Patents

Literature

84results about How to "Reduce manufacturing process steps" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

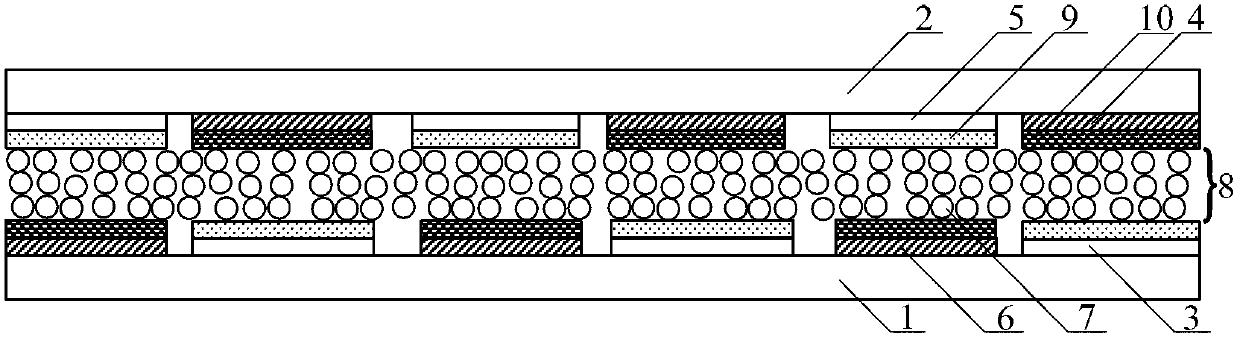

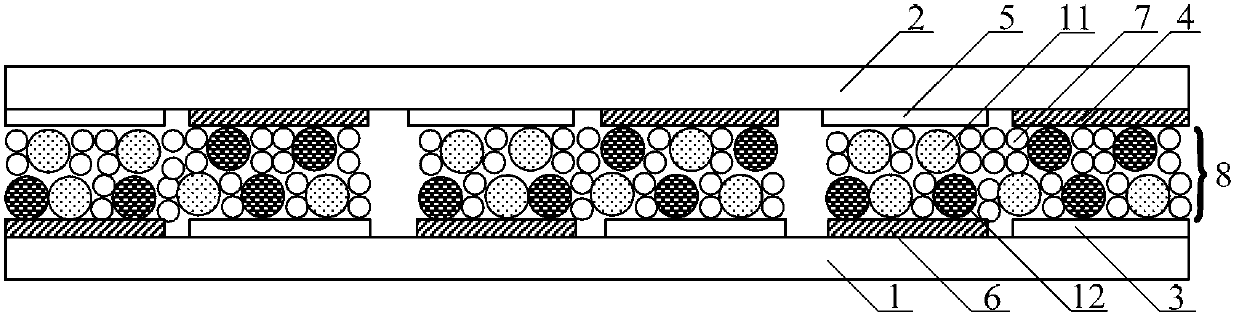

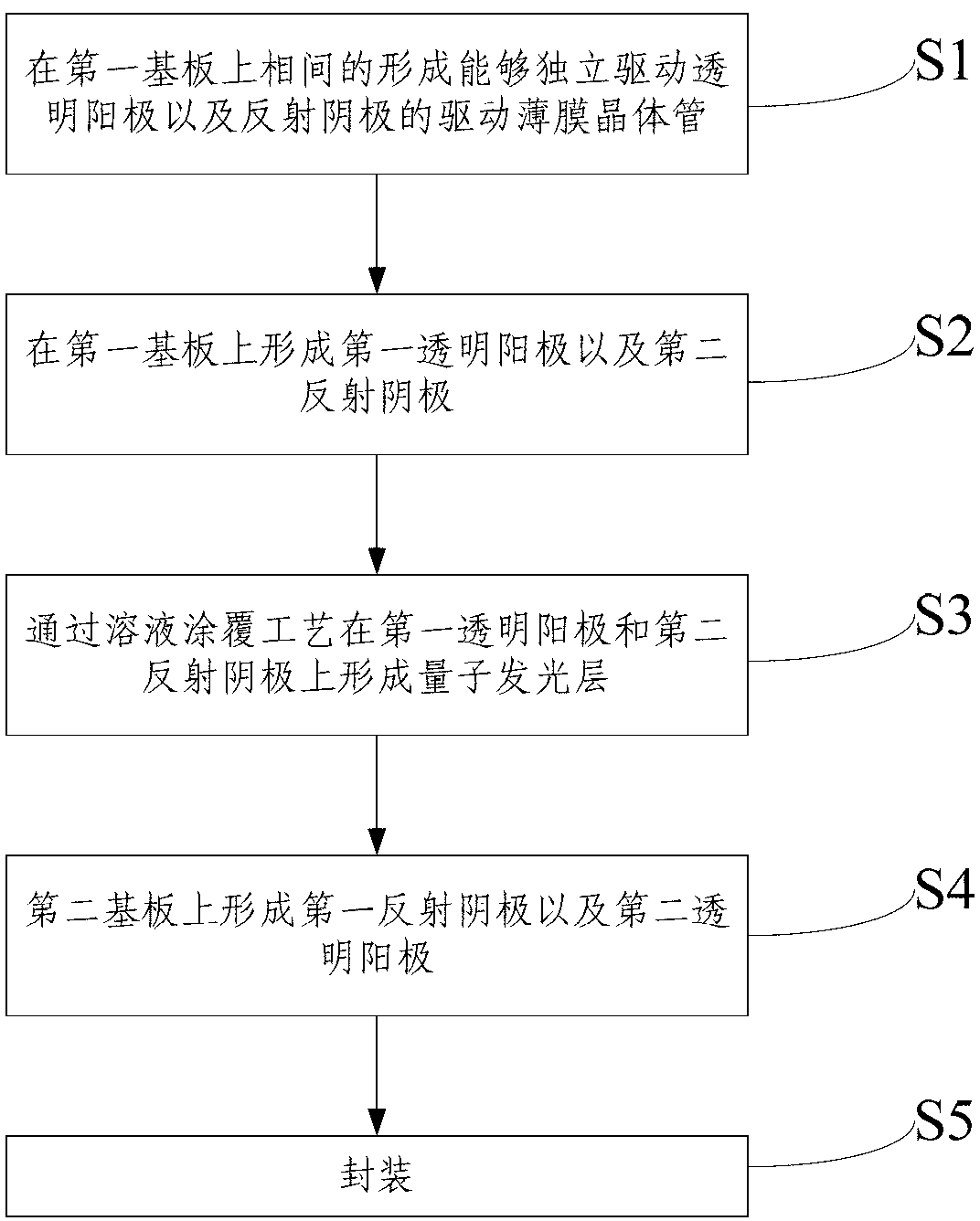

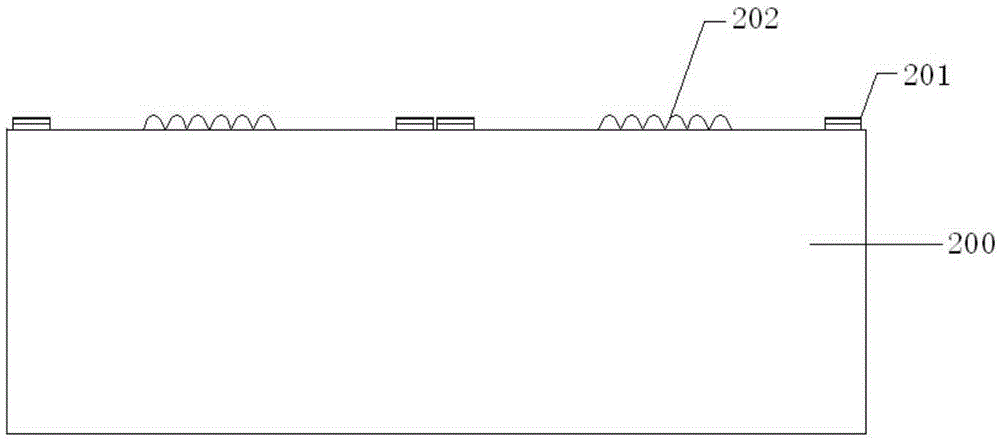

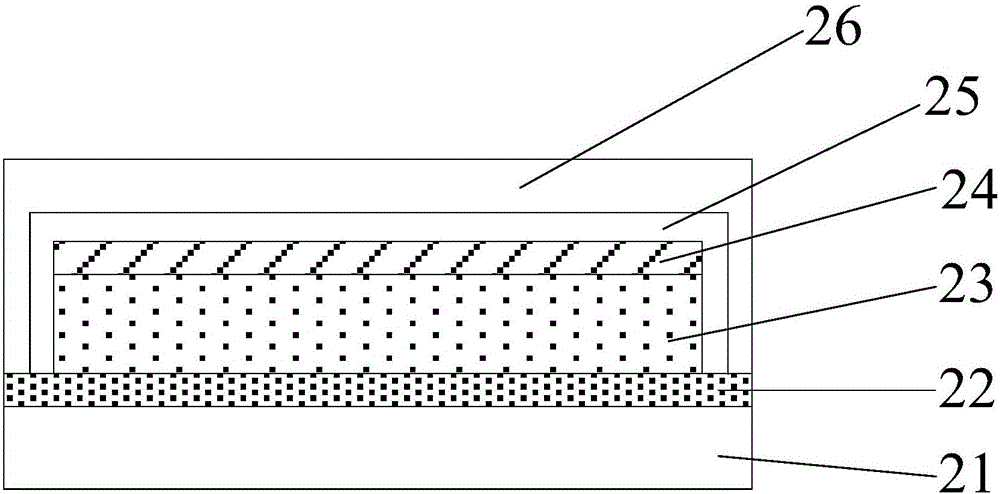

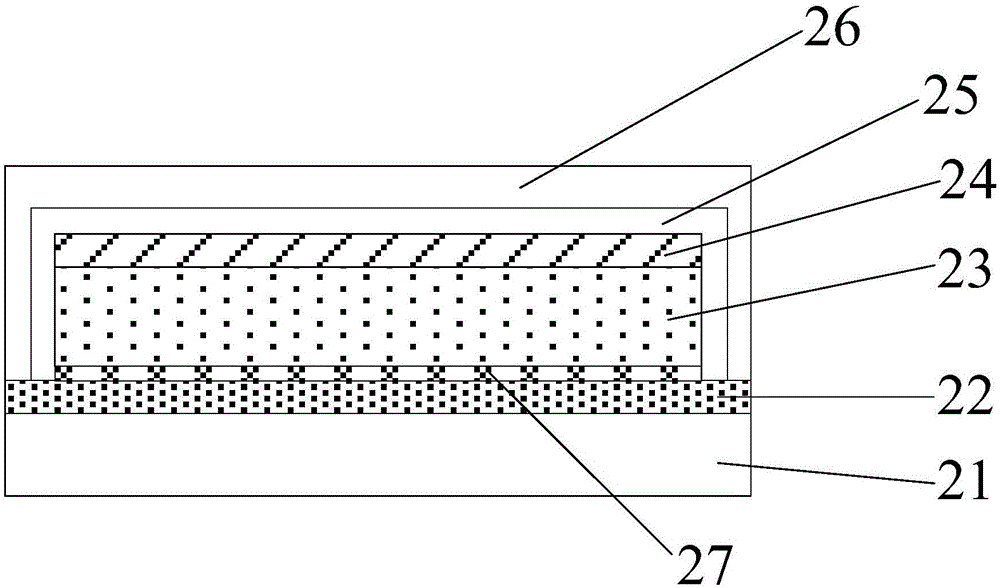

Double-face display device and preparation method thereof

ActiveCN103345884AImprove color gamutIncrease brightnessSolid-state devicesNanoopticsGamutDisplay device

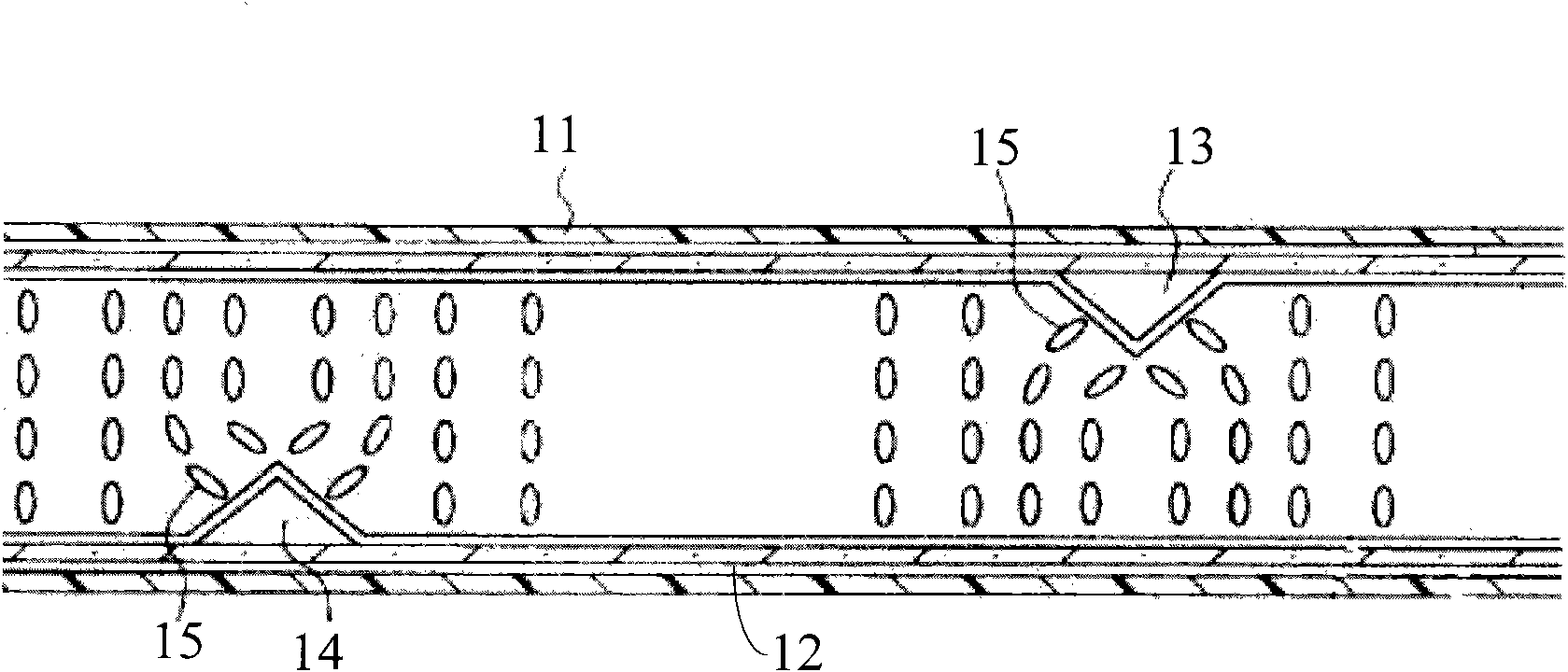

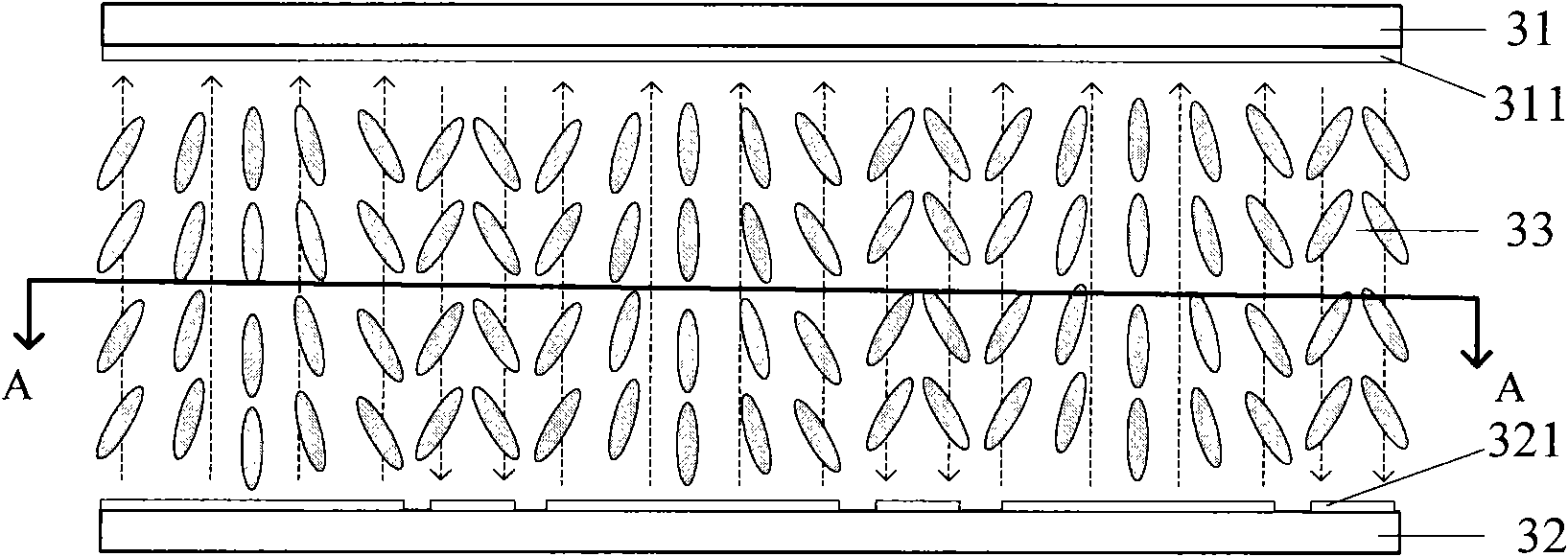

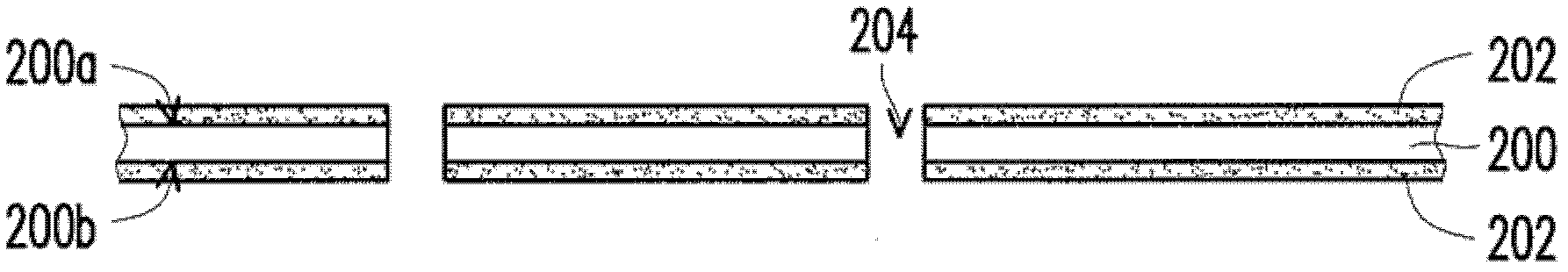

The invention relates to the technical field of display, in particular to a double-face display device and preparation method of the double-face display device. According to the double-face display device, firstly, a quantum luminous layer containing quantum dot luminous materials is arranged between transparent electrodes and reflecting electrodes, and due to the fact that the quantum dot luminous materials are relatively narrow in full width at half maximum of emission peaks and high in luminous purity, the color gamut and the brightness of the double-face display device are improved, and the double-face display device has high display quality; secondly, through the fact that charge transfer particles are mixed in the quantum luminous layer, the structure of the double-face display device is simplified, steps of a preparation technology are reduced, and production cost is lowered; lastly, image display in two directions is achieved through one display panel, both the thickness and the weight are not increased compared with a traditional single-face display device, and therefore the double-face display device has the advantages of being more convenient to carry, light in weight, low in price and the like.

Owner:BOE TECH GRP CO LTD

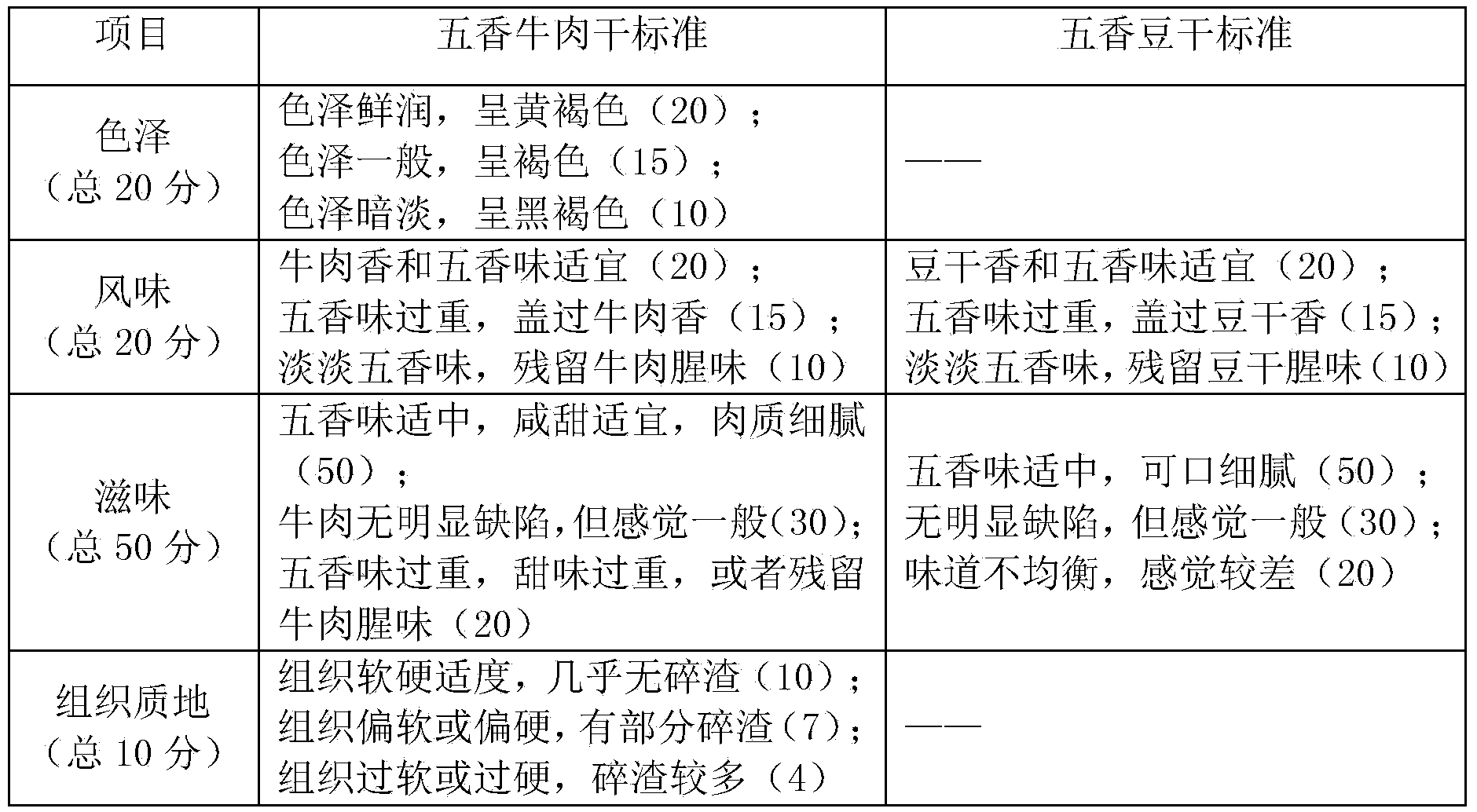

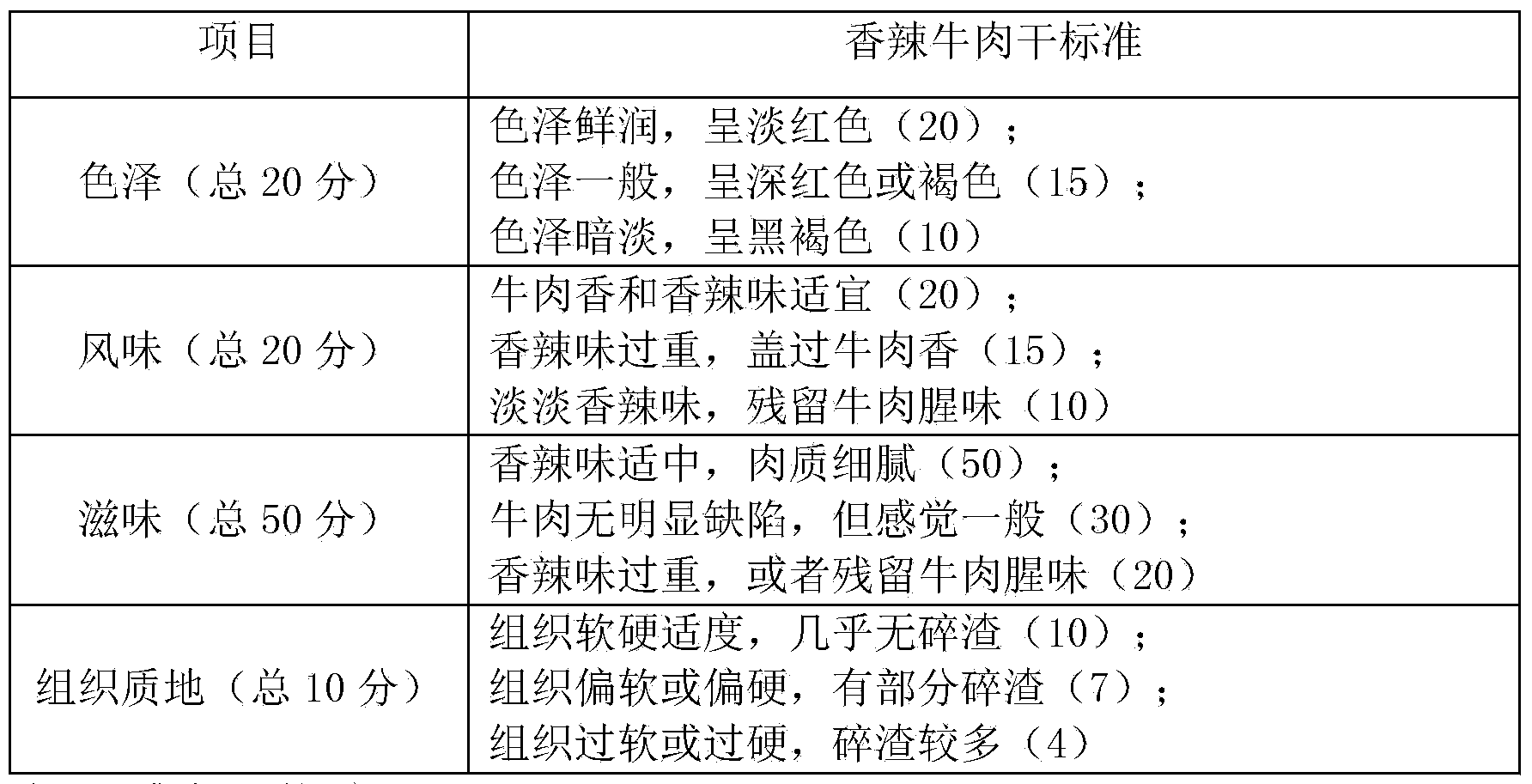

Manufacturing method of spiced beef jerky

ActiveCN103504321ABright colorDelicate tasteFood ingredient functionsFood preparationFlavorAmomum tsao-ko

The invention relates to a manufacturing method of spiced beef jerky. The method comprises the following steps: splitting fresh beef, pickling the cut beef with salt for 8-15 hours, boiling the pickled beef, removing blood-contained water, then slicing the boiled beef; mixing the sliced beef, water, white sugar and spice uniformly according to the proportion of 40-60 parts of beef, 3-5 parts of water, 4-6 parts of white sugar and 1-2 parts of spice; frying the mixed beef at 100-150 DEG C till dry; drying the fried beef at 50-90 DEG C until the moisture in the beef is 15-30%. The spice comprises 5-8 parts of radix angelicae, star aniseed, Chinese prickly ash and amomum tsao-ko each, 2-3 parts of cinnamon, cloves, round cardamom, amomum villosum and rhizoma kaempferiae each, 1 part of old ginger and liquorice each, and 1 part of equally mixed fennel, bay leaf, nutmeg, radix aucklandiae, galanga, mangnolia officinalis, fructus aurantii, tangerine peel and mint. The method has simple steps. The manufactured beef jerky is yellowish brown, bright in color, fine and smooth to be tasted, suitably salty and sweet, and proper in hardness. The spice has the functions of eliminating smell, retaining freshness, tonifying spleen and appetizing, and can be widely applied to seasoning of other food.

