Patents

Literature

78results about How to "Reliable clamping and fixing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

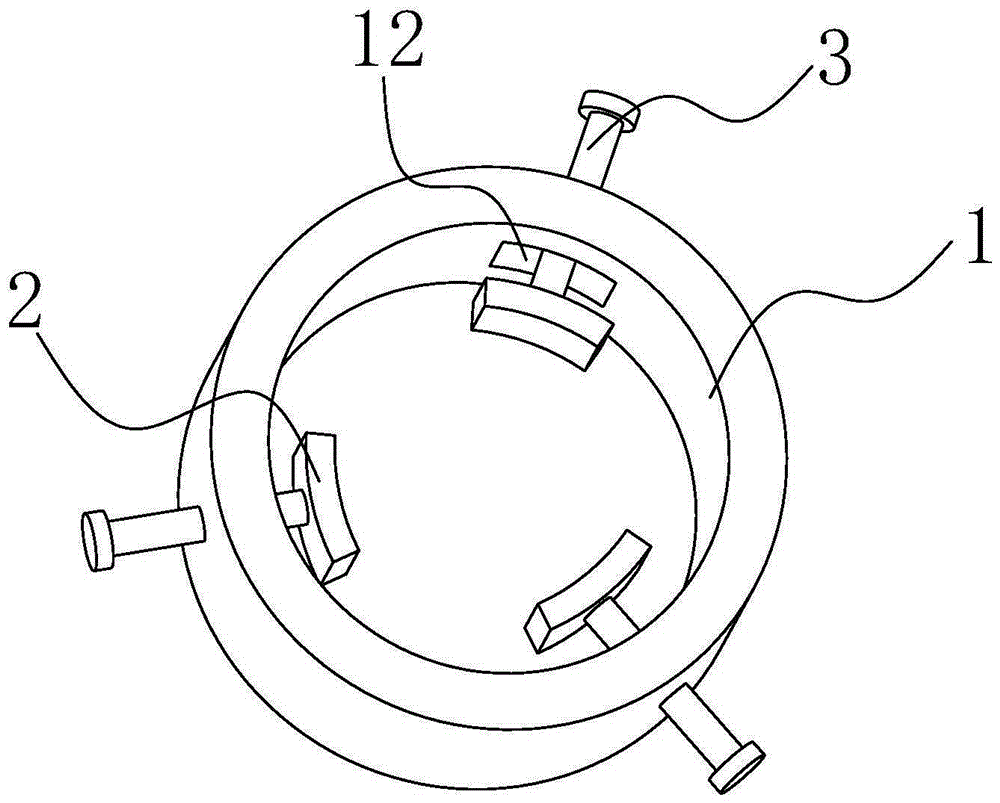

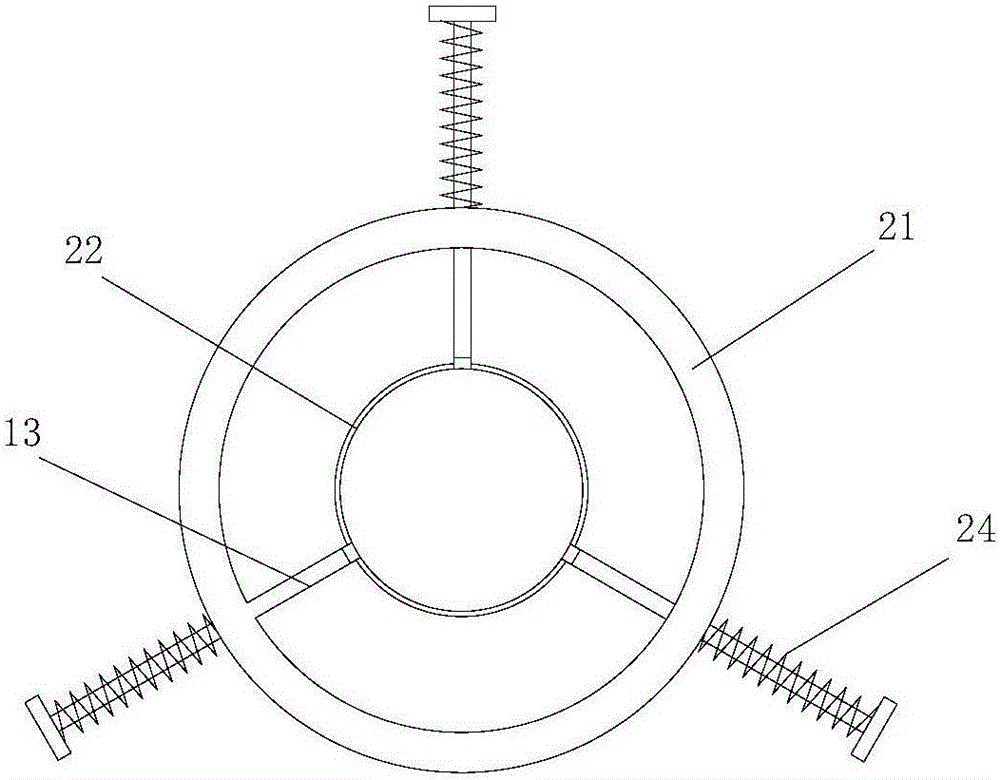

Clamp for round pipe

InactiveCN105170820AReliable clamping and fixingSimple structureMetal-working feeding devicesPositioning devicesFixed frameEngineering

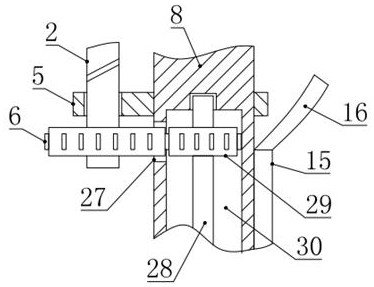

The invention discloses a clamp for a round pipe. The clamp for the round pipe comprises a fixing frame, fixing blocks and adjustment bolts. The fixing frame is arranged to be of a ring structure. Two or more threaded holes are formed in the fixing frame in a centrally symmetrical mode. The fixing blocks are in one-to-one correspondence with the threaded holes and arranged on the inner ring surface of the fixing frame. The adjustment bolts penetrate through the threaded holes and are rotatably connected with the fixing blocks. The distances between the fixing blocks can be changed by rotating the adjustment bolts, and thus round pipes with different diameters can be clamped. The clamp is simple in structure; the distances between the fixing blocks can be changed by adjusting and rotating the adjustment bolts so that the round pipes with different diameters can be clamped, and the round pipes with different diameters can be clamped and fixed through the same clamp.

