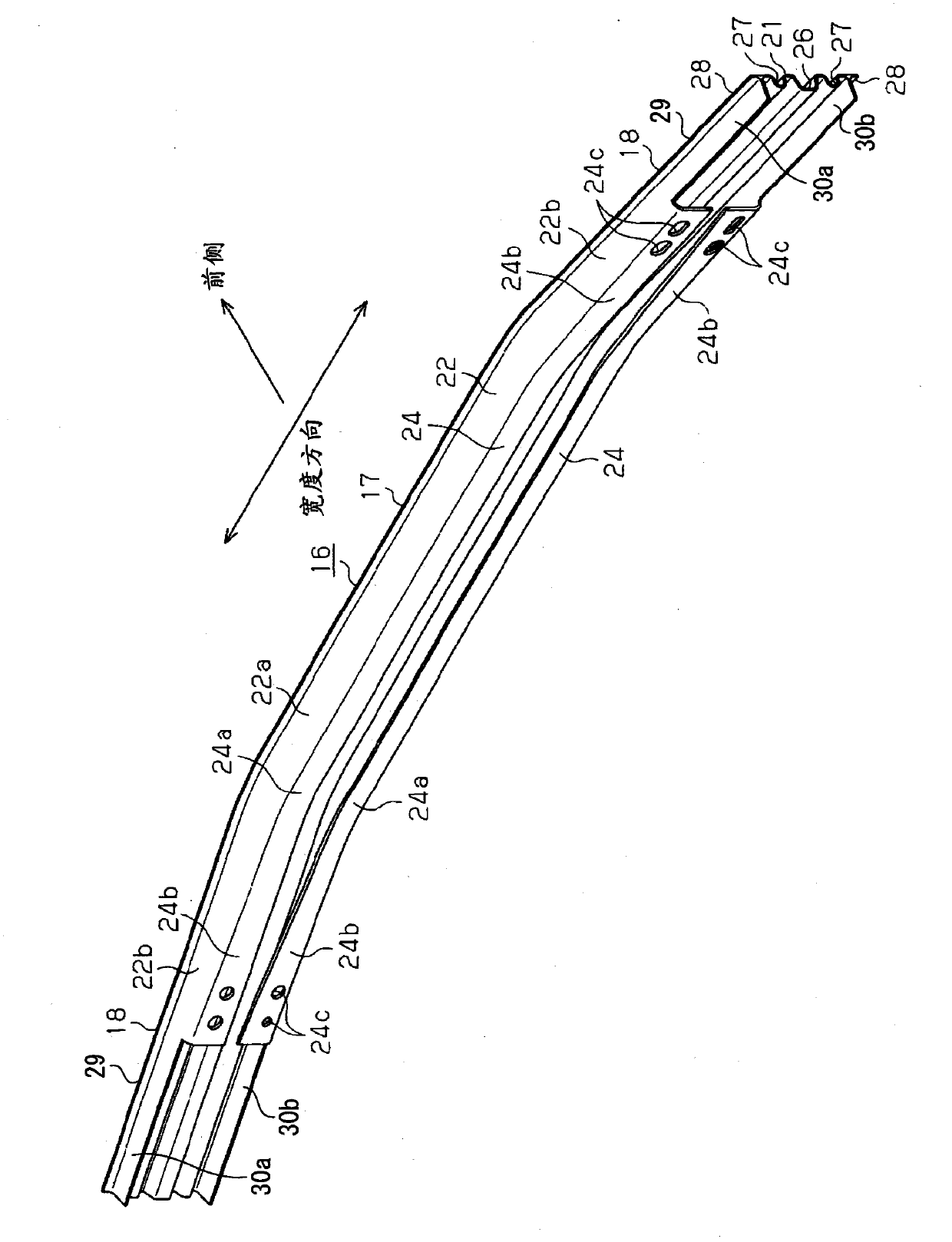

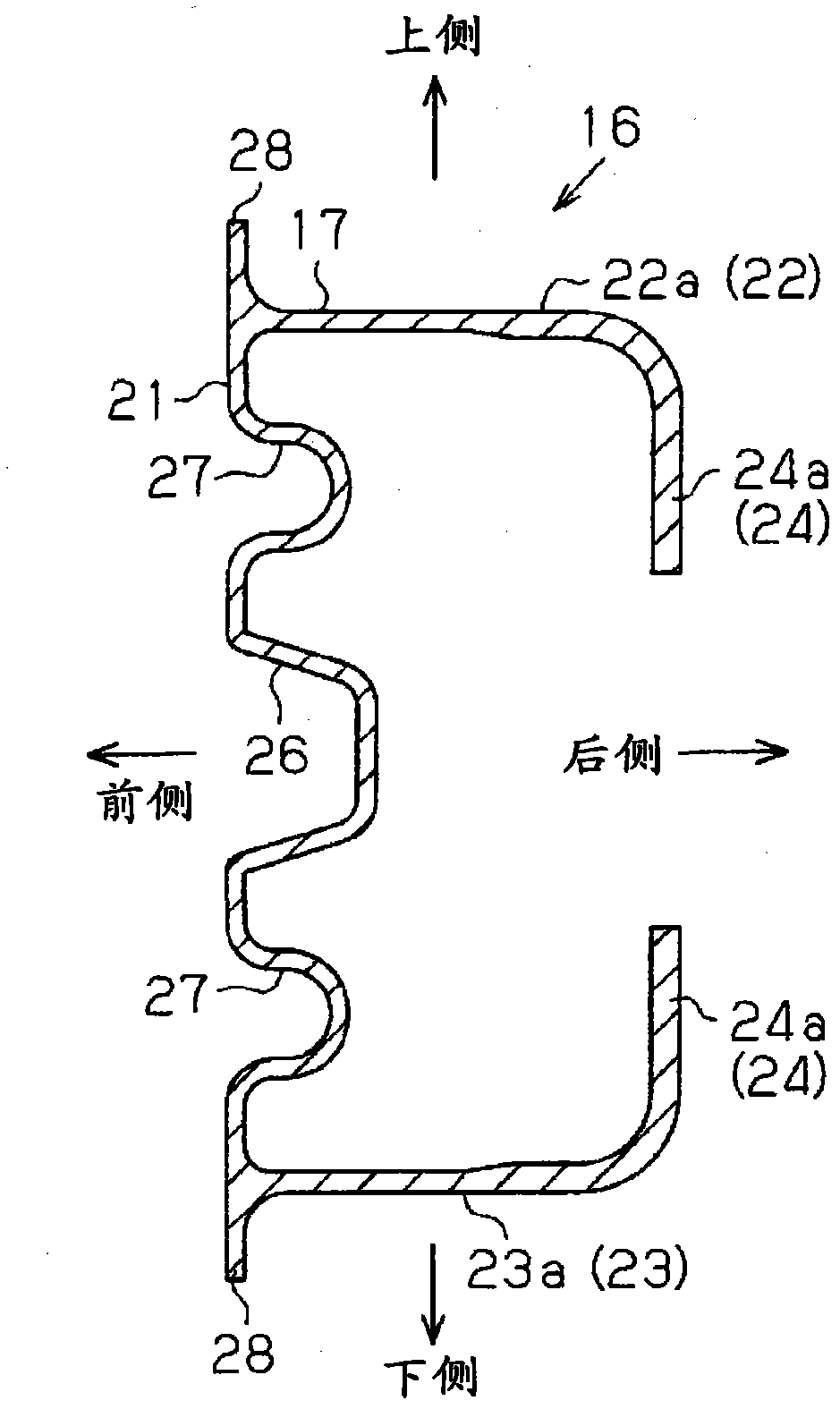

Bumper reinforcement and bumper device for vehicle

Owner:AISIN SEIKI KK +1

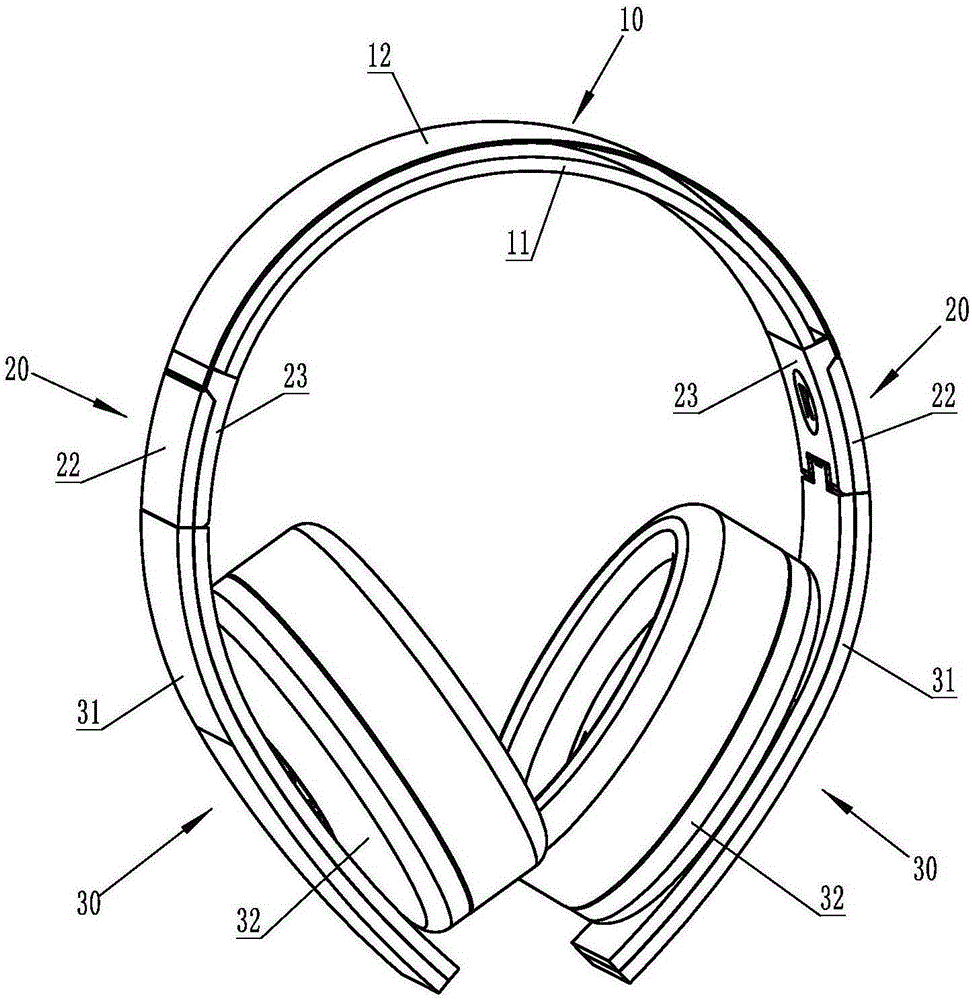

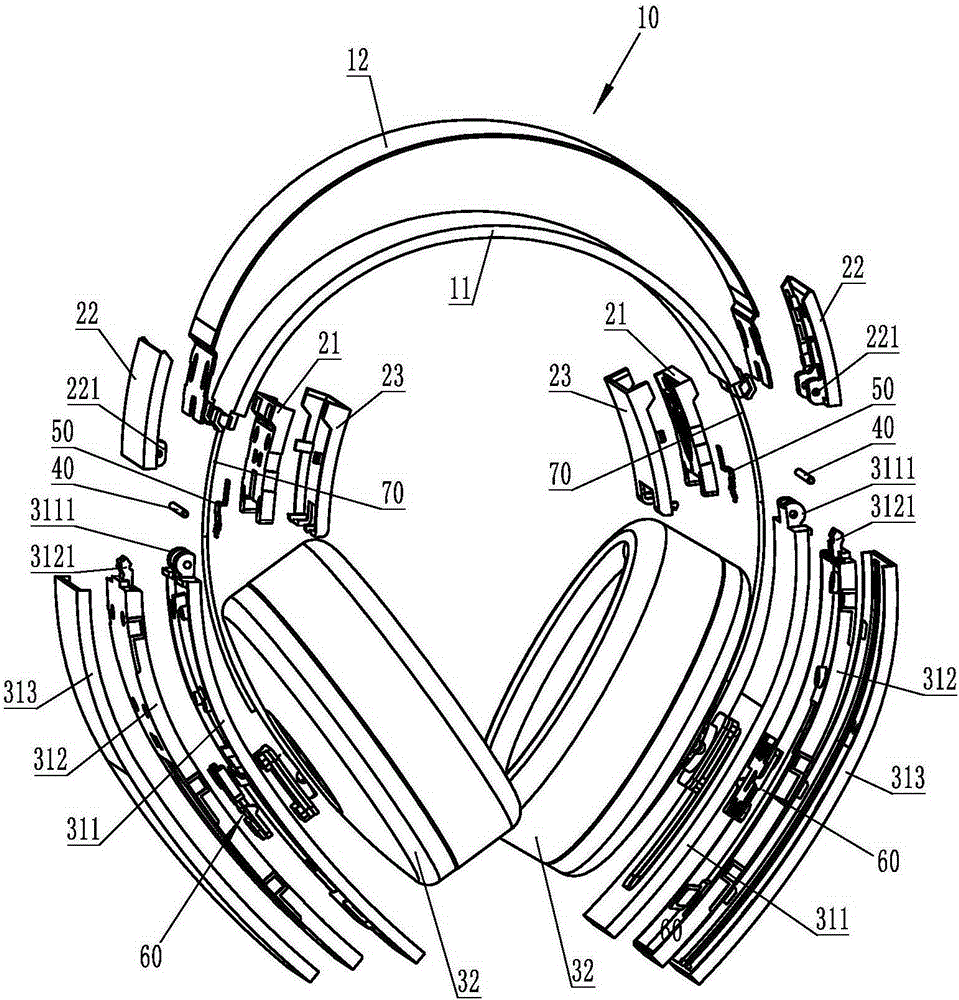

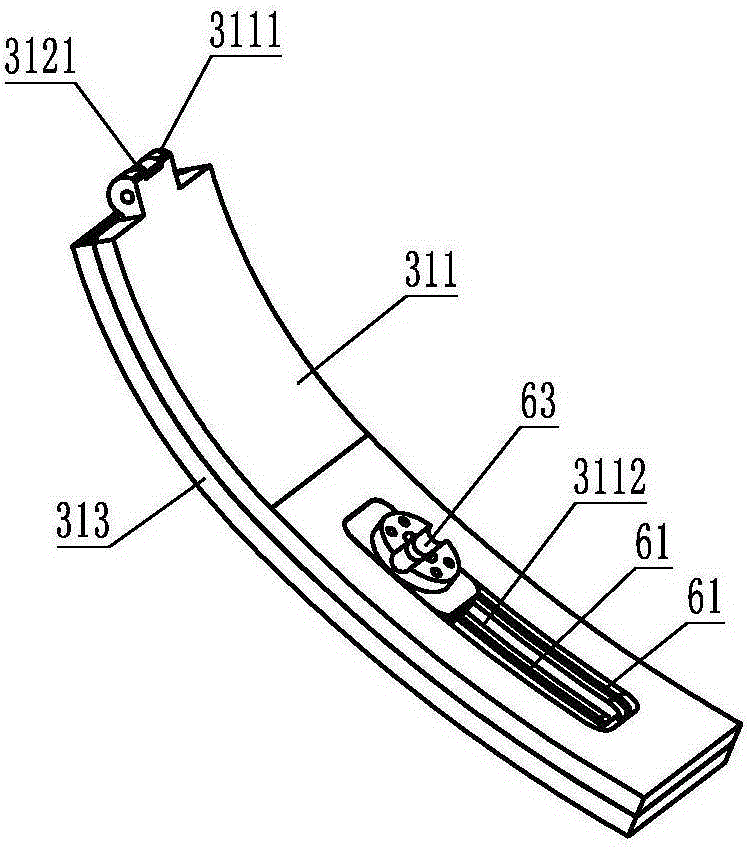

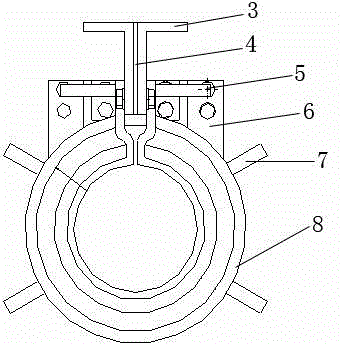

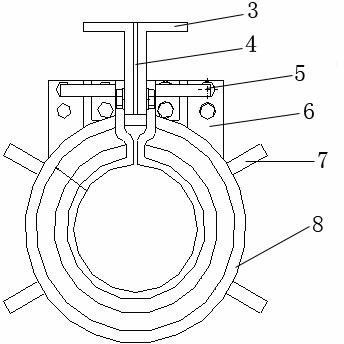

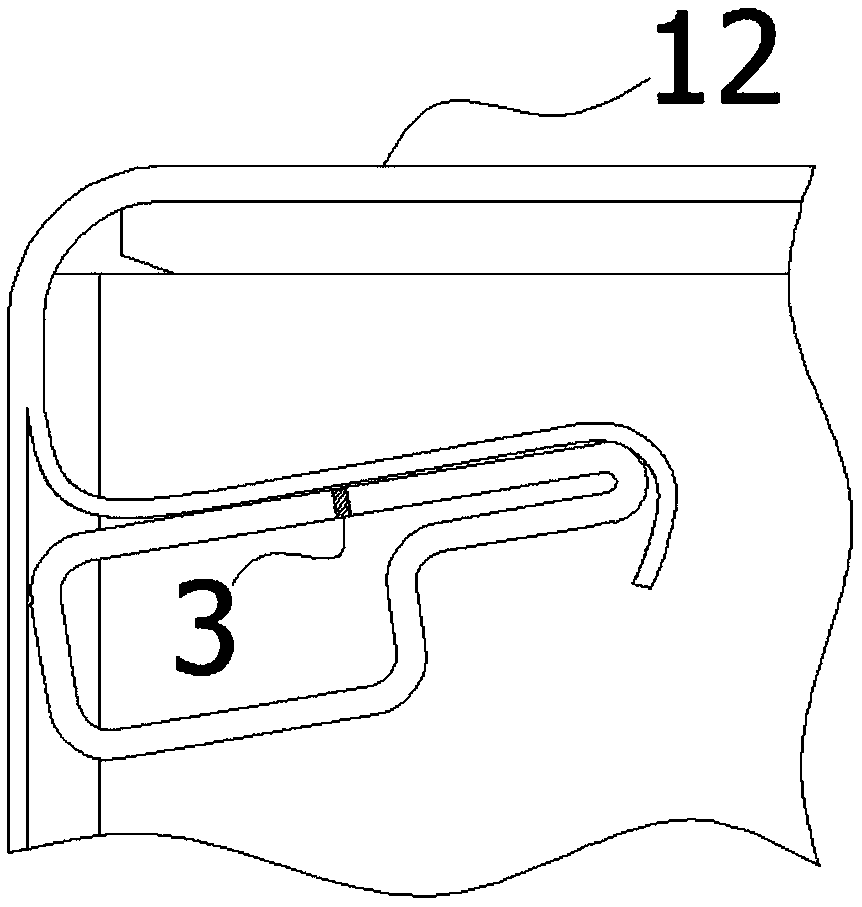

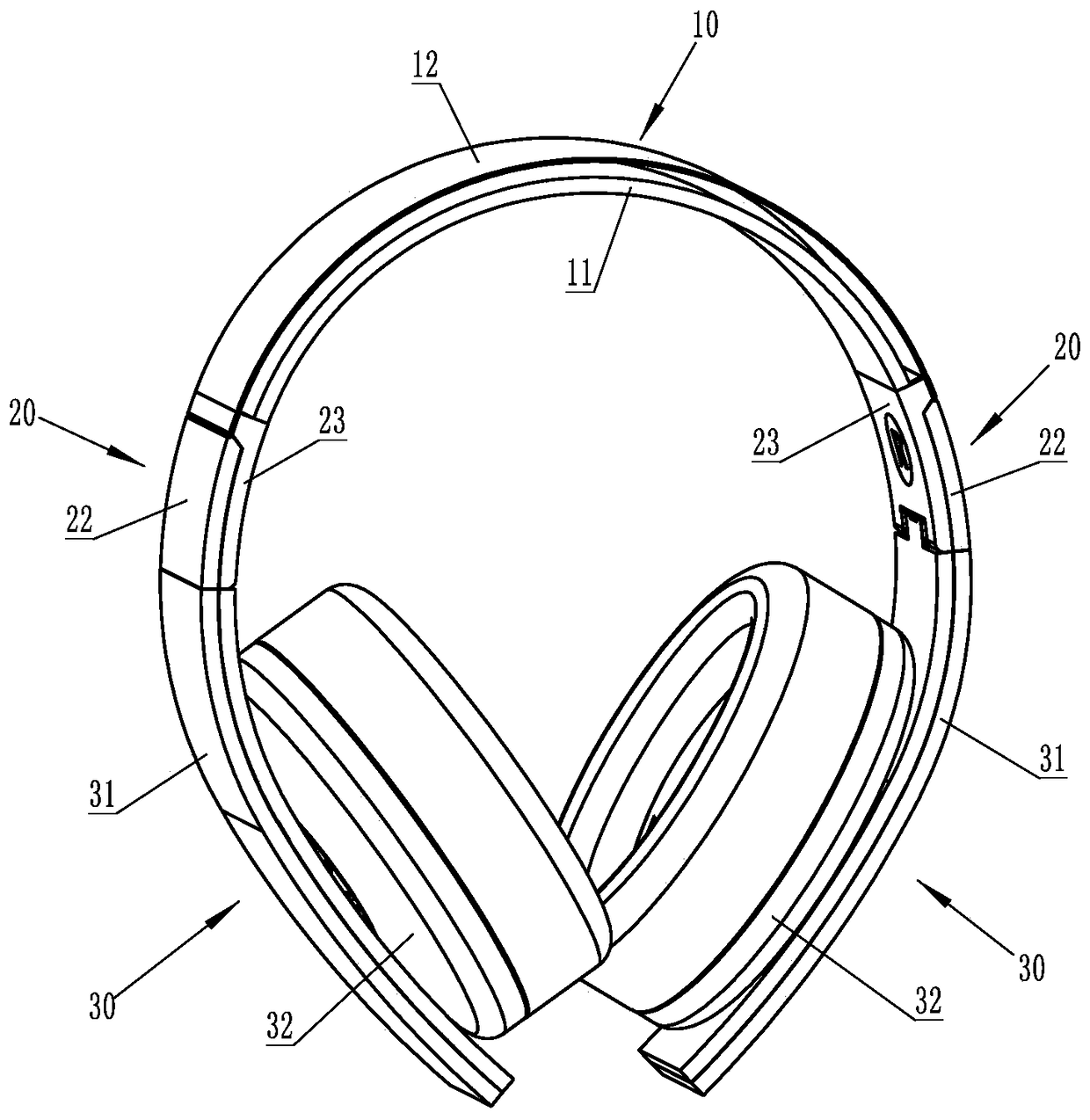

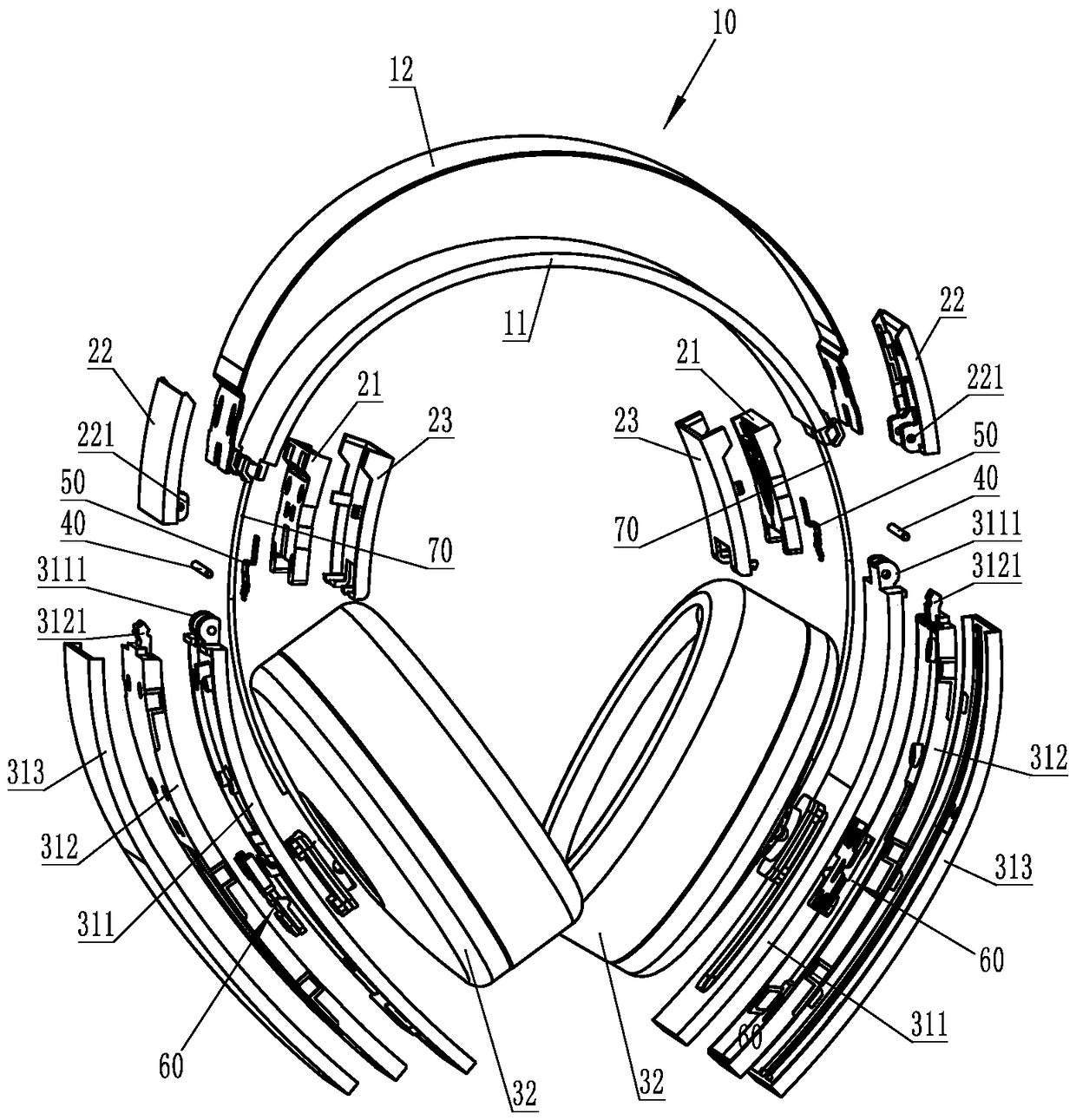

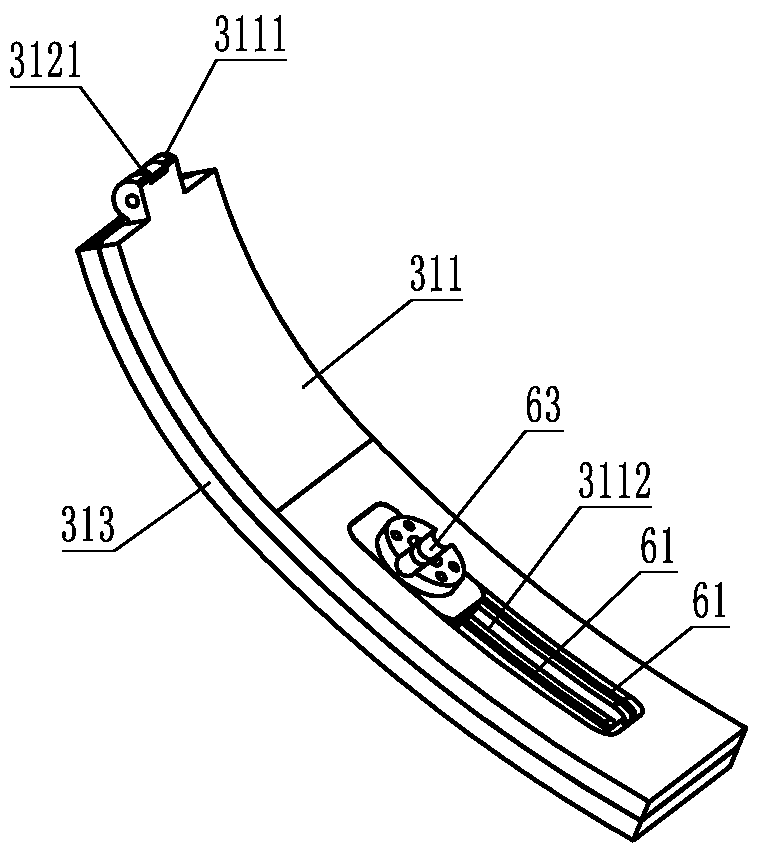

Foldable headphone

ActiveCN105163214AGuaranteed bending strengthPlasticEarpiece/earphone attachmentsEngineeringHeadphones

The invention belongs to the technical field of headphones, and particularly relates to a foldable headphone. The foldable headphone includes an arc-like head band, earphone units arranged on two sides of the head band, two end parts of the head band are each provided with a connecting structure, and each earphone unit is rotatably connected with the connecting structure of the same side and can rotate towards an area that the head band surrounds; the head band includes