Liquid crystal display panel and manufacturing method thereof

A liquid crystal display panel and manufacturing method technology, applied in the direction of instruments, nonlinear optics, optics, etc., can solve problems such as increasing manufacturing costs, increasing manufacturing process steps, affecting product yield, etc., to reduce manufacturing costs and reduce manufacturing process steps , Improve the effect of product yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

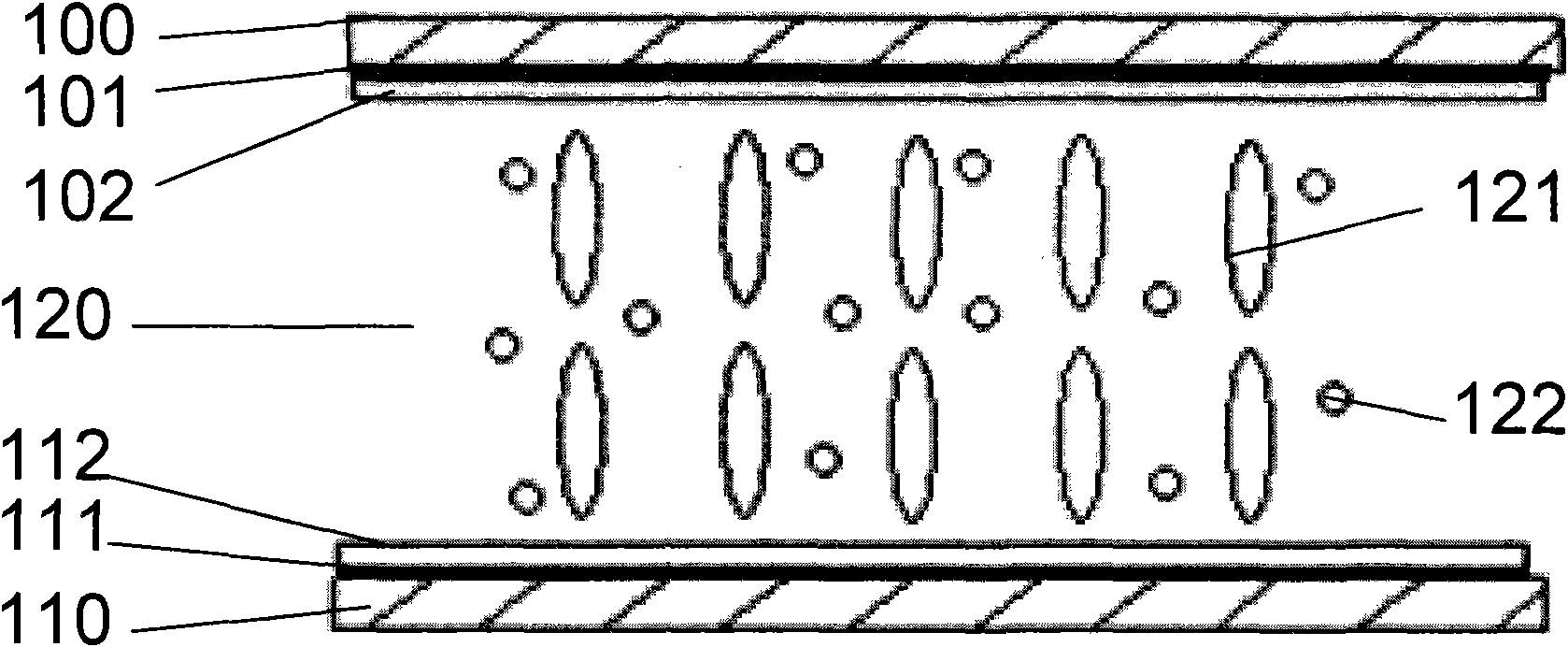

[0067] Figure 2A and Figure 2B It is a schematic structural diagram of the liquid crystal display panel in this embodiment. Only one pixel unit is shown in the figure, and a plurality of such pixel units are arranged in order in the liquid crystal display panel.

[0068] Such as Figure 2A As shown, the liquid crystal display panel includes: a first substrate 100 and a second substrate 110 disposed opposite to each other, and a liquid crystal layer 120 filled between the first substrate 100 and the second substrate 110 .

[0069] The first substrate 100 is, for example, a filter substrate, and the filter substrate 100 has an RGB color filter (not shown in the figure), a transparent electrode layer 101 and The alignment film 102 adjacent to the liquid crystal layer 120, wherein the transparent electrode layer 101 is a common electrode.

[0070] The second substrate 110 is, for example, an array substrate. The side of the array substrate 100 facing the liquid crystal layer...

