Facet film-plating clamp for semiconductor laser chip

A semiconductor and laser technology, which is applied in the direction of semiconductor lasers, lasers, laser parts, etc., can solve the problems of less storage space for chips, complex fixture structure, and decreased precision, and achieve reduced manufacturing process steps, simple fixture components, and reduced shading area. small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

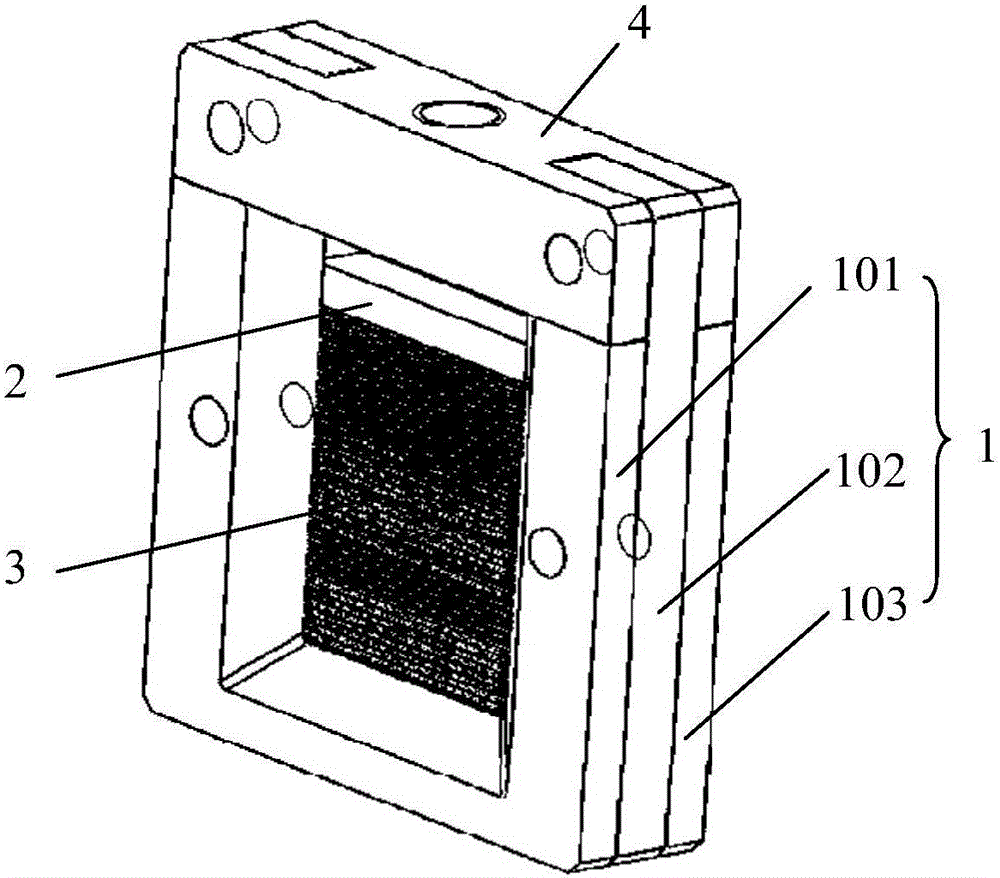

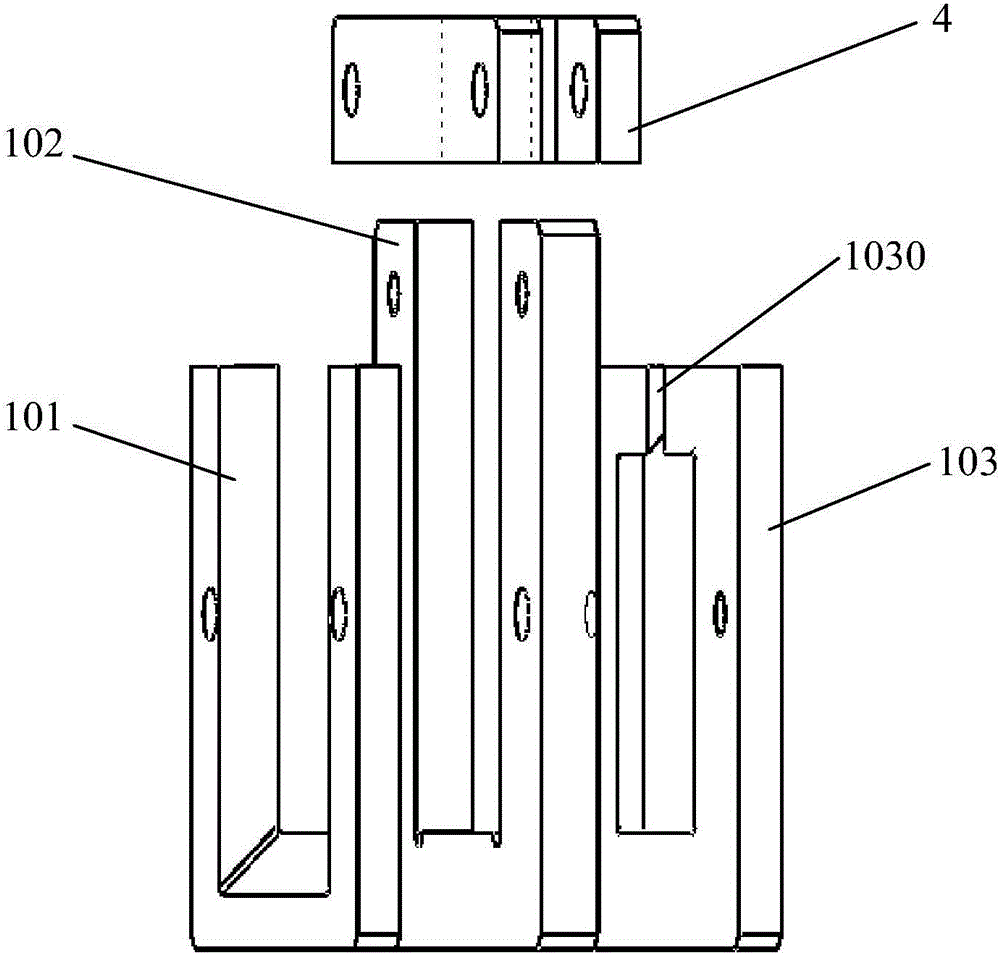

[0036] Such as figure 1 , figure 2 As shown, the coating fixture includes a flat U-shaped frame assembly 1 and a plug assembly located at the U-shaped open end (only the top wire fixing block 4 is shown in the figure), and is surrounded by the flat U-shaped frame assembly and