Owner:胡海山

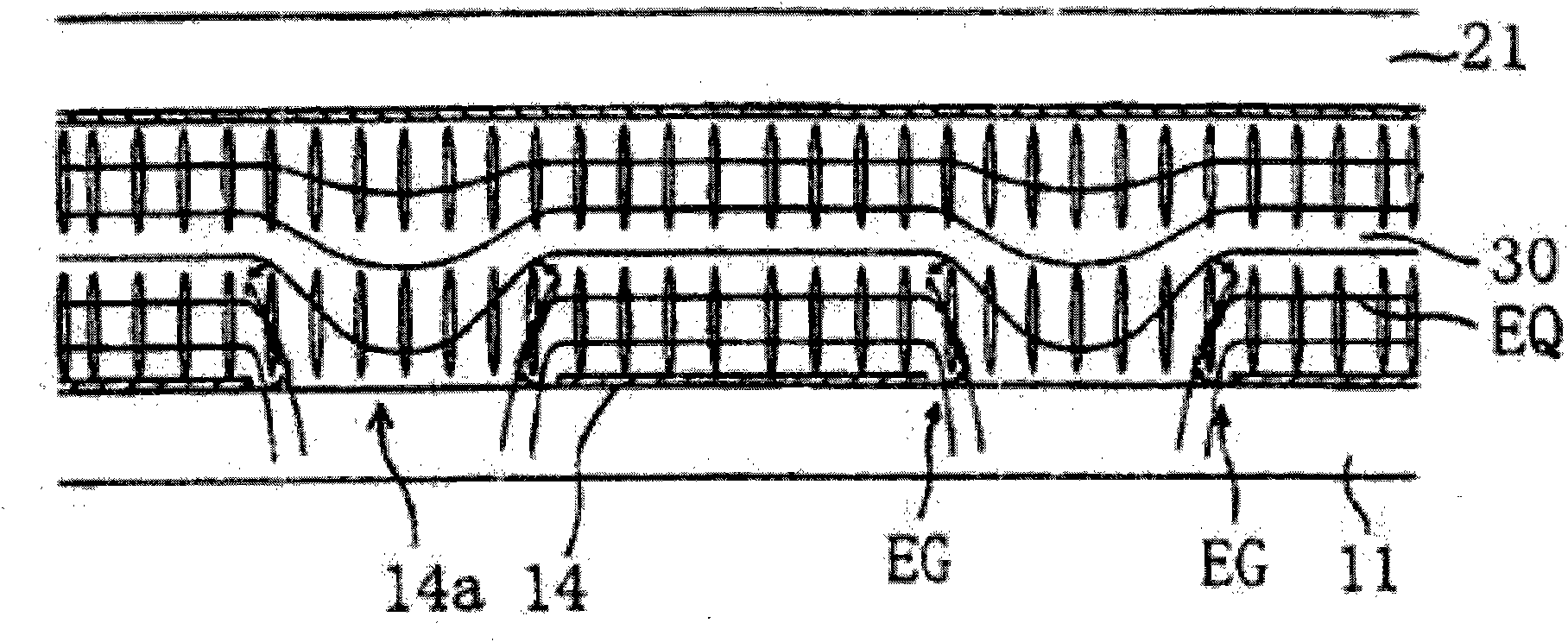

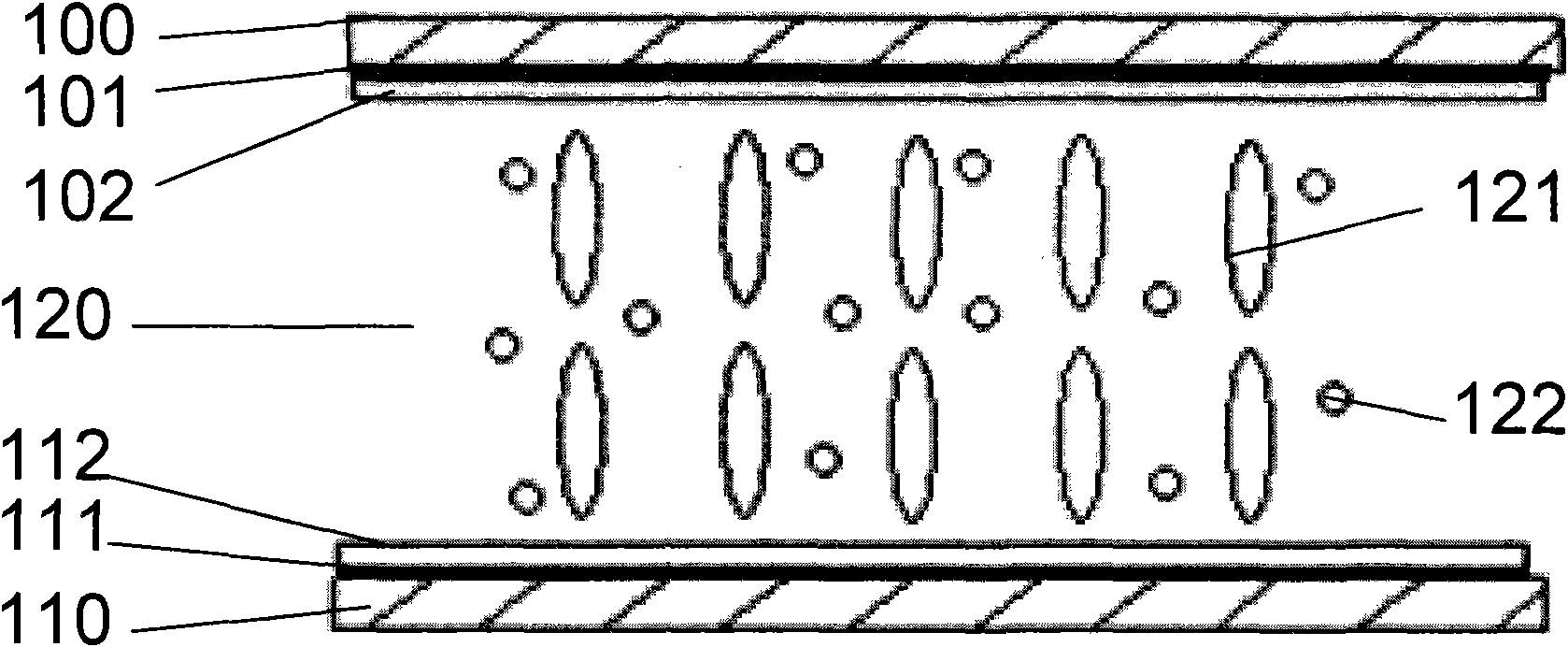

Liquid crystal display panel and liquid crystal display device

ActiveCN102073175AGood pre-tilt effectImprove viewing angleNon-linear opticsVoltage polarityEngineering

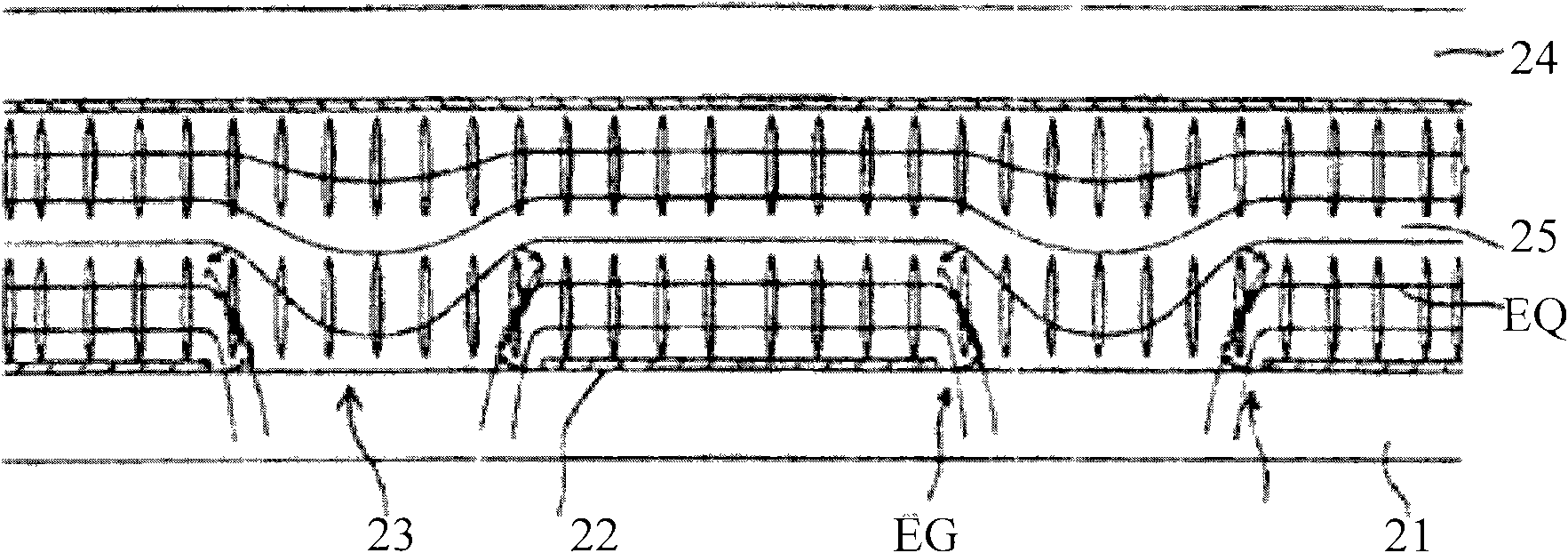

The invention provides a liquid crystal display panel and a liquid crystal display device. The liquid crystal display panel comprises a first substrate and a second substrate opposite to the first substrate; liquid crystal molecules are sandwiched between the first substrate and the second substrate; a transparent electrode layer is arranged on one side of the first substrate close to the liquid crystal molecules; a plurality of sub-pixel electrodes are arranged on one side of the second substrate close to the liquid crystal molecules; each sub-pixel electrode comprises a polygonal display area; at least two sides of display areas of adjacent sub-pixel electrodes are adjacent; each sub-pixel electrode and the transparent electrode layer form a liquid crystal capacitor; and the voltage polarity of each sub-pixel electrode relative to the transparent electrode layer of the first substrate is opposite to that of an adjacent sub-pixel electrode relative to the transparent electrode layer of the first substrate. By comparing the manufacturing process of the liquid crystal display panel with the prior art, manufacturing process steps are reduced, the product yield is high and the manufacturing cost is reduced.

Owner:SHANGHAI TIANMA MICRO ELECTRONICS CO LTD

Manufacturing method of spicy beef jerky

ActiveCN103504323ABright colorDelicate tasteFood ingredient functionsFood preparationFlavorAmomum tsao-ko

The invention relates to a manufacturing method of spicy beef jerky. The method comprises the following steps: splitting fresh beef, pickling the cut beef with salt for 8-15 hours, boiling the pickled beef, removing blood-contained water, then slicing the boiled beef; mixing the sliced beef with water, white sugar and spice uniformly according to the proportion of 40-60 parts of beef, 3-5 parts of water, 4-6 parts of hot pepper-containing water and 0.5-1 parts of spice; frying the mixed beef at 100-150 DEG C till dry; drying the fried beef at 50-90 DEG C until the moisture in the beef is 15-30%. The spice comprises 5-8 parts of radix angelicae, star aniseed, Chinese prickly ash, and amomum tsao-ko each, 2-3 parts of cinnamon, cloves, round cardamom, amomum villosum and rhizoma kaempferiae each, 1 part of old ginger and liquorice each, and 1 part of equally mixed fennel, bay leaf, nutmeg, radix aucklandiae, galanga, mangnolia officinalis, fructus aurantii, tangerine peel and mint. The method has simple steps. The manufactured beef jerky is yellowish brown, bright in color, fine and smooth to be tasted, suitably salty and sweet, and proper in hardness. The spice has the functions of eliminating smell, retaining freshness, tonifying spleen and appetizing.

Owner:胡海山

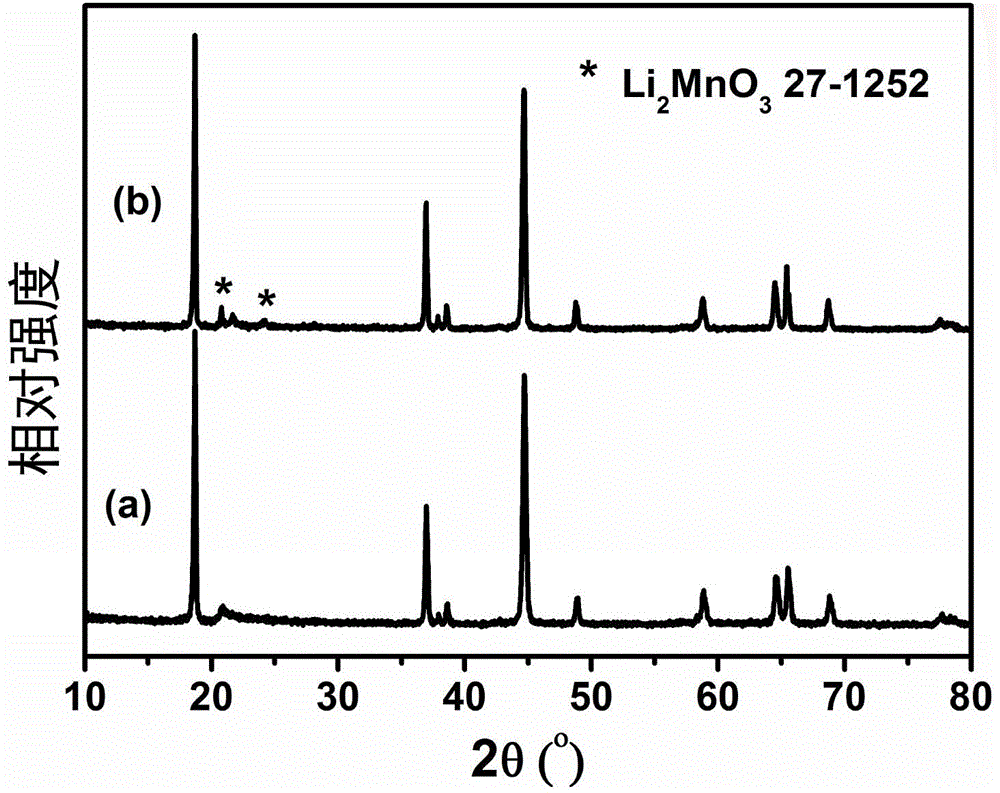

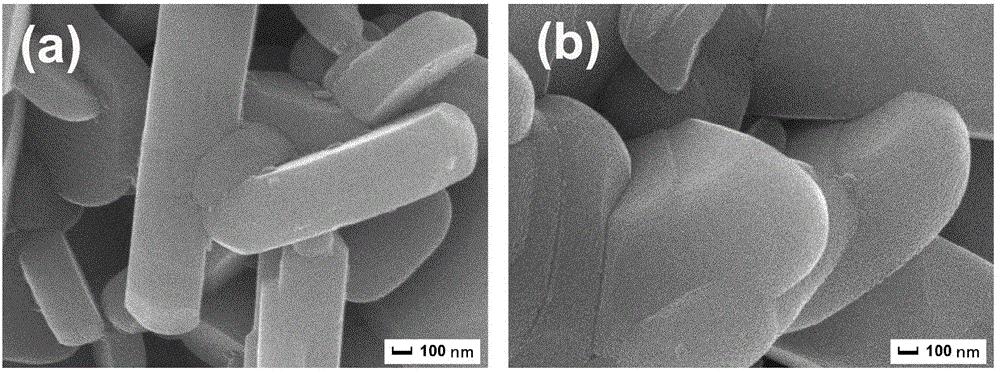

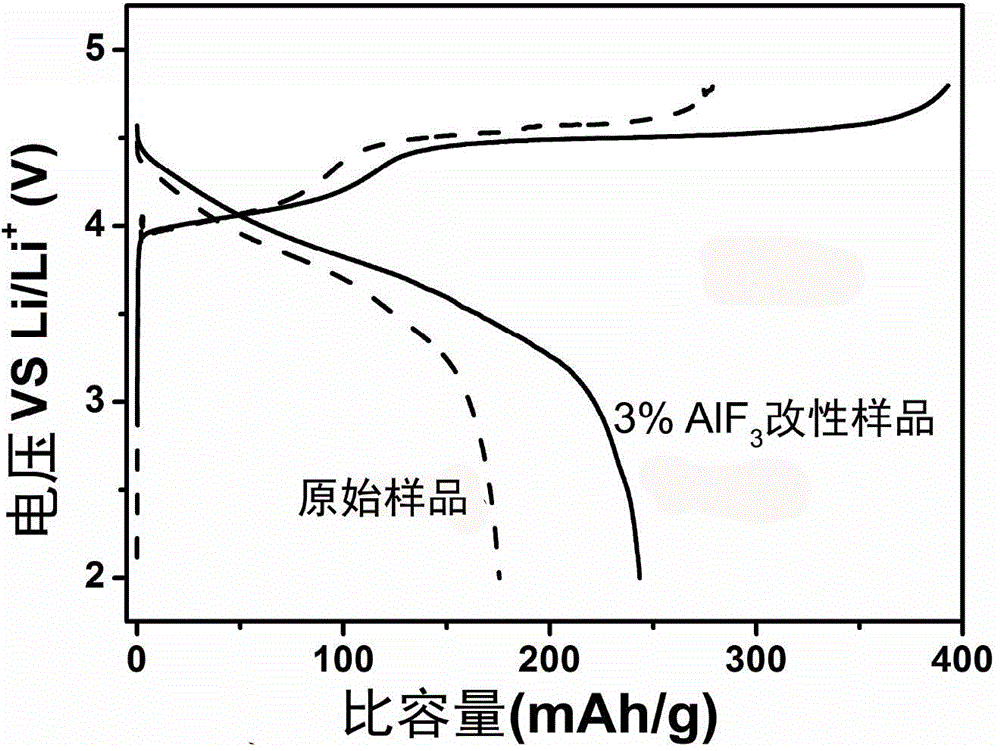

Method for modifying lithium-rich manganese-based cathode material

ActiveCN104681809ARealize regulationReduce manufacturing process stepsCell electrodesLithium carbonateManganese

The invention discloses a method for modifying a lithium-rich manganese-based cathode material. The method comprises the following steps: preparing a precursor of the lithium-rich manganese-based cathode material, uniformly mixing the precursor with lithium carbonate and doping and modifying metal villiaumite, sintering the uniformly mixed mixture at a high temperature to obtain a modified lithium-rich manganese-based cathode material. The modification process of the method disclosed by the invention is simple and easy to control, the steps of the existing preparation process are not added, and the electrochemical performance of the product is excellent.

Owner:CHANGSHA RES INST OF MINING & METALLURGY

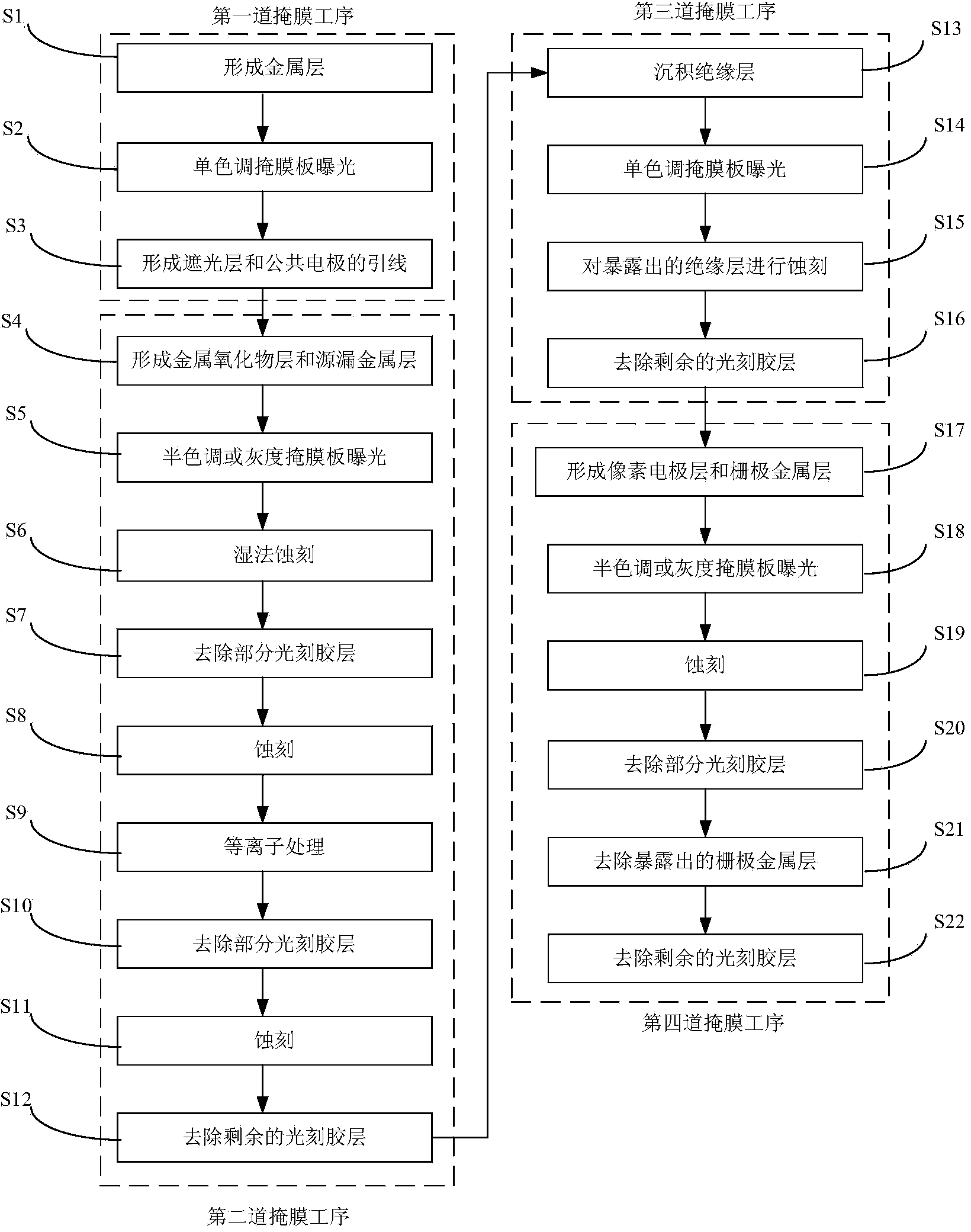

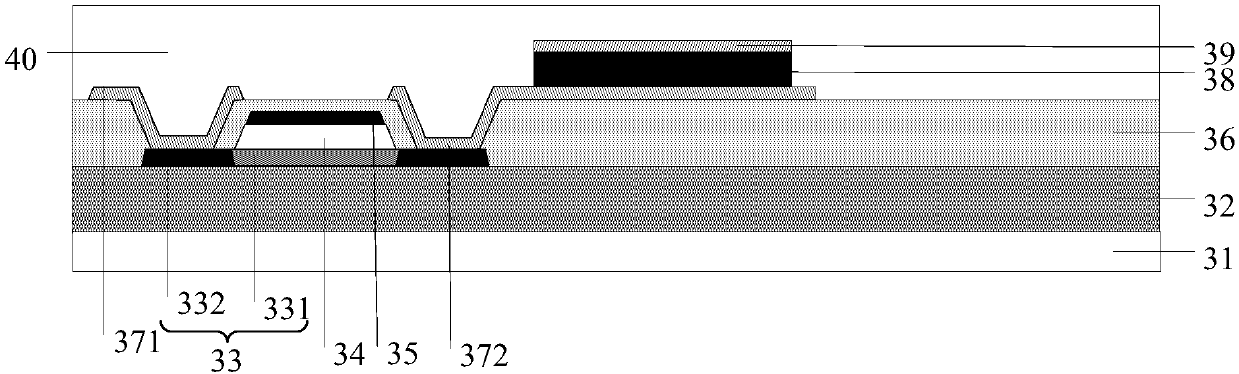

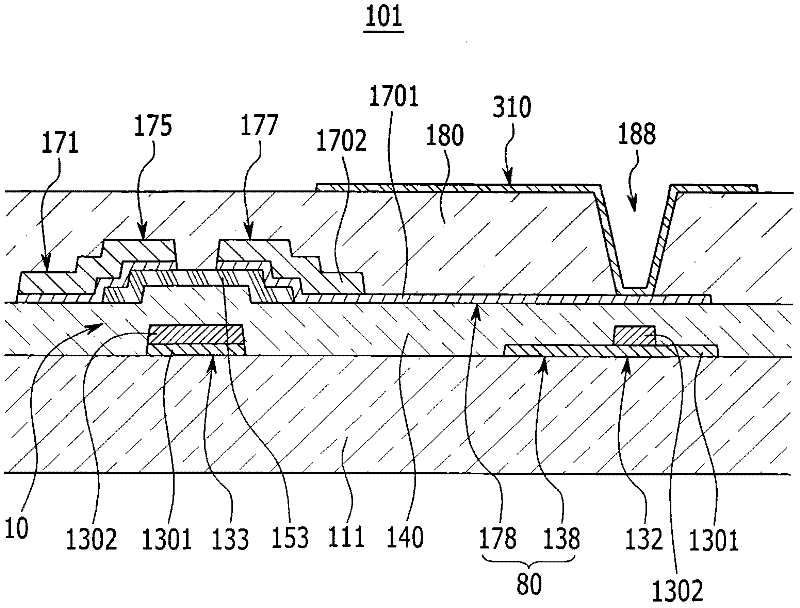

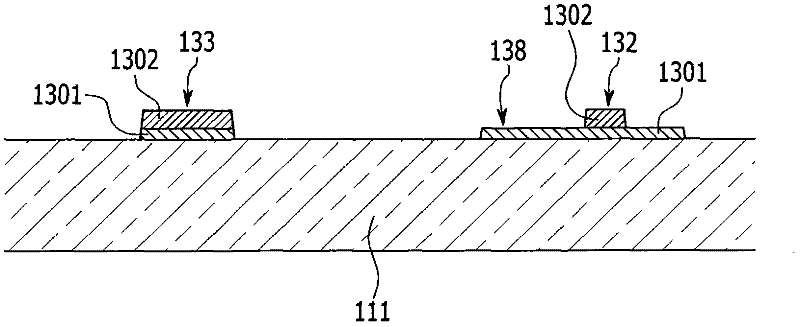

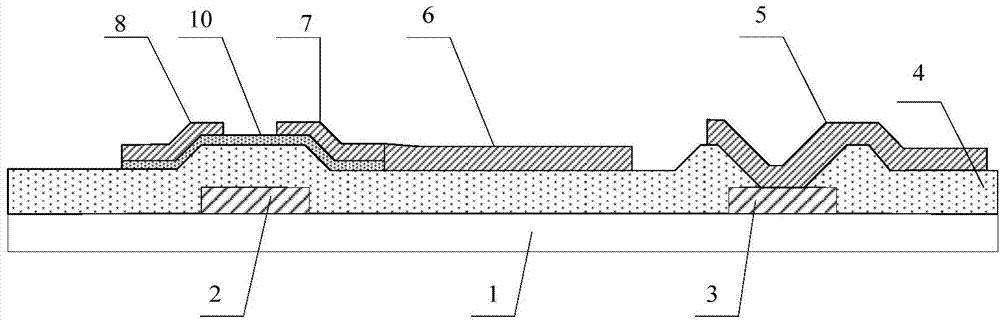

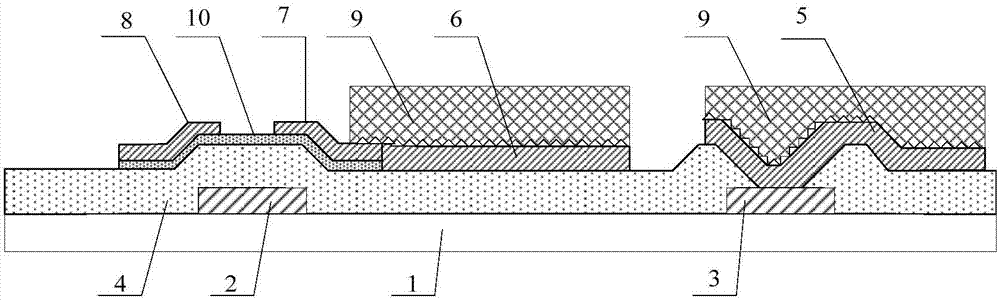

Array substrate, manufacturing method thereof and display device

ActiveCN103715137AReduce manufacturing process stepsReduce manufacturing costSolid-state devicesSemiconductor/solid-state device manufacturingDisplay deviceTransmittance

The invention relates to an array substrate, a manufacturing method of the array substrate and a display device. The manufacturing method of the array substrate is characterized in that a source electrode, a drain electrode, an active layer and a first transparent electrode of a thin film transistor in the array substrate are formed through a masking work procedure, the active layer and the first transparent electrode are formed by the same metal oxide layer, the source electrode and the drain electrode are located above the active layer, the first transparent electrode corresponds to a first semi-light-transmitting region of a mask plate, a channel region of the thin film transistor corresponds to a second semi-light-transmitting region of the mask plate, the source electrode and the drain electrode of the thin film transistor correspond to the non-light-transmitting region of the mask plate, and the light transmittance of the first semi-light-transmitting region of the mask plate is larger than the light transmittance of the second semi-light-transmitting region of the mask plate.