Owner:HUANGSHI UNIVERSE AUTO EQUIP

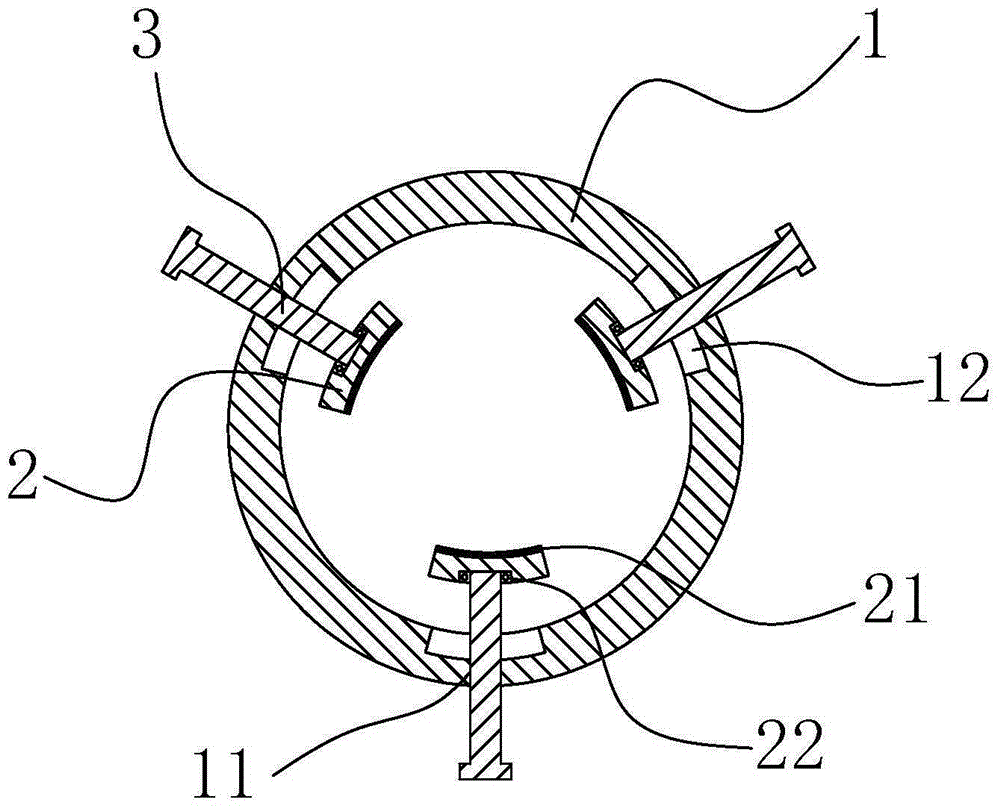

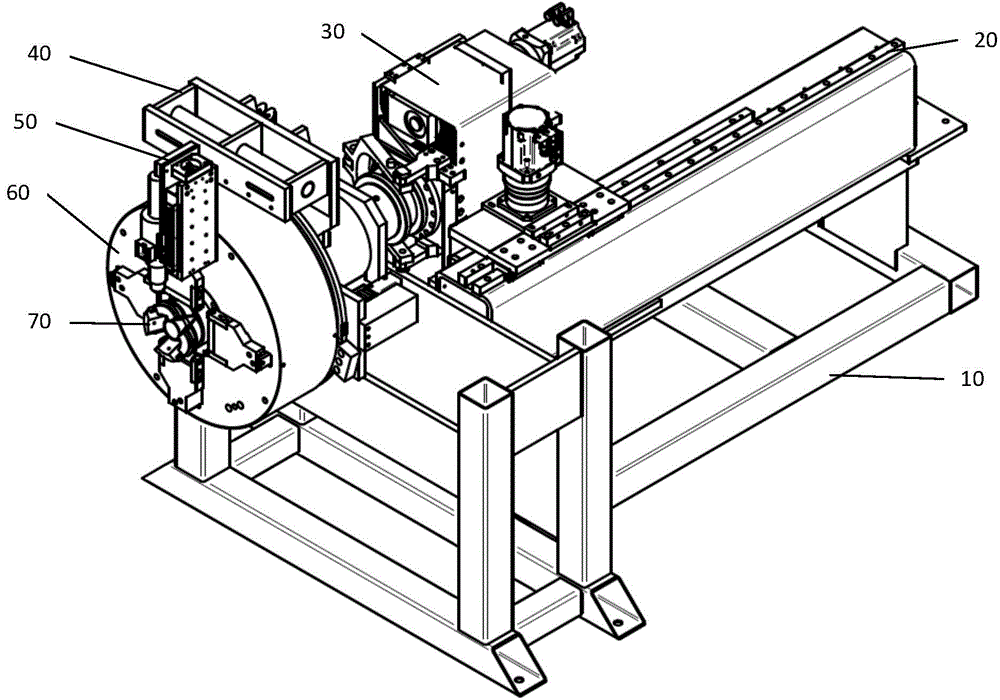

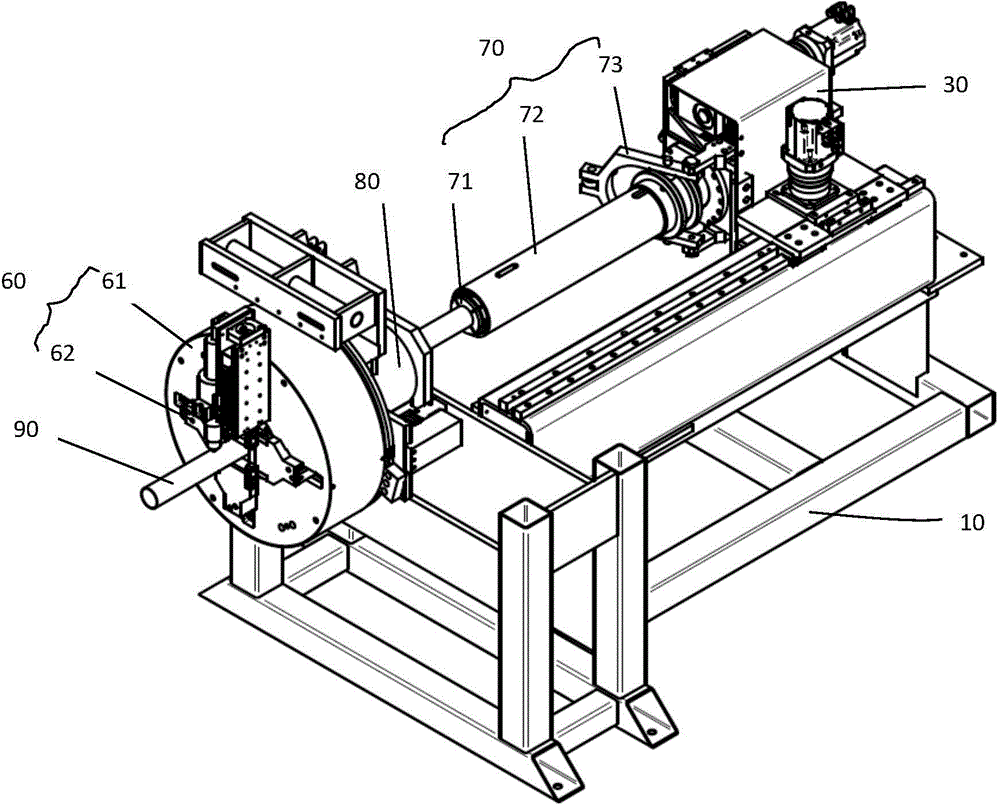

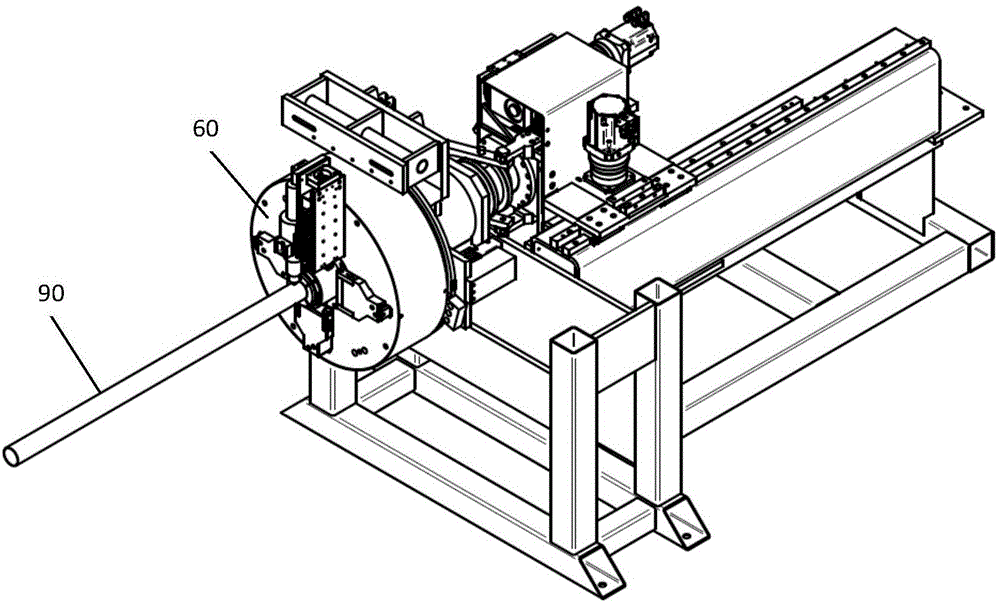

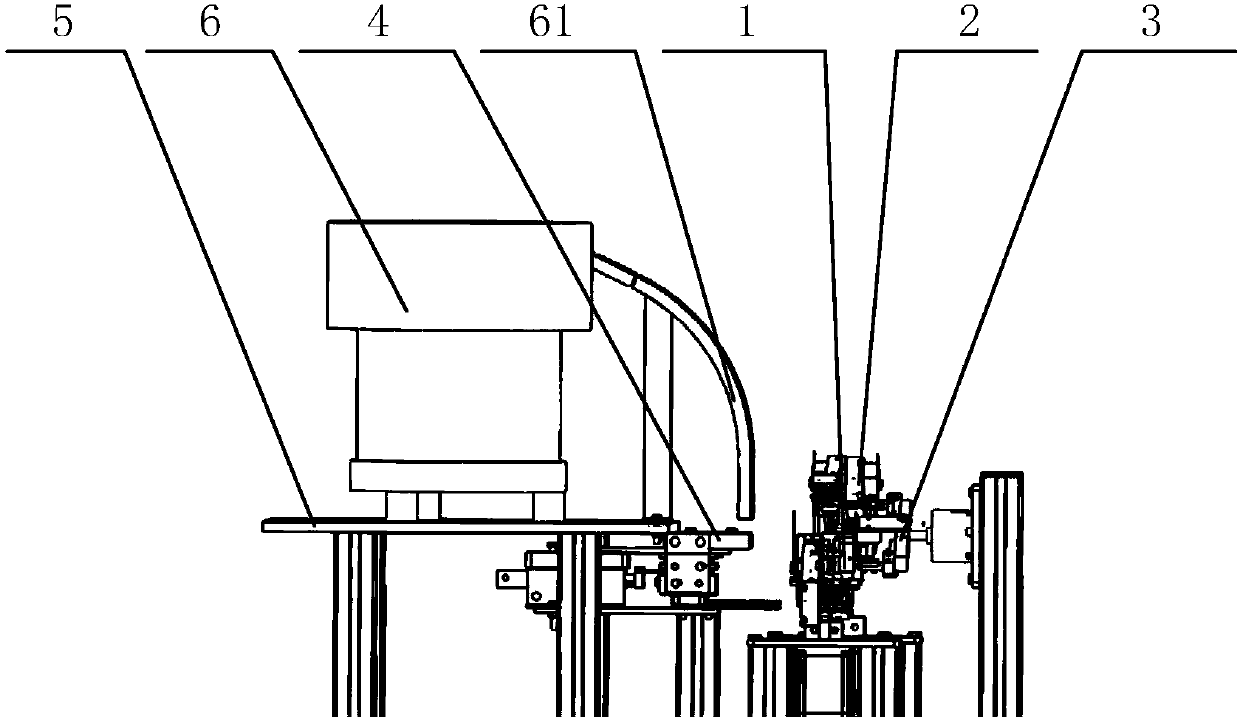

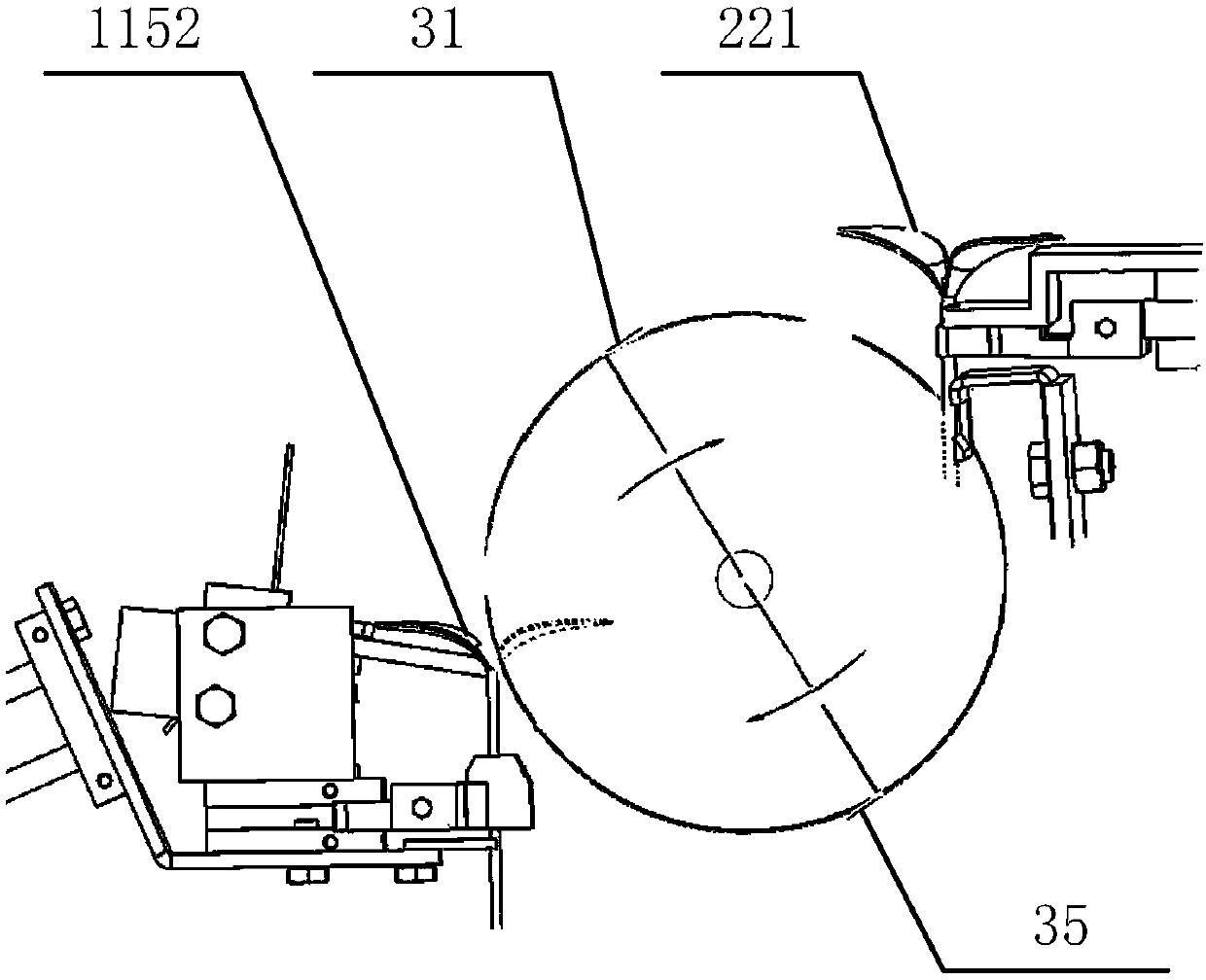

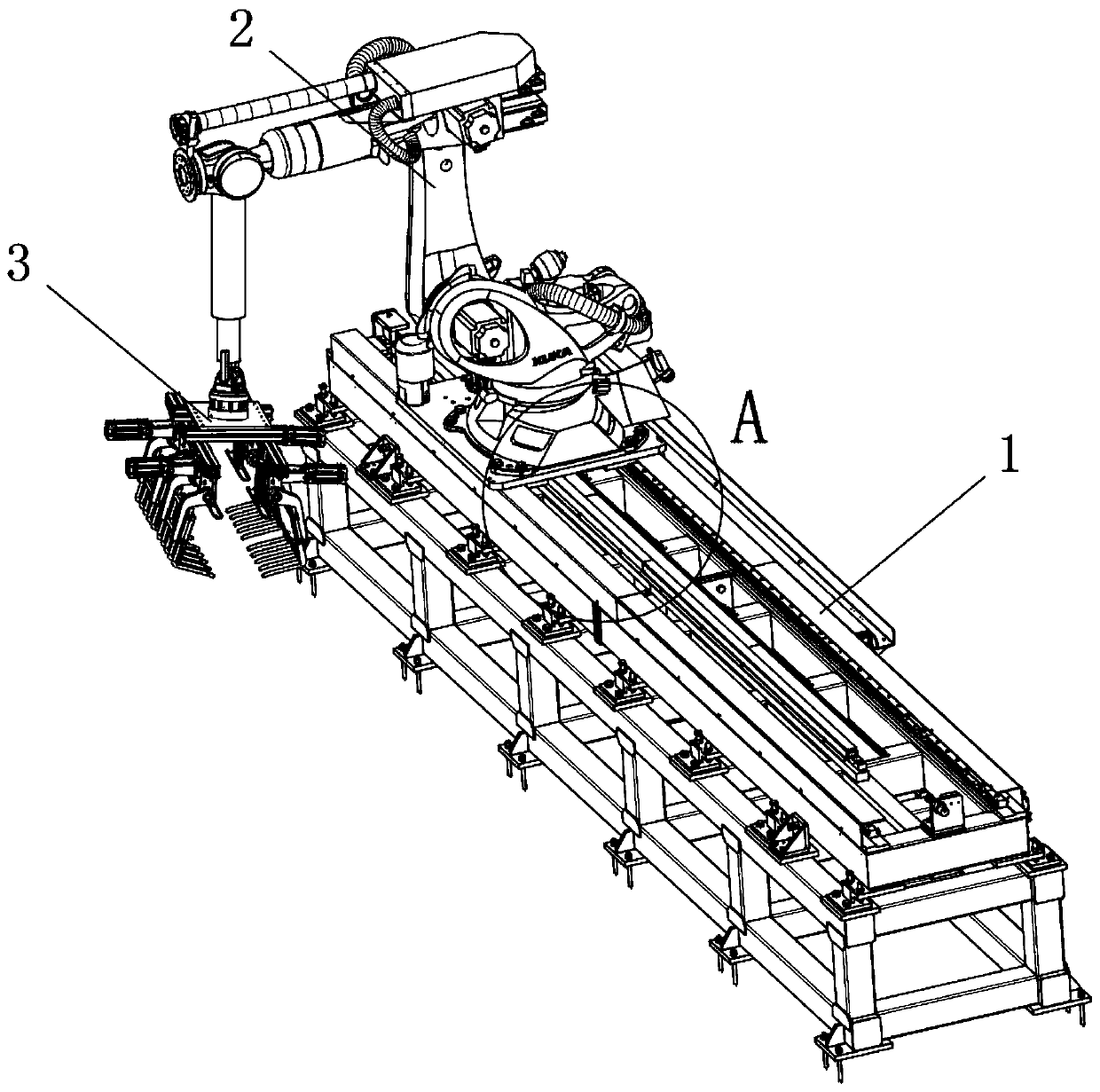

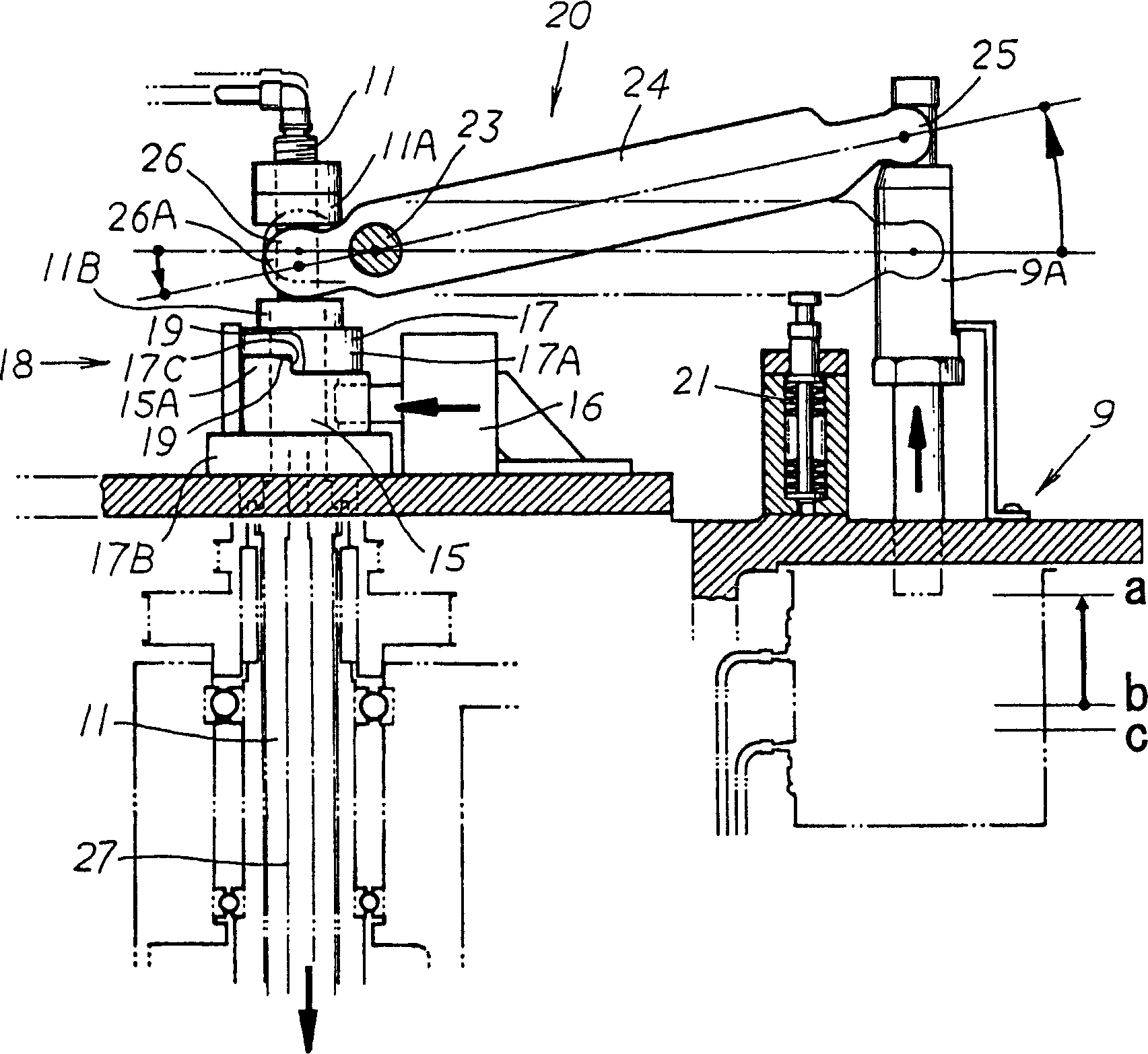

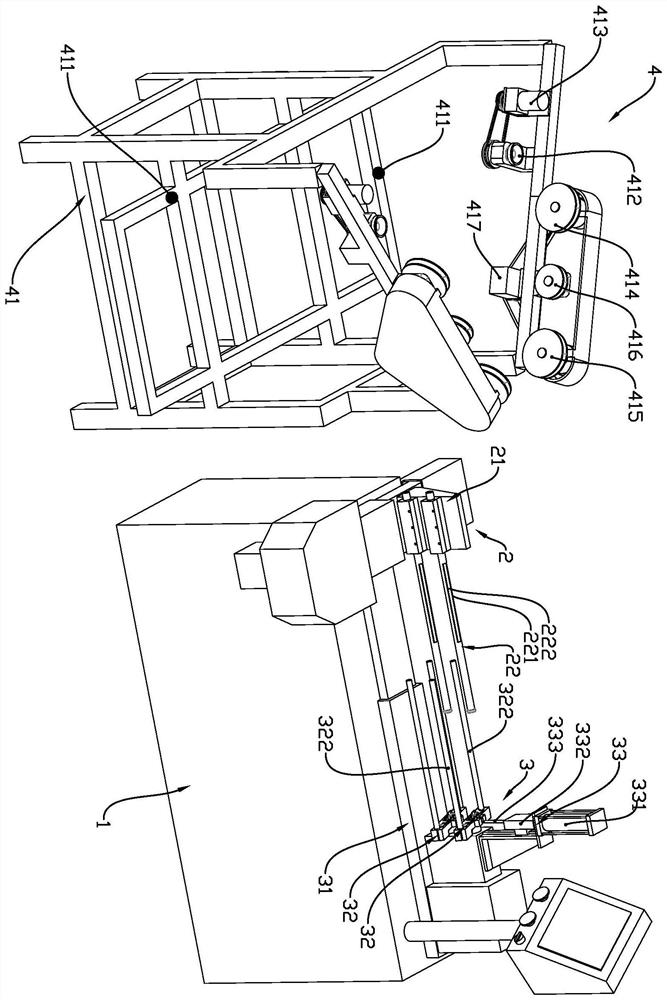

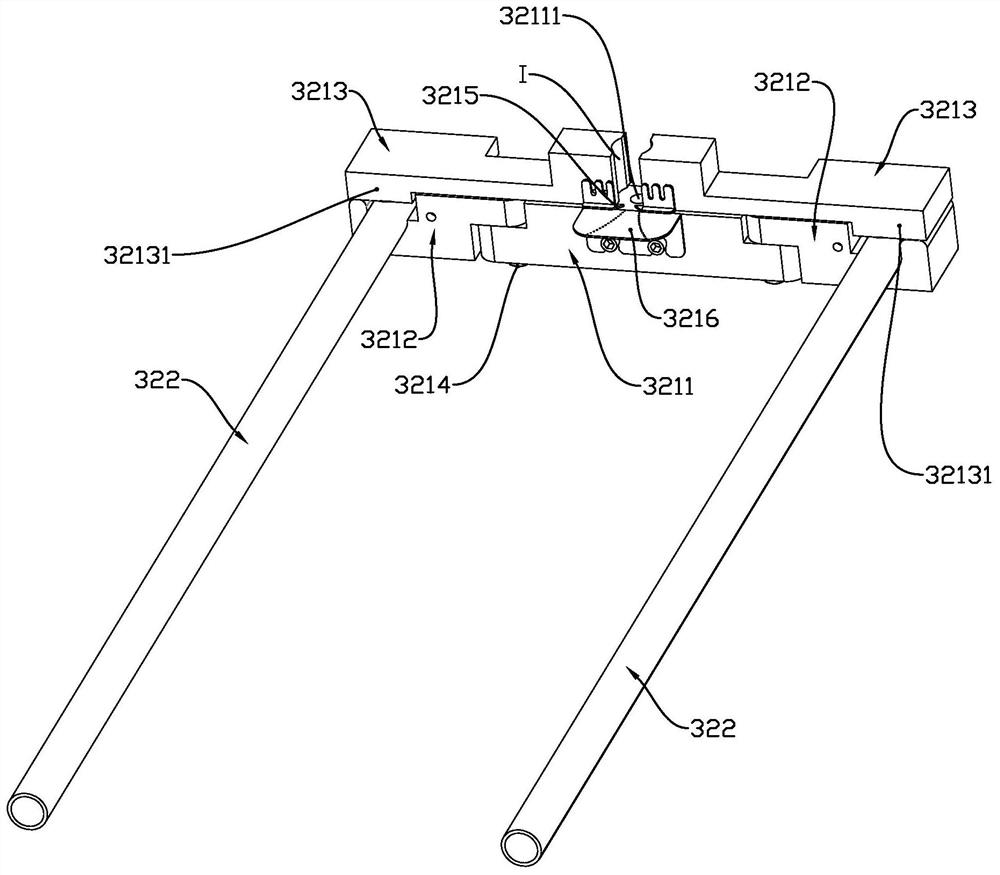

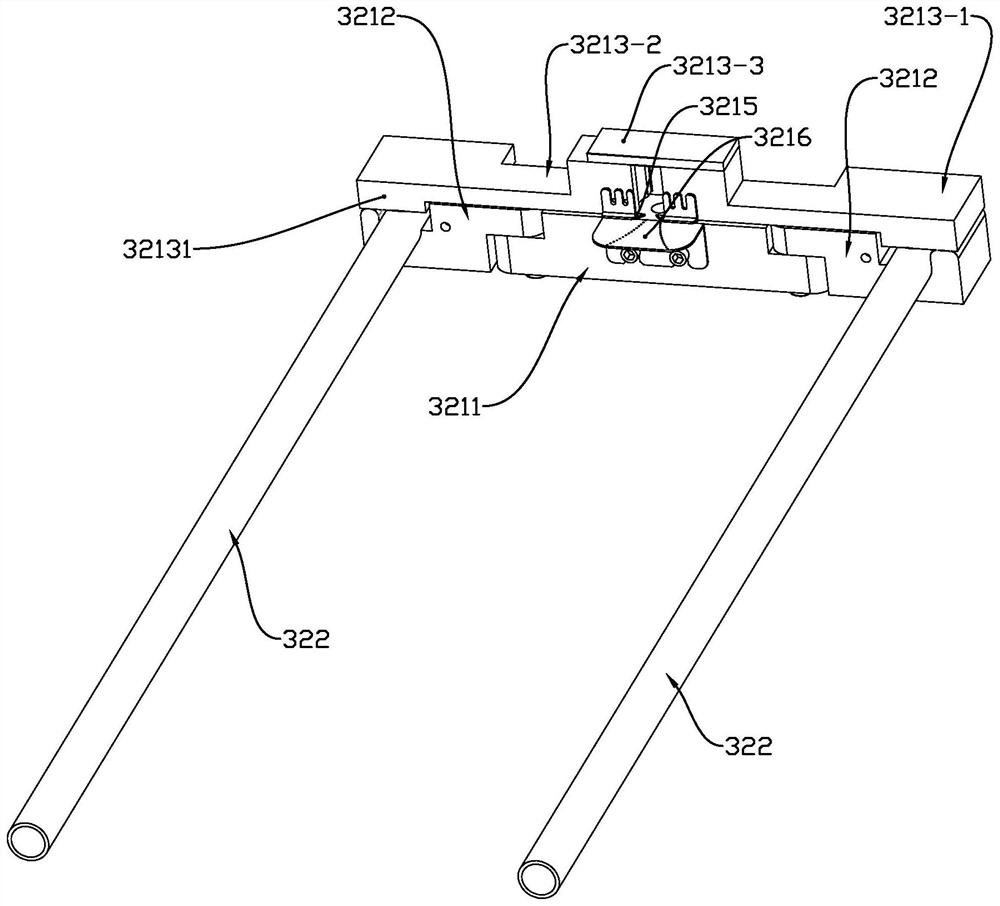

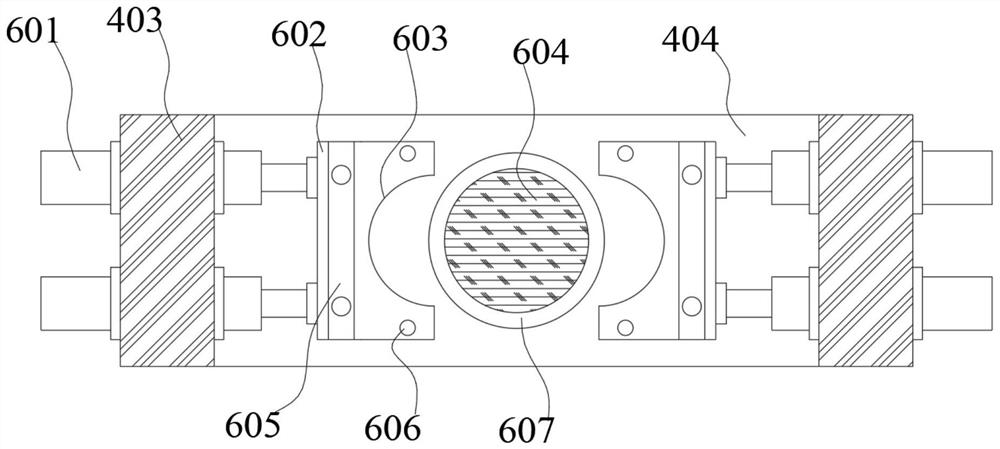

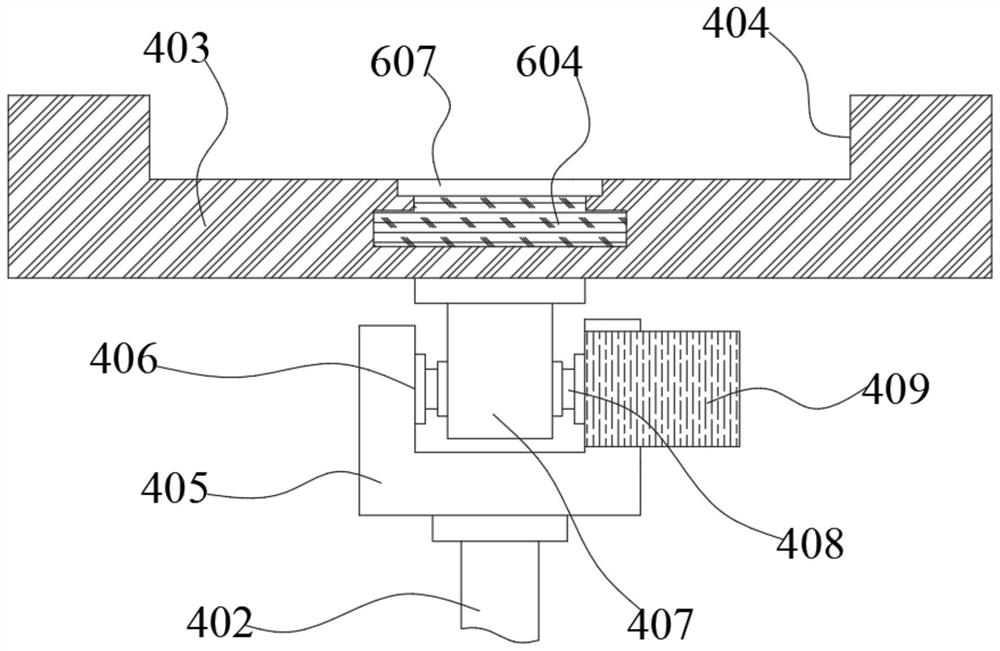

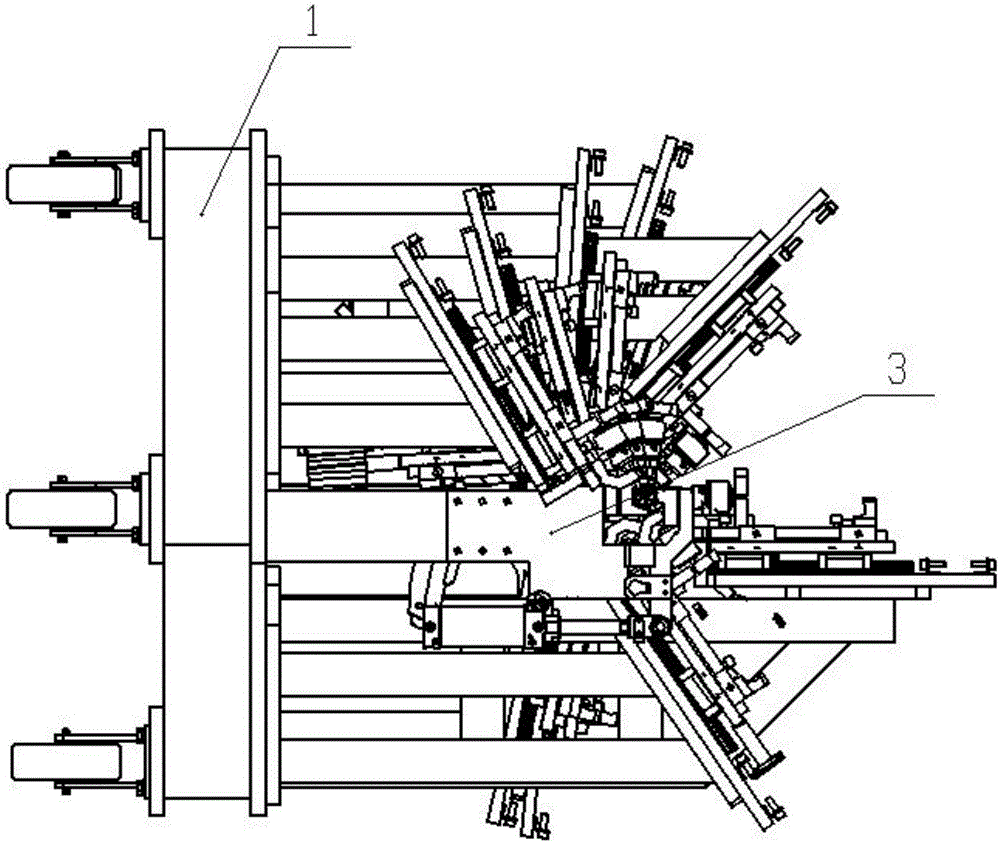

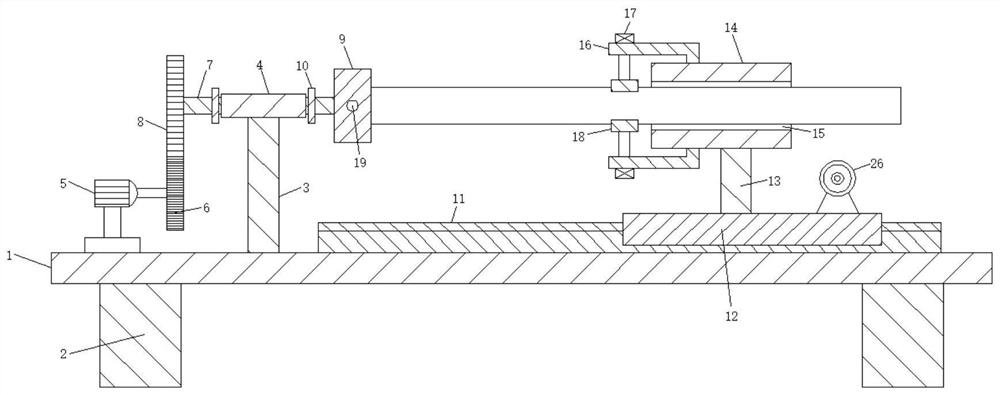

Jig for pipeline laser cutting machine and pipeline laser cutting machine