a flexible head strip at an inner side and a steel sheet at an outer side, distance is reserved between a middle position of the flexible head strip and a middle position of the steel sheet, an end part of the steel sheet is fixedly connected with the connecting structure, and an end part of the flexible head strip is hinged to the connecting structure in a width direction. Each earphone unit includes a support one end of which is rotatably connected with the end part of the connecting structure, an earphone arranged on an inner side face of the support and an electrical connecting line, and the electrical connecting line is embedded in the flexible head strip. The foldable headphone can ensure bending strength and can also ensure wearing comfort of a head top part, and volume space can be effectively reduced when the headphone is folded, and thus the headphone is convenient to carry.

Owner:QINGDAO GOERTEK

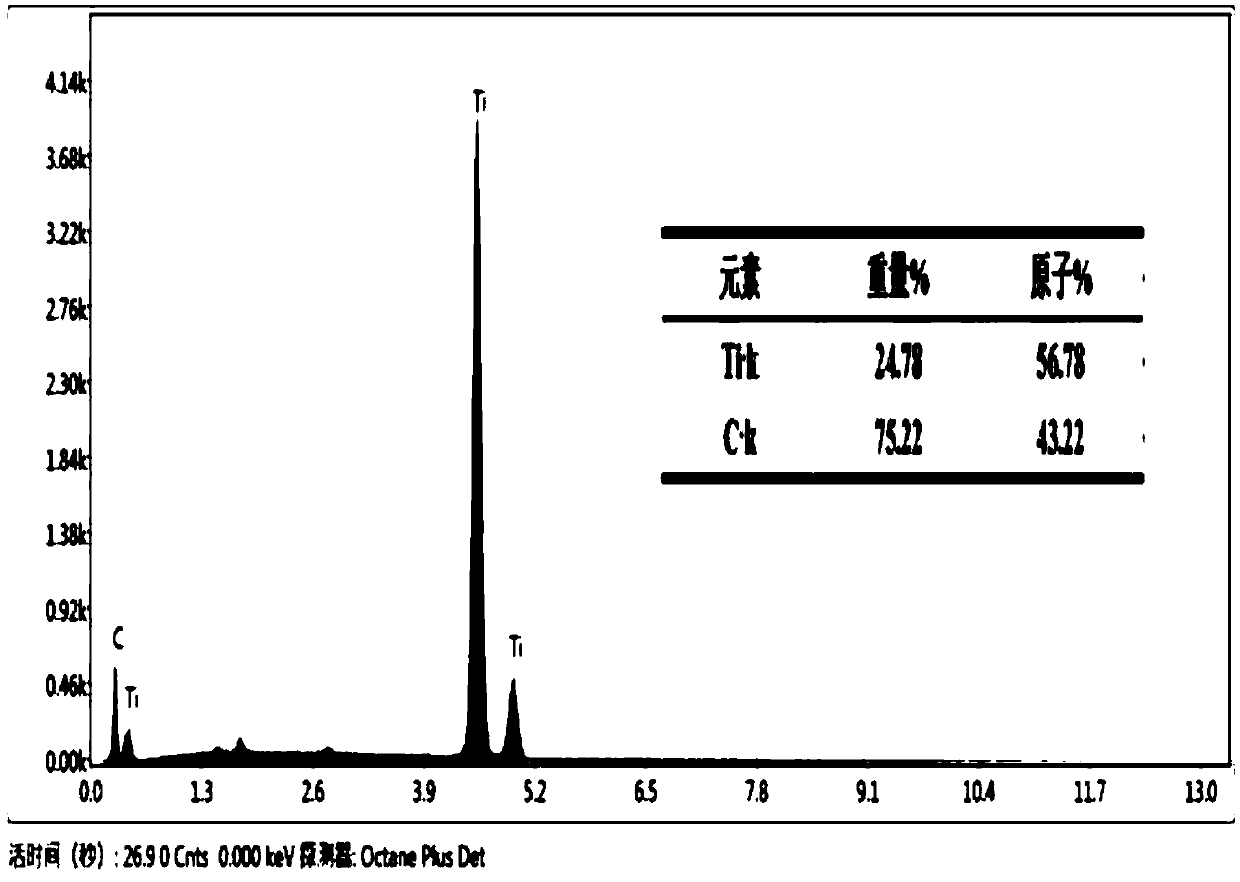

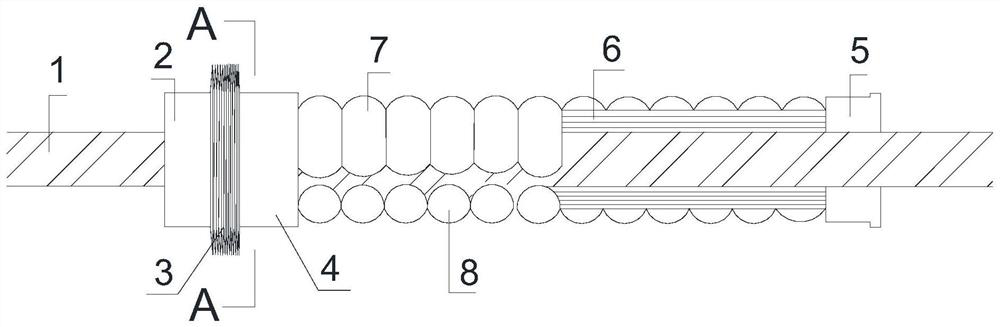

TiC/SiC/Al composite material

The invention relates to a TiC / SiC / Al composite material. An outer layer of the TiC / SiC / Al composite material is a TiC reaction layer, and the interior of the TiC / SiC / Al composite material is a SiC / Alcomposite layer. A preparation method of the composite material comprises the following steps of (1) preparation of an aluminum alloy, specifically, the aluminum alloy comprises the elements of, by mass, 50-90% of Al, 5-20% of Ti and 5-30% of Si; (2) pretreatment of SiC ceramic; (3) reaction infiltration process, specifically, the aluminum alloy prepared in the step (1) is smelted in a box-type furnace to obtain aluminum alloy liquid, the SiC ceramic processed in the step (2) is immersed into the aluminum alloy liquid and put into the box-type furnace for heat preservation, the infiltrating temperature is1150-1200 DEG C, the infiltrating time is 0.5-8 h, a sample is taken out and cooled to room temperature to obtain the TiC / SiC / Al composite material. The TiC / SiC / Al composite material hasgood fracture toughness under the premise of ensuring bending strength, and the preparation process is simple, and the TiC / SiC / Al composite material is suitable for large-scale industrialized production.