Owner:BOE TECH GRP CO LTD

Liquid crystal display panel and manufacturing method thereof

The invention provides a liquid crystal display panel and a manufacturing method thereof. The liquid crystal display panel comprises a first substrate, a second substrate which is opposite to the first substrate and a liquid crystal layer which is arranged between the first and the second substrates, wherein under the situation of non-electrification, liquid crystal molecules in the liquid crystal layer are arranged to be vertical to the first substrate, and the liquid crystal layer comprises an anchoring substance; the liquid crystal molecule which is close to the surface of the first substrate or the second substrate is pre-inclined under the situation of non-electrification through the anchoring substance. The liquid crystal display panel and the manufacturing method thereof are free from forming projection or crack and from changing other structures of a pixel unit, can realize the pre-inclination of the liquid crystal molecules, can simplify the manufacturing process procedure, can improve the yield of the product, and can reduce the cost.

Owner:SHANGHAI TIANMA MICRO ELECTRONICS CO LTD

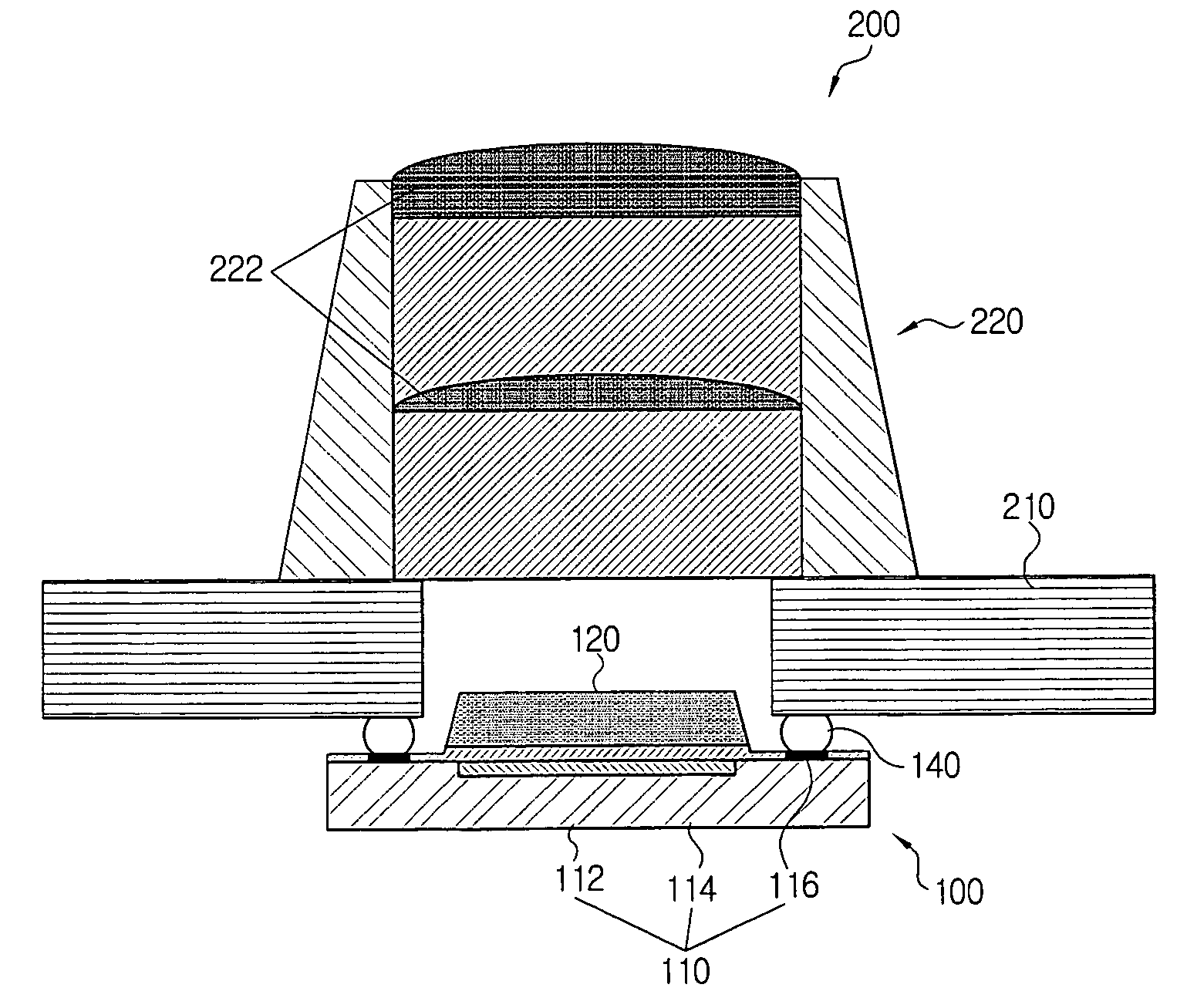

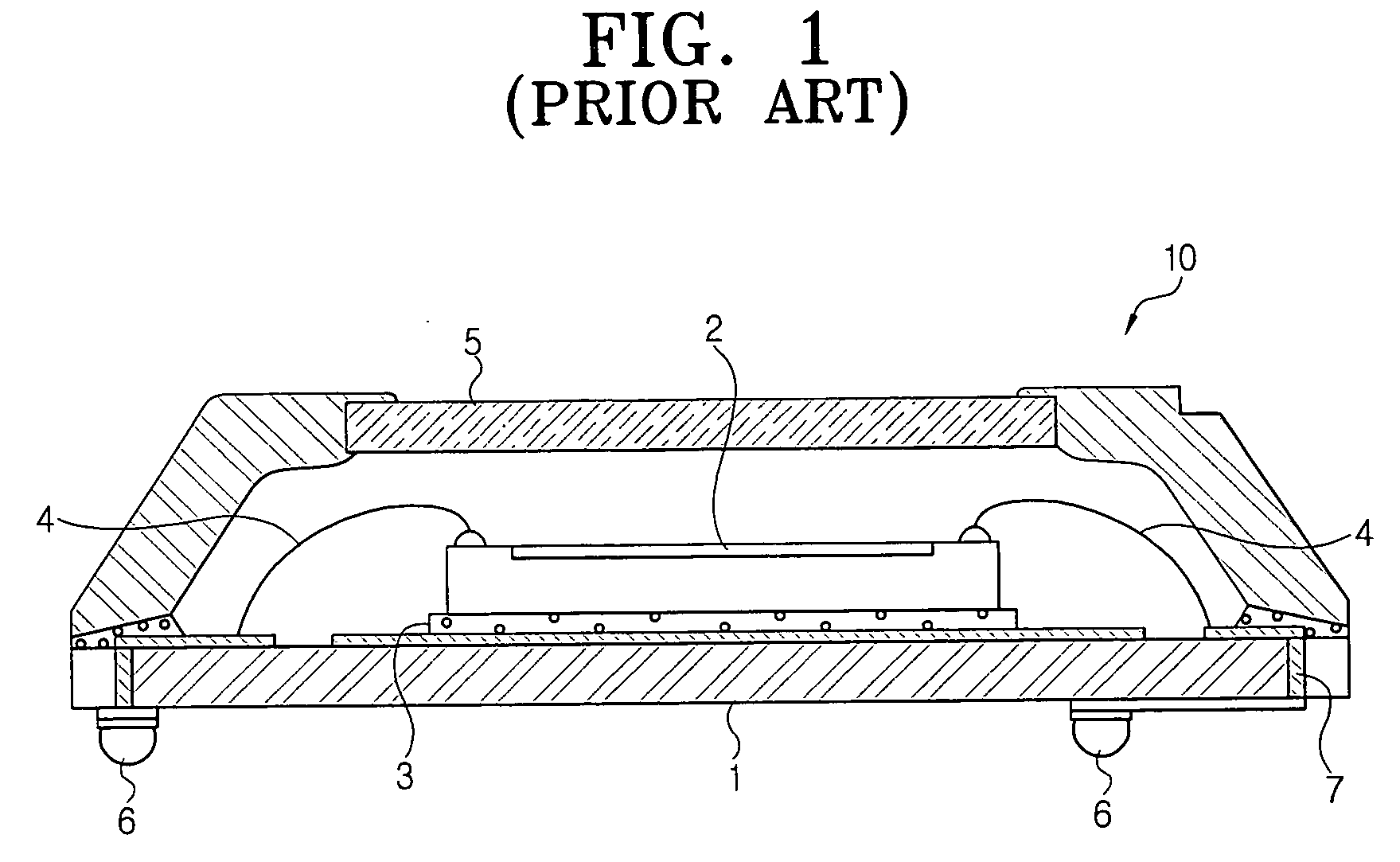

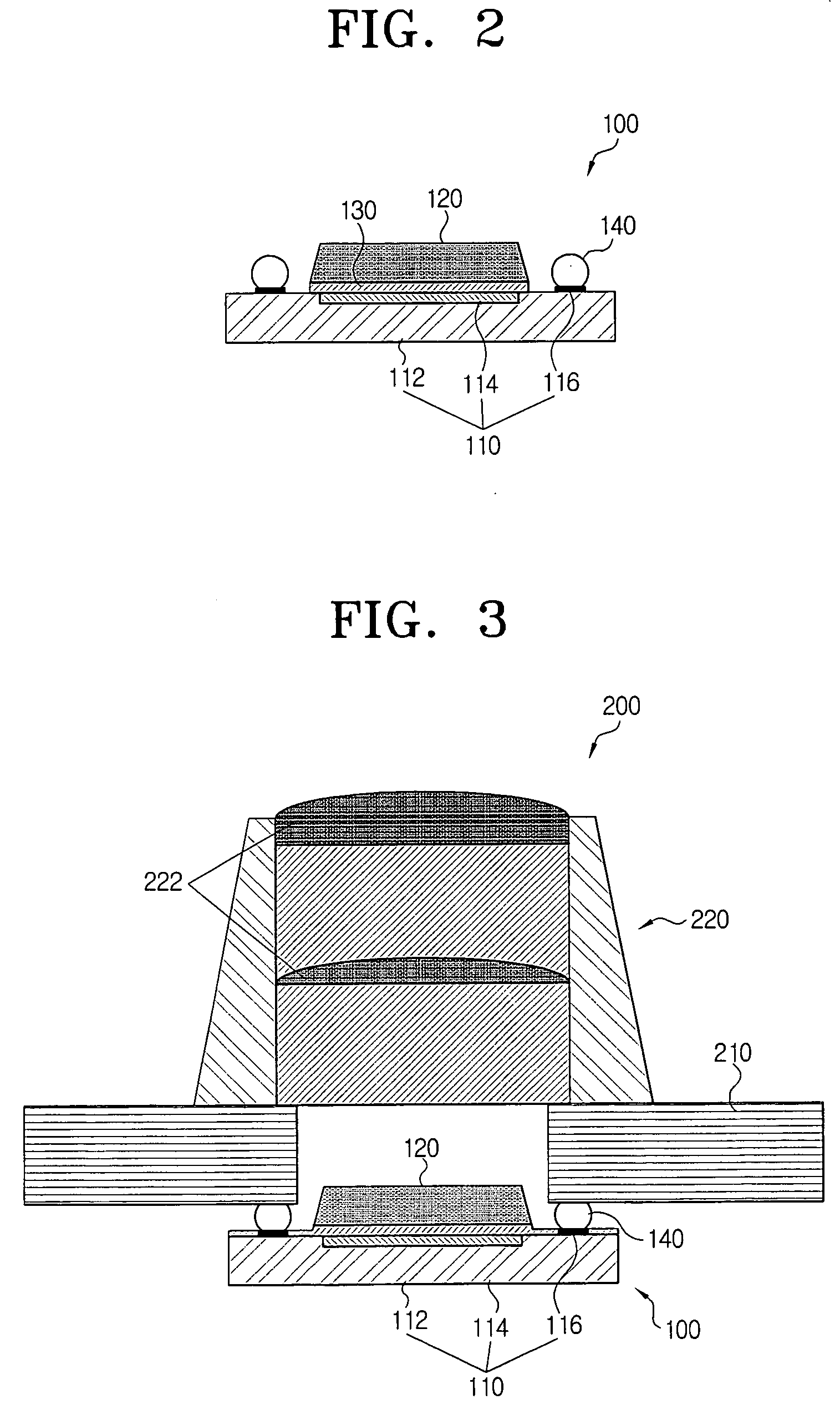

Image sensor package, solid state imaging device, and fabrication methods thereof

InactiveUS20060138579A1Reduce manufacturing process stepsReduce processing stepsSemiconductor/solid-state device detailsSolid-state devicesAdhesiveSolid-state

An image sensor package and a solid state imaging device. The image sensor package includes an image sensor having an image sensor and connection pads on a wafer. A transparent plate is attached to the upper surface of the image sensor chip via an adhesive. The connection pads include connectors, and the image sensor package exchanges signals with a main board of the solid image device through the connectors.

Owner:SAMSUNG ELECTRONICS CO LTD

Composite modified superhigh molecular polyethylene material and method for making mining pipes by employing the same

InactiveCN101134827ANo wearImprove processing fluidityLiquid crystal compositionsTubular articlesPolymer scienceUltimate tensile strength

The present invention is one kind of composite modified ultrahigh molecular weight polyethylene material and the process of making mine pipe with the material, and belongs to the field of polyethylene material modifying technology. The composite modified ultrahigh molecular weight polyethylene material consists of ultrahigh molecular weight polyethylene 100-400 weight portions, liquid crystal polymer material 10-20 weight portions, flexibilizer 15-30 weight portions, and modifier 0.5-1.5 weight portions. It has tensile strength over 28.5-32 MPa, shock strength over 150 KJ / sq m, elongation at break 420-470 % and other excellent performance. It may be applied in making various kinds of pipes for use in coal mine.

Owner:江苏常盛管业有限公司

Touch display and manufacturing method of touch display

ActiveCN110471551AReduce the number of layersReduce distanceNon-linear opticsInput/output processes for data processingDisplay deviceComputer science

The invention discloses a touch display which comprises a substrate, a thin film transistor, a touch signal line, a first insulating layer, a first transparent conducting layer, a second insulating layer, a first connecting hole, a second connecting hole and a second transparent conducting layer. The thin film transistor and the touch signal line are arranged on the substrate. The first insulatinglayer, the first transparent conducting layer and the second insulating layer are sequentially arranged on the thin film transistor and the touch signal line, wherein the first transparent conductinglayer comprises a pixel electrode. The first connecting hole and the second connecting hole are located in the first insulating layer and the second insulating layer, the first connecting hole exposes a part of the pixel electrode and a part of the drain electrode of the thin film transistor, and the second connecting hole exposes a part of the touch signal line. The second transparent conductinglayer is arranged on the second insulating layer and comprises a touch electrode and a connecting electrode, and the connecting electrode and the control electrode extend into the first connecting hole and the second connecting hole respectively and are electrically insulated from each other.

Owner:HANNSTAR DISPLAY CORPORATION

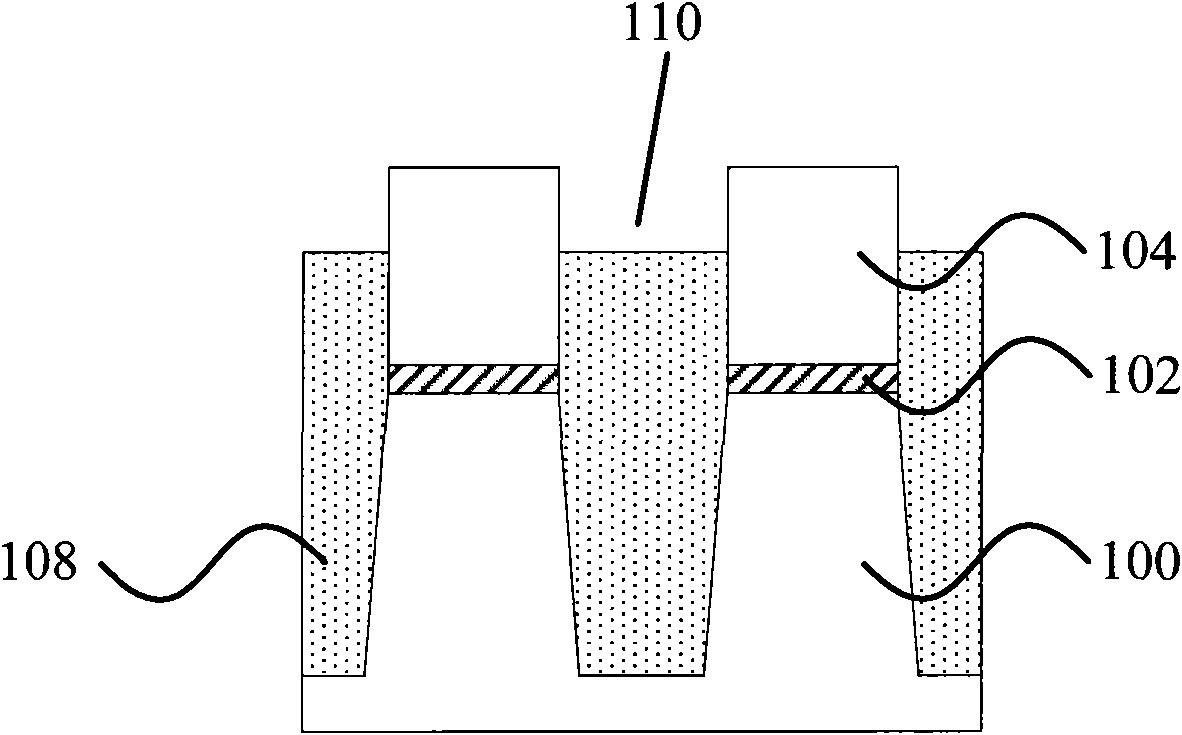

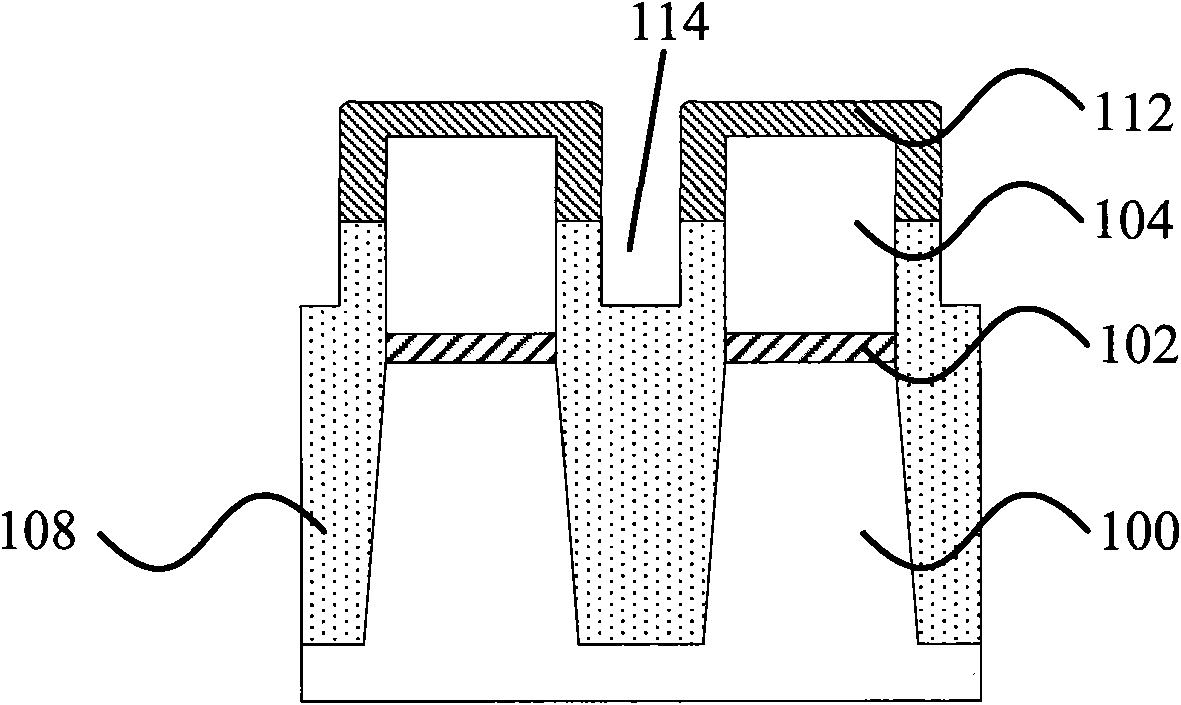

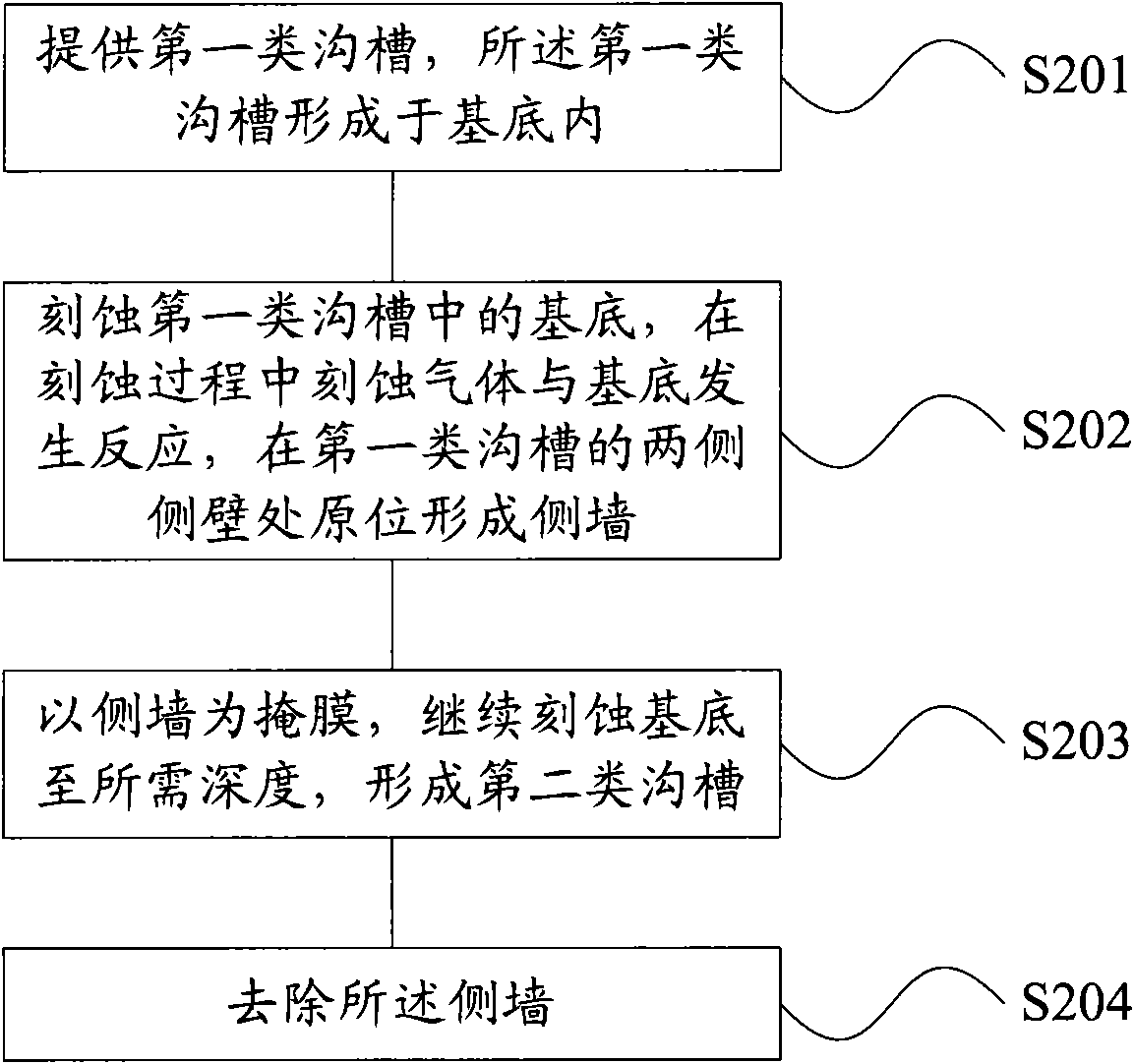

Forming method of groove

ActiveCN101599419AShorten the timeReduce manufacturing process stepsSemiconductor/solid-state device manufacturingBiochemical engineeringMedia layer

The invention relates to a forming method of a groove, which comprises the following steps: providing a first groove, wherein the first groove is formed in a base; etching a base in the first groove, wherein etching gases react with the base during the etching, home positions of two side walls of the first groove are provided with side walls; continuously etching the base until reaching the needed depth so as to form a second groove by using the side walls as a mask; and removing the side walls. Reaction products of the etching gases and the base at the two side walls of the first groove are formed into polymer side walls at the home positions in the process of dry-etching the base in the first groove, the polymer side walls replace multilayered medium layer side walls at two side walls of the first groove before the etching of the second groove and are used as a hard mask of continuously etching the second groove, thereby improving the efficiency of the semiconductor fabrication process and optimizing the process.