ActiveCN104816097AWon't wasteAchieve clampingWelding/cutting auxillary devicesAuxillary welding devicesLaser cuttingMechanical engineering

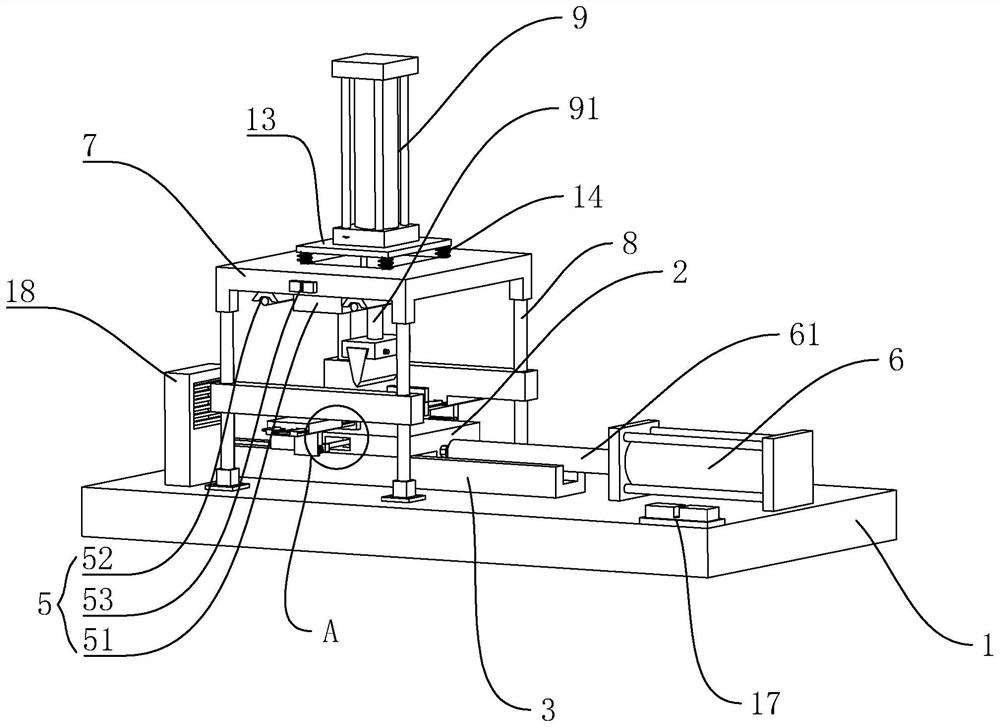

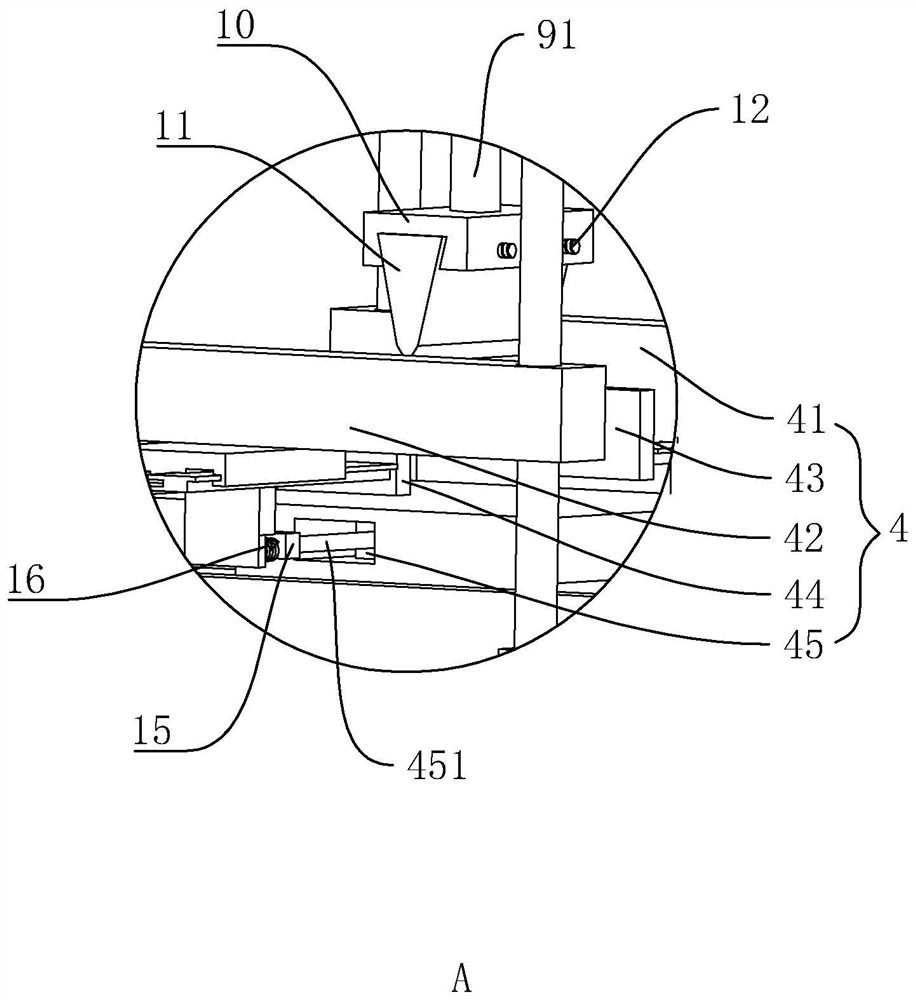

The invention discloses a jig for a pipeline laser cutting machine. The jig for the pipeline laser cutting machine comprises a cutting clamping unit, a guide mechanism and a feed clamping mechanism, wherein the cutting clamping unit is provided with a disc, the end surface of one side of the disc is provided with multiple clamping claws for clamping the pipeline tightly, the guide mechanism is an annular body which is axially arranged with the disc and used for guiding the pipeline entering into the disc, and the feed clamping mechanism is arranged behind the guide mechanism and used for tightly clamping the tail end of the long pipeline to be cut and conducting cutting and feeding. The feed clamping mechanism is a hollow cylinder body, the diameter of the periphery of the cylinder body is smaller than the inner diameter of the center through hole of the disc, thus the feed clamping mechanism can directly enter the center through hole of the disc, enables the clamping claws of the cutting clamping unit to clamp the tail end pipe wall of the pipeline and completes the final cutting of the pipeline. The jig for the pipeline laser cutting machine can realize accurate and efficient cutting of the pipeline, especially can greatly reduce the material waste caused by two much remaining lengths of the pipeline in the conventional cutting machinery.