Owner:HEBEI UNIV OF TECH

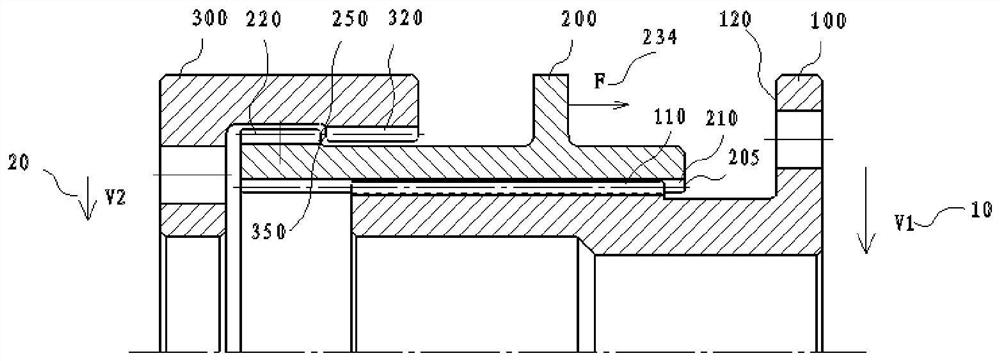

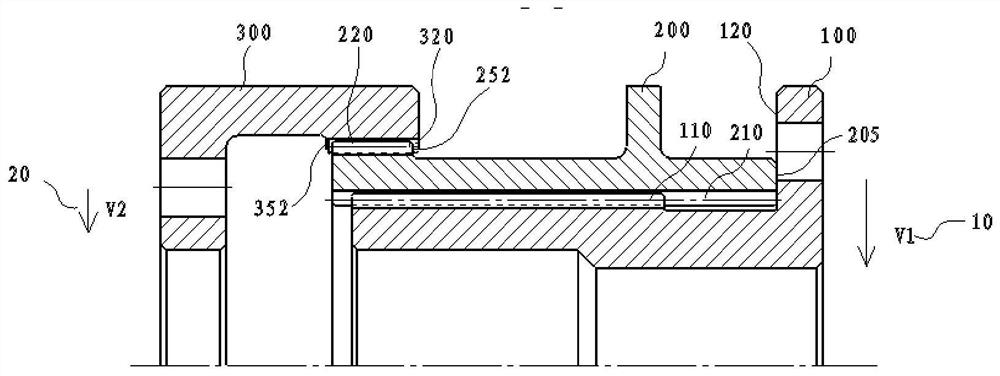

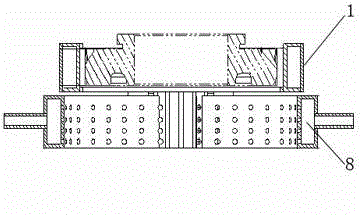

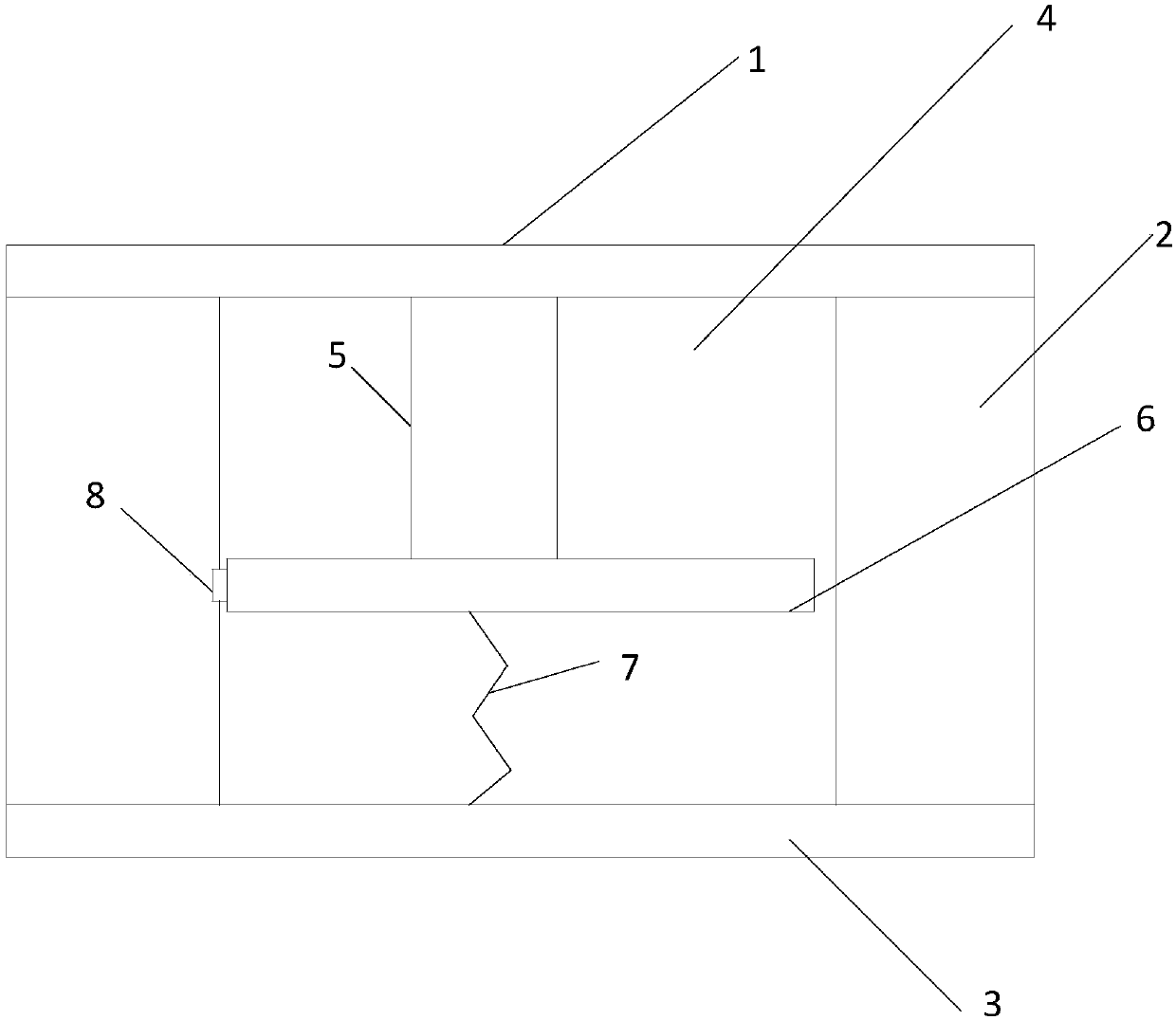

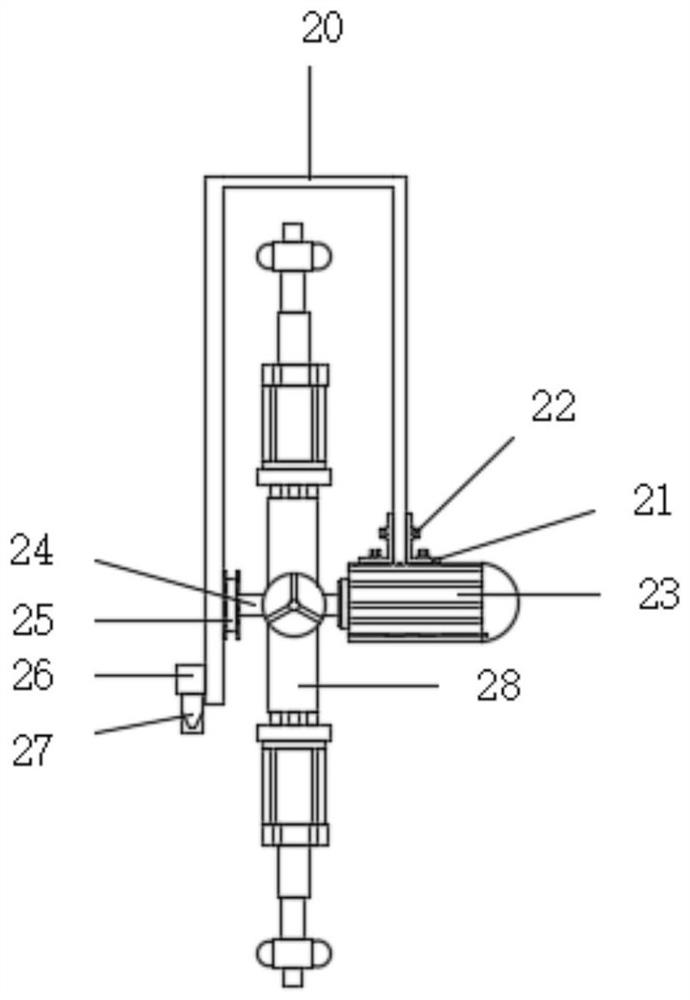

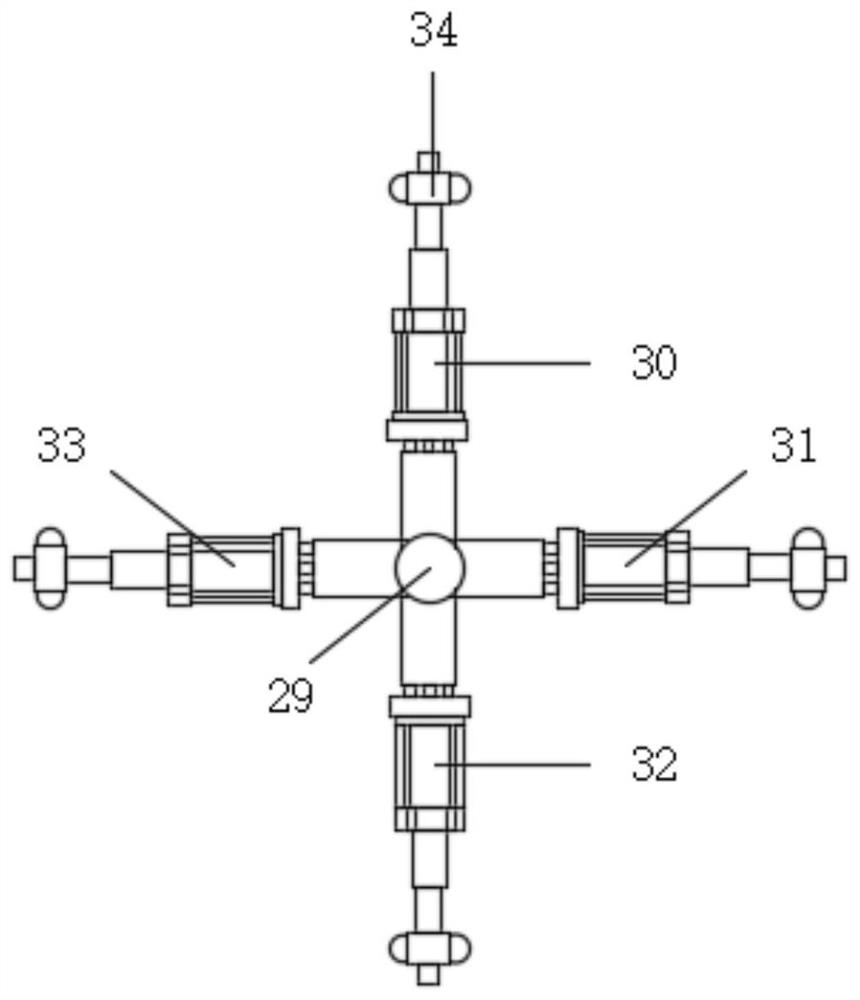

Prefabricated on-site bending forming connecting device, FRP rib bending forming method and FRP rib material

ActiveCN111877643AExert strengthSolve the durability problemBuilding reinforcementsFirming agentStructural engineering

The invention discloses a prefabricated on-site bending forming connecting device, an FRP rib bending forming method and an FRP rib material. The connecting device comprises a connecting piece, the two ends of the connecting piece are provided with a first end and a second sleeve respectively, and the first end comprises a casing pipe, a telescopic pipe and a first sleeve which are fixedly connected in sequence. A curing agent capsule and an epoxy resin capsule body are arranged outside the connecting piece, after a telescopic pipe is stretched, the tail end of the first sleeve is arranged onthe second sleeve in a sleeving mode, the telescopic pipe wraps the connecting piece, the curing agent capsule and the epoxy resin capsule body, and a blade is fixed in the first sleeve. By utilizingthe property that a curing agent and epoxy resin glue are cured after being mixed, the curing agent and the epoxy resin glue are separated firstly, and when bending is needed, the blade is driven to move by means of the telescopic performance of the telescopic pipe, so that the curing agent and the epoxy resin glue are mixed to connect and fix FRP ribs broken due to bending.