Embodiment 2

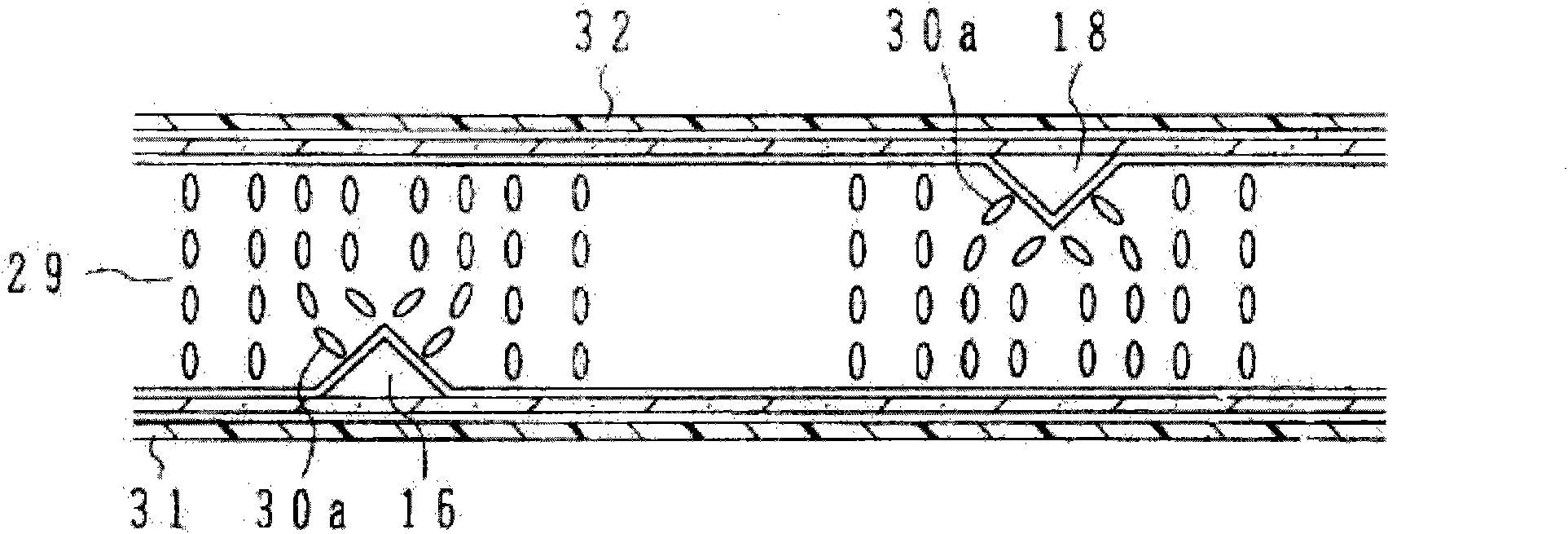

[0078] Figure 3A , Figure 3B and Figure 3C It is a schematic structural diagram of the liquid crystal display panel in this embodiment.

[0079] Such as Figure 3A As shown, the liquid crystal display panel includes: a first substrate 200 and a second substrate 210 disposed opposite to each other, and a liquid crystal layer 220 filled between the first substrate 200 and the second substrate 210 .

[0080] The first substrate 200 is, for example, a filter substrate, and the filter substrate 200 has RGB color filters (not shown in the figure), a transparent electrode layer 201 and an alignment film 202, wherein the transparent electrode layer 201 is the common electrode. The second substrate 210 is, for example, an array substrate. The array substrate 200 has a transparent electrode layer 211 and an alignment film 212, wherein the transparent electrode layer 211 is a pixel electrode; 200 and the anchor 222 of the negative liquid crystal molecule 221 pretilt angle on the ...

Embodiment 3

[0089] Figure 4 It is a schematic structural diagram of a liquid crystal display panel in this implementation.

[0090] As shown in the figure, the LCD panel includes:

[0091] The first substrate 300; the second substrate 310, arranged opposite to the first substrate 300; the liquid crystal layer 320, sandwiched between the first substrate 300 and the second substrate 310, the liquid crystal layer 320 contains a An anchor 322 for the pretilt angle of liquid crystal molecules 321 in the liquid crystal layer 320 on the surface of the first substrate 300 or the surface of the second substrate 310 ; the external electrode 305 is located on the side of the first substrate 300 facing away from the liquid crystal layer 320 . The composition and structure of the liquid crystal display panel are similar to those in the first embodiment, and will not be repeated one by one. In other embodiments of the present invention, the external electrodes may also be located on the side of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com