Owner:湖北金飞翼智能科技有限公司

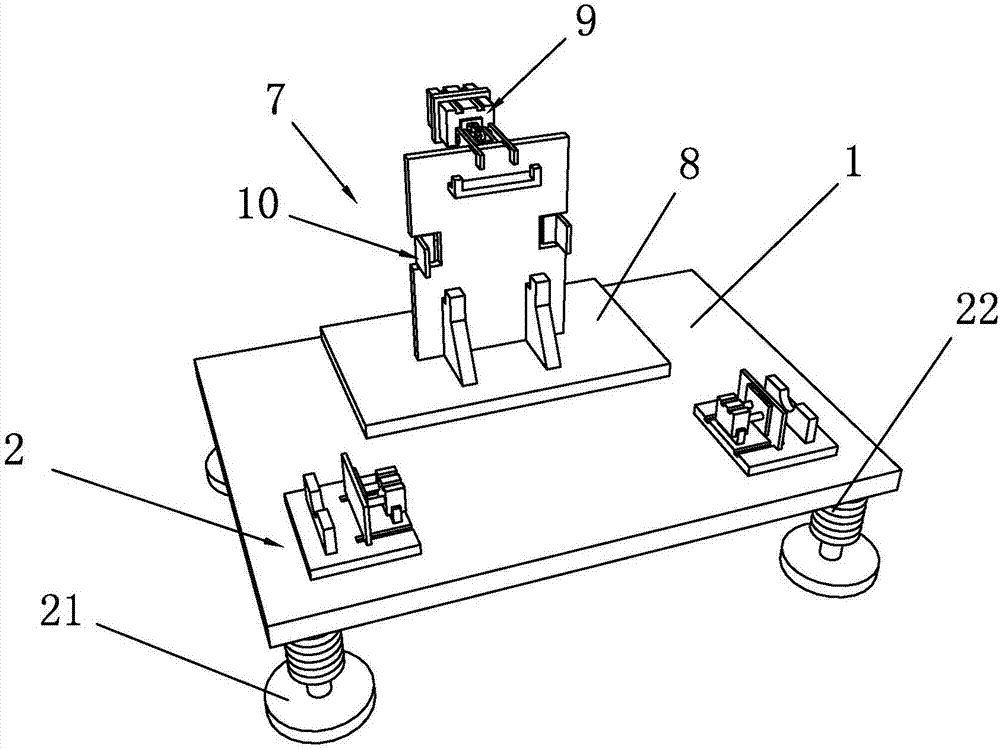

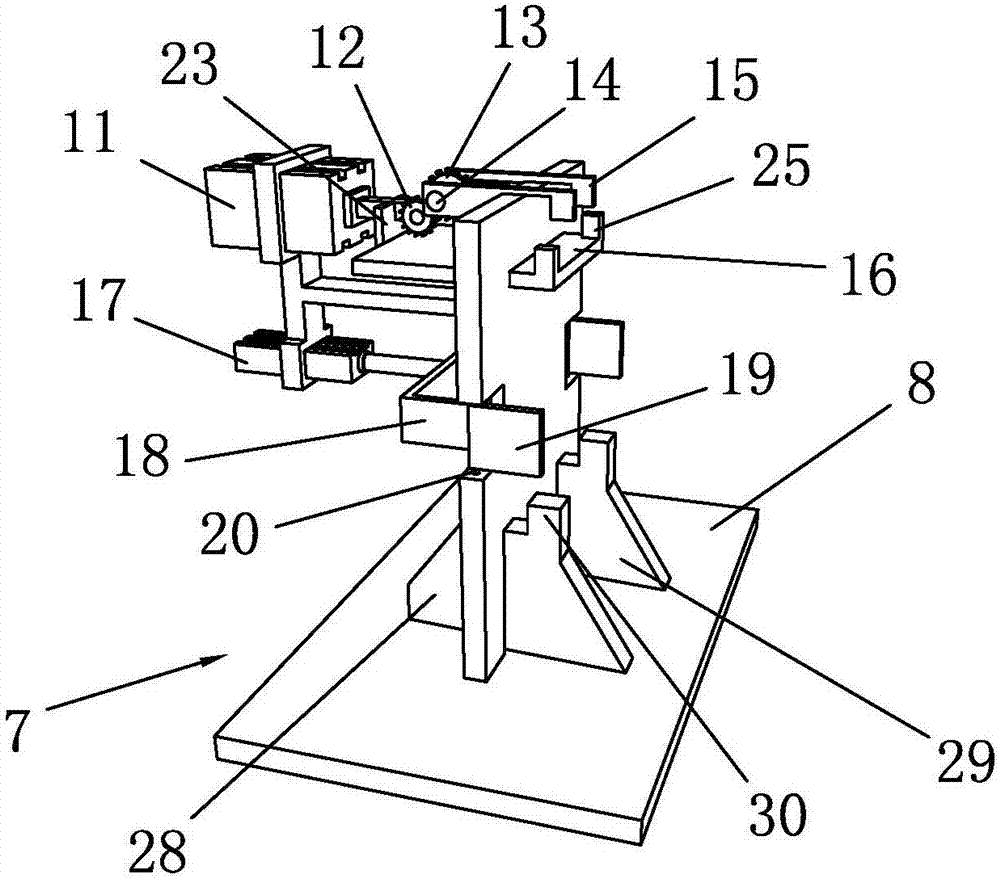

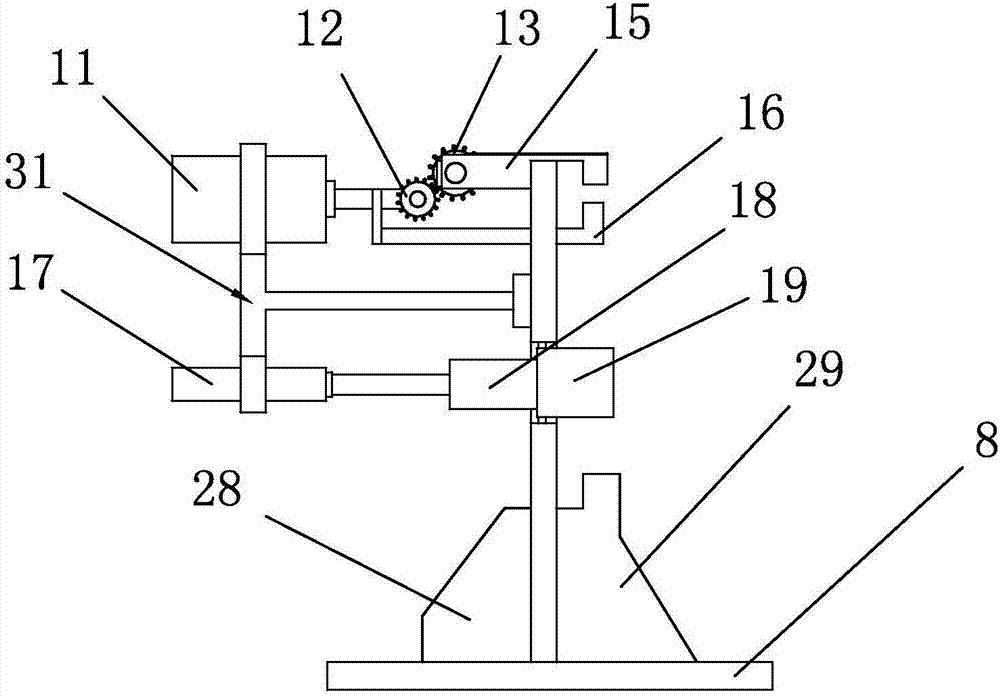

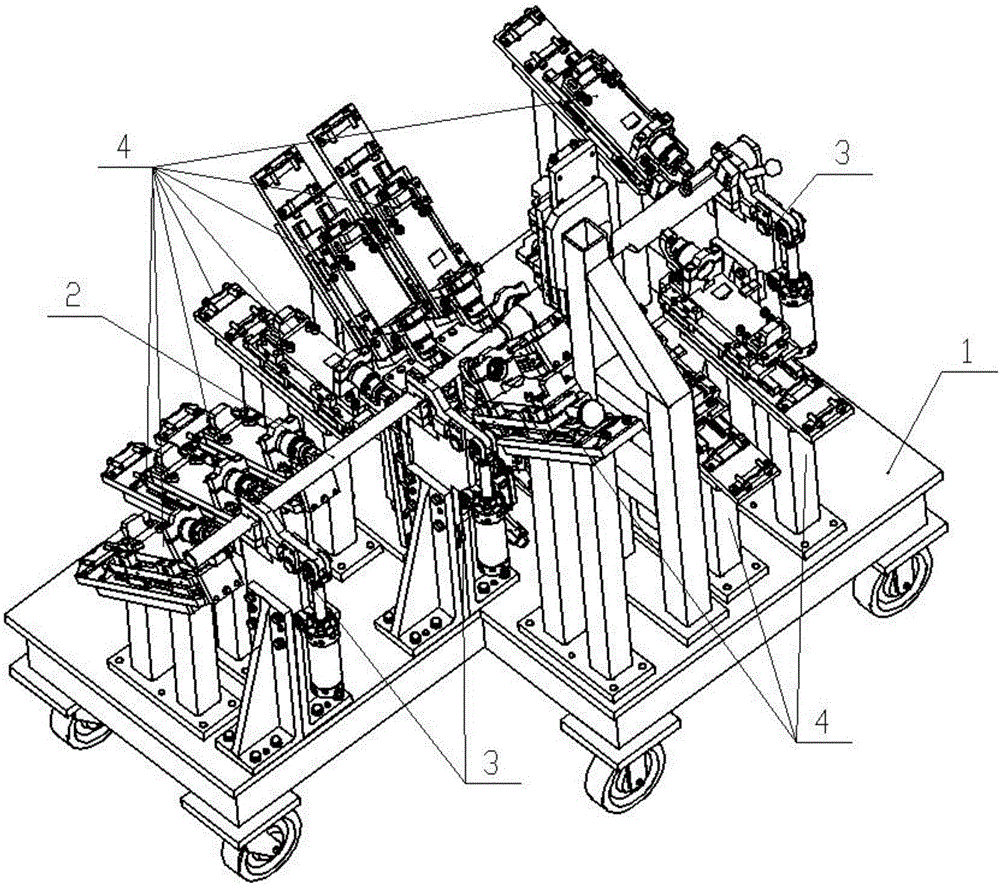

Tool fixture for automobile accessory welding

InactiveCN106975880AStable structureImprove support stabilityWelding/cutting auxillary devicesAuxillary welding devicesTelescopic cylinderEngineering