Owner:SEMICONDUCTOR MANUFACTURING INTERNATIONAL (BEIJING) CORP

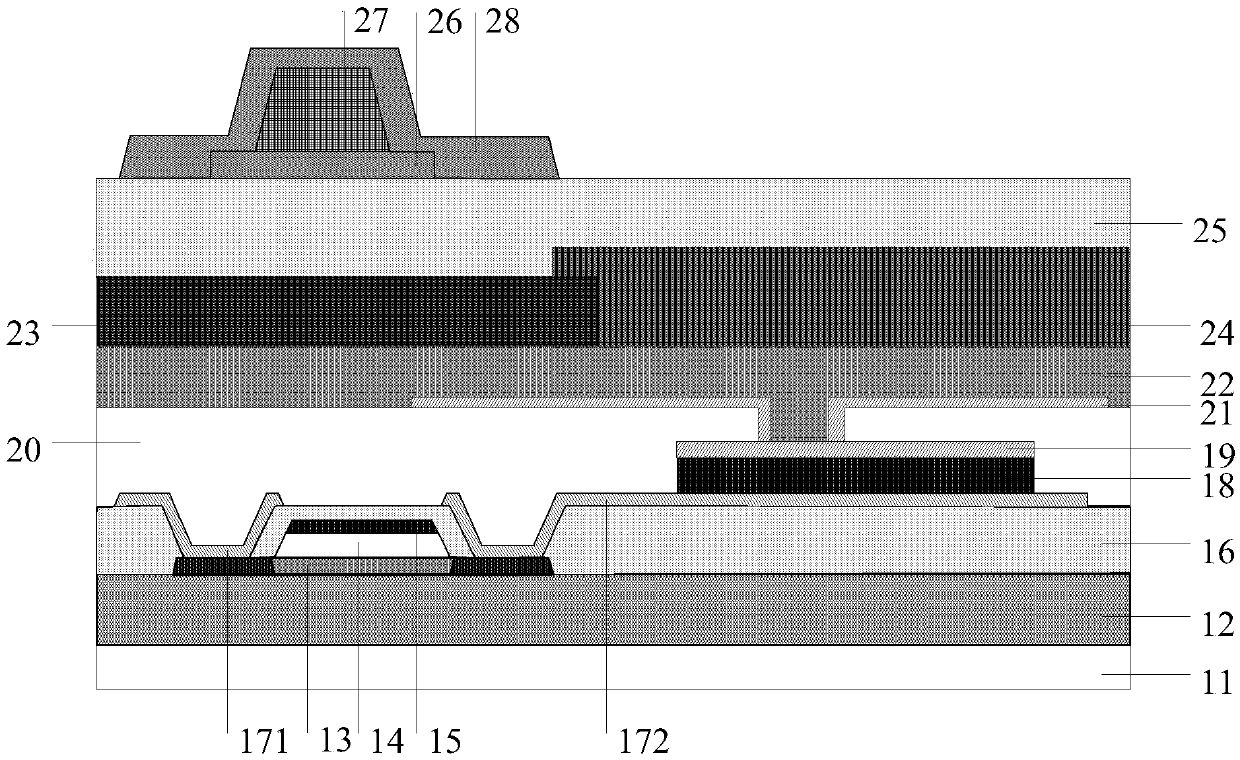

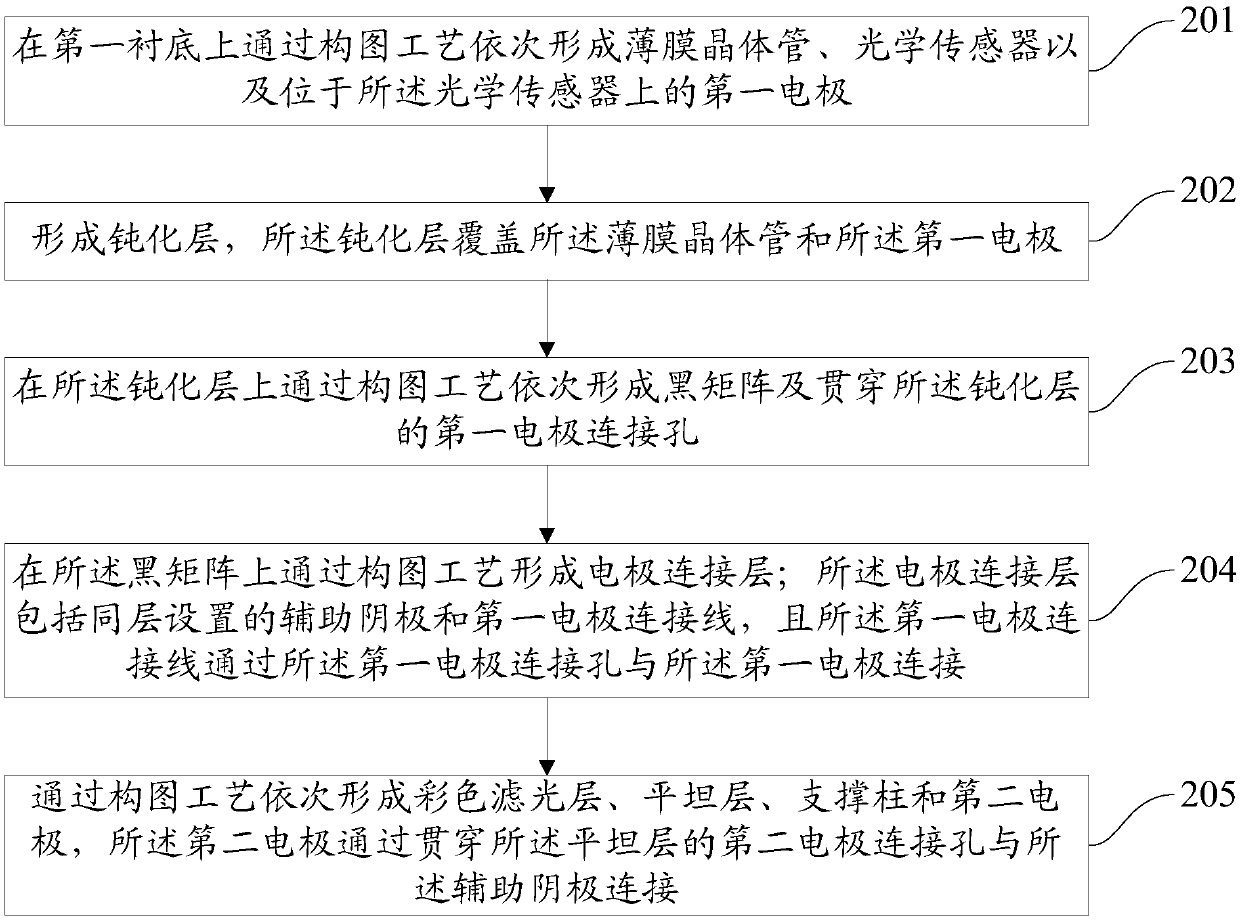

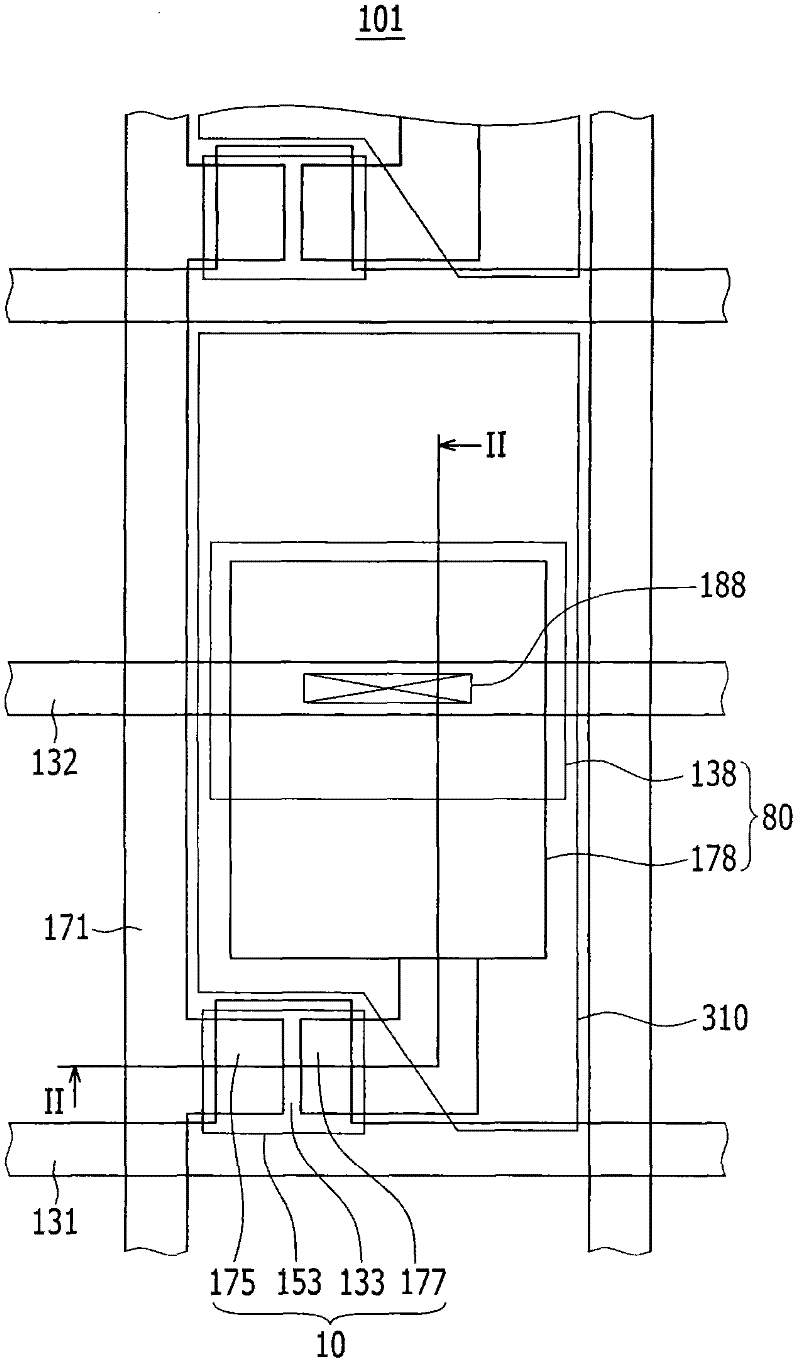

Cover plate and manufacturing method thereof, display panel and display device

ActiveCN109004015ASmall footprintReduce manufacturing process stepsSolid-state devicesSemiconductor/solid-state device manufacturingComposition processDisplay device

The invention provides a cover plate and a manufacturing method thereof, a display panel and a display device, which relate to the technical field of display. A thin film transistor, an optical sensorand a first electrode located on the optical sensor are are sequentially formed on a first substrate by a composition process, a passivation layer is formed, a black matrix and a first electrode connection hole penetrating the passivation layer are sequentially formed on the passivation layer through a composition process, An electrode connecting layer is formed on the black matrix by a composition process, the electrode connecting layer comprising an auxiliary cathode and a first electrode connecting wire arranged in the same layer, and the first electrode connecting wire is connected with the first electrode through a first electrode connecting hole, and a color filter layer, a flat layer, a support column and a second electrode are sequentially formed by the composition process. As theauxiliary cathode and the first electrode connecting wire are formed by the one-time composition process, the manufacturing process steps are reduced, the manufacturing cost is reduced, and the auxiliary cathode and the first electrode connecting wire are arranged on the same layer, so that the occupied space of the cover plate can be saved.

Owner:BOE TECH GRP CO LTD

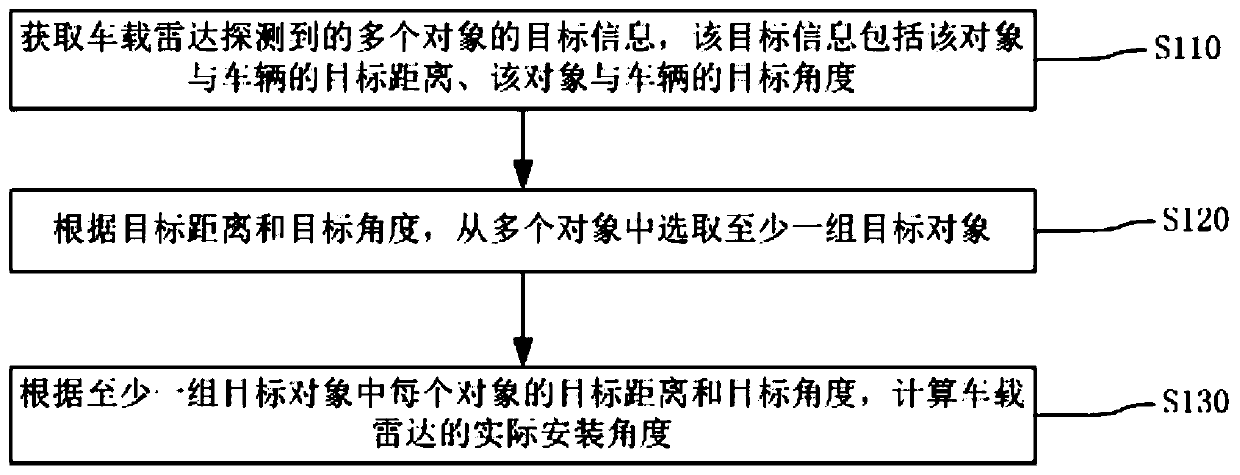

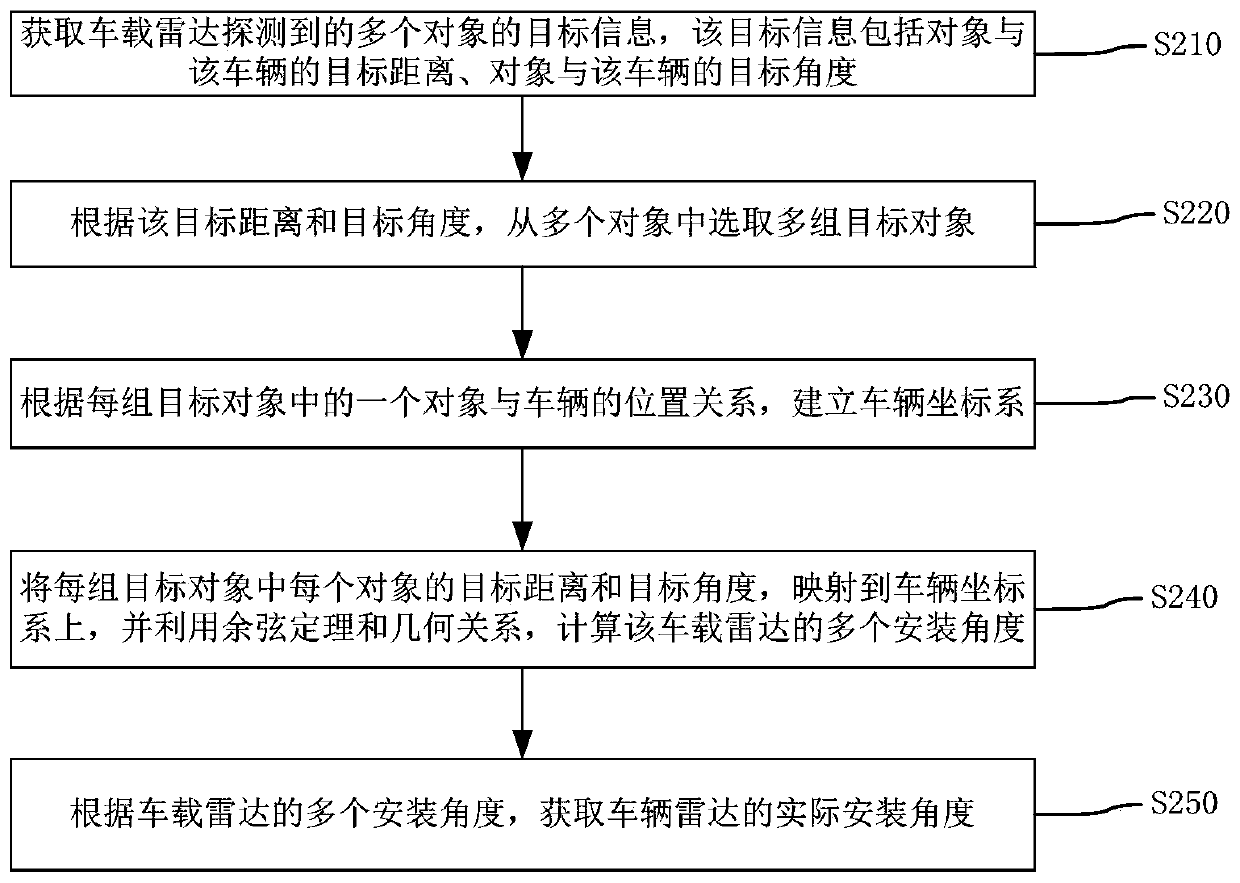

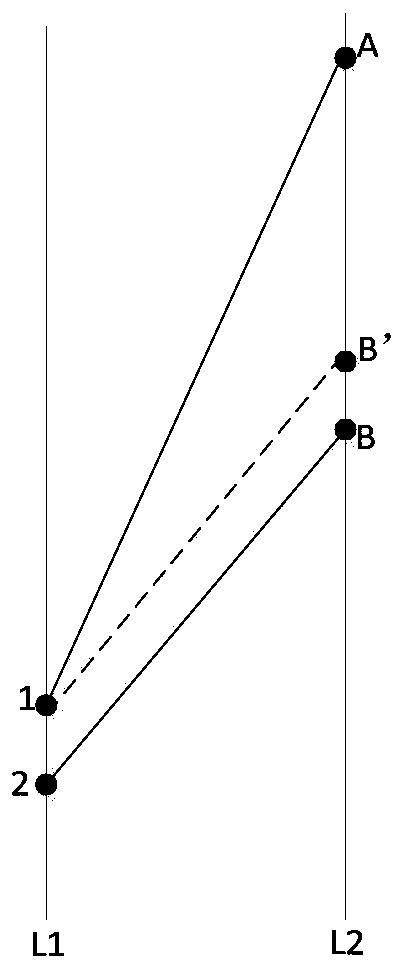

Method and device for calibrating installation angle of vehicle-mounted radar and related equipment

PendingCN111521979AImprove assembly productivityReduce manufacturing process stepsWave based measurement systemsIn vehicleEngineering

The invention discloses a method and device for calibrating an installation angle of a vehicle-mounted radar, and related equipment. The method for calibrating the installation angle of the vehicle-mounted radar comprises the following steps of acquiring the target information of a plurality of objects detected by the vehicle-mounted radar, wherein the target information comprises a target distance between the object and the vehicle and a target angle between the object and the vehicle; selecting at least one group of target objects from a plurality of objects according to the target distanceand the target angle, each group of target objects including two objects satisfying a preset condition; and calculating an actual installation angle of the vehicle-mounted radar according to the target distance and the target angle of each object in the at least one group of target objects. The method is advantaged in that dynamic calibration of the radar installation angle is achieved when the vehicle is subjected to road testing, so steps of the whole vehicle manufacturing process of the vehicle can be reduced, the time and labor can be effectively saved, and vehicle assembly production efficiency is improved.

Owner:BYD CO LTD

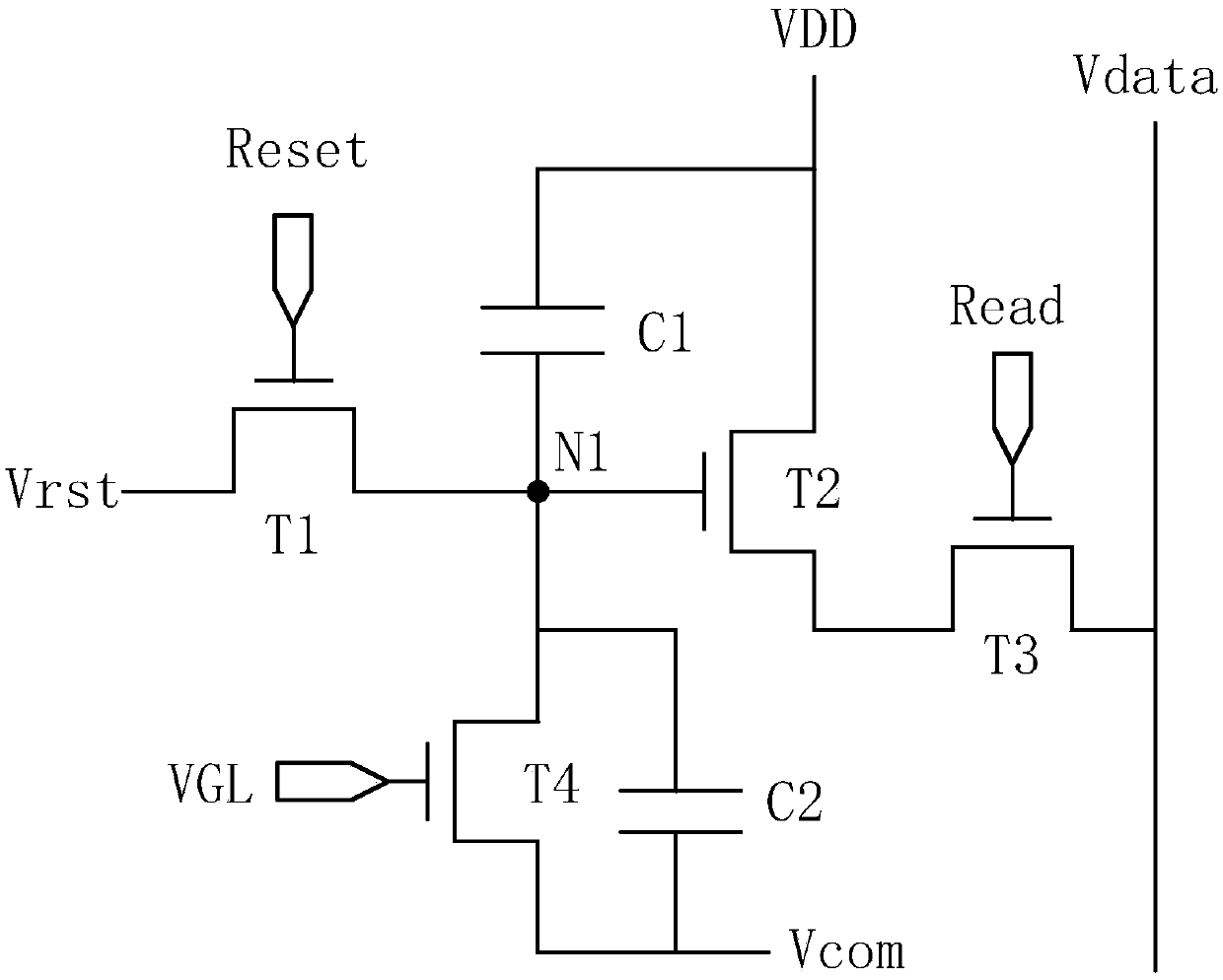

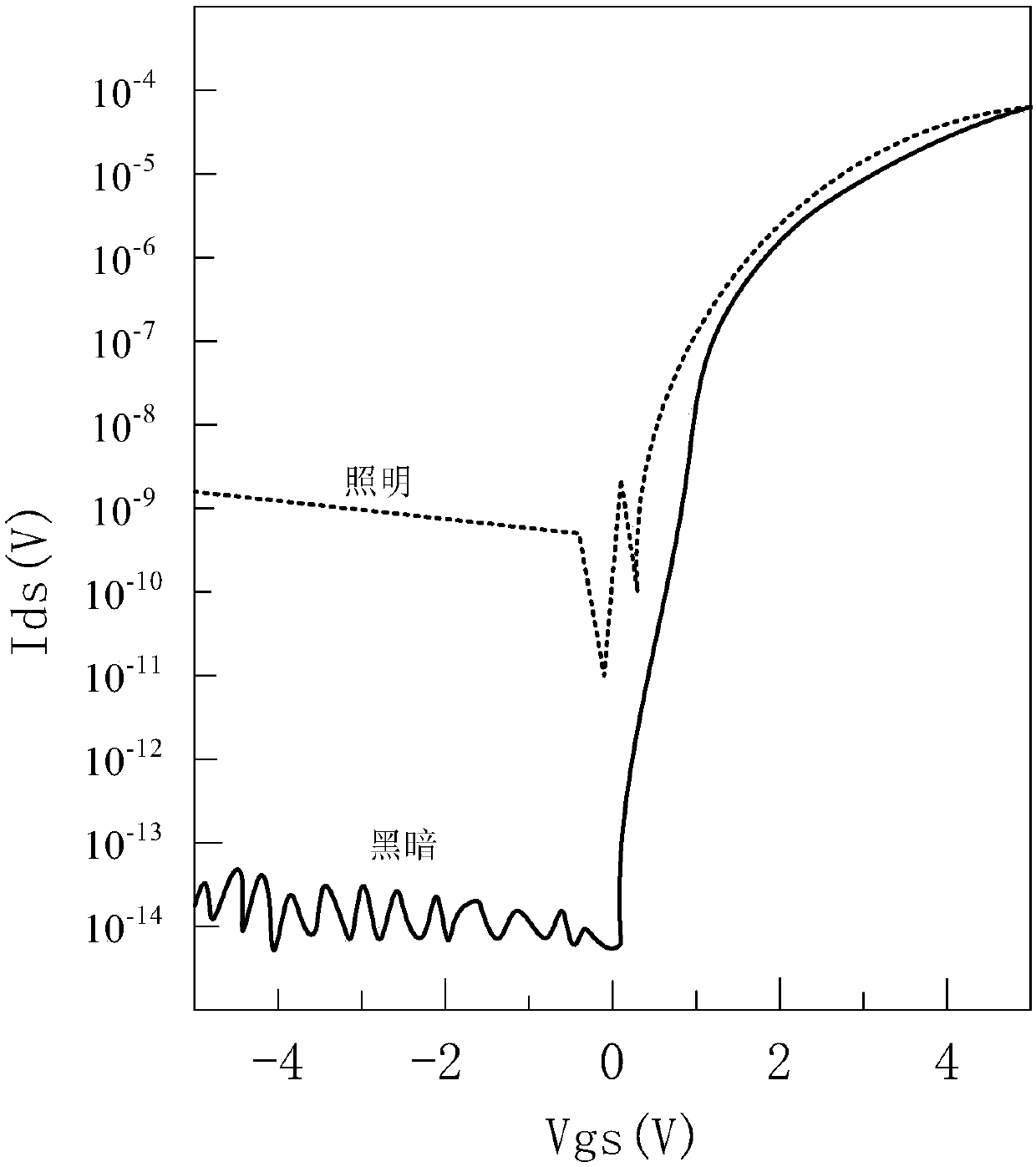

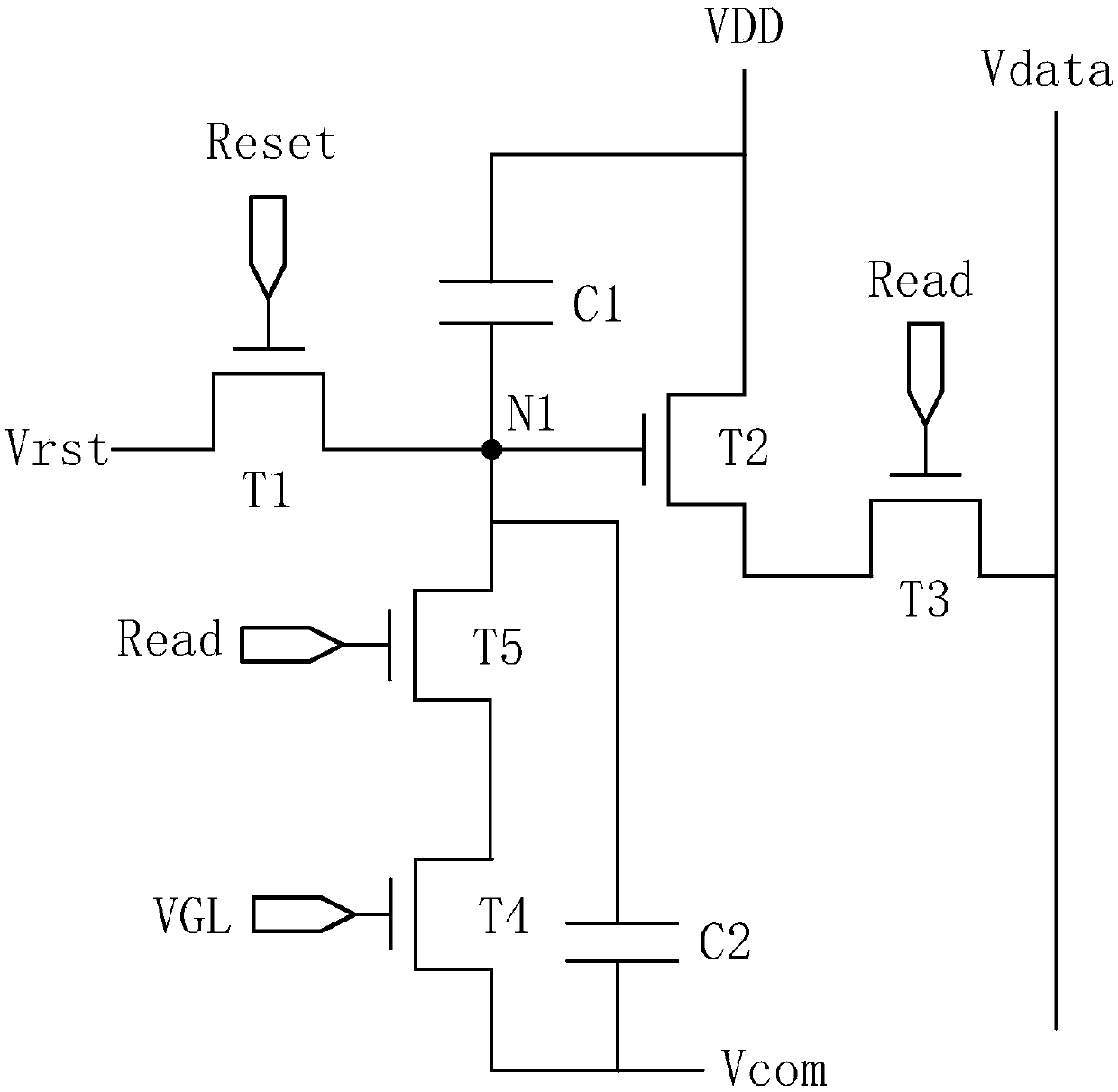

Light sensing circuit and driving method thereof, display panel and display device

ActiveCN109686301AFacilitate thinningSensitive to lightStatic indicating devicesElectricityLight sensing

The invention discloses a light sensing circuit and a driving method thereof, a display panel and a display device, belonging to the technical field of display. The light sensing circuit comprises that: the gate of a first transistor is electrically connected to a first control terminal, the first pole is electrically connected to a first voltage terminal, and the second pole is electrically connected to a first node; the gate of a second transistor is electrically connected to the first node, the first pole is electrically connected to a second voltage terminal, and the second pole is electrically connected to the first pole of a third transistor; the gate of the third transistor is electrically connected to a second control terminal, and the second pole is electrically connected to a data line; the gate of a fourth transistor is electrically connected to a third control terminal, the first pole is coupled to the first node, and the second pole is electrically connected to a third voltage terminal; the first transistor and the fourth transistor comprise active layers formed of metal oxide, and the fourth transistor is multiplexed into a light sensing element; and the second transistor and the third transistor comprise active layers formed of polysilicon. Compared with the prior art, the invention is advantageous to reduce the process steps and thin the display panel.