the plug assembly. In the closed area of the plane, several bars 3 and the stainless steel pads 2 provided at both ends are stacked and arranged sequentially from the U-shaped closed end to the U-shaped open end.

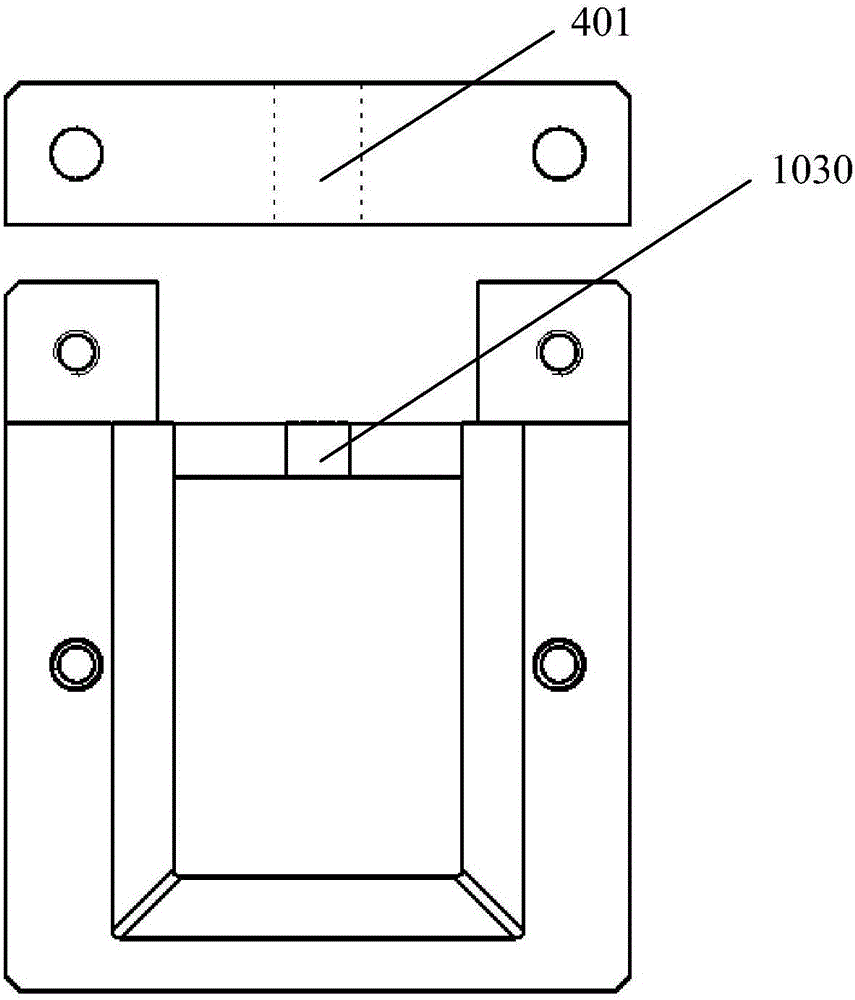

[0037] The flat U-shaped frame assembly is mainly composed of a U-shaped upper plate 101, a U-shaped middle plate 102 and a closed-loop lower plate 103, which are stacked in sequence in the vertical direction and fixed through screws. The inner width of the U-shaped middle plate 102 is larger than The inner width of the closed-loop lower plate 103 and the U-shaped upper plate 101, wherein the side cavities at both ends of several bars are just supported on the rail surface left by the close...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com