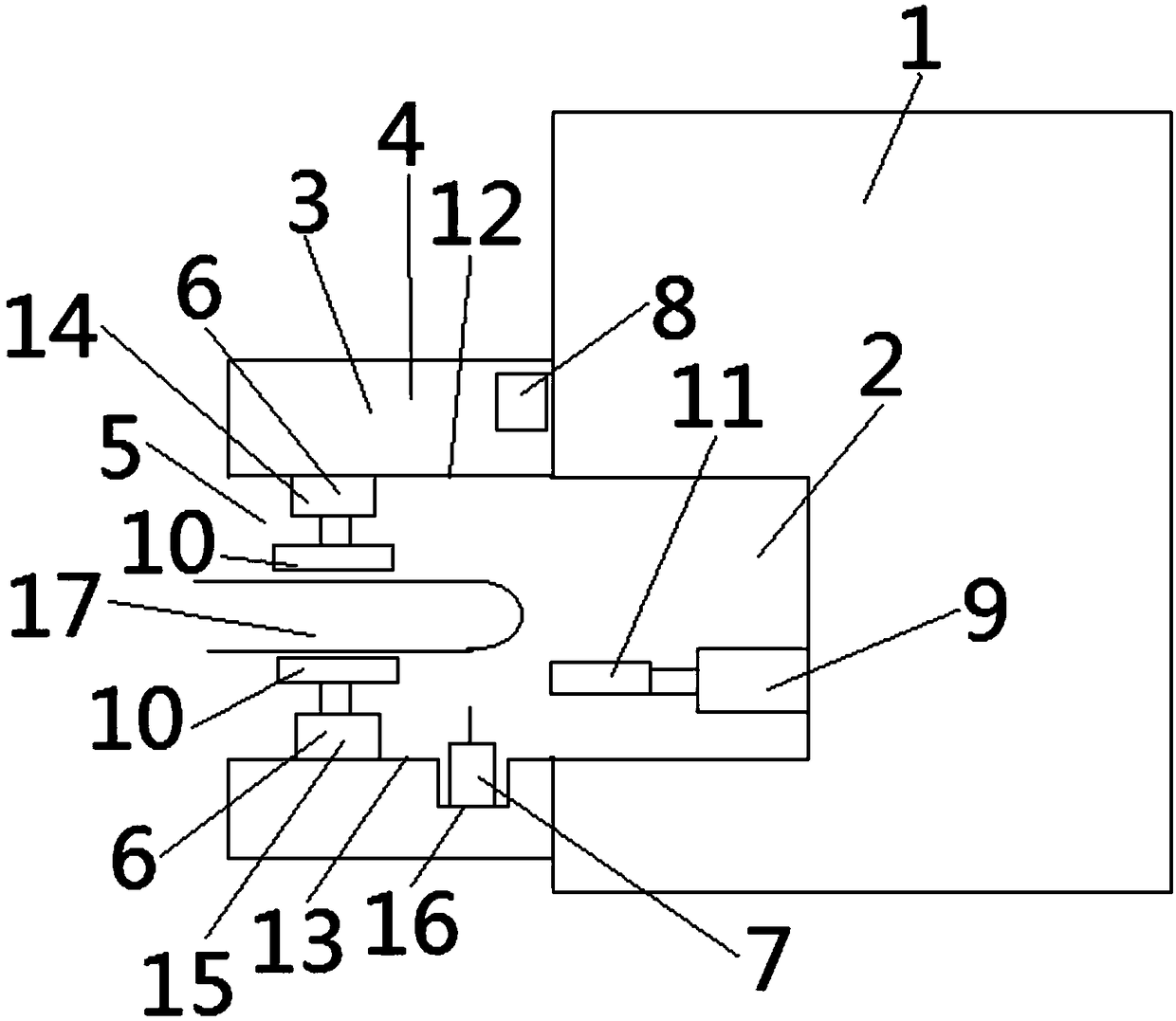

The invention mainly discloses a tooling fixture for auto parts welding, which includes a workbench on which left and right symmetrical auxiliary clamping parts are arranged. The auxiliary clamping parts include a fixing plate, a clamping cylinder, a clamping plate and a limiting plate. The rear side of the auxiliary clamping part is provided with a main clamping part, and the main clamping part is fixedly connected with the workbench through a T-shaped mounting plate. The main clamping part includes a first clamping group and a second clamping group, and the first clamping The group includes a limit cylinder, a driving wheel, a driven wheel, a rotating shaft, a limit clamp and a sliding plate, and the second clamping group includes a telescopic cylinder, a U-shaped plate and a rotating splint. The invention has strong practicability, more automatic use and operation, and improves the structure according to the welding requirements and shape diversity of parts in auto parts, so that the design of the fixture is more targeted, and it is more suitable for the welding and clamping of auto parts, so that Auto parts have better welding quality and higher structural strength.

Owner:嵊州市万协汽车配件有限公司

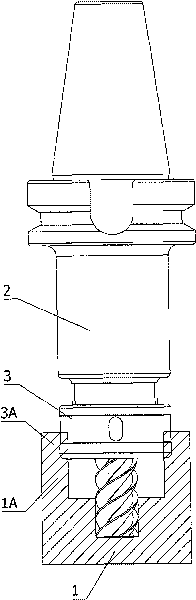

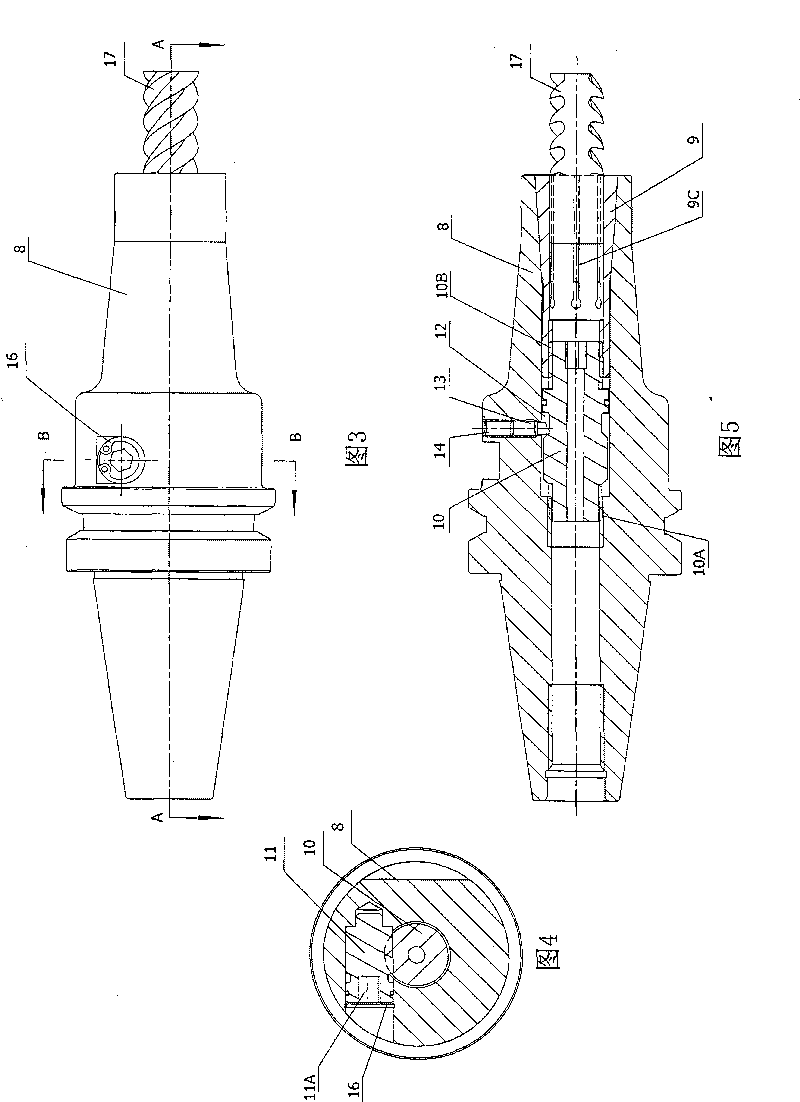

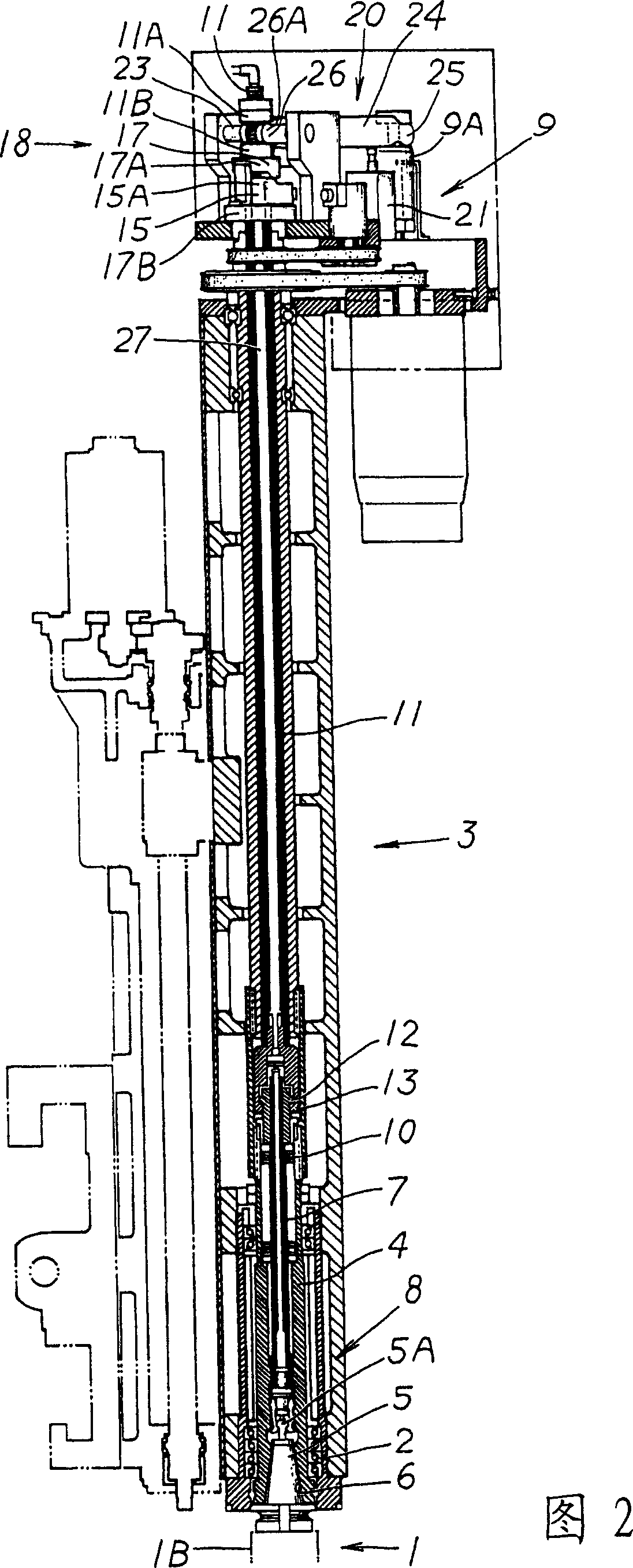

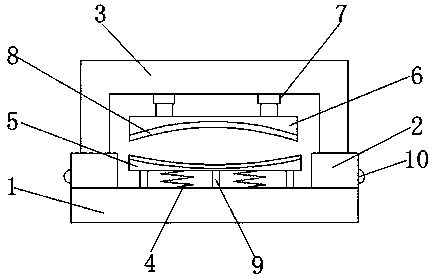

Worm-gear type collet chuck locking mechanism

InactiveCN101733671APrecise clamping and fixingReliable clamping and fixingPositioning apparatusMetal-working holdersLocking mechanismEngineering

The invention relates to a locking mechanism of machine tools and provides a lock device which is characterized by convenient replacement and regulation of tool, compact structure and high holding precision and can accurately, reliably and conveniently hold and fix the tool. The technical scheme of the invention is that a worm-gear type collet chuck locking mechanism comprises a main body having a cavity on a right half part; the right end of the cavity is of a cone shape; a cone-shaped collet chuck which is used for holding a knife handle and is matched with the cavity is arranged in the cavity; and the cone-shaped collet chuck is provided with a plurality of contraction joints along a cone-shaped bus direction. The inner side of the main body is provided with a pair of worm-gear mechanisms used for exerting an acting force on the cone-shaped collet chuck along the axial direction of the main body. A worm wheel in the worm-gear mechanism is coaxially arranged on the main body; the left end thereof is matched with the main body by the thread; the right end is matched with the left end of the cone-shaped collet chuck by the thread; and the thread directions of the left and right ends are reverse.