Owner:CHANGAN UNIV

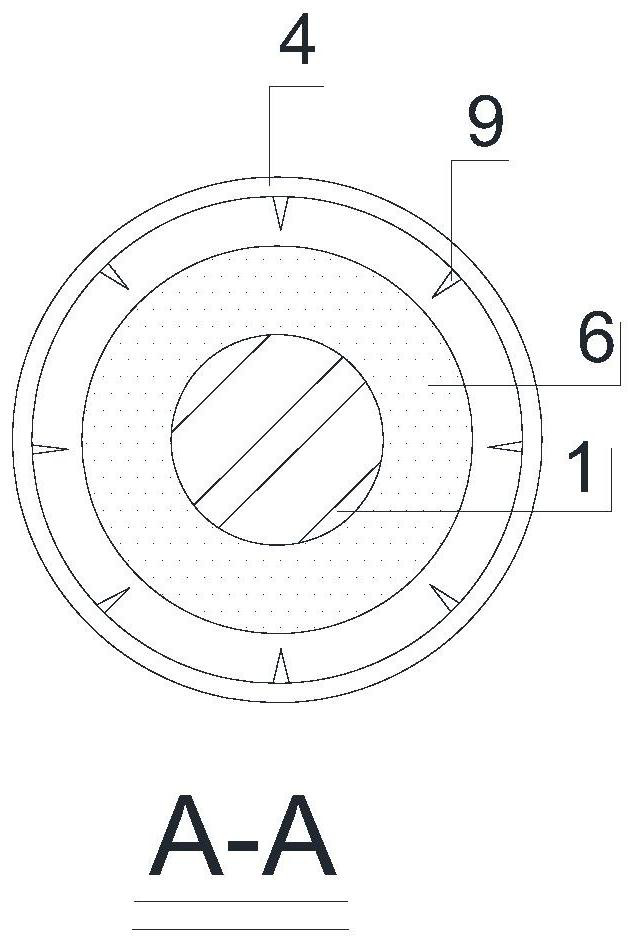

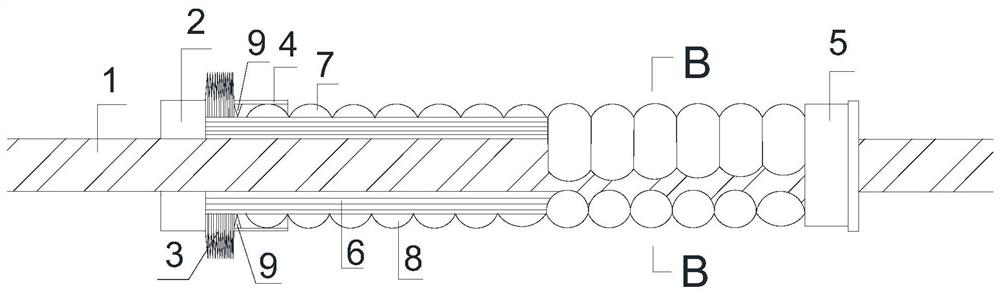

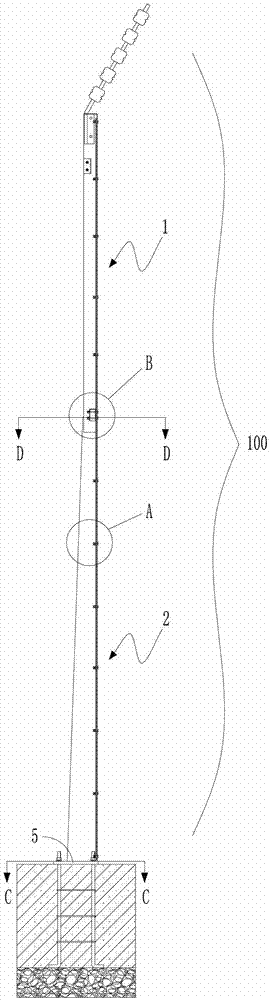

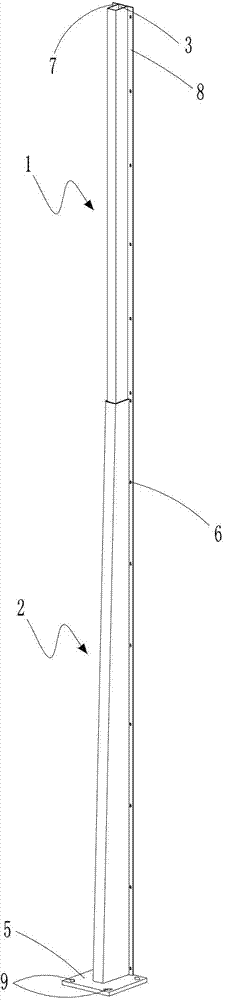

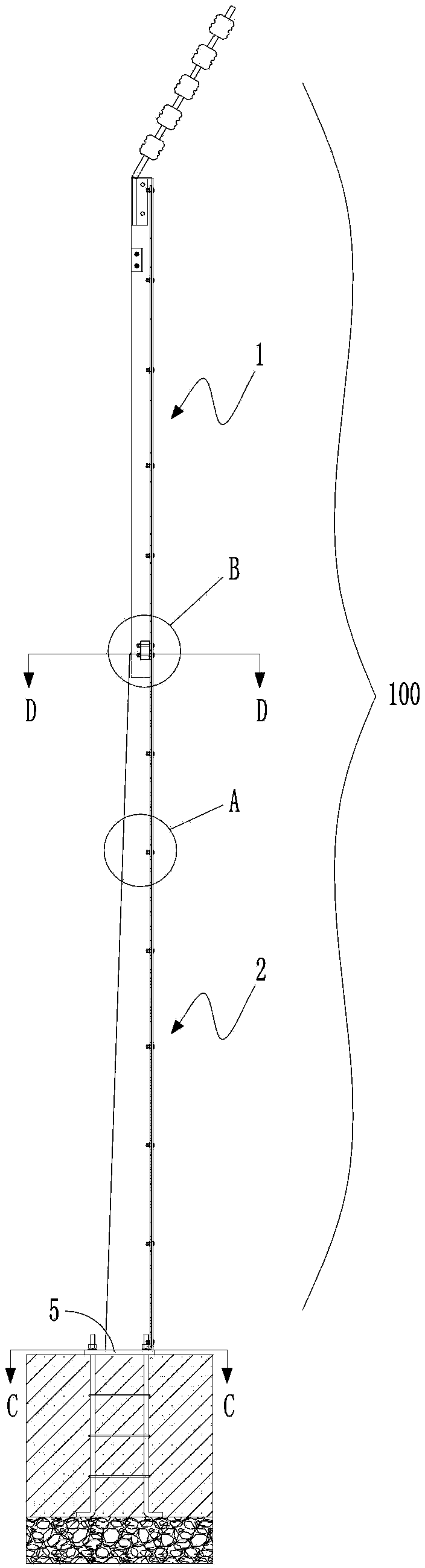

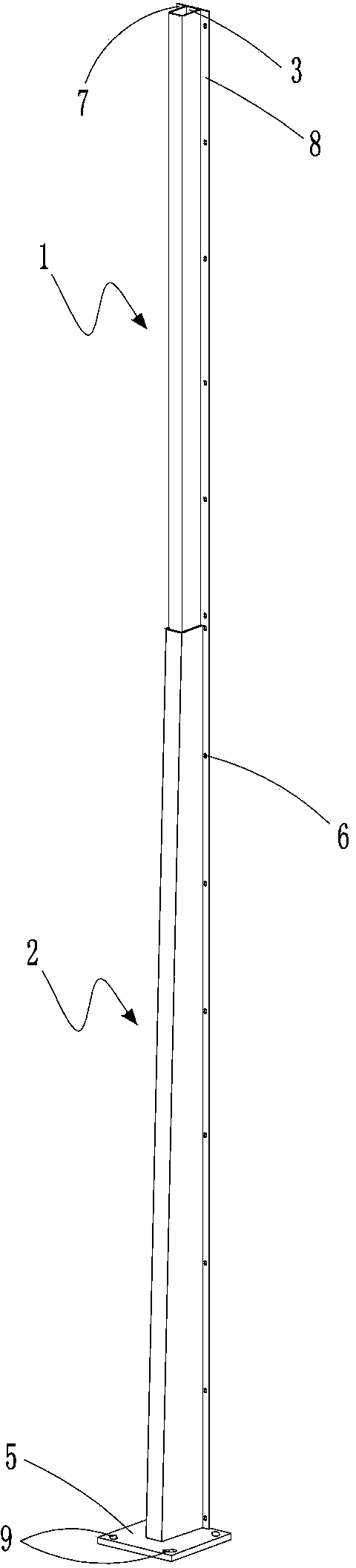

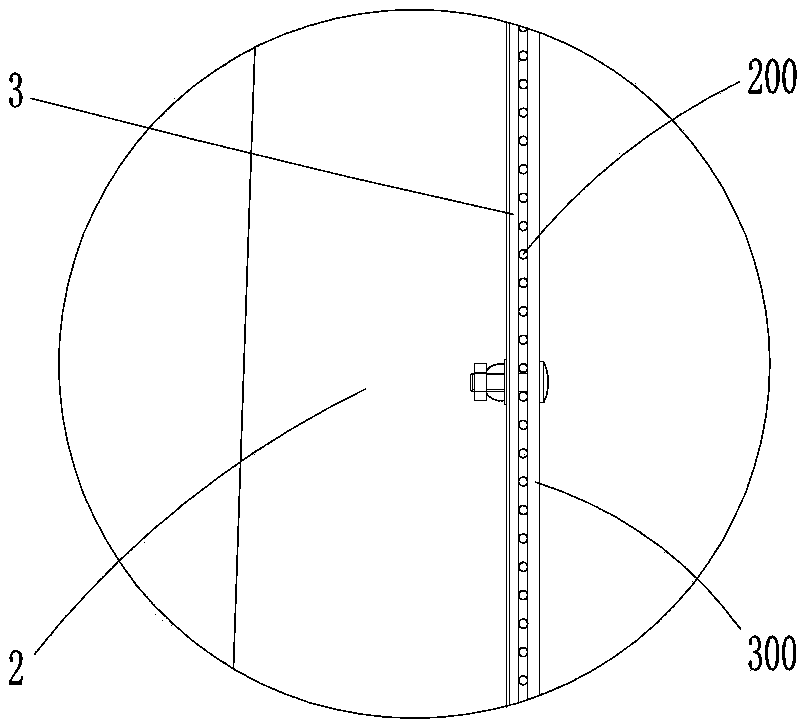

Fence upright

ActiveCN102852384AMeet high requirementsEnhances upright stabilityFencingStructural engineeringMechanical engineering

The invention discloses a fence upright; the fence upright is a metal upright and total height of the fence upright is not less than 4 m; the fence upright at least comprises a first hollow upright section and a second hollow upright section, wherein the first upright section is positioned above the second upright section; the lower end part of the first upright section is fixed together with the upper end part of the second upright section; the cross section of the second upright section is gradually reduced from bottom to top; and the area of the cross section of the first upright section is not more than minimum cross section area of the second upright section. According to the invention, as the fence upright adopts a structure of which the cross section is gradually reduced from bottom to top, a purpose of enhancing upright stability of the upright is achieved, raw materials are saved and the cost is reduced. Because of the structural characteristics, the fence upright disclosed by the invention can reach a height of 4 m and higher and can satisfy height requirements of fences in special places; and through the adoption of the structure which is thick at the lower part and thin at the upper part, the stability can be guaranteed.

Owner:ZHANGJIAGANG GOLDNET FENCING SYST

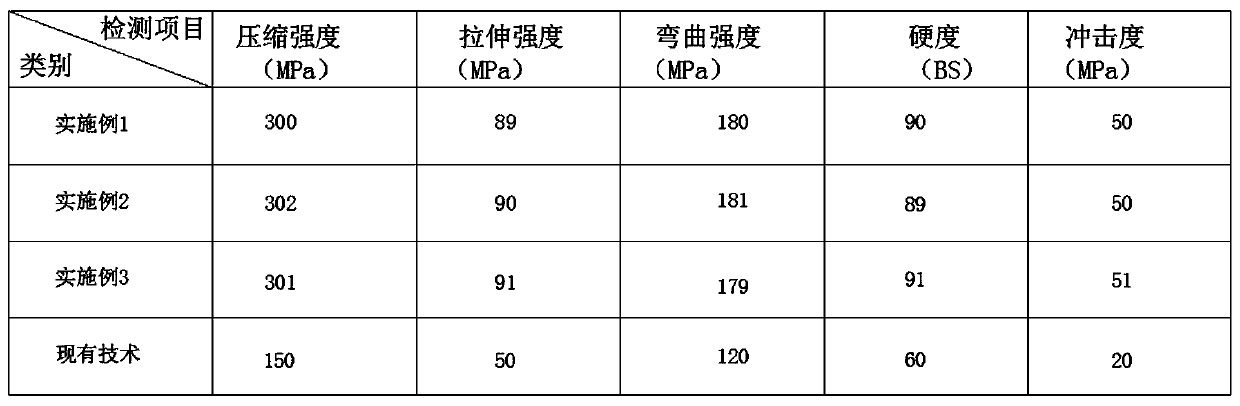

Fast-degradation plant fiber material and preparation method thereof

InactiveCN110819130AGuaranteed compressive strengthGuaranteed tensile strengthPolyvinyl alcoholPlant fibre

The invention discloses a fast-degradation plant fiber material. The fast-degradation plant fiber material comprises, by mass, 60-80% of plant fibers, 30-60% of natural starch, 6-10% of polypropylene,8-12% of polyvinyl chloride, 10-14% of polyvinyl alcohol, 5-9% of a reactive assistant, 10-20% of a plasticizer, 11-17% of talcum powder, 11-17% of paper pulp, 6-12% of an adhesive, 8-10% of a fillerand 2-4% of a cross-linking agent. The plant fiber material can be fast degraded, and still can ensure the compression strength, the tensile strength, the bending strength, the hardness and the impact degree.

Owner:浙江新亚伦纸业有限公司

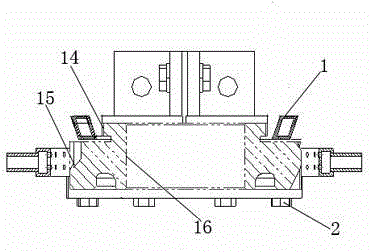

Gear clutch with high meshing success probability

InactiveCN112696439AGuaranteed bending strengthGuaranteed shear strengthPortable liftingInterengaging clutchesGear wheelTorque transmission

The invention provides a gear clutch with the high meshing success probability. A section of inclined face is manufactured on the side, close to a non-torque-transmission gear face, of the gear tooth end face of a movable sleeve gear and the gear tooth end face of a static sleeve gear, a straight face is reserved on the side close to a torque-transmission gear face, and the width of the inclined face accounts for about 95% of the gear thickness. The inclination direction of the movable sleeve tooth end face slope is opposite to the moving direction of the movable sleeve teeth, the inclination direction of the static sleeve tooth end face slopes is the same as the moving direction of the movable sleeve teeth, and the inclination angles of the tooth end face slopes of the movable sleeve teeth and the static sleeve teeth are equal. During meshing, the movable sleeve teeth move downwards to the static sleeve teeth under the action of an external force, the inclined faces of the tooth end faces of the movable sleeve teeth and the inclined faces of the tooth end faces of the static sleeve teeth make contact with each other, and along with rotation of the movable sleeve teeth, due to the action of the inclined faces, the movable sleeve teeth generate an axial movement distance L relative to the static sleeve teeth; when the gear teeth of the movable sleeve gear rotate over the current static sleeve gear tooth in contact with the gear teeth and are in contact with the working tooth surface of the next static sleeve gear tooth, the distance L can avoid the tooth collision phenomenon, the probability of one-time meshing success of the sleeve gear is improved, and the torque transmission strength of the sleeve gear is kept not to be reduced.