Owner:XIAMEN TIANMA MICRO ELECTRONICS

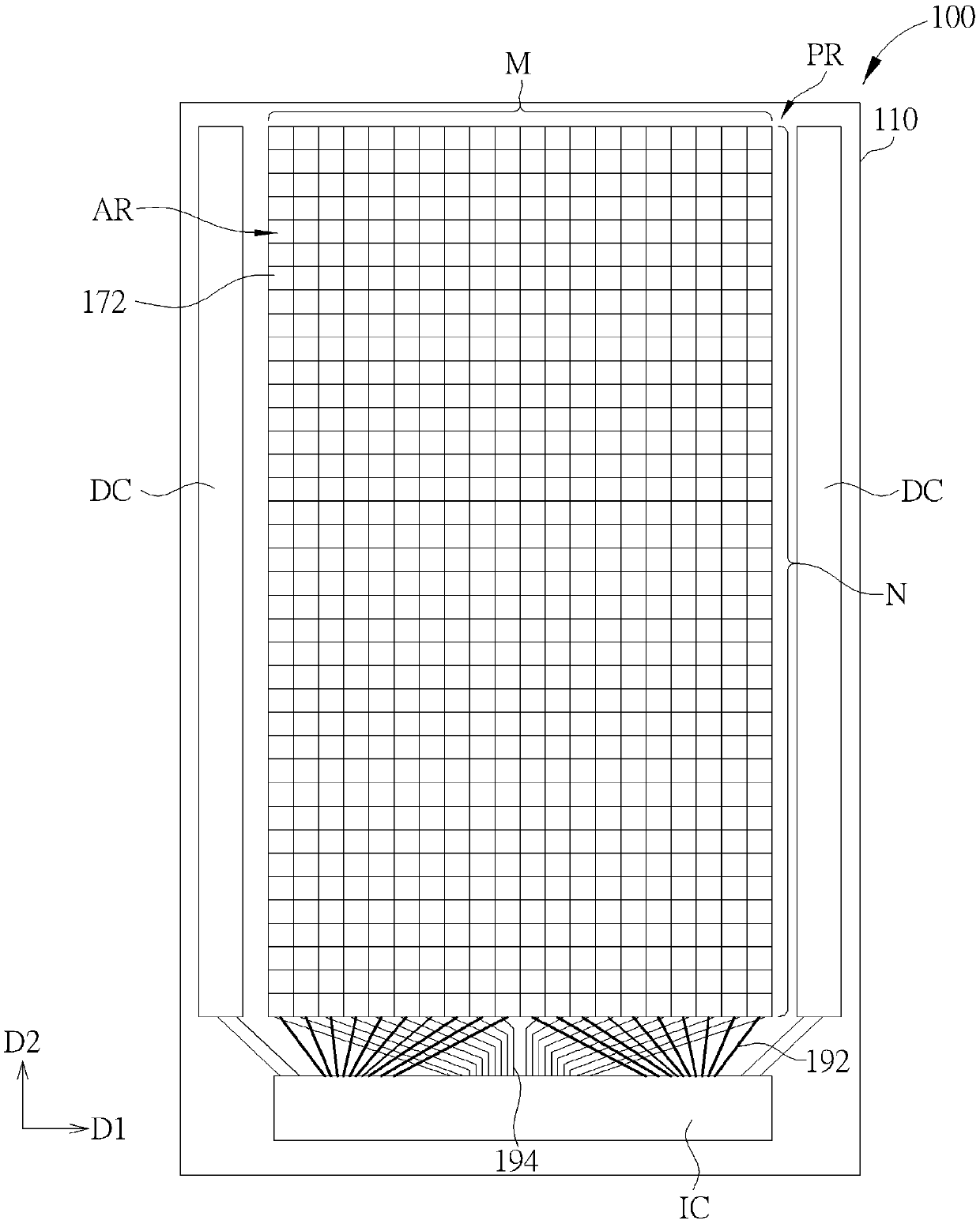

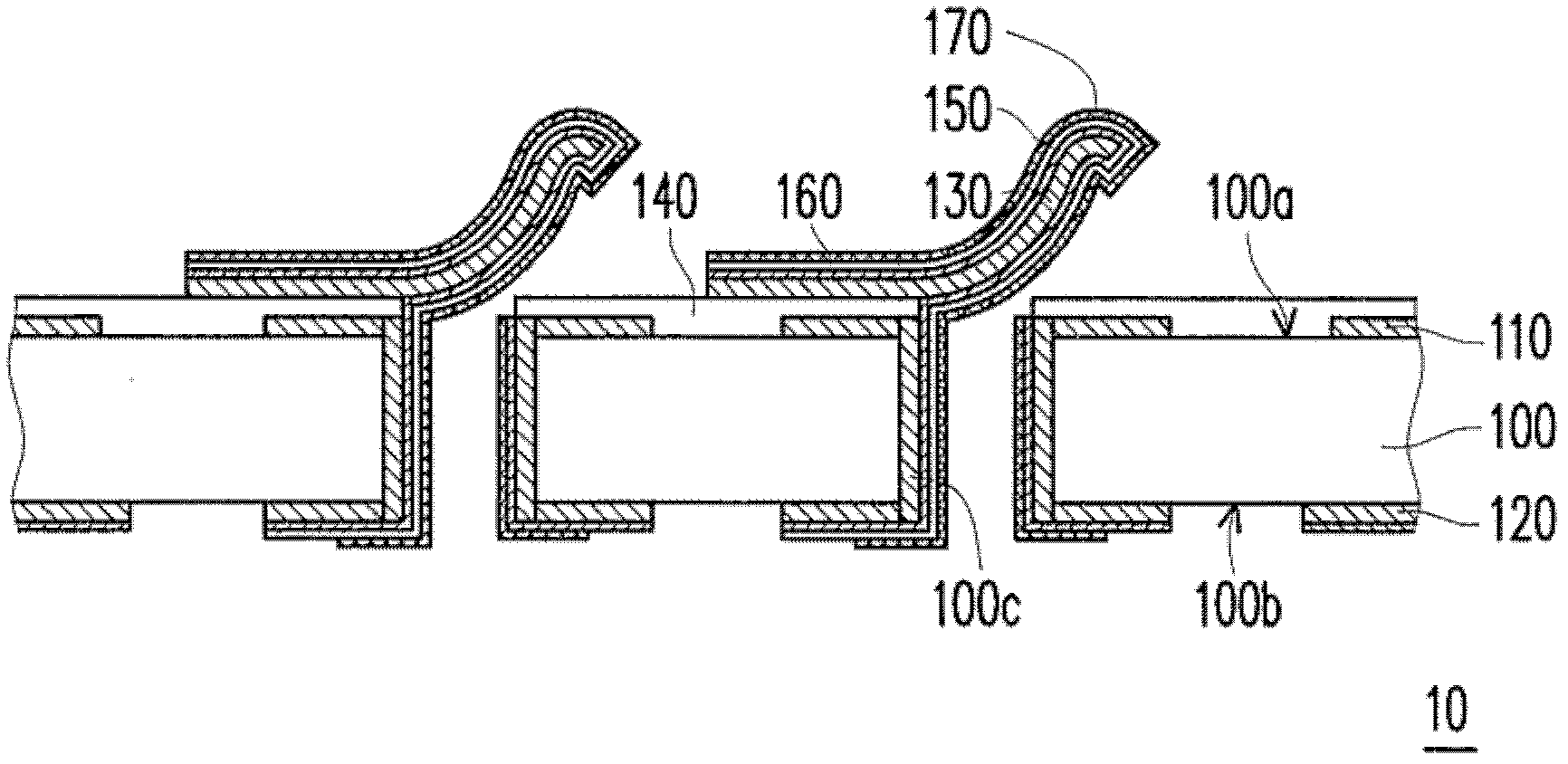

Display device and method for manufacturing the same

ActiveCN102456696AReduce manufacturing process stepsSolid-state devicesSemiconductor/solid-state device manufacturingDisplay deviceSemiconductor

A display device according to an exemplary embodiment includes: gate wires, at least one of the gate wires having a first multi-layered structure including a first transparent conductive layer formed on the substrate and a first metal layer formed on the first transparent conductive layer and at least another one of the gate wires having a first single-layered structure formed with the first transparent conductive layer; a semiconductor layer formed on a part of the gate wires; and data wires with at least one of the data wires having a second multi-layered structure including a second transparent conductive layer formed on the semiconductor layer and a second metal layer formed on the second transparent conductive layer and at least another one of the data wires having a second single-layered structure formed with the second transparent conductive layer.

Owner:SAMSUNG DISPLAY CO LTD

Connector structure and manufacture method thereof

ActiveCN103138072AReduce thicknessReduce manufacturing process stepsLine/current collector detailsElectrically conductive adhesive connectionsEngineeringCantilever

The invention discloses a connector structure and a manufacture method thereof. The connector structure comprises an adhesive coating, at least one first conductive elastic cantilever and at least one second conductive elastic cantilever. At least one through hole is formed in the adhesive coating, conductive resin is filled in the through hole, the first conductive elastic cantilever is arranged on a first surface of the adhesive coating in a matched mode, and the first conductive elastic cantilever is provided with a first fixed end portion and a first free end portion which is connected with the first fixed end portion, wherein the upper surface of the first free end portion is higher than the upper surface of the first fixed end portion, and the first fixed end portion is connected with the conductive resin. The second conductive elastic cantilever is arranged on a second surface of the adhesive coating in a matched mode and is provided with a second fixed end portion and a second free end portion which is connected with the second fixed end portion, wherein the upper surface of the second free end portion is higher than the upper surface of the second fixed end portion, and the second fixed end portion is connected with the conductive resin.

Owner:UNIMICRON TECH CORP

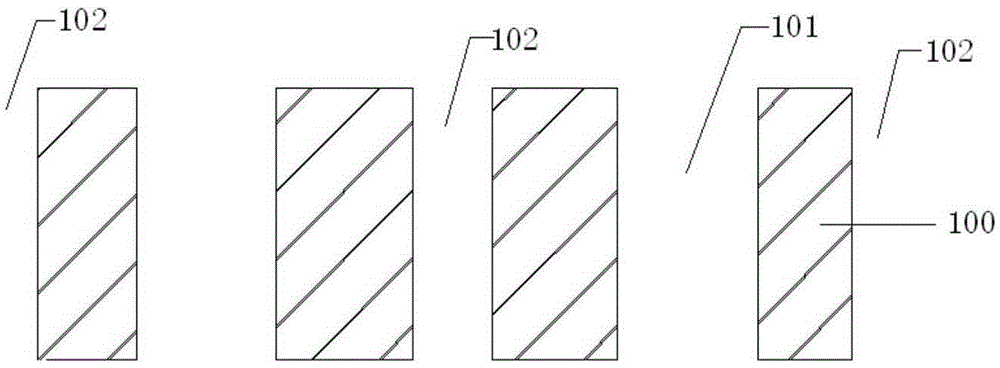

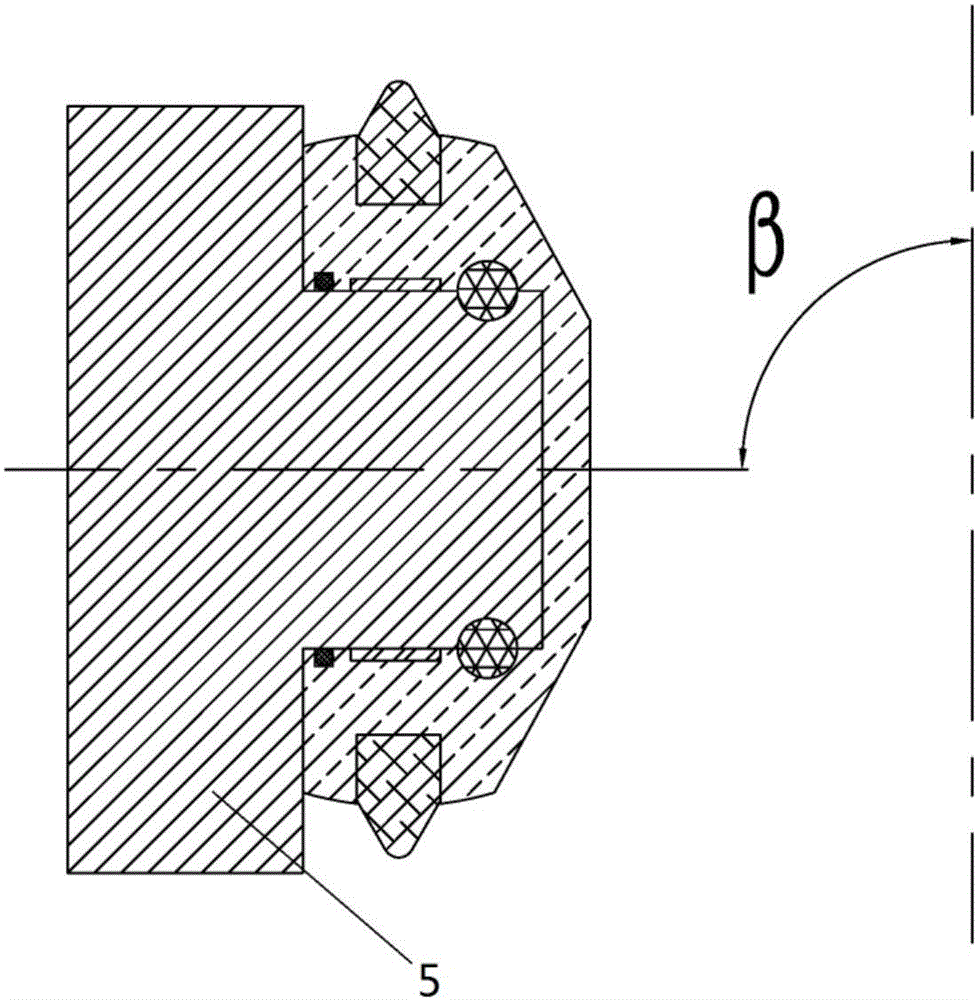

Facet film-plating clamp for semiconductor laser chip

InactiveCN106025789AEasy to processHigh precisionLaser detailsSemiconductor lasersEngineeringMechanical engineering

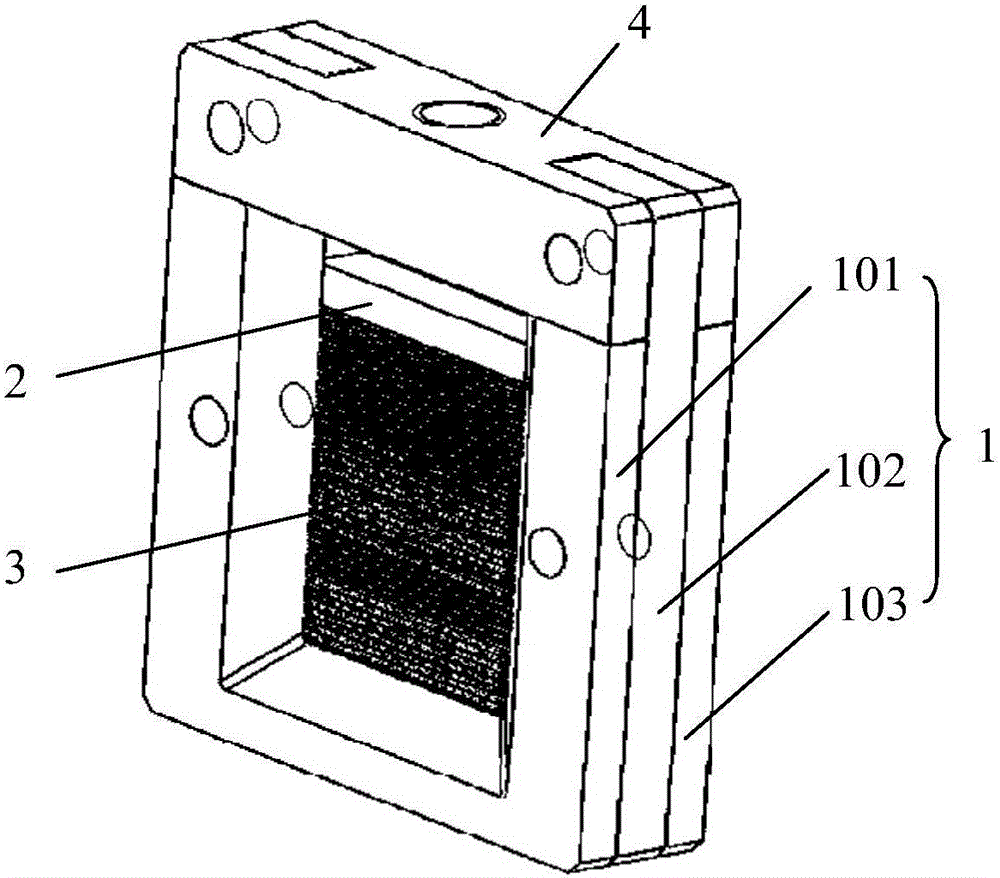

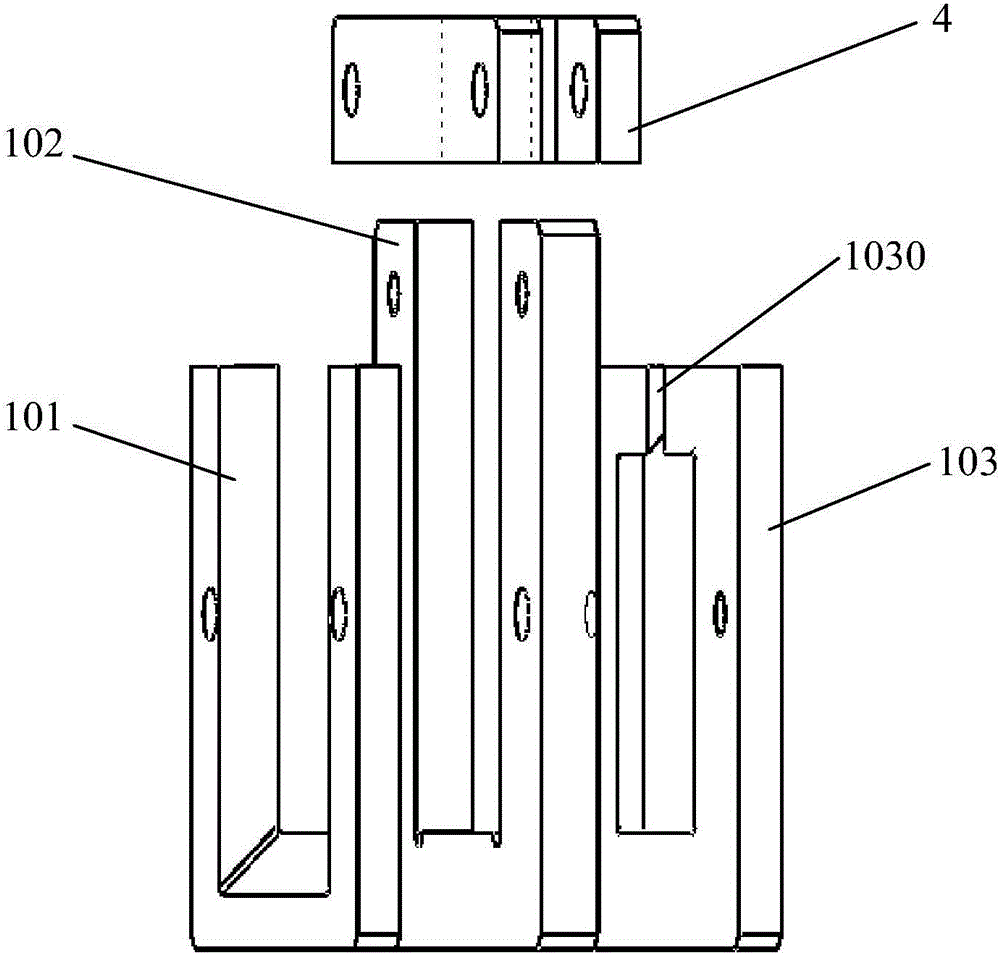

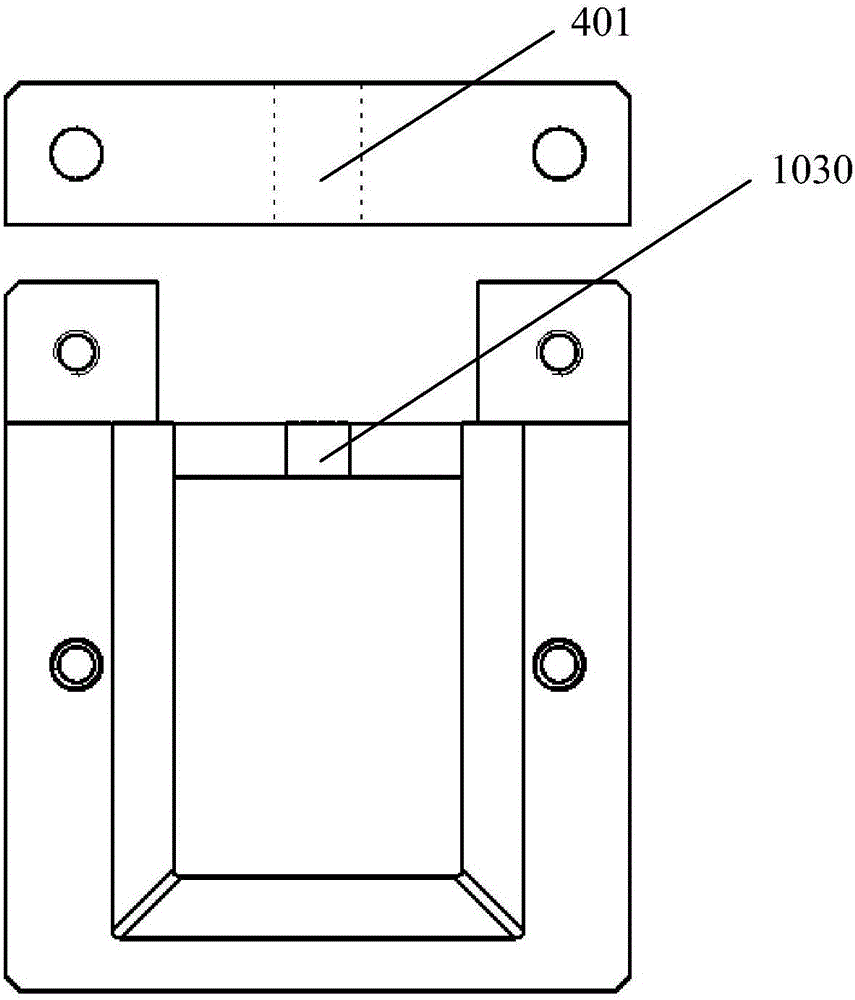

The invention provides a novel facet film-plating clamp for a semiconductor laser chip. The clamp has advantages of stable clamping, simple structure, convenient operation, and easy processing; and film plating can be carried out products in batches and the plated film quality can be improved effectively. The clamp comprises a flat-panel U-shaped frame assembly and a choke plug assembly arranged at a U-shaped opening end; and a plurality of bars are stacked successively from a U-shaped closing end to the U-shaped opening end in a planar closing area encircled by the flat-panel U-shaped frame assembly and the choke plug assembly. The inner side width of a U-shaped middle plate of the flat-panel U-shaped frame assembly is larger than inner side widths of a lower plate and a U-shaped upper plate, so that side cavity parts at the two ends of the multiple bars are supported on a rail surface reserved by the lower plate, are pressed and covered by a rail surface reserved by the U-shaped upper plate, and are limited by the U-shaped middle plate in a horizontal direction. The choke plug assembly applies tightening pressures on the multiple bars from the U-shaped opening end to the U-shaped closing end.