Owner:JIAXING YONGJIA PRECISION MASCH MFG CO LTD

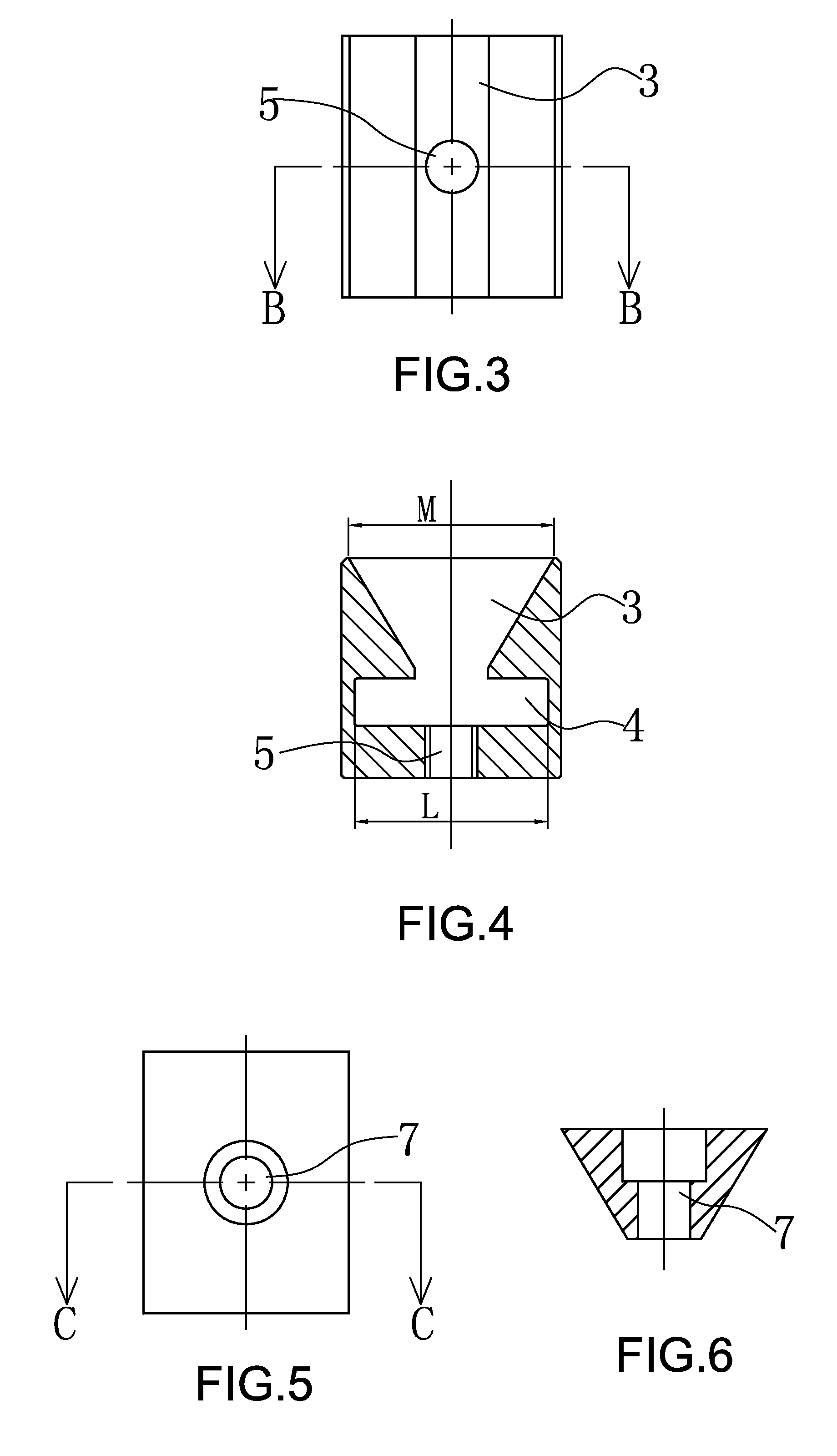

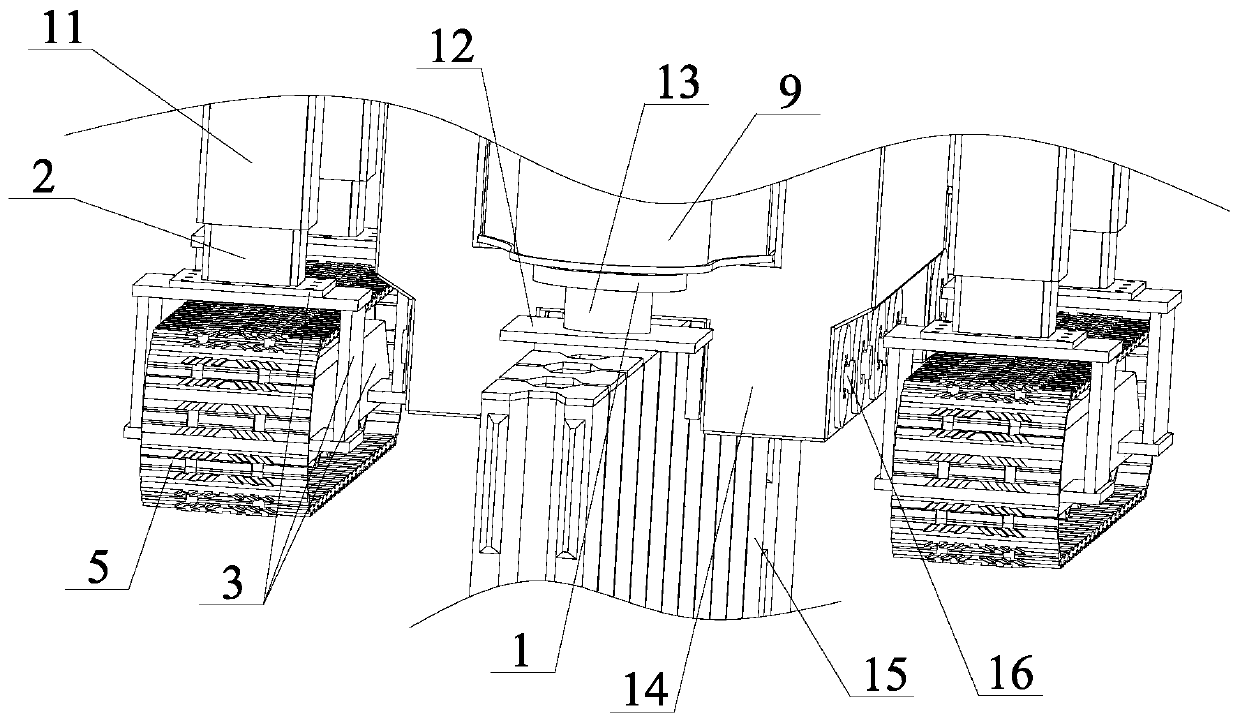

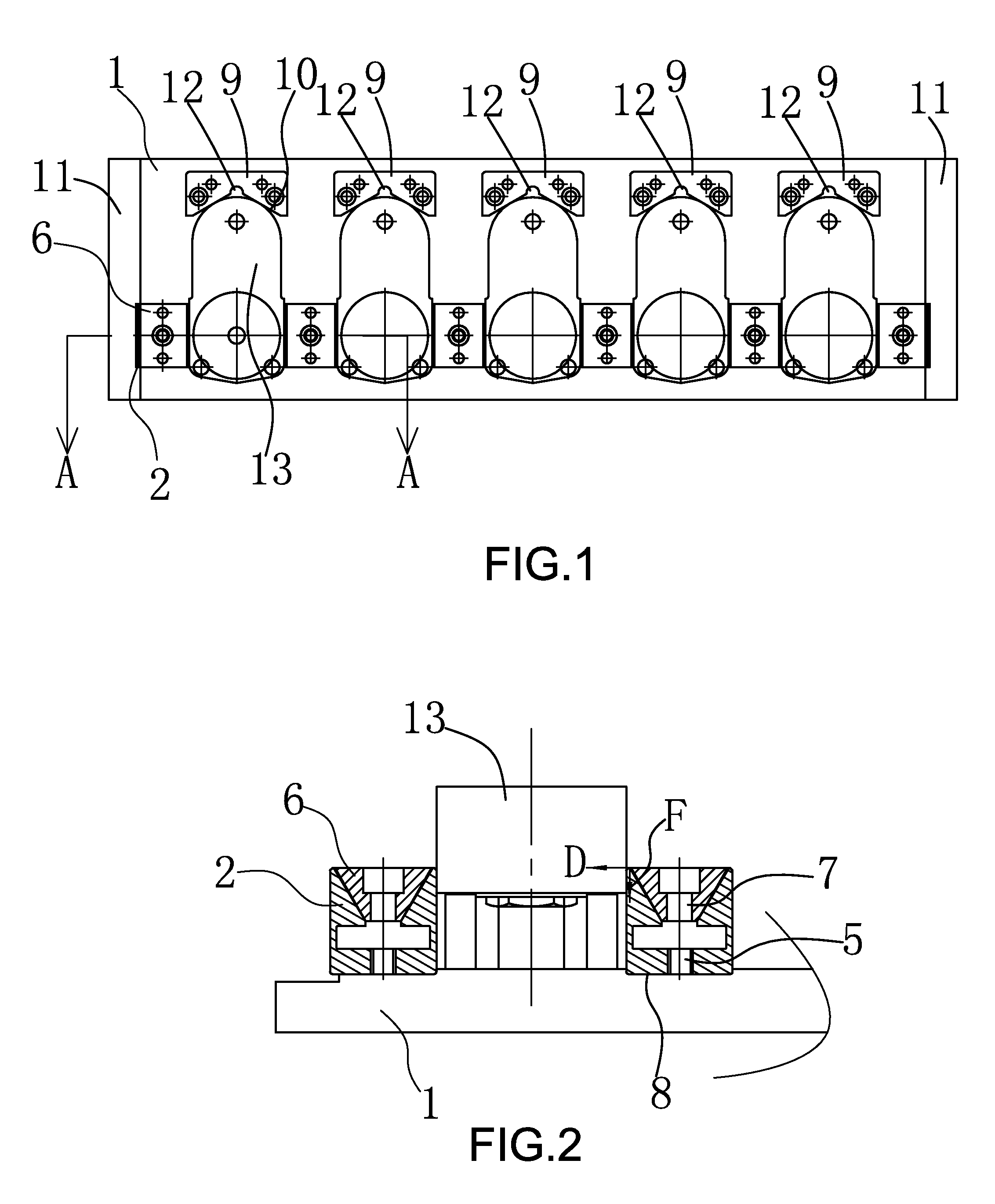

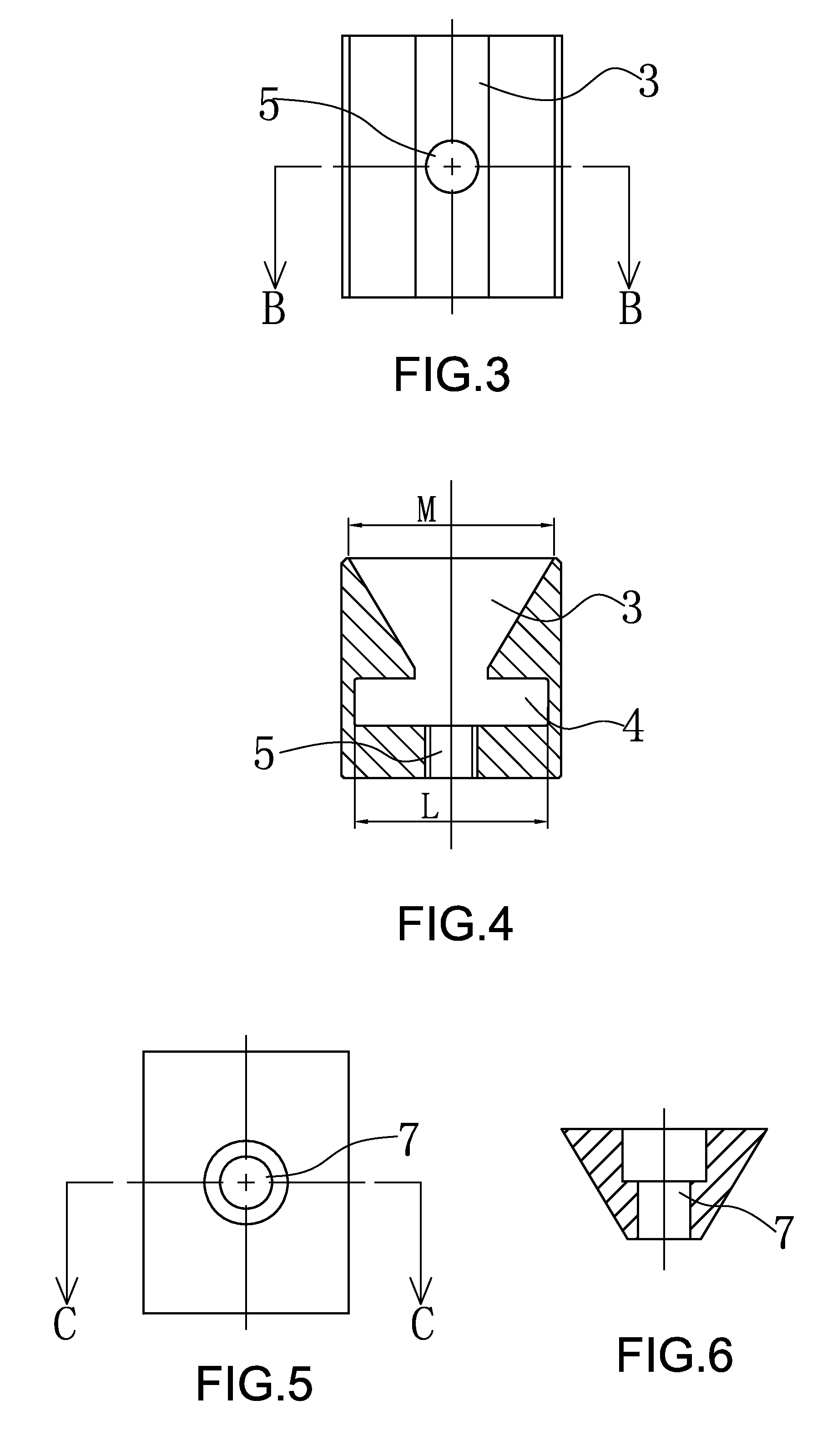

Tool for Clamping Using Sides of Workpieces

InactiveUS20140077433A1Reliable clampingEasy to fixSemiconductor/solid-state device manufacturingDrawing boardsEngineering

The invention relates to a tool for clamping using sides of workpieces, in particular to a tool for clamping and processing workpieces like boxes using sides of the box workpieces, belonging to the technical field of tools for clamping used in the processing center to process workpieces. The tool for clamping using sides of workpieces comprises a soleplate, wherein one side of the soleplate is fixed with multiple elastic seats arranged at interval, the elastic seats are provided with vertical V-shaped grooves, the bottom of each vertical V-shaped groove is provided with a rectangle groove, the bottom of the rectangle groove is provided with a threaded hole, a V-shaped pressing block is fitted in the vertical V-shaped groove, a through hole which is coaxial with the threaded hole on the bottom of the rectangle groove is formed on the V-shaped pressing block, and a bolt passes through the through hole on the V-shaped pressing block to fit with the threaded hole on the bottom of the rectangle groove; and, the other side of the soleplate opposite to the elastic seats is provided with multiple V-shaped locating blocks arranged at interval, the gap between each two adjacent elastic seats corresponds to one V-shaped locating block, and each V-shaped locating block is provided with a horizontal V-shaped groove, the opening of which faces the gap between two adjacent elastic seats.