Owner:中国船舶重工集团公司第七0三研究所

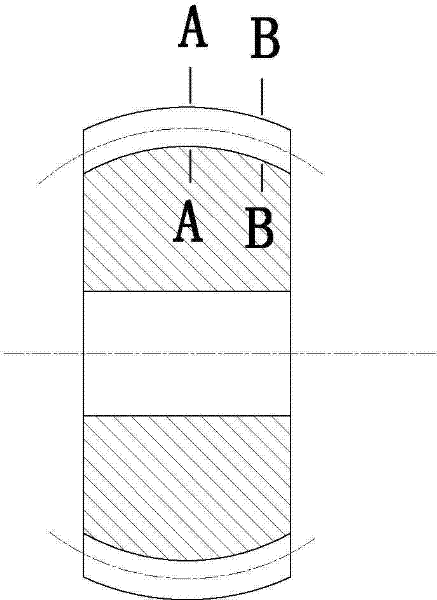

Commercial vehicle gear box three-speed gear induction quenching process

InactiveCN102409142BGuaranteed bending strengthReasonable structural designFurnace typesIncreasing energy efficiencyProduction rateFlexural strength

The invention relates to a commercial vehicle gear box three-speed gear induction quenching process, which is characterized by comprising the following specific steps of: sequentially performing induction heat quenching on gear parts, namely a joint gear, a meshing gear and a bearing hole. The requirements of gear material selection and induction quenching technical requirement design can be met; three quenching parts, namely the meshing gear, the joint gear and the bearing hole, have a rational technical flow to avoid a mutual tempering phenomenon; a hardened layer of a tooth root of the meshing gear is more than 1 mm and tooth root bending strength is guaranteed; a joint gear inductor has rational structural design, and uniform distribution of the hardened layer in the gear width direction is guaranteed; a sectional continuous heat quenching mode is adopted by the bearing hole, and crack tendency of the bearing hole and an oil hole is eliminated; one-piece gear material and heat treatment comprehensive cost saving ratio is over 20 percent; and the productivity is improved by over 15 percent.

Owner:CHINA FIRST AUTOMOBILE

Commercial vehicle gear box three-speed gear induction quenching process

InactiveCN102409142AGuaranteed bending strengthReasonable structural designFurnace typesIncreasing energy efficiencyGear wheelInduction hardening

The invention relates to a commercial vehicle gear box three-speed gear induction quenching process, which is characterized by comprising the following specific steps of: sequentially performing induction heat quenching on gear parts, namely a joint gear, a meshing gear and a bearing hole. The requirements of gear material selection and induction quenching technical requirement design can be met; three quenching parts, namely the meshing gear, the joint gear and the bearing hole, have a rational technical flow to avoid a mutual tempering phenomenon; a hardened layer of a tooth root of the meshing gear is more than 1 mm and tooth root bending strength is guaranteed; a joint gear inductor has rational structural design, and uniform distribution of the hardened layer in the gear width direction is guaranteed; a sectional continuous heat quenching mode is adopted by the bearing hole, and crack tendency of the bearing hole and an oil hole is eliminated; one-piece gear material and heat treatment comprehensive cost saving ratio is over 20 percent; and the productivity is improved by over 15 percent.

Owner:CHINA FIRST AUTOMOBILE

High heat resistance modified synthetic resin material

InactiveCN101104717AGuaranteed impact strengthGuaranteed tensile strengthHeat deflection temperatureFlexural strength

Disclosed is a high heat resistance modified synthetic resin, whose main components comprise ABS resin, poly alpha-methyl styrene and poly N-phenyl-maleimide. Wherein, the ABS resin is 40 parts by weight, the poly alpha-methyl styrene is 45 parts by weight and the poly N-phenyl-maleimide is 15 parts by weight. A novel twin-screw intermeshing co-rotating extruder and a two-stage vacuum device are adopted to mix the materials for preparing the high heat resistance modified synthetic resin. Because the high heat resistance modified synthetic resin mixed and prepared on the basis of the poly alpha-methyl styrene and the poly N-phenyl-maleimide being added simultaneously into the ABS resin, thermal deformation temperature of the material is improved under the precondition of the indexes such as impact intensity, tensile intensity and bending intensity of the ABS are guaranteed.

Owner:SHANGHAI RAINBOW COLOR PLASTICS

Sand plastic floor

InactiveCN109851883ASolve the problem of losing the effect of stimulating negative ionsImprove efficacyFlooringPollutionIon

The invention provides a sand plastic floor. According to a preparation method, a negative ion generation material is dispersed in a sand plastic plate, so that problems in the prior art that shedding, wearing, pollution, and failure of negative ion excitation effect are caused by arrangement of negative ion generation materials on material surfaces are solved. And in addition, the environment-protection sand plastic plate in the invention possesses following advantages: the functions of conventional sand plastic plates are increased, and sand plastic plate application range is widened.

Owner:BEIJING RECHSAND SCI & TECH GRP

High-strength heat-resistant polyethylene material and preparation method thereof

The invention discloses a high-strength heat-resistant polyethylene material and a preparation method thereof. The high-strength heat-resistant polyethylene material is prepared from the following raw materials in parts by weight: 55 to 75 parts of polyethylene resin, 20 to 40 parts of maleic anhydride grafted polypropylene, 5 to 15 parts of silicon-containing aryne resin, 15 to 25 parts of heat-resistant modified filler, 5 to 10 parts of nano zirconium carbide, 3 to 8 parts of modified carbon nanotubes, 5 to 15 parts of graphene, 0.5 to 5 parts of antioxidant, 2 to 8 parts of polyethylene wax, 5 to 12 parts of basalt fiber powder, 2 to 5 parts of a rare earth compound, 3 to 6 parts of a flexibilizer and 2 to 5 parts of a compatilizer. On the premise of ensuring that the polyethylene material has certain tensile strength and bending strength, the heat resistance of the polyethylene material is greatly improved, and the polyethylene wax and the compatilizer are added, so that the bonding condition of a two-phase interface in a blending system can be improved, and the stability of the multiphase system between various inorganic fillers and resin is realized.

Owner:胜利油田兴达高祥新材料有限责任公司

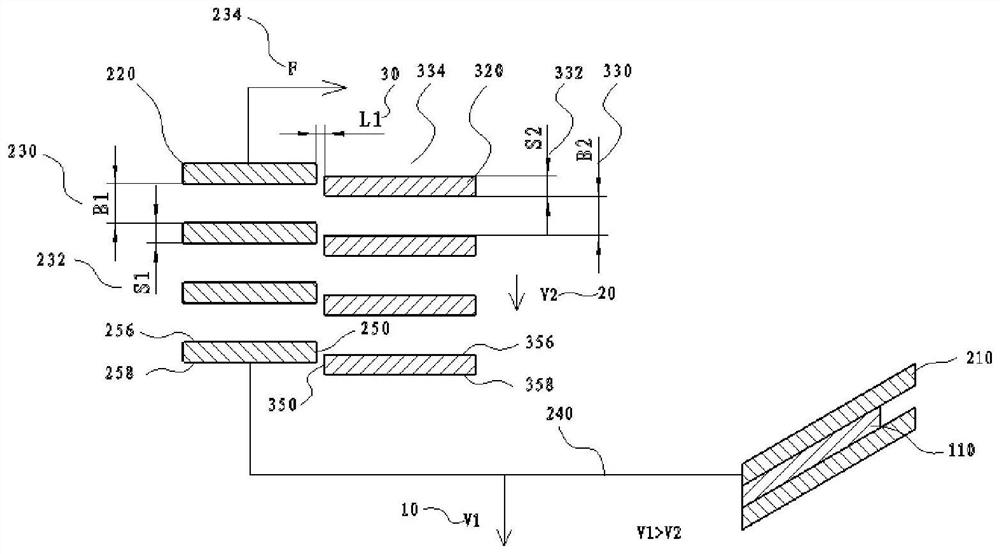

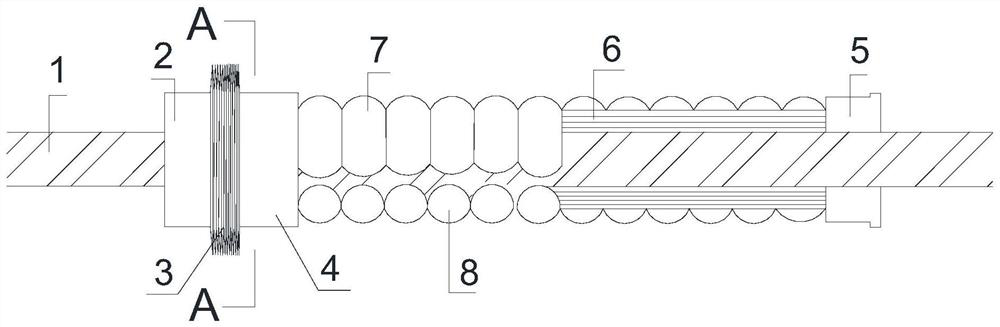

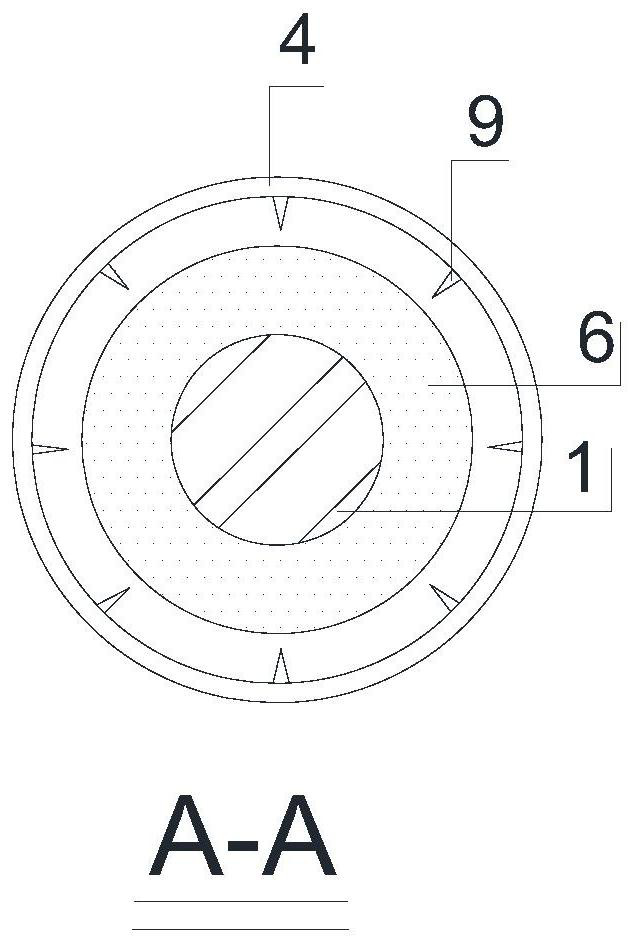

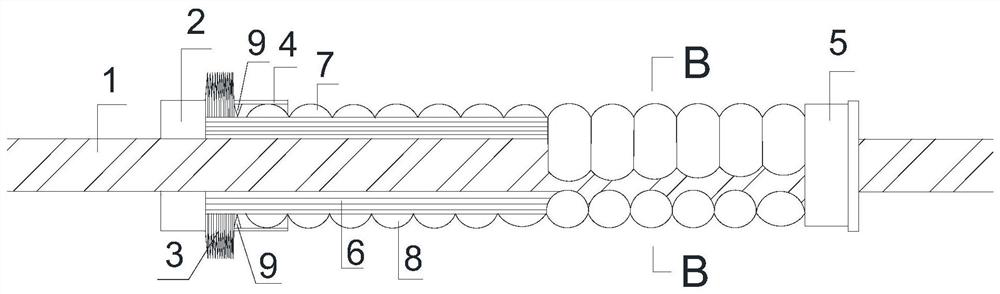

P-shaped pipe, P-shaped pipe forming process and P-shaped pipe forming equipment

InactiveCN110701392ASimple structureReduce manufacturing process stepsDomestic cooling apparatusLighting and heating apparatusRoll formingPipe

The invention provides a P-shaped pipe, a P-shaped pipe forming process and P-shaped pipe forming equipment and relates to the technical field of refrigerating equipment. The P-shaped pipe comprises awide cavity part and a narrow cavity part. The wide cavity part and the narrow cavity part are distributed along the width direction of the P-shaped pipe and are integrally formed, and a piece is arranged on the end surface of the side, far away from the narrow cavity part, of the wide cavity part and stretches along the length of the P-shaped pipe. The P-shaped pipe is manufactured at one time by means of the P-shaped pipe forming process adopting a roll forming technology, and the piece is located on the side wall, far away from the narrow end, of the P-shaped pipe. The P-shaped forming equipment comprises a plurality of groups of forming rollers. Each group of forming rollers comprises an upper guide roller and a lower guide roller arranged oppositely up and down. The P-shaped pipe issimple in structure and free of welding, so that the manufacturing process is cut down. The P-shaped pipe forming process can form the P-shaped pipe directly at one time, so that the shape structure and the curvature of the P-shaped pipe are ensured, the assembling property of the P-shaped pipe is improved, and the production efficiency is improved. The P-shaped pipe forming equipment is low in manufacturing cost, rapid to form and convenient to operate and maintain.