Owner:XIAN LIXIN PHOTOELECTRIC SCI & TECH

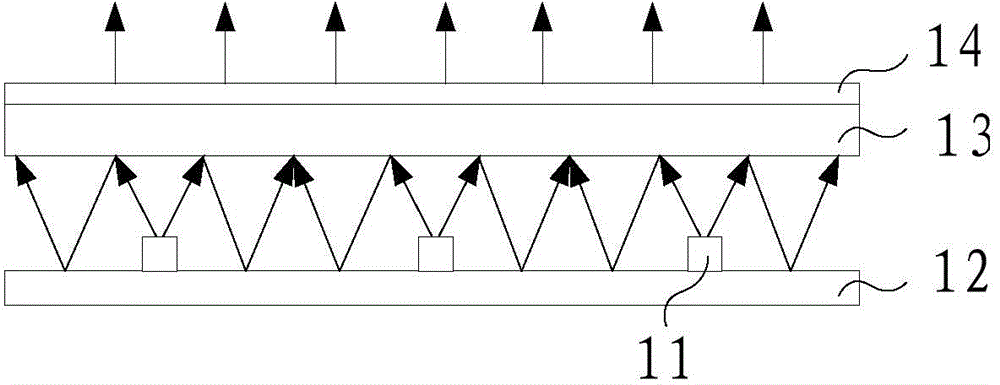

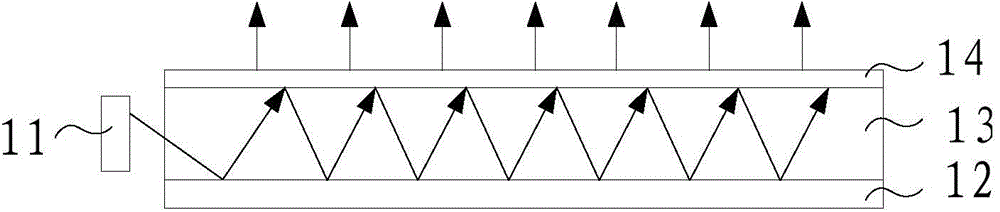

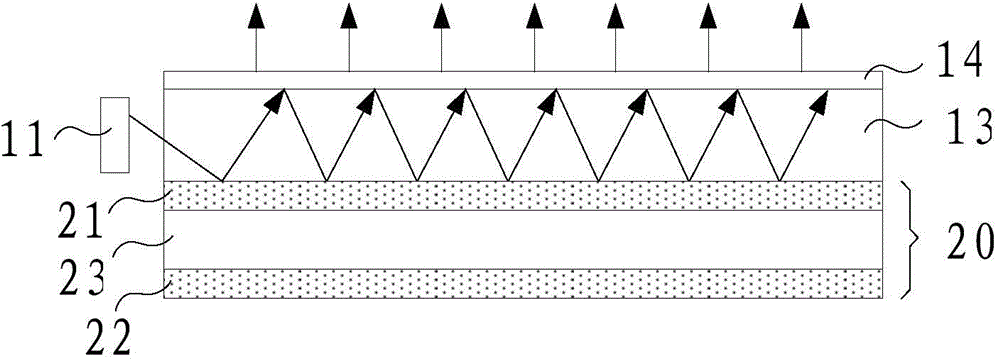

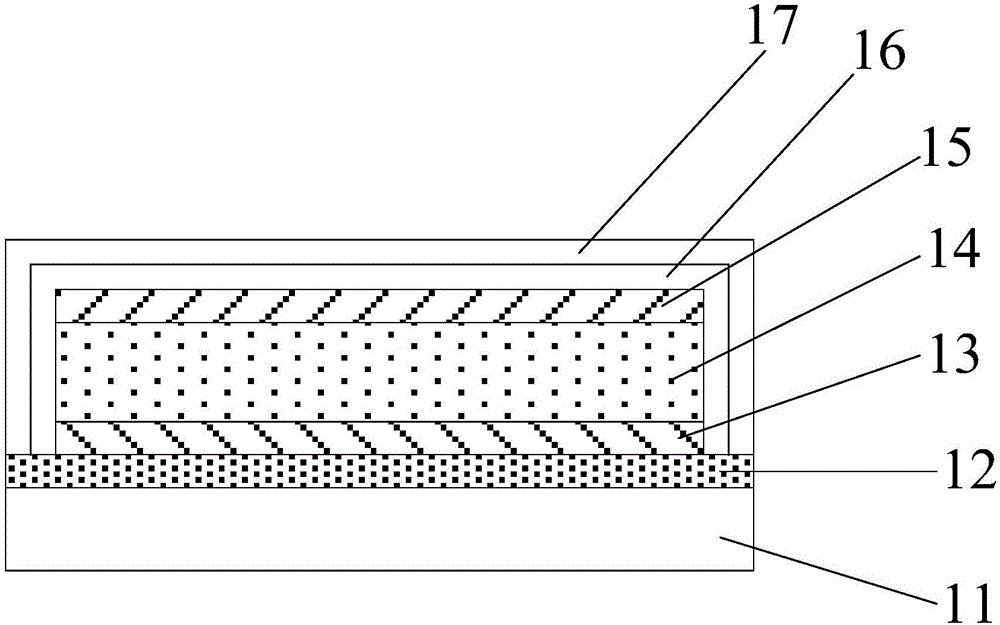

Backlight module, manufacturing method thereof, and display device

InactiveCN104566121AEasy to integrateFacilitate thinningElectric circuit arrangementsWith built-in powerLight guideDisplay device

The invention provides a backlight module, a manufacturing method thereof and a display device, relates to the technical field of display, and solves the problems that an existing display device can only rely on power provided by other power supply devices, and the display device is not integrated with a power generating unit. The backlight module comprises a light guide plate and at least one power generating unit. Each power generating unit comprises a first electrode, a second electrode and a power generating layer located between the first electrode and the second electrode. Each power generating unit is disposed on one side opposite to the light emitting direction of the light guide plate. The first electrode of at least one of the power generating unit is in direct contact with the light guide plate. Each first electrode can reflect light, and one side, facing the light guide plate, of the first electrode is a reflecting surface.

Owner:BOE TECH GRP CO LTD

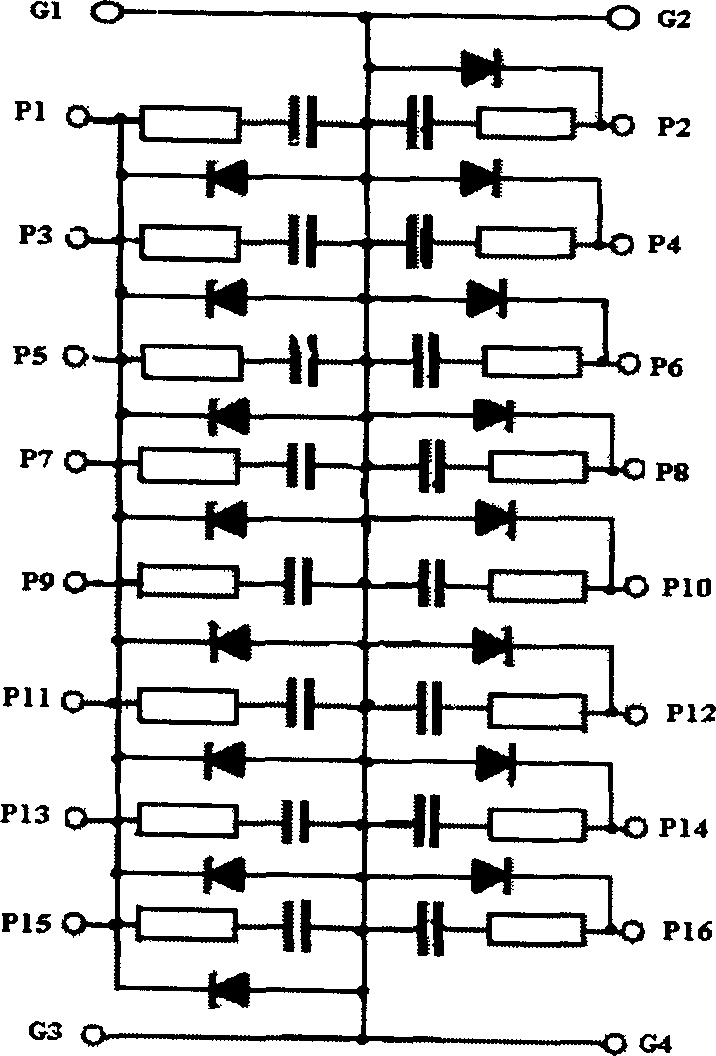

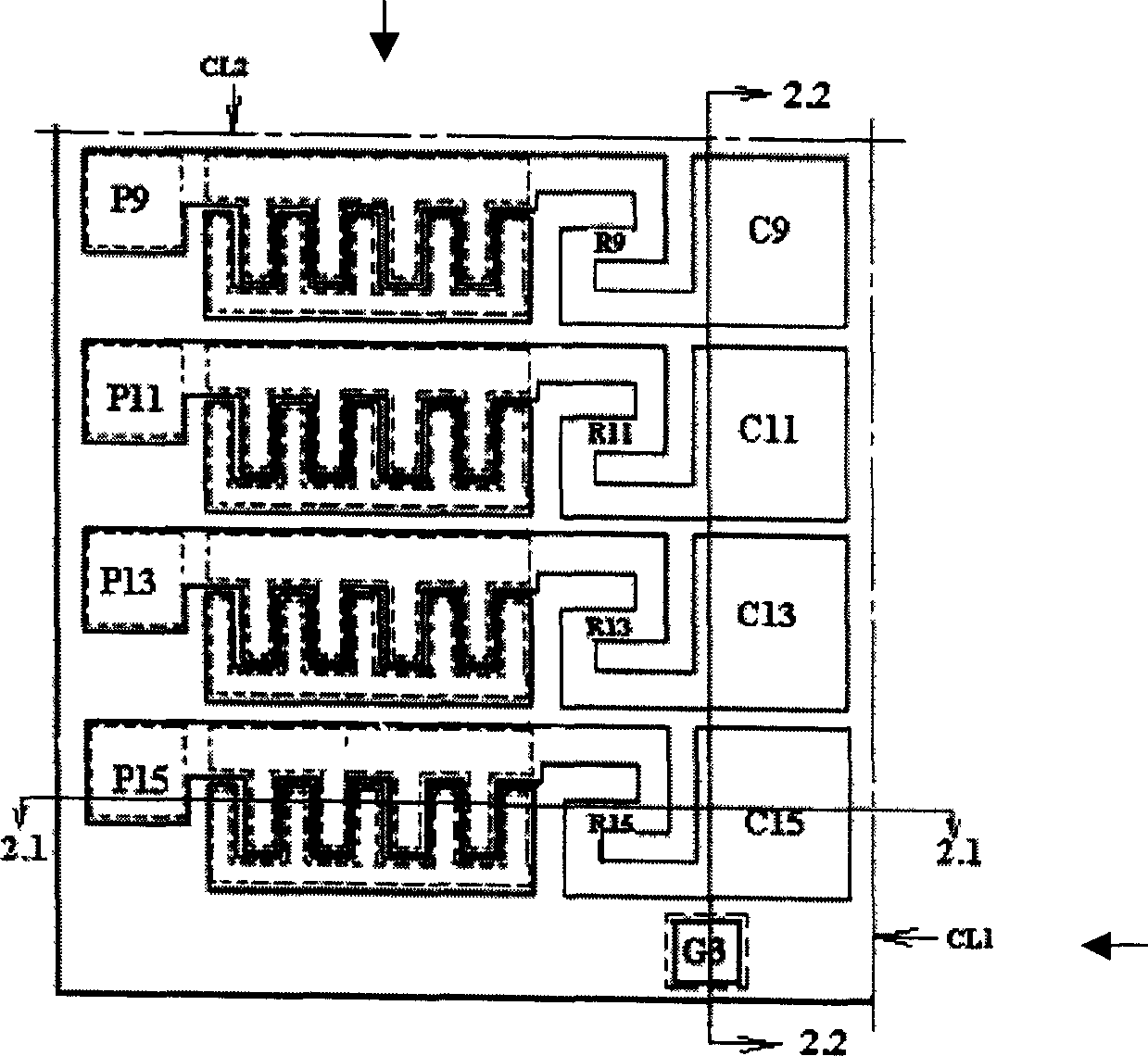

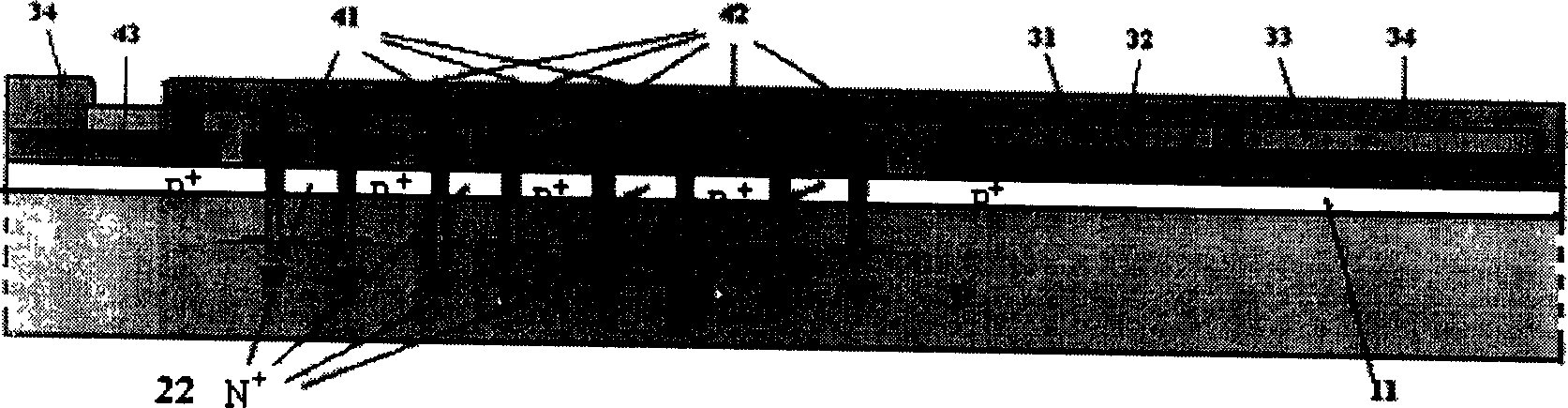

Structure and manufacture of resistance(R) - capacitance(C) - diode(D) network thin-film IC with transverse venting diode

InactiveCN1731582AReduce manufacturing costReduce manufacturing process stepsSolid-state devicesSemiconductor/solid-state device manufacturingCapacitanceEngineering

The invention discloses a resistance(R)-electric capacity(C) net thin-film integrated circuit structure that comprises crosswise diodes and the preparing method, adopting common silicon pellet (P) to prepare network thin-film integrated circuit of high conductive layer and over voltage protection. P+ area (11) formed with boron diffusion works as the public ground conductive layer, base of the crosswise diode (D) and bottom electrode of the capacitor (C). N+ area (22) formed with phosphor diffusion works as emitter area of the crosswise diode. The W area between P+ and N+ area is the lead area of the diode with reverse bias voltage. Prepare SiO2 and Si3N4 insulating dielectric medium (31) by means of chemical vapor deposition (CVD) on the surface of silicon pellet. The aluminum layer is taken as metallic layer, after photo etching, forming internal connection leads of circuit, pressure point are aluminum layer (43) and ground (G) press welding point. Deposition phosphor doping SiO2 (34) forms chip inactivation layer, preparing chip after photo-etching press welding point (43) and grounding point (G).

Owner:HEILONGJIANG BADA UNIVERSAL SEMICON

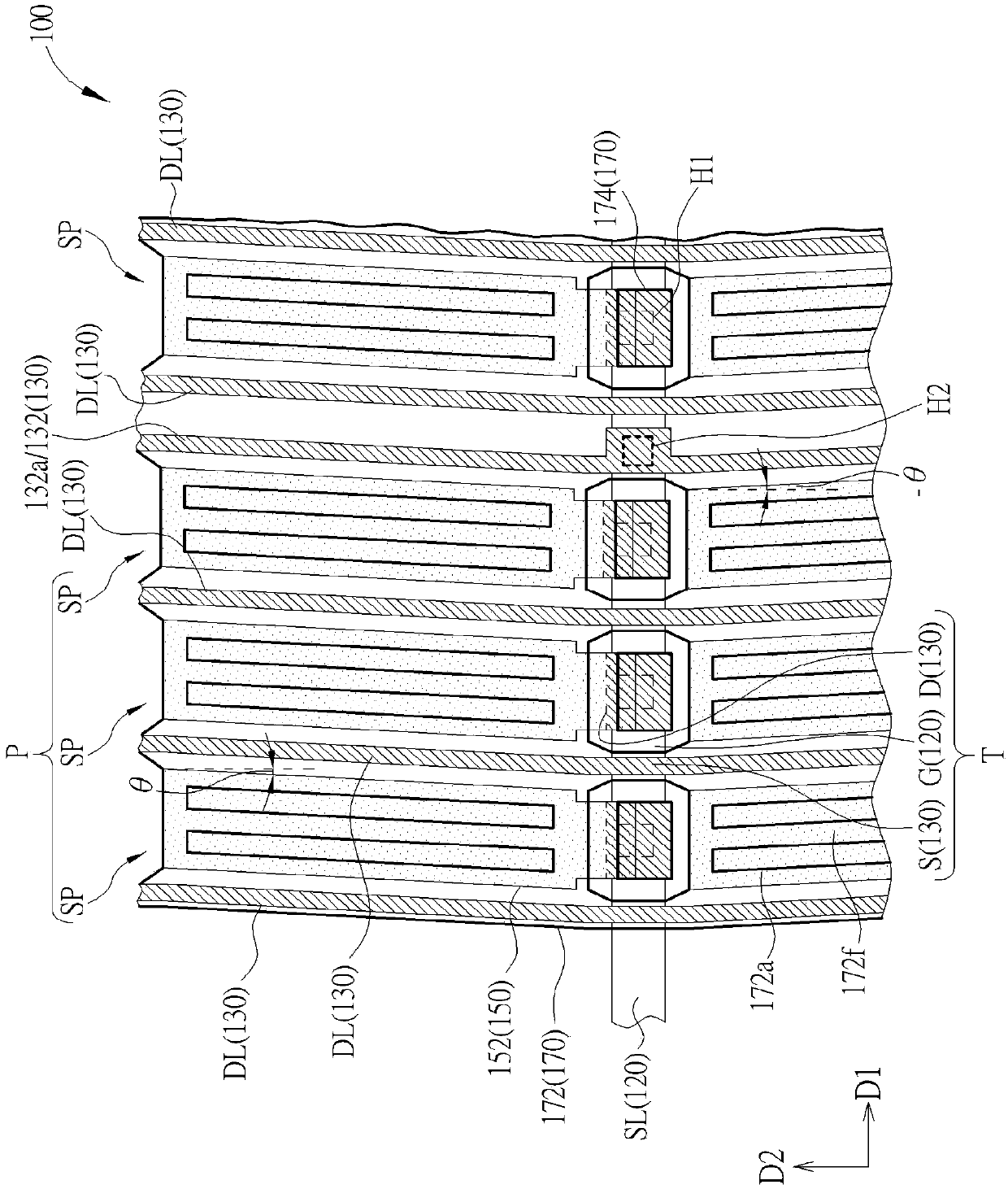

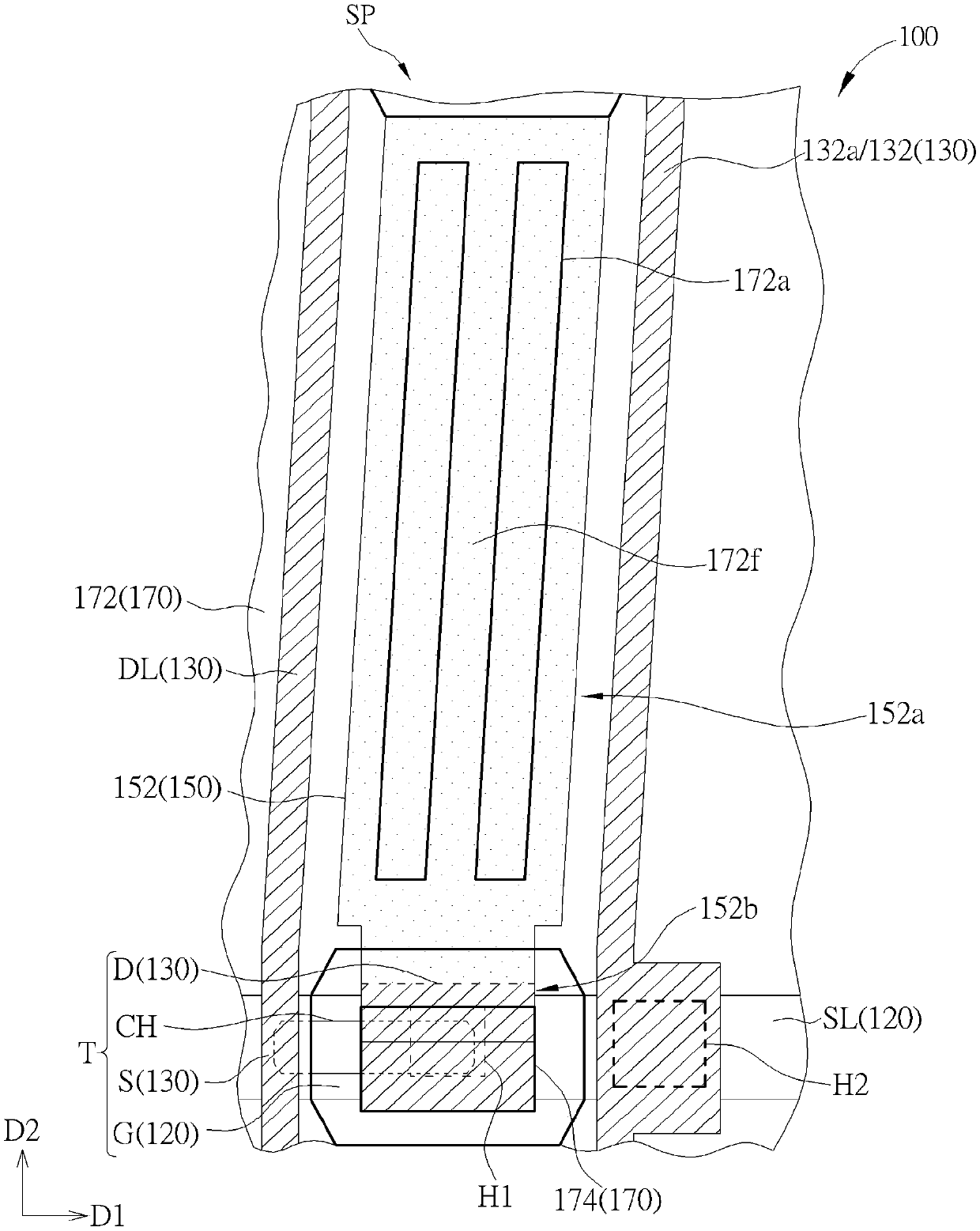

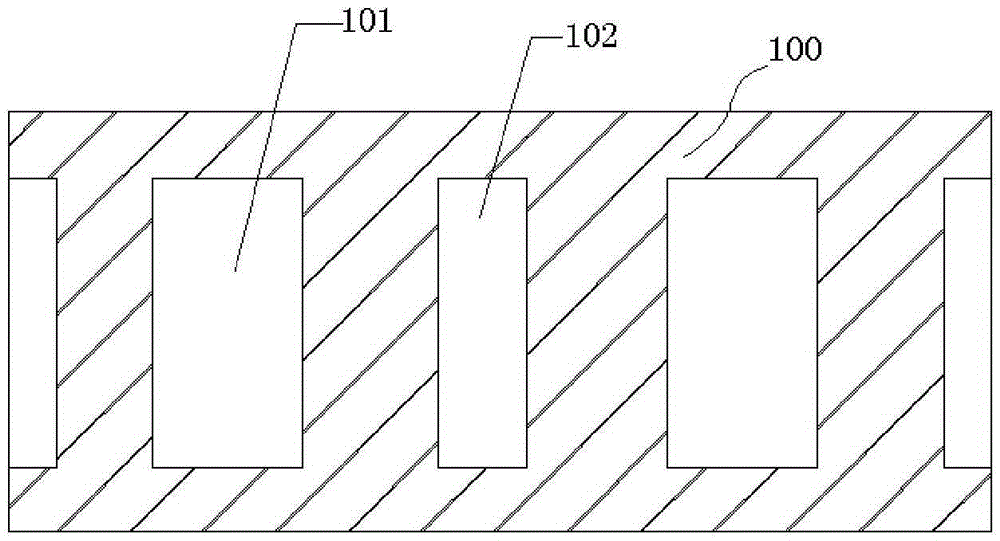

Array substrate, preparing method thereof and display device

ActiveCN103928401AReduce manufacturing process stepsReduce manufacturing costSolid-state devicesSemiconductor/solid-state device manufacturingManufacturing technologyDisplay device

The invention relates to the technical field of displaying, in particular to an array substrate, a preparing method of the array substrate and a display device. The preparing method of the array substrate comprises the following steps that firstly, a pattern comprising a grid electrode, a grid electrode insulating layer, an active layer, a source electrode and a drain electrode is formed on a substrate body; secondly, a transparent conducting layer is formed on the substrate body on which the first step is carried out, and a pattern comprising a pixel electrode and a data line is formed through the one-time pattern composition technology. According to the array substrate, the pixel electrode and the data line are formed through the one-time pattern composition technology at the same time, the steps of the manufacturing technology are reduced, production cost is reduced, and production efficiency is improved; furthermore, the transparent conducting layer is made of graphene or nanometer silver wire materials, and the pixel electrode and the data line are formed, so that the pixel electrode and the data line have low resistance values and high light transmissivity, and the performance of the array substrate is improved.

