Rupture disk for non-welding gas cylinders

A bursting disc, non-welding technology, applied in safety valves, engine components, balance valves, etc., can solve the problems of anti-corrosion treatment liquid harmful to human body, rising bursting pressure of bursting discs, hazards to safe operation of equipment, etc., to achieve excellent corrosion resistance , reduce the manufacturing process, reduce the effect of product prices

Inactive Publication Date: 2010-06-16

DALIAN LIGONG SAFETY EQUIP

View PDF0 Cites 4 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

For austenitic stainless steel materials, after heat treatment, the structural strength will decrease. If the manufacturing process is not strictly controlled, instability will easily occur. Once the instability occurs, the bursting pressure of the rupture disc will increase significantly, which will greatly increase the safety of the equipment. bring harm

Foreign products are made of special low-carbon steel. Although the product has good performance and low cost, it is very easy to rust, and the product must be anti-rust. This process will pollute the environment. The anti-corrosion treatment liquid is harmful to the human body and environmentally friendly. The facilities are not up to standard and not easy to use

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

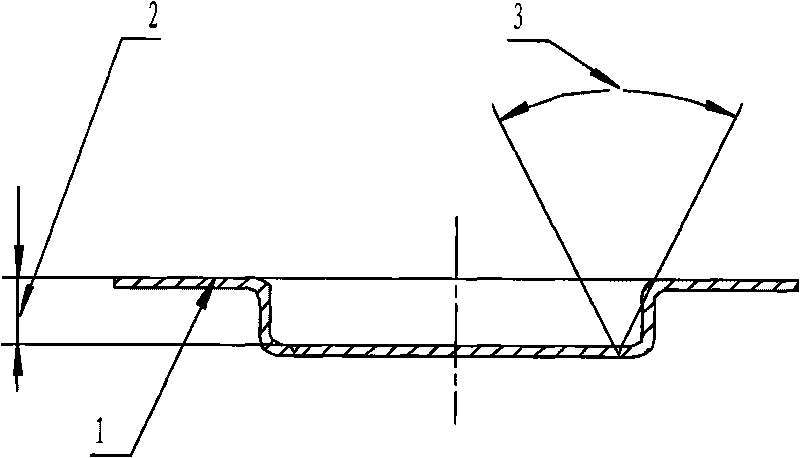

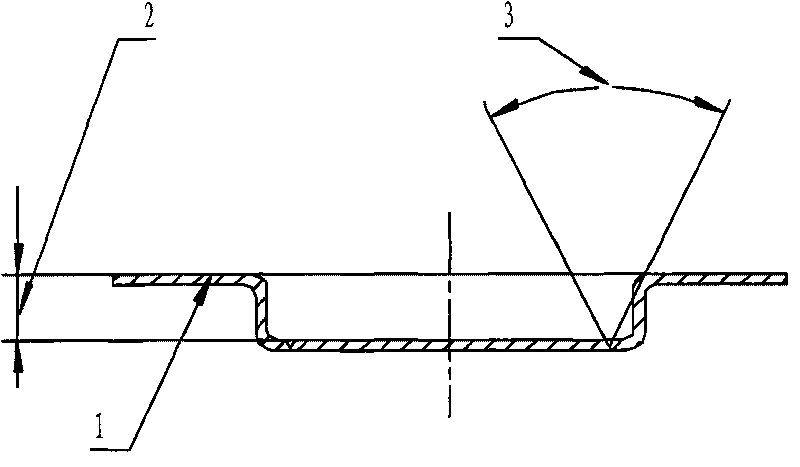

[0010] Such as figure 1 As shown, a rupture disc for a non-welded gas cylinder is made of JYH21CT high chromium stainless steel material 1, the rupture disc forming height 2 is 4.5mm, and the rupture disc weakening groove angle 3 is 45°.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Login to View More

Abstract

The invention belongs to the technical field of pressure vessel safety equipment, and relates to a safe pressure relief device for fluid overpressure, in particular to a rupture disk for non-welding gas cylinders. The rupture disk adopts JYH21CT high-chromium stainless steel material. As the JYH21CT high-chromium stainless steel has excellent corrosion resistance, low cold-work hardening property, high yield strength, good ductility and no nickel serving as rare metal, manufacturing processes and cost can be reduced. Meanwhile, by utilizing the ultra-low carbon and low titanium content of the material, the weldability and high yield strength of the material are increased. The molding height of the rupture disk is between 4.0 to 4.7 mm, and a weakening groove of the rupture disk is at an angle of 40 to 45 degrees. By utilizing the characteristics of no expensive nickel serving as rare metal contained by the material, no cold deformation hardening of products and no need for high-temperature heat treatment, the invention greatly reduces the price of the products, and by utilizing precise molding technology and processing technology, the forward bursting pressure and the reverse bursting pressure of the products are basically consistent, so that the safety of the products is greatly improved.

Description

Technical field [0001] The invention belongs to the technical field of pressure vessel safety equipment, and relates to a safety relief device for fluid overpressure, in particular to a bursting disc for a non-welded gas cylinder. Background technique [0002] At present, rupture discs for non-welded gas cylinders are made of 304 or 316L stainless steel in China, and special low-carbon steel materials are used abroad. For the use of austenitic stainless steel materials, there is a high cost, because high nickel materials, and nickel is a scarce and non-renewable metal, the international market price fluctuates greatly, and the material prices are high. In addition, austenitic stainless steel has strong cold work strain hardening characteristics. After the product is stretched and deformed, it is generally subjected to high-temperature solution heat treatment, otherwise the hardness of the deformed area is too high, and it is very easy to crack during the groove; while the JYH21CT...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): F16K17/40

Inventor 李岳徐忠慧喻友良王振伟温殿江

Owner DALIAN LIGONG SAFETY EQUIP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com