Owner:SUZHOU SAMSUNG ELECTRONICS CO LTD +1

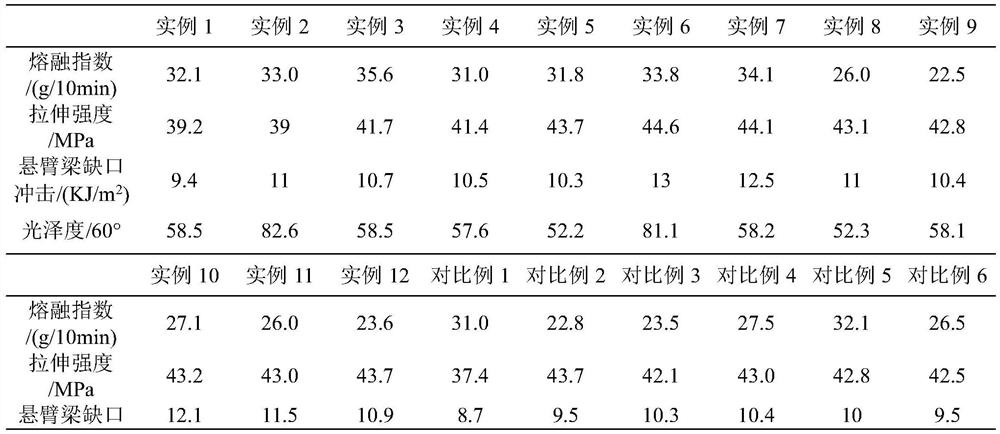

High-fluidity and high-toughness ASA material and preparation method thereof

The invention discloses a high-fluidity and high-toughness ASA (acrylonitrile-styrene-acrylate) material, which is prepared from the following materials in parts by mass: 8-26 parts of high-rigidity resin; 32 to 48 parts of high flow resin; 20 to 32 parts of small particle size ASA powder; 8-20 parts of large particle size ASA powder; 0-2 parts of matting powder; 0.1 to 0.2 part of a main antioxidant; 0.2 to 0.3 part of an auxiliary antioxidant; 0.2 to 0.5 part of a light stabilizer; 0.2 to 0.5 part of an ultraviolet light absorber; 0.3 to 0.5 part of a lubricant; according to the scheme, through a mode of compounding two resins, the problem of compatibility is solved, the flowability is improved, the performance reduction amplitude is small, and the purpose of reducing the cost is achieved while the performance is ensured; the two ASA powder with different particle sizes are compounded for use, so that a synergistic effect can be achieved, the toughness of the material can be improved by the whole ASA, a better impact-resistant effect can be achieved under the condition that less ASA powder can be used, and the cost is reduced; the glossiness of the ASA material is improved by adopting the matting powder, so that sunlight reflection is reduced, and visual influence on drivers and passersby is avoided.

Owner:QINGDAO GON TECHNOLOGY CO LTD

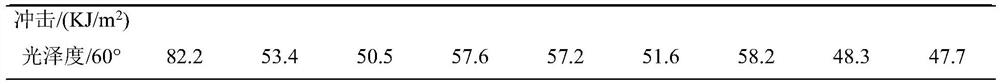

Flame-retardant polypropylene plastic and preparation method thereof

InactiveCN111647232AGuaranteed tensile strengthGuaranteed bending strengthPolymer scienceTitanium chloride

The invention relates to the technical field of polypropylene plastics. The invention relates to the field of polypropylene plastics, in particular to a flame-retardant polypropylene plastic and a preparation method thereof, wherein the polypropylene plastic comprises the following components in percentage by mass: propylene, ethylene propylene diene monomer, glass fiber, titanium tetrachloride, triethyl aluminum, talcum powder, a flame retardant, a coupling agent, an antioxidant and a catalyst, the sum of the contents of the components being 100%. The preparation method comprises the following steps: step 1, selecting raw materials; 2, preparing polypropylene; 3, mixing and stirring the raw materials; 4, manufacturing plastic; 5, carrying out low-temperature air cooling; step 6, inspecting and packaging a finish product. The polypropylene plastic prepared by the preparation method not only has certain tensile strength and bending strength and greatly improved impact resistance, but also has good flame retardance and heat resistance, and is safe and reliable; the preparation process is simple and rigorous, the raw material cost is low, the production cost is greatly saved, and production and processing are facilitated.