Owner:BOE TECH GRP CO LTD +1

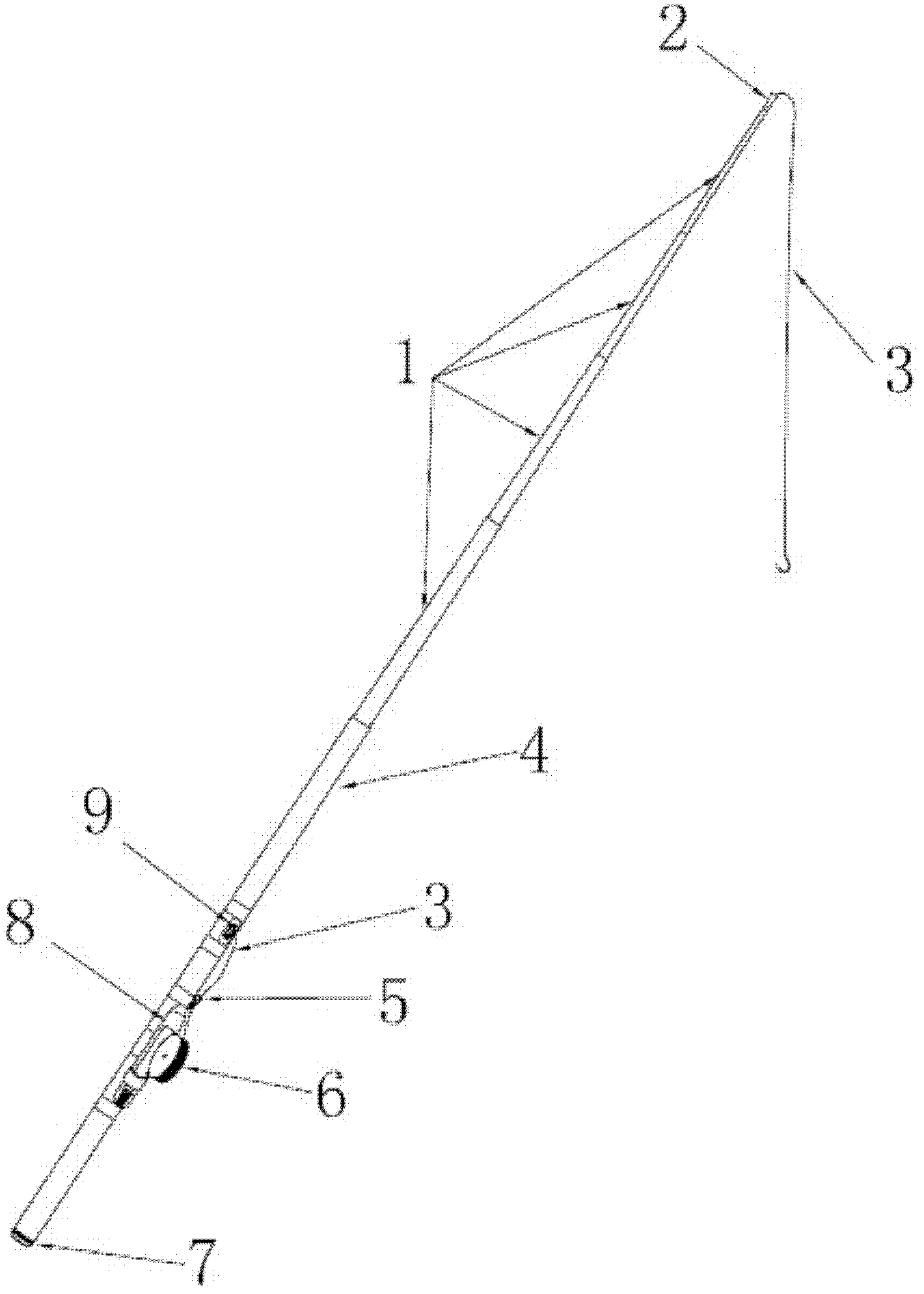

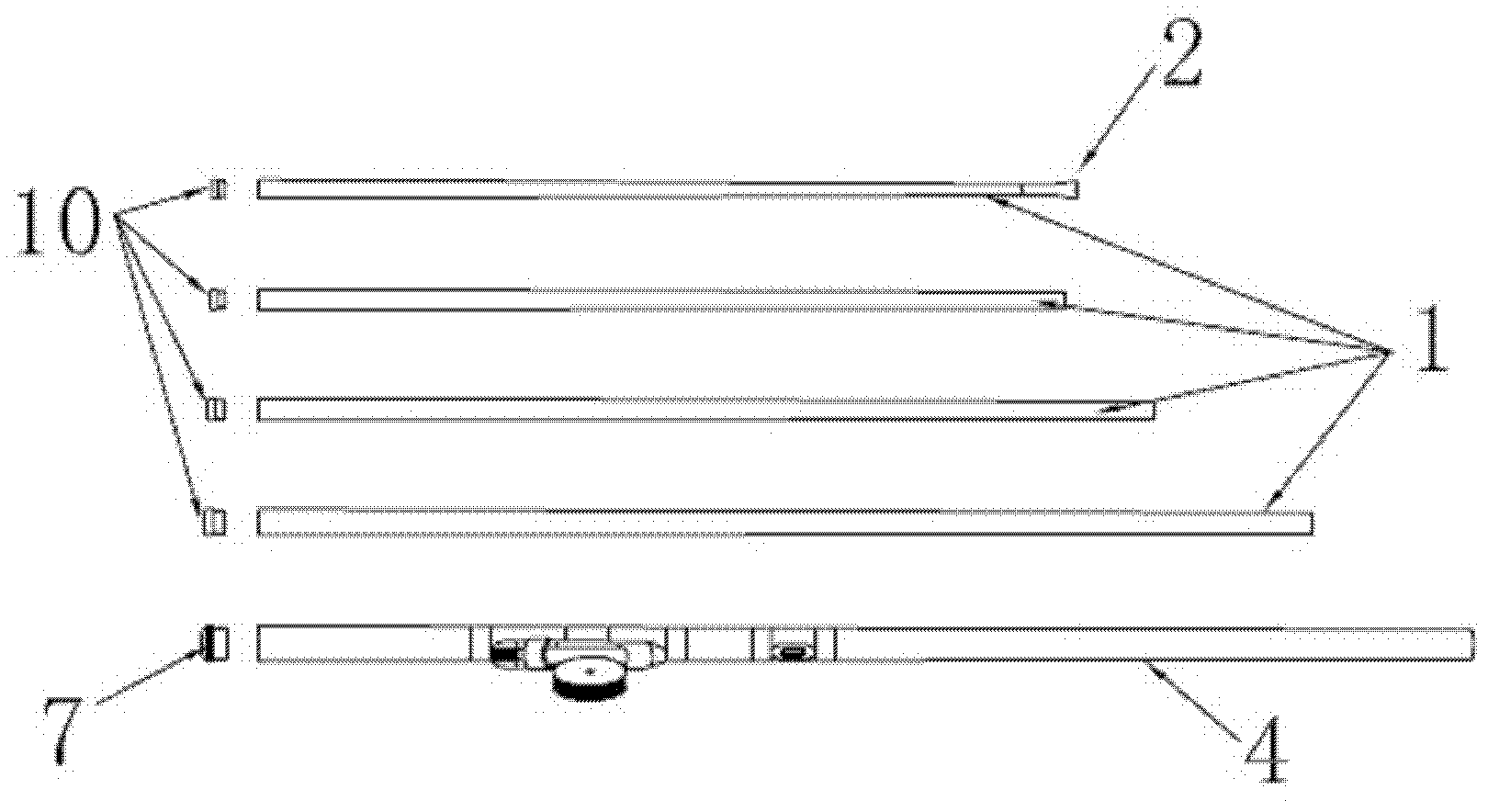

Manufacturing method of throwing dual-purpose telescopic hollow fishing rod

The invention relates to a manufacturing method of a throwing dual-purpose telescopic hollow fishing rod. A carbon fiber is covered on an iron core die by rolling press, an o-phenylphenol (OPP) strip film is wound on an outer layer of the carbon fiber or a glass fiber, and demoulding is performed and the OPP strip film is removed after high-temperature sintering so that corresponding rod sections (1) and handle sections (4) are formed; the rod sections (1) are combined into a group of interconnecting hollow rod bodies which can be stretched and retracted; surface grinding, colored paint coating and labeling are carried out to the hollow rod bodies and the handle sections (4); a mounting plate type wire piece (9), a plate type wire clamping wheel seat (8) and a hook piece (5) are fixedly wound on the rod bodies of the handle sections (4) according to required design positions through cotton thread; and an upper wire end ring piece (2) is installed at the front ends of the hollow rod bodies, and an inner wire ring piece (10) is fixed at the bottoms of the rod sections (1).The fishing rod is simple in structure, few in manufacturing processes, convenient to assemble, small in volume and convenient to carry, a fishing line is long, and a bait can be thrown to a far area.

Owner:NINGBO EVER WINNER INDAL FISHING TACKLE

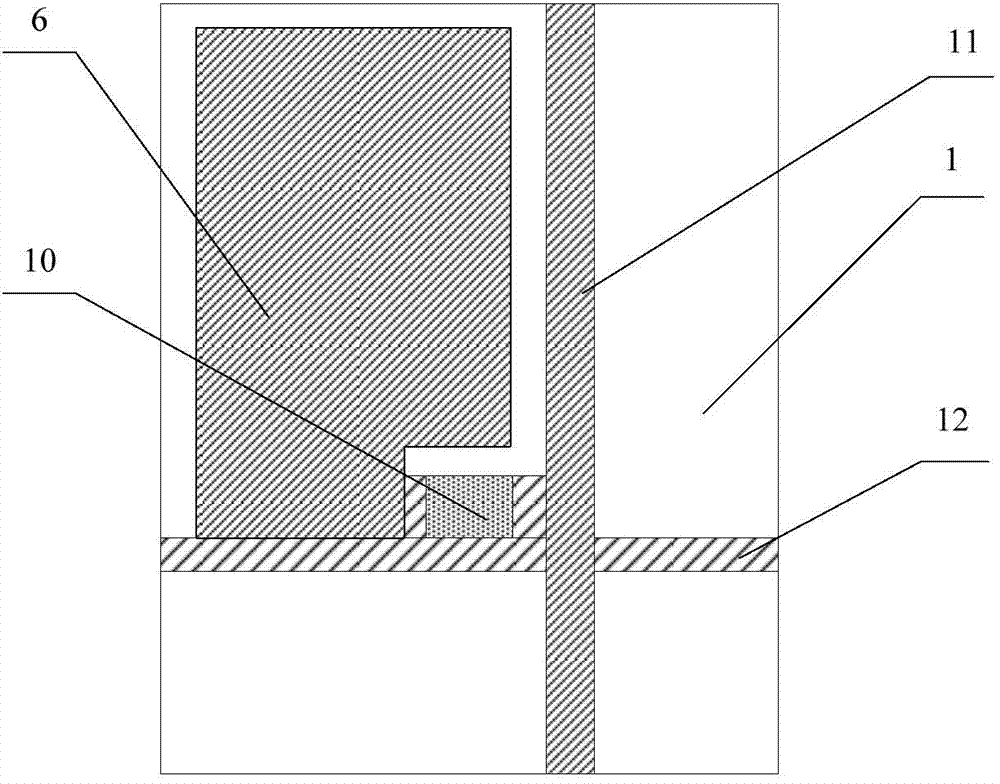

Packaging structure and packaging method of high-pixel image sensing chip

ActiveCN105355641AImprove cooling effectReduce volumeSolid-state devicesSemiconductor/solid-state device manufacturingInsulation layerElectric properties

The invention discloses a packaging structure and packaging method of a high-pixel image sensing chip. A first through hollow cavity is manufactured in a carrier board, a second through hollow cavity is manufactured at the same time, the carrier board and the first hollow cavity in the carrier board can provide a large gap for a sensing region of the high-pixel image sensing chip and a light-transmission substrate, a role in protecting the sensing region from being polluted or damaged is played in the packaging process, and packaging reliability and stability are improved. Welding pads of the image sensing chip are exposed through the second hollow cavity, the electric property of the image sensing chip can be leaded out to a functional substrate through direct routing; compared with the traditional silicon through hole process, the packaging method does not need to lay an insulation layer, a metal circuit layer and the like but directly leads out the electric property, has the advantages of the simple manufacture procedure and the small volume of a packaging body, and can effectively save economic cost at the same time; and the first through hollow cavity is manufactured in the carrier board, the second through hollow cavity is manufactured at the same time, so the manufacturing process steps are reduced, and the process is very simple.

Owner:HUATIAN TECH KUNSHAN ELECTRONICS

Luminous device and manufacturing method thereof

InactiveCN106784378AReduce manufacturing process stepsReduce manufacturing costOLED manufacture/treatment processesSolid-state devicesWater vaporOxygen

The invention discloses a luminous device and a manufacturing method thereof, wherein the luminous device comprises a base plate, a conducting hydrophobic layer, an organic luminous layer, an electrode layer and a passivation layer, wherein the conducting hydrophobic layer is arranged on the base plate; the organic luminous layer is arranged on the conducting hydrophobic layer; the electrode layer is arranged on the organic luminous layer; the passivation layer is arranged on the electrode layer so as to at least cover the organic luminous layer and the electrode layer. Therefore the conducting hydrophobic layer is arranged between the base plate and the organic luminous layer; meanwhile, an effect of preventing water vapor and oxygen from entering the luminous device and the electrode is achieved; the process steps of additionally installing the blocking layer can be omitted, so that the manufacturing technical steps of the luminous device can be reduced; the manufacturing cost of the luminous device is reduced.

Owner:GUAN YEOLIGHT TECH CO LTD

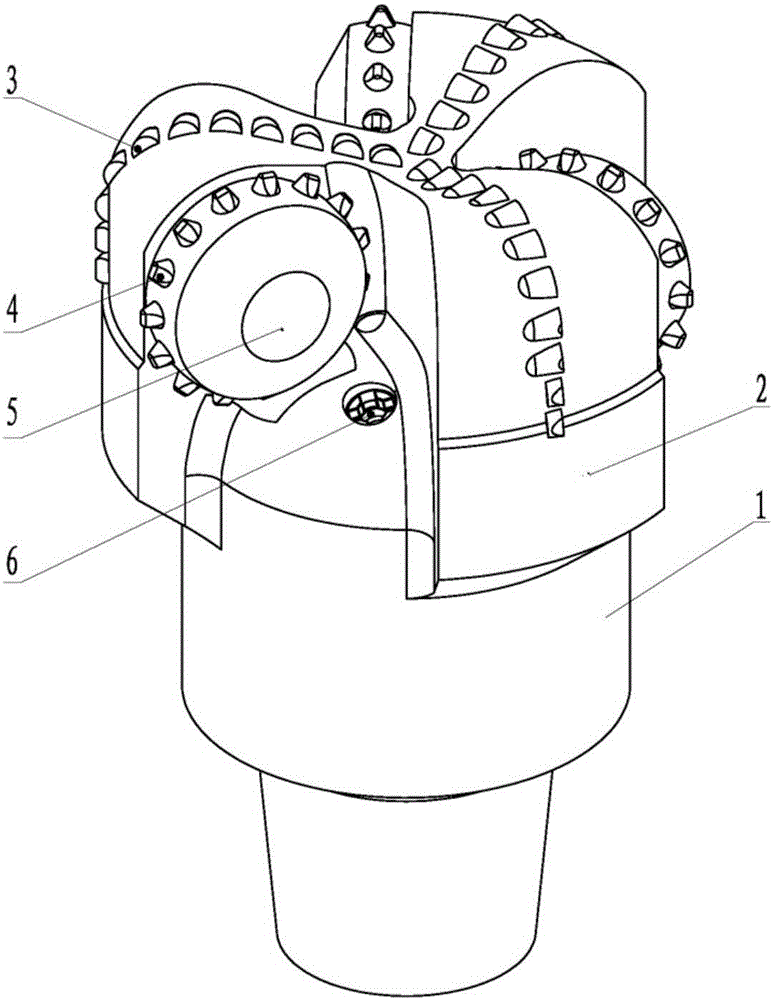

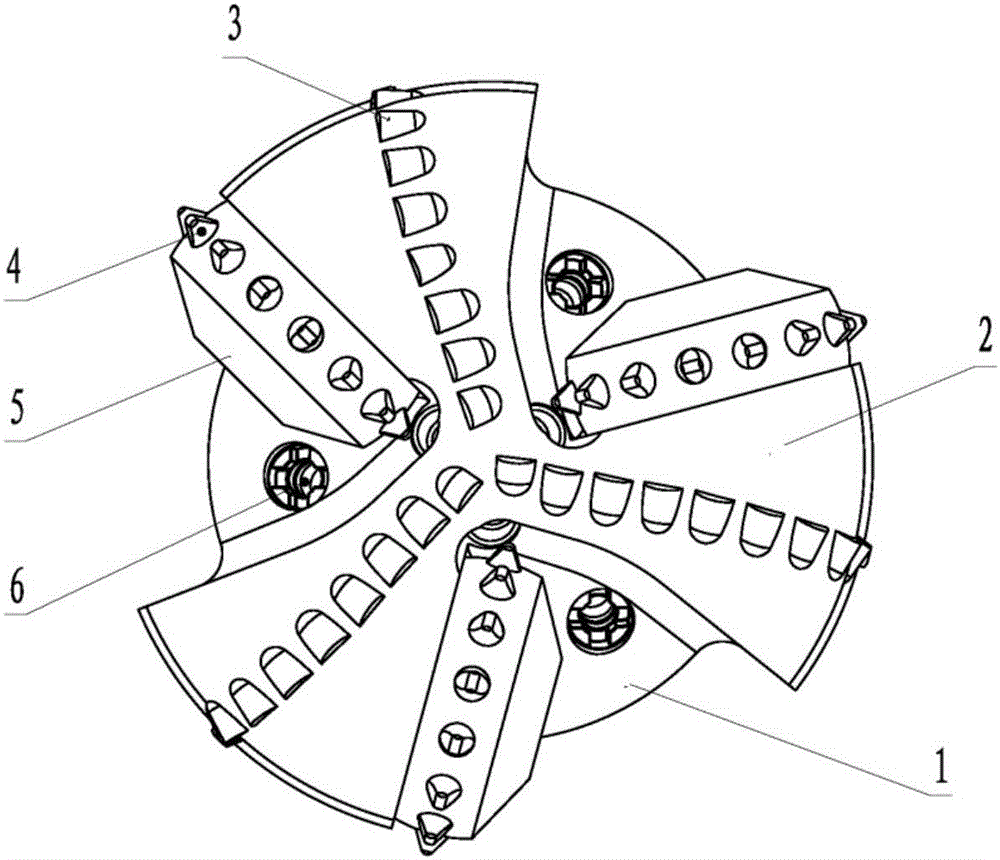

Composite drill bit with roller cone arranged on tool blade

InactiveCN106285490AImprove space utilizationQuality improvementConstructionsSpray nozzleEngineering

The invention discloses a composite drill bit with a roller cone arranged on a tool blade. The composite drill bit comprises a drill bit body, wherein the fixed tool blade and a spray nozzle are arranged on the drill bit body; fixed cutting teeth and the roller cone are arranged on the fixed tool blade; cone roller cutting teeth are arranged on the roller cone. The composite drill bit with the roller cone arranged on the tool blade has the advantages that rock is impacted and pre-crushed by the roller cone cutting teeth, and the fixed cutting teeth on the fixed tool blade are assisted to effectively enter the rock; by arranging the roller cone on the tool blade, the space utilization rate of the composite drill bit is increased, jaws are not used, manufacturing technological steps are reduced, the assembly error is reduced, and the quality of the drill bit is improved.

Owner:BAOJI PETROLEUM MASCH CO LTD

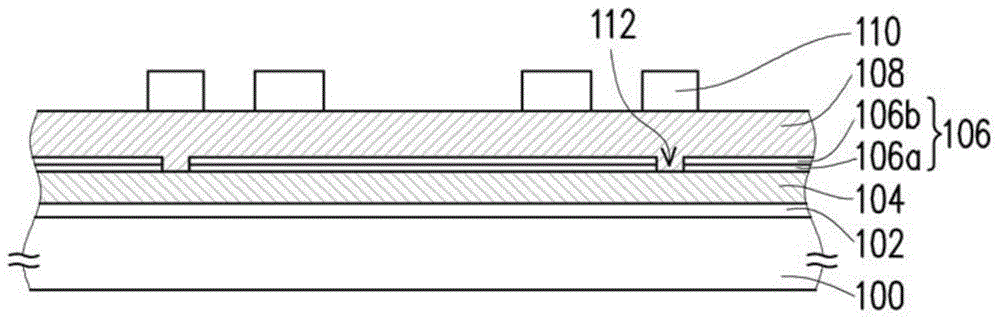

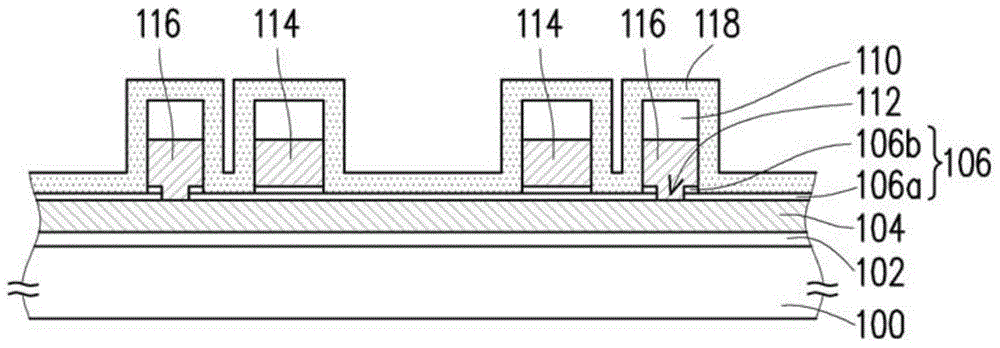

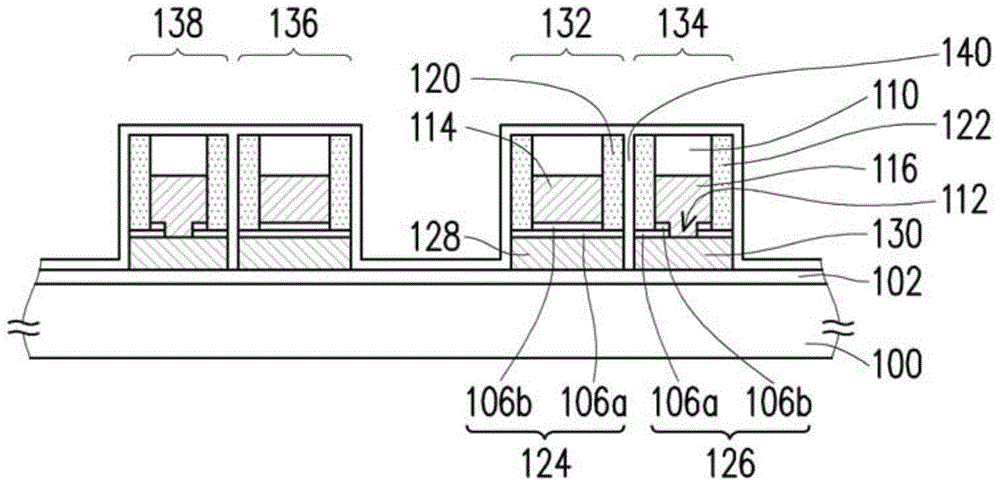

Non-volatile Memory And Fabricating Method Thereof

ActiveCN105789206AEasy to controlReduce manufacturing process stepsSolid-state devicesSemiconductor/solid-state device manufacturingElectrical conductorEngineering

A non-volatile memory including a substrate, a first stacked structure, a second stacked structure, a fifth conductive layer, a first doped region, and a second doped region is provided. The first stacked structure includes a first conductive layer and a second conductive layer stacked on the substrate in order and isolated from each other. The second stacked structure is separately disposed from the first stacked structure and includes a third conductive layer and a fourth conductive layer stacked on the substrate in order and connected to each other. The fifth conductive layer is disposed on the substrate at one side of the first stacked structure away from the second stacked structure. The first doped region is disposed in the substrate below the fifth conductive layer. The second doped region is disposed in the substrate at one side of the second stacked structure away from the first stacked structure.

Owner:POWERCHIP SEMICON MFG CORP

Bouyei sour soup and preparation process thereof

The invention provides a bouyei sour soup and a preparation process thereof. The bouyei sour soup comprises, by weight, 90.0-120.0 parts of small tomato, 2.7-3.6 parts of apple, 5.5-7.0 parts of roxburgh rose, 0.9-1.2 parts of lemon, 1.8-2.4 parts of pear, 9.0-12.0 parts of red pepper sauce, 0.9-1.2 parts of pungent litse fruit, 1.3-1.9 parts of salt, 0.4-0.7 part of rock sugar and 0.1-0.3 part ofhard liquor. A red pepper sauce processing method includes first cleaning red pepper, then placing the red pepper in a grinder to grind the red pepper, then placing the ground red pepper in a vegetable pulping machine to pulp the red pepper to make the red pepper sauce. The bouyei sour soup is mainly made of the small tomato, so that the sour soup contains a large amount of vitamins, and fewer raw materials are used. The bouyei sour soup is less in preparation step and convenient to use and provides convenience for people.

Owner:贵州芳香园民族特色食品股份有限公司

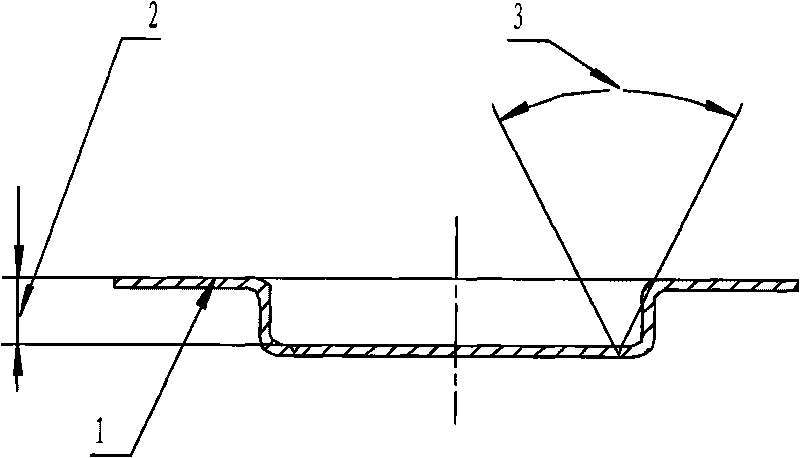

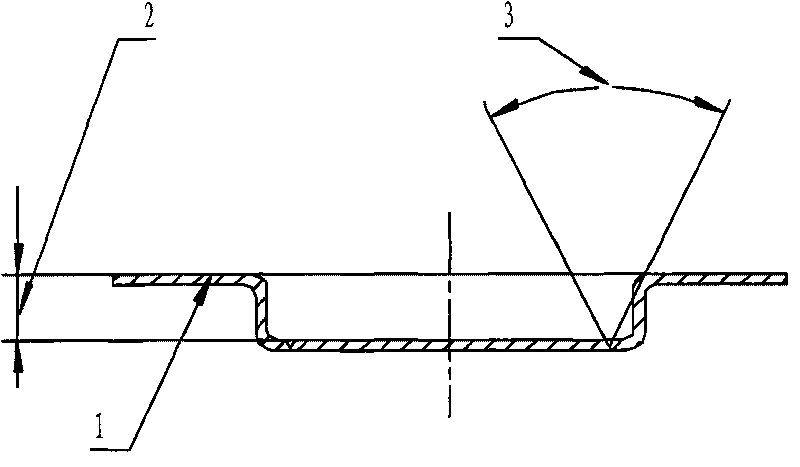

Rupture disk for non-welding gas cylinders

InactiveCN101737540AImprove corrosion resistanceHigh yield strengthEqualizing valvesSafety valvesGas cylinderHeat treated

The invention belongs to the technical field of pressure vessel safety equipment, and relates to a safe pressure relief device for fluid overpressure, in particular to a rupture disk for non-welding gas cylinders. The rupture disk adopts JYH21CT high-chromium stainless steel material. As the JYH21CT high-chromium stainless steel has excellent corrosion resistance, low cold-work hardening property, high yield strength, good ductility and no nickel serving as rare metal, manufacturing processes and cost can be reduced. Meanwhile, by utilizing the ultra-low carbon and low titanium content of the material, the weldability and high yield strength of the material are increased. The molding height of the rupture disk is between 4.0 to 4.7 mm, and a weakening groove of the rupture disk is at an angle of 40 to 45 degrees. By utilizing the characteristics of no expensive nickel serving as rare metal contained by the material, no cold deformation hardening of products and no need for high-temperature heat treatment, the invention greatly reduces the price of the products, and by utilizing precise molding technology and processing technology, the forward bursting pressure and the reverse bursting pressure of the products are basically consistent, so that the safety of the products is greatly improved.