Owner:QINGDAO HAIER NEW MATERIAL R&D CO LTD

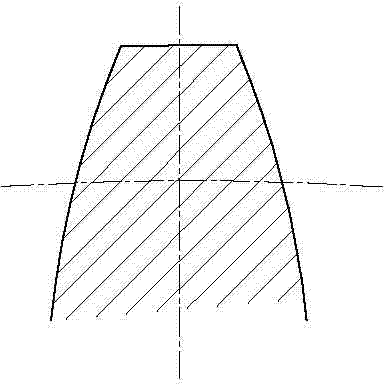

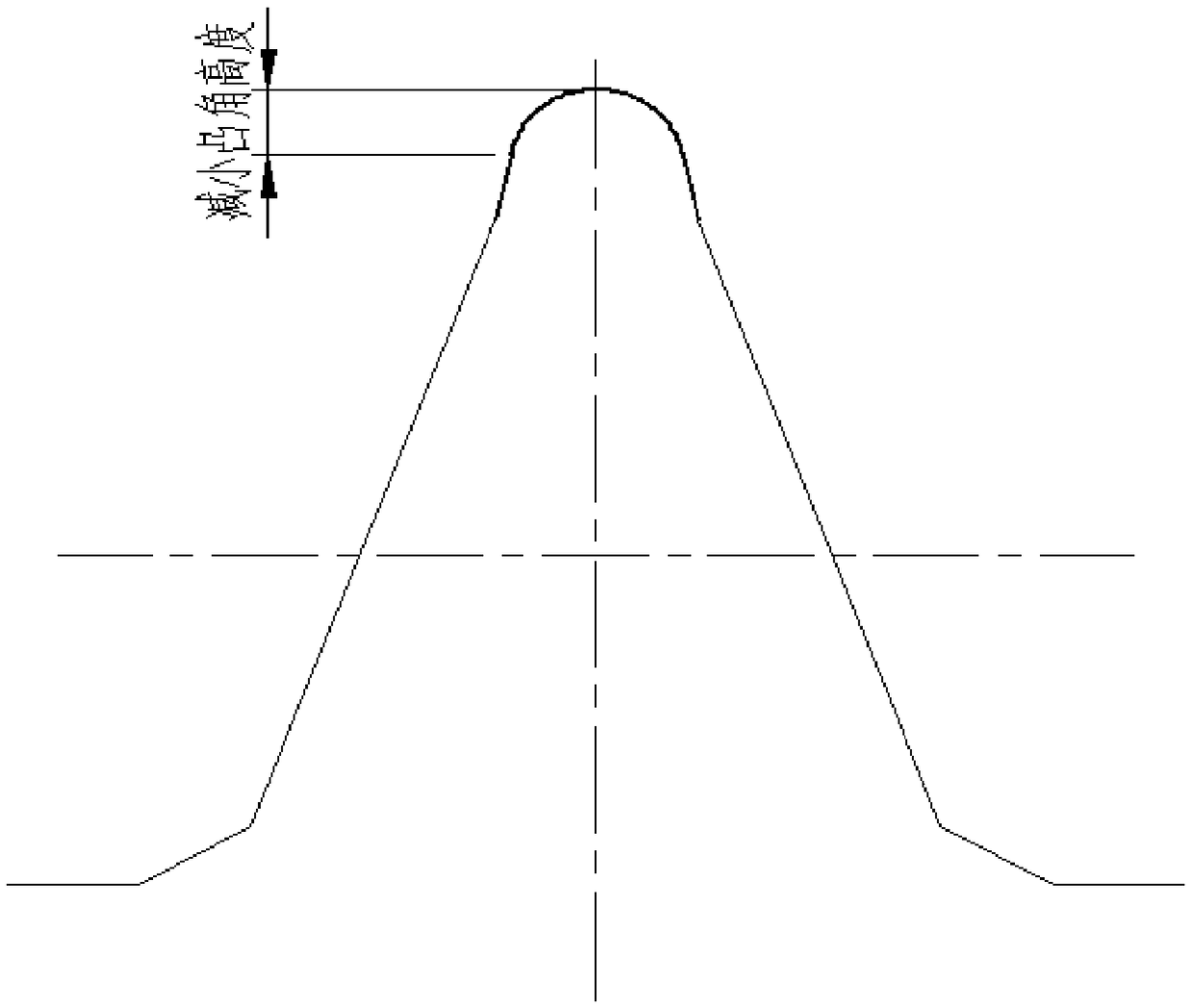

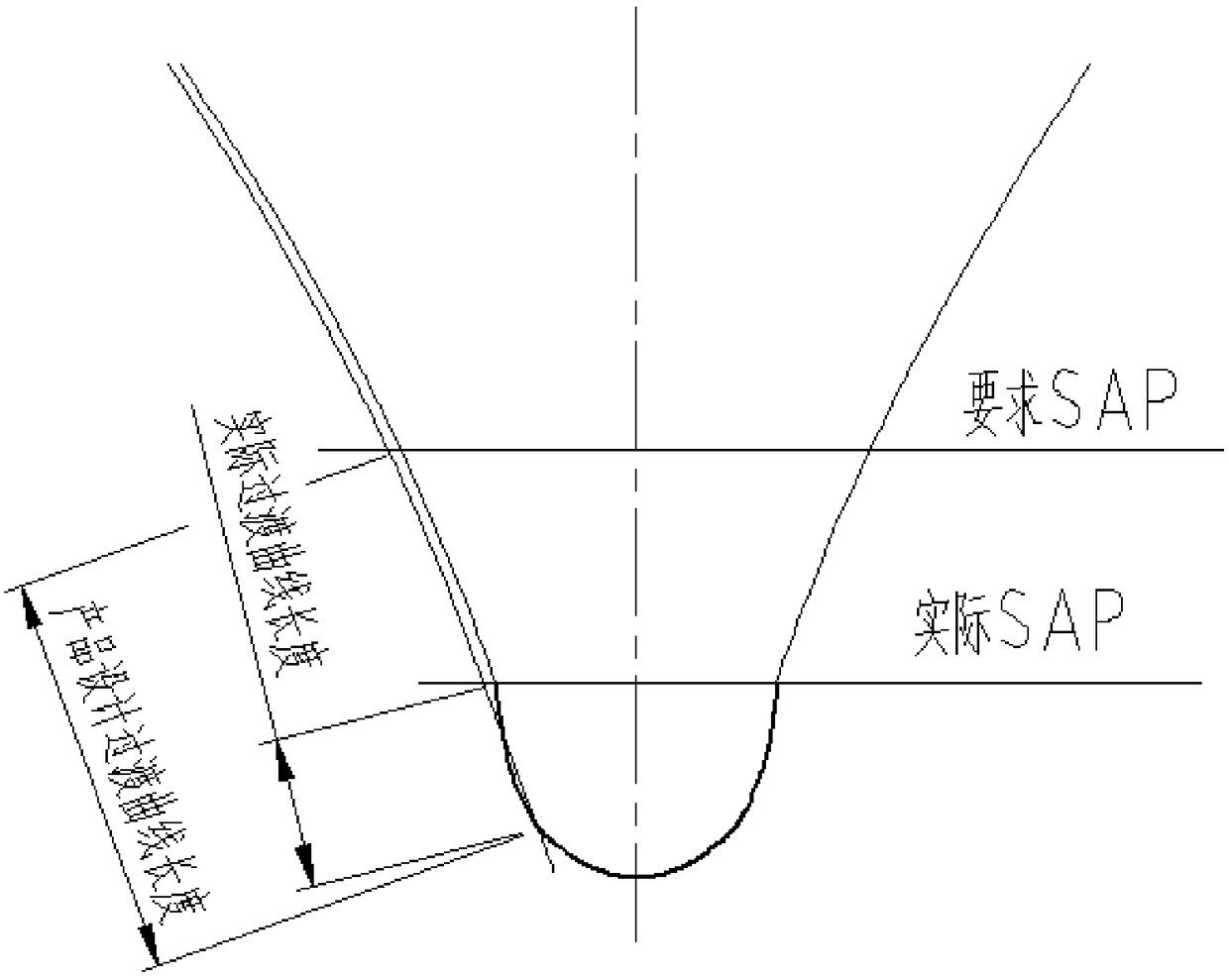

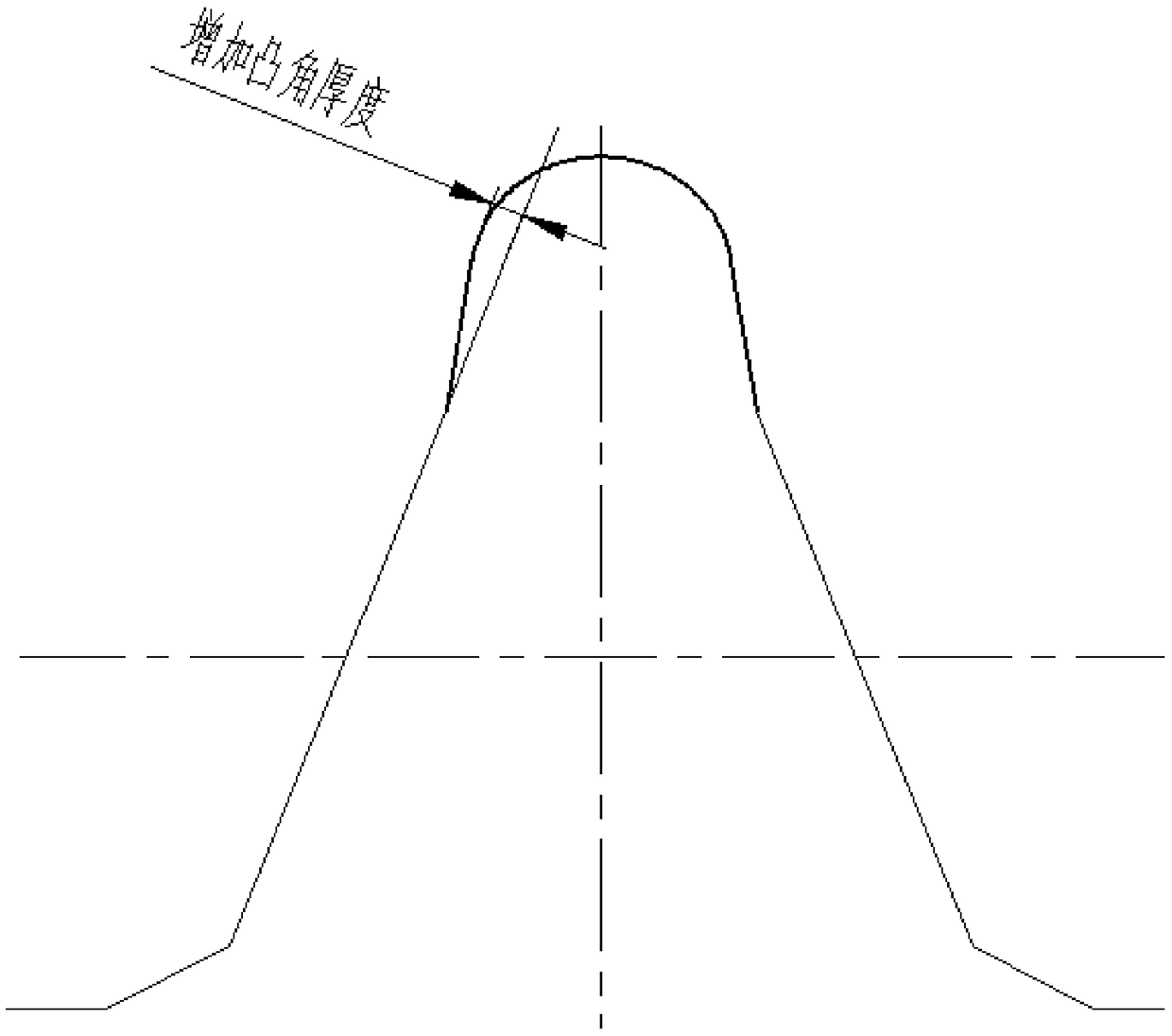

Convex-angle type hobbing cutter and manufacturing method thereof

PendingCN109304524AGuaranteed bending strengthShorten the lengthGear teeth manufacturing toolsGear teethHobbingEngineering

The invention relates to a convex-angle type hobbing cutter and a manufacturing method thereof, and mainly aims to solve the problem that when the difference value between an SAP circle and a Df circle in gear parameters is too big, an existing convex-angle type hobbing cutter manufacturing method cannot effectively guarantee the thickness of SAP, Df and tooth roots. The convex-angle type hobbingcutter comprises a tooth tip circular arc, a linear cutting blade, a transition cutting blade and a main cutting blade arranged sequentially, wherein the linear cutting blade and the main cutting blade are arranged in parallel; and the linear cutting blade and the tooth tip circular arc are tangentially arranged. Meanwhile, the inventio further provides the convex-angle type hobbing cutter manufacturing method which comprises the steps of (1) acquiring known parameters of a gear; (2) calculating parameters of the convex-angle type hobbing cutter according to the parameters in the step (1); and(3) processing the convex-angle type hobbing cutter according to the parameters acquired through the step (2).

Owner:XIAN FASHITE AUTOMOBILE TRANSMISSION CO LTD

Fence upright

ActiveCN102852384BMeet high requirementsEnhances upright stabilityFencingStructural engineeringMechanical engineering

The invention discloses a fence upright; the fence upright is a metal upright and total height of the fence upright is not less than 4 m; the fence upright at least comprises a first hollow upright section and a second hollow upright section, wherein the first upright section is positioned above the second upright section; the lower end part of the first upright section is fixed together with the upper end part of the second upright section; the cross section of the second upright section is gradually reduced from bottom to top; and the area of the cross section of the first upright section is not more than minimum cross section area of the second upright section. According to the invention, as the fence upright adopts a structure of which the cross section is gradually reduced from bottom to top, a purpose of enhancing upright stability of the upright is achieved, raw materials are saved and the cost is reduced. Because of the structural characteristics, the fence upright disclosed by the invention can reach a height of 4 m and higher and can satisfy height requirements of fences in special places; and through the adoption of the structure which is thick at the lower part and thin at the upper part, the stability can be guaranteed.

Owner:ZHANGJIAGANG GOLDNET FENCING SYST

Environment-friendly sand-p0lastic composite material and preparation method thereof

The invention provides an environment-friendly sand-p0lastic composite material. A nano negative ion activating material is dispersed in the sand-p0lastic composite material, so that the problem thata material loses the negative ion activating function as the negative ion generating material arranged on the surface of the material is easy to fall off and is worn and polluted in the prior art. Inaddition, according to the environment-friendly sand-p0lastic composite material provided by the invention, the functions of an existing sand-p0lastic composite material are expanded, and the application range of the sand-p0lastic composite material is expanded.

Owner:BEIJING RECHSAND SCI & TECH GRP

Preparation method of free radical type flame-retardant modified polypropylene

The invention discloses a preparation method of free radical type flame-retardant modified polypropylene. The preparation method comprises the following steps: preparing raw materials, preparing triethyl aluminum, titanium tetrachloride, propylene, polyphenylene sulfide, polyethylene wax, glass fibers, modified rubber, an antistatic agent, an antioxidant, talcum powder and the like in proportion, and sequentially processing according to procedures to finally obtain the flame-retardant modified polypropylene. The obtained flame-retardant modified polypropylene has tensile strength, bending strength, impact resistance, chemical resistance and high glossiness, has an anti-static effect, can delay or inhibit the oxidation process of the polypropylene, is low in raw material cost, and is beneficial to production and processing.

Owner:甘肃诺尔达工贸有限公司

A split flat membrane

ActiveCN104226119BRealize secondary valueLow costSemi-permeable membranesSustainable biological treatmentFiltration membraneButt joint

The invention discloses a split type flat membrane. The split type flat membrane comprises a plurality of flat membrane units which can be stacked up and down, wherein each flat membrane unit comprises an edge strip framework, a support body and filtration membranes; the edge strip frameworks are formed by a plurality of edge strips; corresponding welding line strips and a plurality of riveting buttons are arranged on the inner side of the edge strip framework; the support body is mounted on the edge strip framework by virtue of the welding line strips; a water discharging channel connected with a water collecting runner is formed at the edge of the outer side of the edge strip framework; a plurality of runners and clamping openings are formed in the support body; the filtration membranes are paved on the upper side and the lower side of the support body; the riveting buttons are adapted with the clamping openings and can be directly clamped into the clamping openings; and the edge strips are in seamless butt joint with the support body. According to the split type flat membrane, the edge strips and the support body are combined for use and can be in seamless butt joint with each other to form an integrated support plate; the manufacturing cost of the flat membrane can be reduced; the problem that the flat membrane is difficult to be applied in a large scale can be solved; the investment cost of the flat membrane is equivalent to that of a hollow fiber membrane; the support body can be repeatedly used after the edge strips are demounted; and the secondary value of the support body is realized.

Owner:南京瑞洁特膜分离科技有限公司

A foldable headset

ActiveCN105163214BGuaranteed bending strengthPlasticEarpiece/earphone attachmentsEngineeringHeadphones

The invention belongs to the technical field of headphones, and particularly relates to a foldable headphone. The foldable headphone includes an arc-like head band, earphone units arranged on two sides of the head band, two end parts of the head band are each provided with a connecting structure, and each earphone unit is rotatably connected with the connecting structure of the same side and can rotate towards an area that the head band surrounds; the head band includes a flexible head strip at an inner side and a steel sheet at an outer side, distance is reserved between a middle position of the flexible head strip and a middle position of the steel sheet, an end part of the steel sheet is fixedly connected with the connecting structure, and an end part of the flexible head strip is hinged to the connecting structure in a width direction. Each earphone unit includes a support one end of which is rotatably connected with the end part of the connecting structure, an earphone arranged on an inner side face of the support and an electrical connecting line, and the electrical connecting line is embedded in the flexible head strip. The foldable headphone can ensure bending strength and can also ensure wearing comfort of a head top part, and volume space can be effectively reduced when the headphone is folded, and thus the headphone is convenient to carry.

Owner:QINGDAO GOERTEK

Prefabricated on-site bending and forming connection device, frp tendon bending and forming method and frp tendon

ActiveCN111877643BExert strengthSolve the durability problemBuilding reinforcementsFirming agentKnife blades

The invention discloses a prefabricated on-site bending and forming connection device, an FRP bar bending and forming method, and an FRP bar, wherein the connecting device includes a connecting piece, and the two ends of the connecting piece are respectively provided with a first end and a second sleeve , the first end includes a sleeve, a telescopic tube and a first sleeve fixedly connected in sequence, and a curing agent capsule and an epoxy resin capsule are arranged on the outside of the connecting piece. After stretching the telescopic tube, the first sleeve The end of the sleeve is put on the second sleeve, and the telescopic tube wraps the connecting piece, the curing agent capsule and the epoxy resin capsule body. The blade is fixed in the first sleeve, and the curing agent and the epoxy resin glue are mixed and cured. First separate the curing agent and epoxy resin. When bending is required, the expansion and contraction properties of the telescopic tube are used to drive the blade to move, so that the curing agent and epoxy resin glue are mixed to connect and fix the broken FRP bars due to bending.

Owner:CHANGAN UNIV

A carbon-ceramic brake pad for high-speed trains and its preparation method

ActiveCN103511525BLess impact on friction and wear propertiesHigh and stable coefficient of frictionFriction liningFiberCeramic composite

The invention relates to a carbon ceramic braking pad for a high-speed train and a preparation method of the carbon ceramic braking pad. The carbon ceramic braking pad is made of carbon ceramic composite material; the carbon ceramic composite material comprises the following components in percentage by mass: 16-30 percent of carbon fibers, 20-36 percent of pyrolytic carbon, 28-46 percent of silicon carbide, 6-12 percent of molybdenum disilicide and 2-6 percent of simple substance silicon; the density of the carbon ceramic composite material is 1.8-2.4g / cm<3>; the carbon fibers are uniformly distributed in the carbon ceramic composite material in a three-dimensional network structure. According to the invention, after the high-temperature heat treatment is performed on a carbon fiber felt with the density of 0.20-0.65g / cm<3>, the pyrolytic carbon is generated in the carbon fiber felt through the thermal-gradient chemical vapor deposition carburizing treatment, then the catalytic graphitization treatment, non-immersion type melting infiltration and assembly are performed, so that the carbon ceramic braking pad for the high-speed train is obtained.The carbon ceramic braking pad is simple in preparation technology, moderate in friction coefficient, good in abrasion performance, stable in braking and strong in environmental suitability and can meet braking requirements of the high-speed train with the speed of 200Km / h.

Owner:HUNAN SHIXIN NEW MATERIALS CO LTD

A plate bending limit device for commercial kitchen

ActiveCN110102606BImprove work efficiencySimple structureShaping toolsMetal working apparatusClassical mechanicsStructural engineering

The invention discloses a plate bending limiting device for a commercial kitchen, which comprises a bracket and a base plate, load-bearing blocks are connected around the lower end of the base plate, a number of grooves are uniformly arranged on the upper end of the base plate, and a groove is arranged between the grooves and on the base plate. There are brackets on both sides of the bottom plate, the upper end of the bracket is fixedly connected with a horizontal plate, and a linear guide rail is installed under the horizontal plate. Both ends of the linear guide rail are fixedly connected with the inner walls on both sides of the bracket, and a bending mechanism that can move horizontally is set. At the same time, the No. 2 servo motor drives the bending mechanism to rotate. Different bending dies can be clamped between the three-jaw chucks in advance, and the corresponding bending dies can be converted through sensor alignment recognition. Realize the continuous multi-mold bending of the kitchen plate, ensure the bending strength and improve the bending efficiency. The structure of the mechanism adopted in this design is simple and efficient, which greatly improves the operation of the plate bending limit device efficiency.

Owner:瑞安市佳祥家纺有限公司

Bumper reinforcement and bumper device for vehicle

Owner:AISIN SEIKI KK +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com