Owner:DALIAN LIGONG SAFETY EQUIP

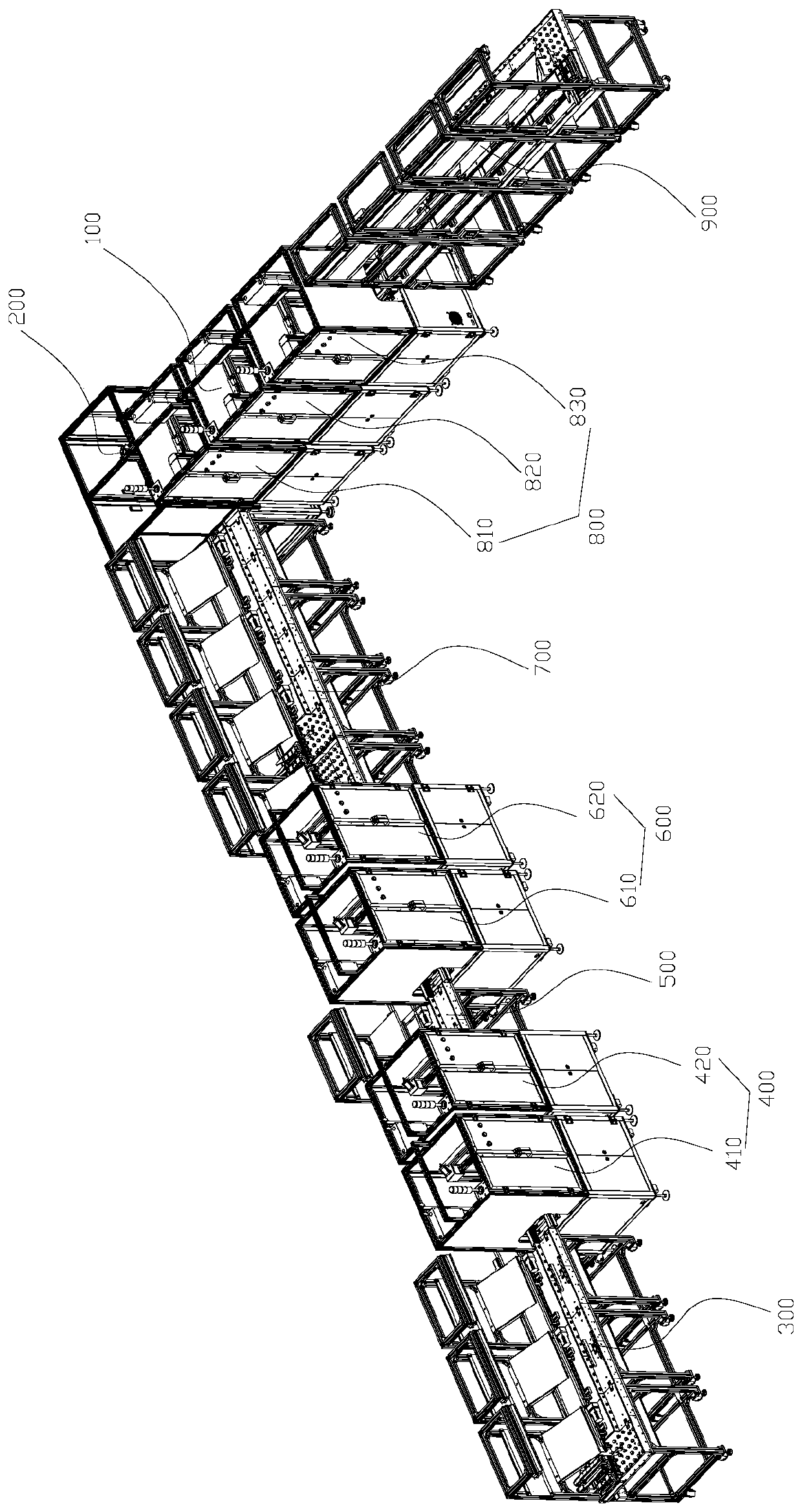

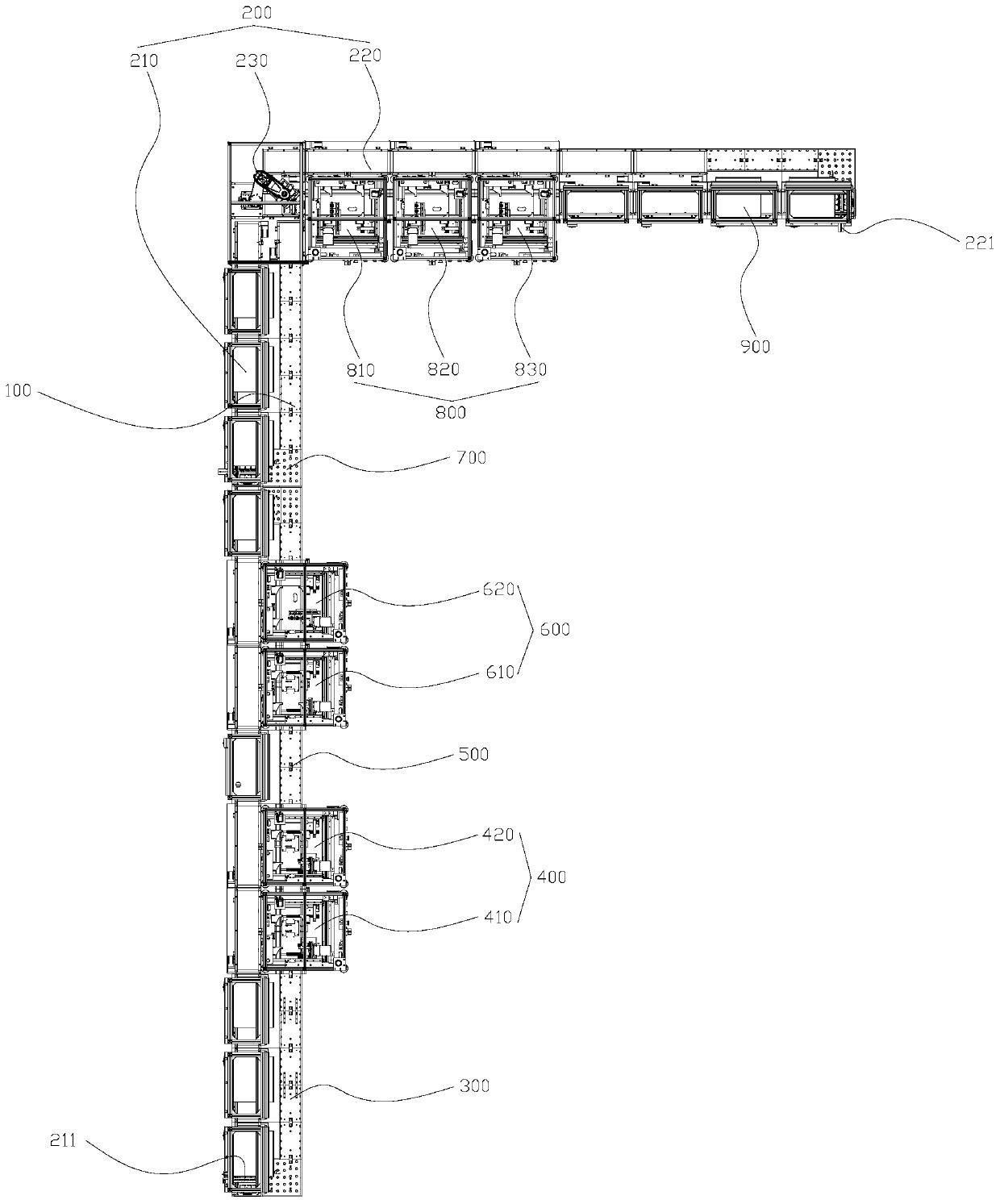

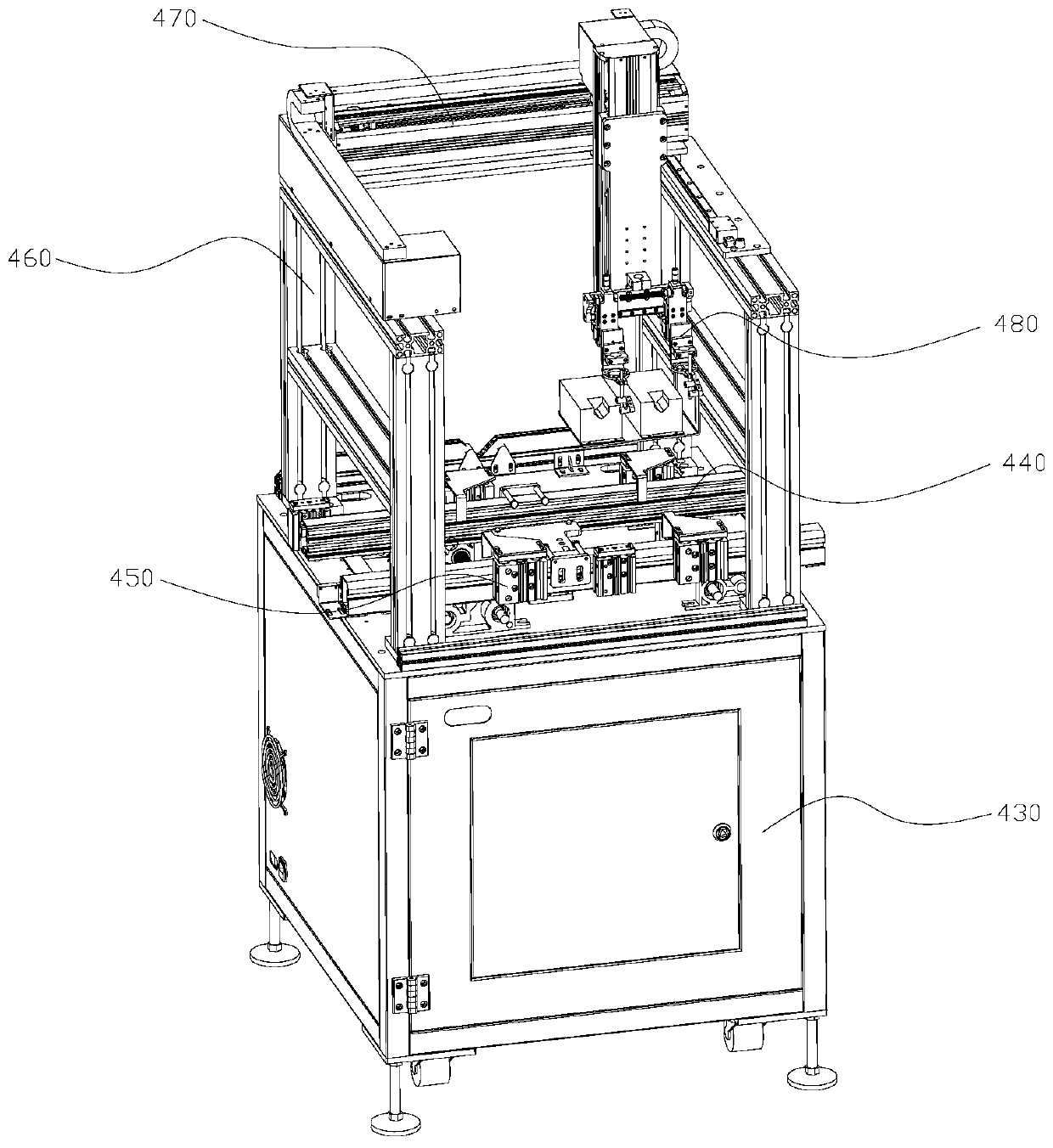

Mobile phone charger final assembly production line

PendingCN111408499AReduce manufacturing process stepsIncrease productivityLiquid surface applicatorsSpraying apparatusProcess engineeringElectrical and Electronics engineering

The invention belongs to the technical field of mobile phone accessory production equipment, and relates to the a mobile phone charger final assembly production line. The mobile phone charger final assembly production line comprises a mobile phone charger machining line and a carrier backflow line which are mounted in parallel, the mobile phone charger machining line comprises a lead penetrating station, an automatic welding device, an after-welding visual inspection station, an oil spraying and dispensing device, an insulation piece and bottom shell assembling station, an automatic dispensingdevice and a covering and conveying-out station which are connected in sequence, the carrier backflow line surrounds the outer side of the mobile phone charger machining line, the two ends of the carrier backflow line are connected with the lead penetrating station at the input end of the mobile phone charger machining line and the covering and conveying-out station at the output end of the mobile phone charger machining line, through the more scientific procedure design, the manufacturing process step of a mobile phone charger can be greatly shortened, participation and intervention of automation equipment are facilitated, feasibility of the full-automatic production line of a mobile phone charger can be improved, and the mobile phone charger production efficiency is higher.

Owner:广东金滨智能科技有限责任公司 +6

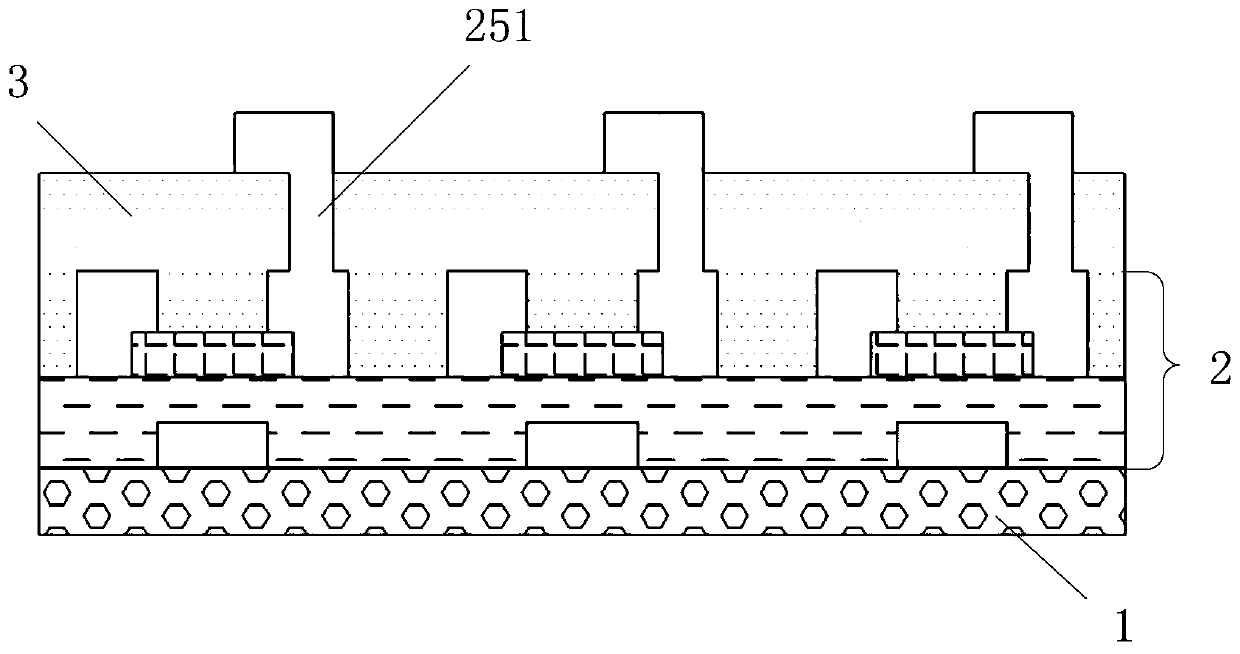

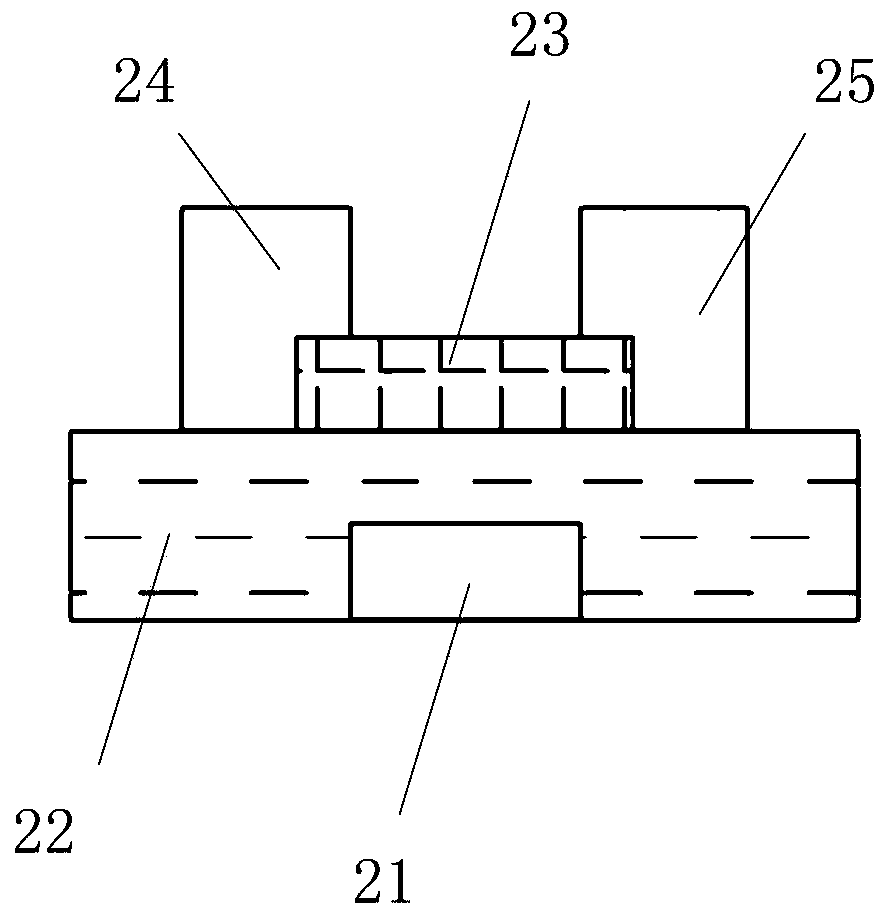

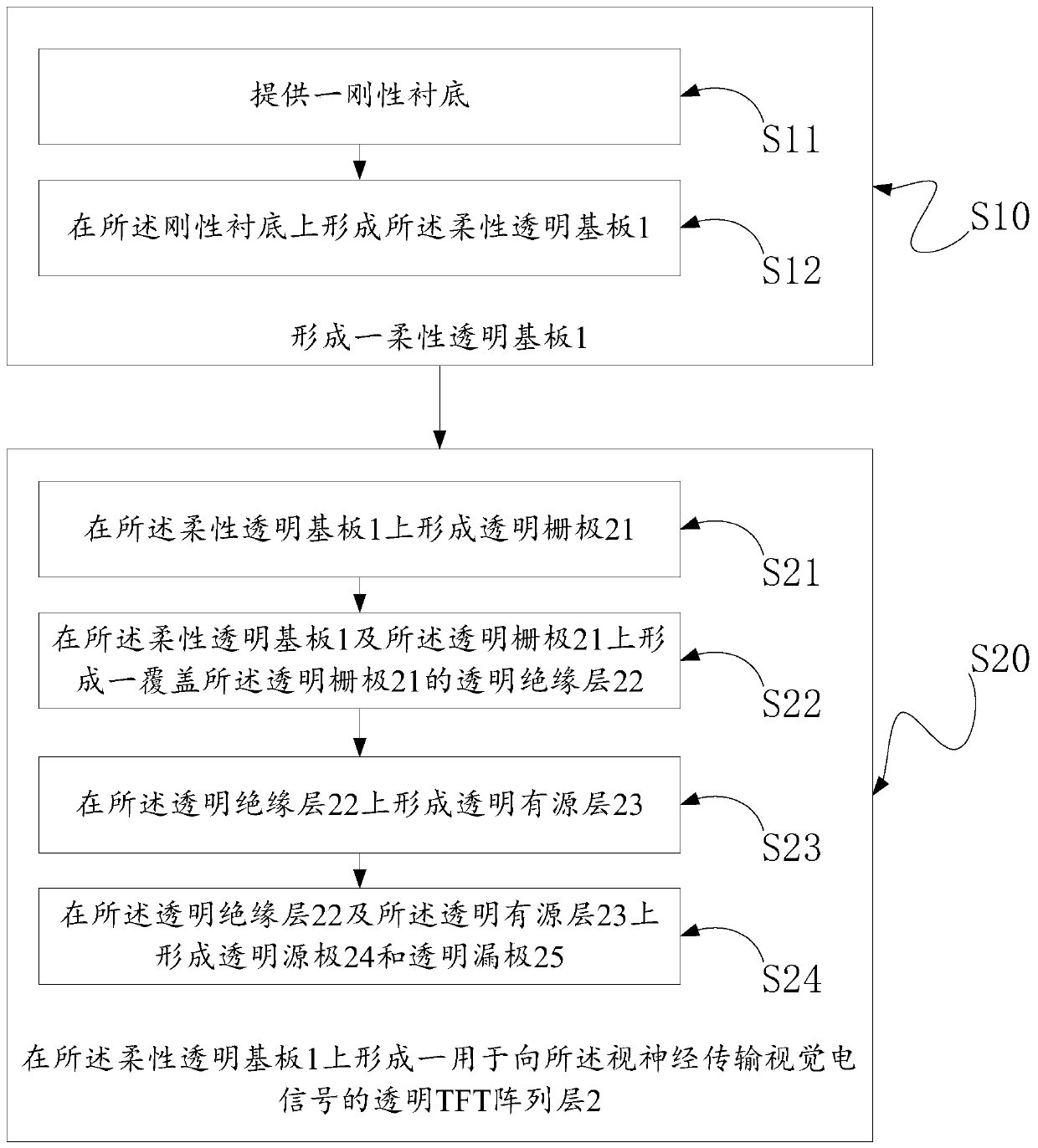

Artificial retina nerve flexible microelectrode device and manufacturing method thereof

InactiveCN110215606ADoes not affect visionImprove applicabilityHead electrodesDecorative surface effectsElectricityButt joint

Owner:WUHAN CHINA STAR OPTOELECTRONICS TECH CO LTD

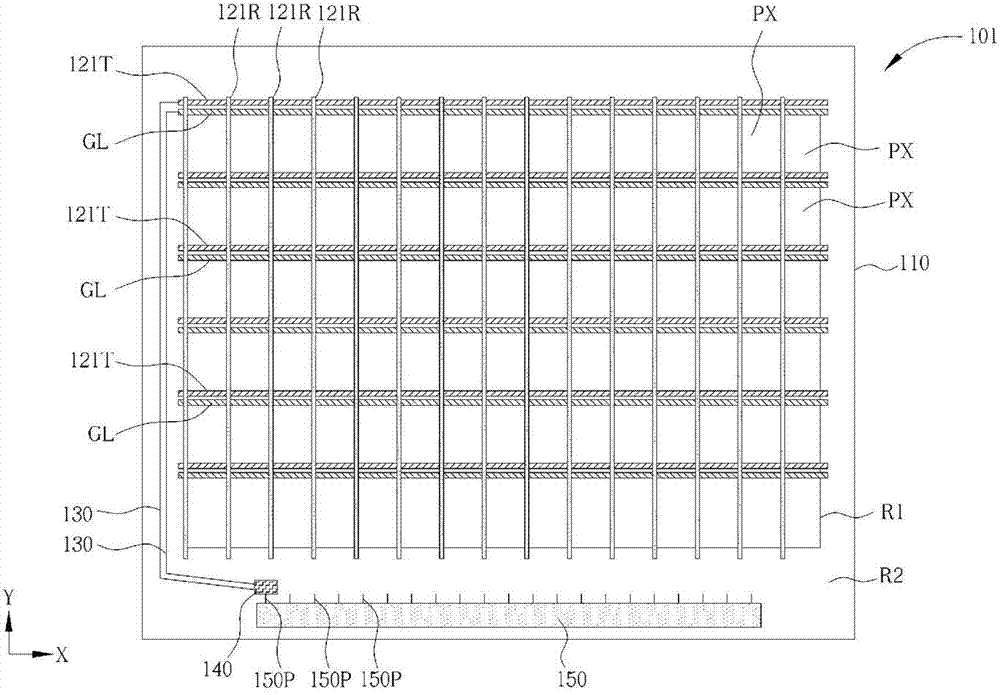

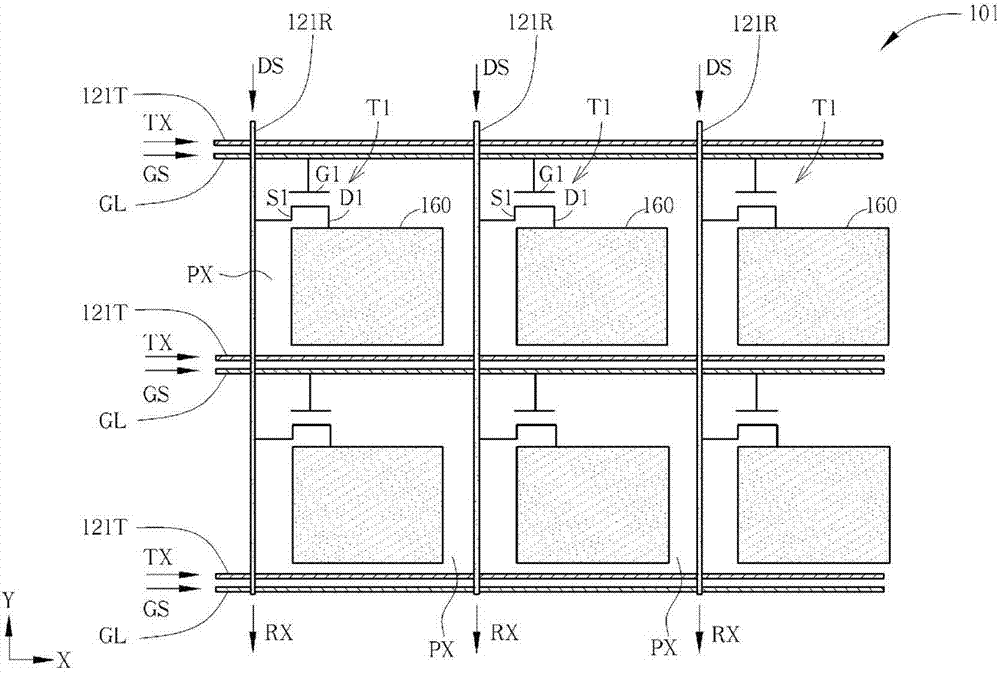

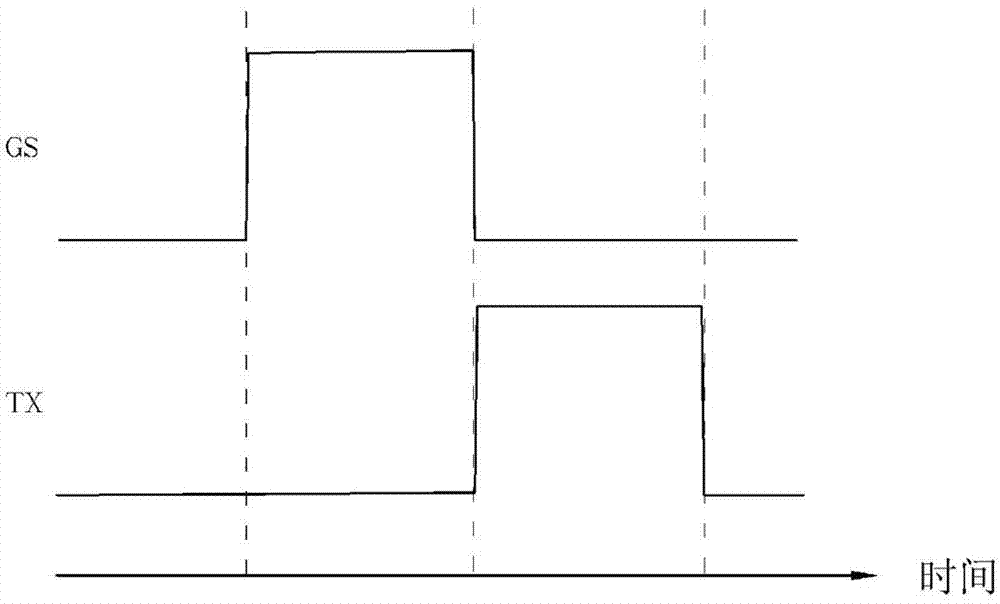

Touch Control Display Device

ActiveCN103927037AReduce manufacturing process stepsSimplify the processInput/output processes for data processingEngineeringDisplay device

The invention discloses a touch control display device which comprises the components of: a plurality of sub-pixel areas, a plurality of display control assemblies, a plurality of pixel electrodes, a plurality of touch control signal transmitting electrodes and a plurality of touch control signal receiving electrodes. The display control assemblies are respectively arranged in each sub-pixel area. Furthermore each display control assembly comprises a first gate electrode, a first source electrode and a first drain electrode. The pixel electrodes are arranged in each sub-pixel area. Furthermore each pixel electrode is electrically connected with a corresponding first drain electrode. The touch control signal transmitting electrodes are used for transmitting a touch control driving signal. At least one selected from each touch signal transmitting electrode and each touch control signal receiving electrode is used for transmitting a display gate signal to a corresponding first gate electrode or transmitting a display data signal to a corresponding first source electrode.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com