Owner:ZHEJIANG LINIX MOTOR

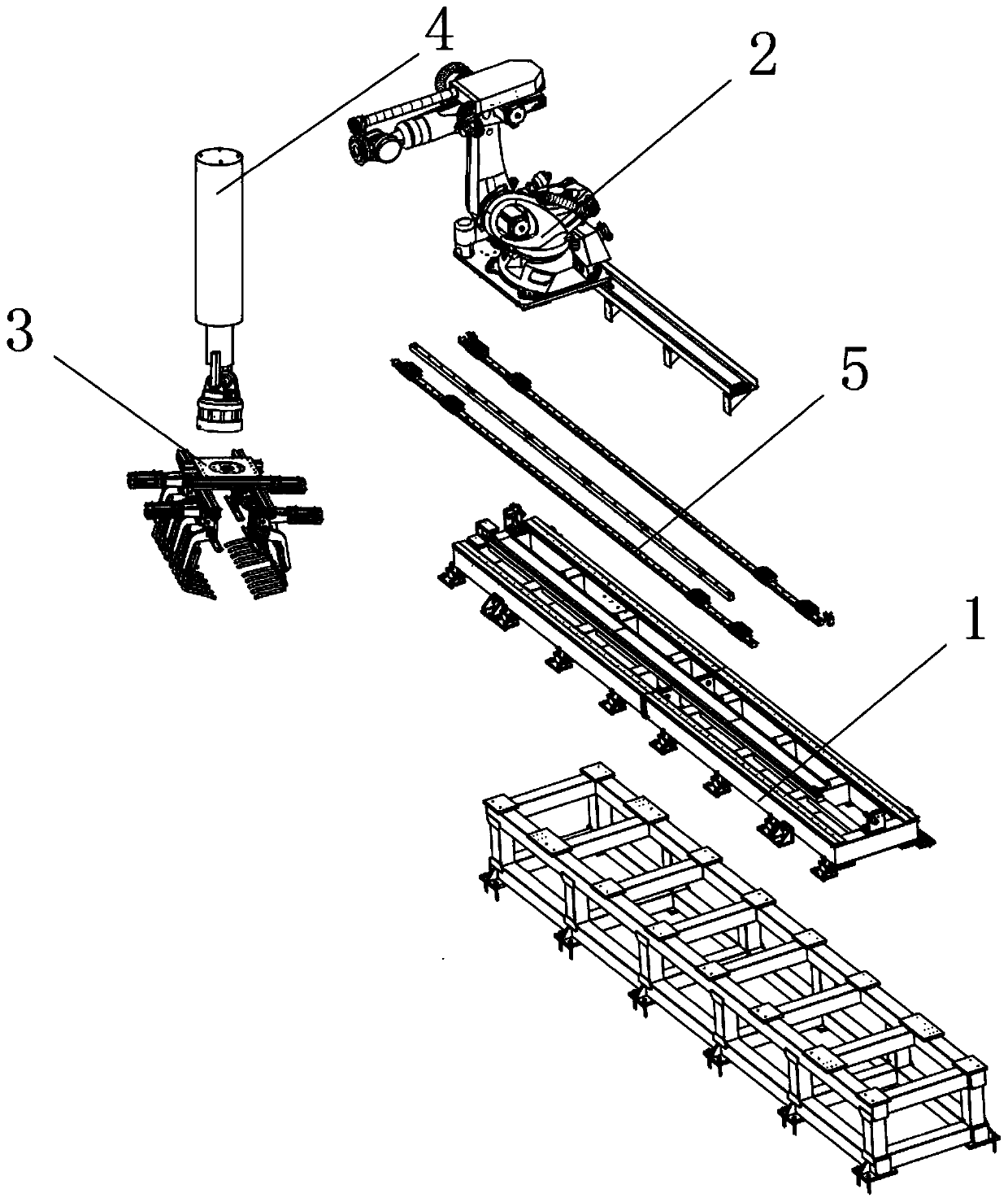

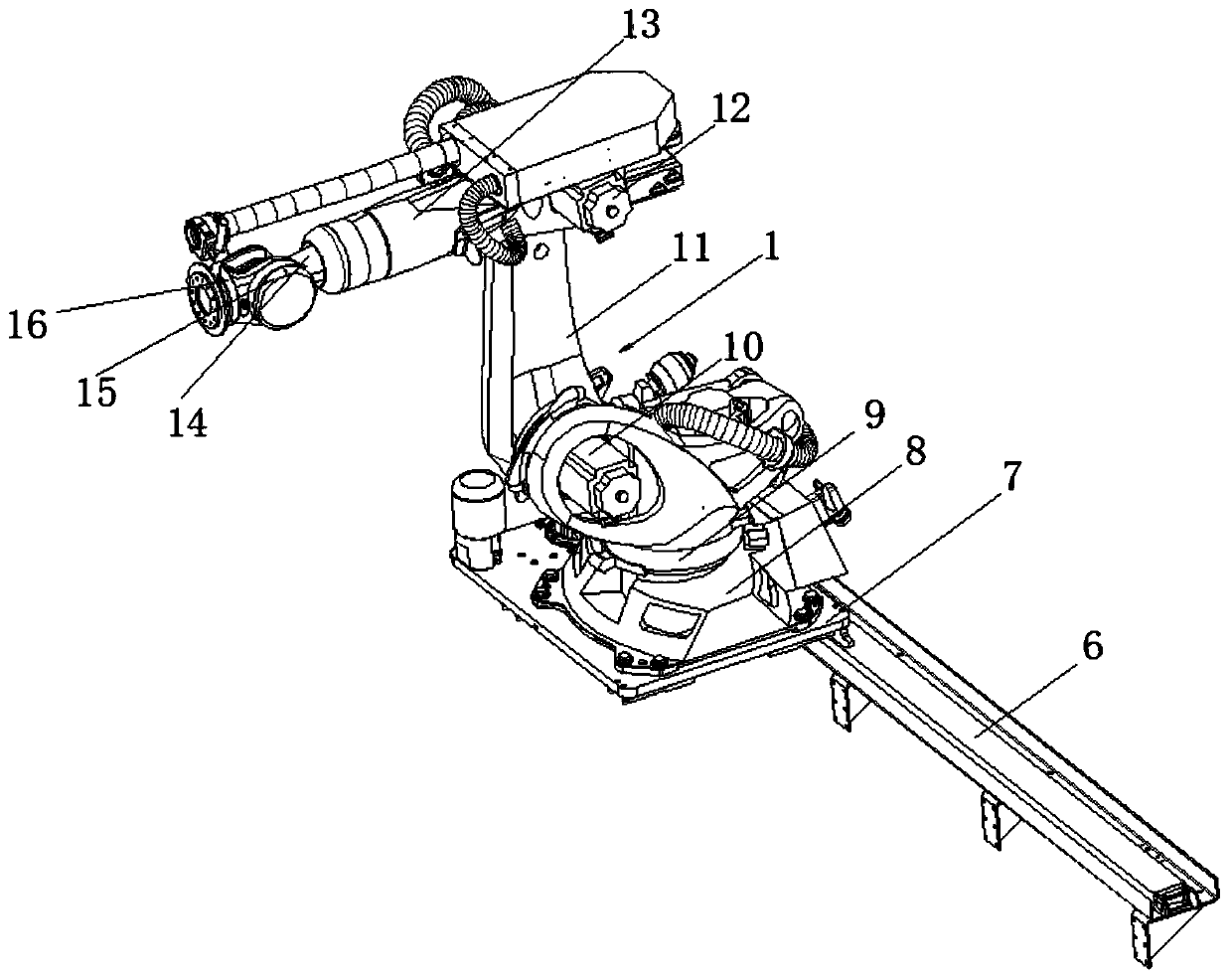

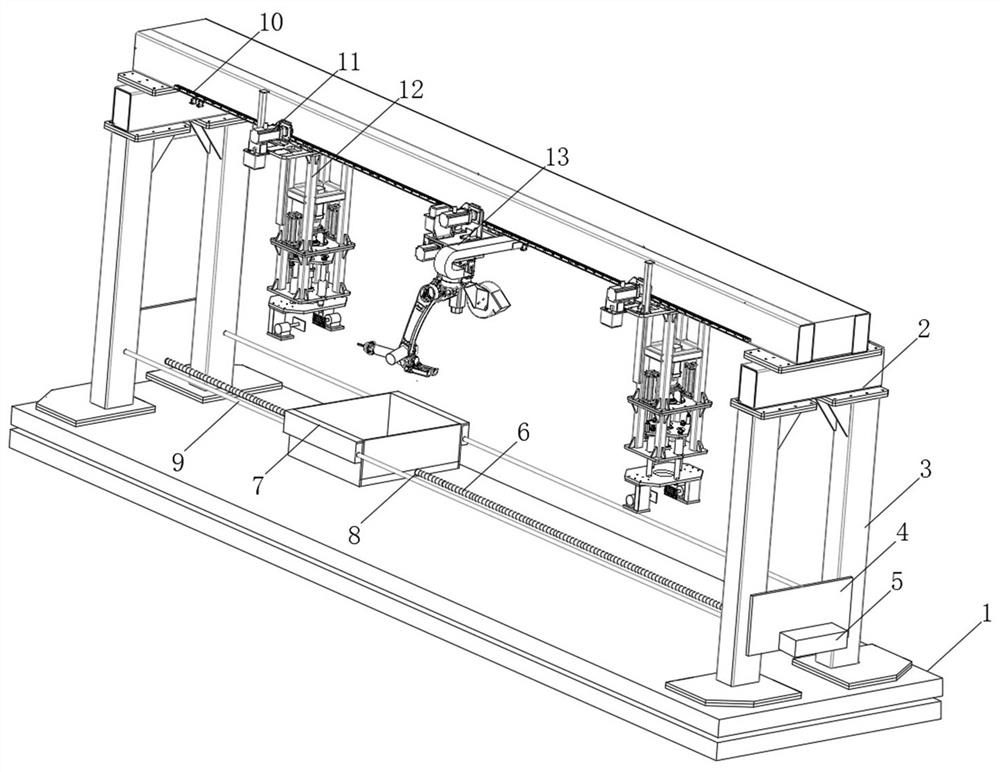

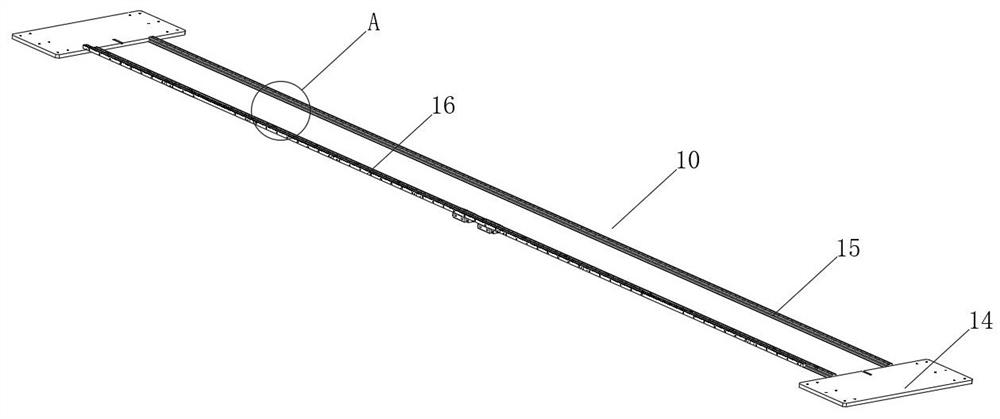

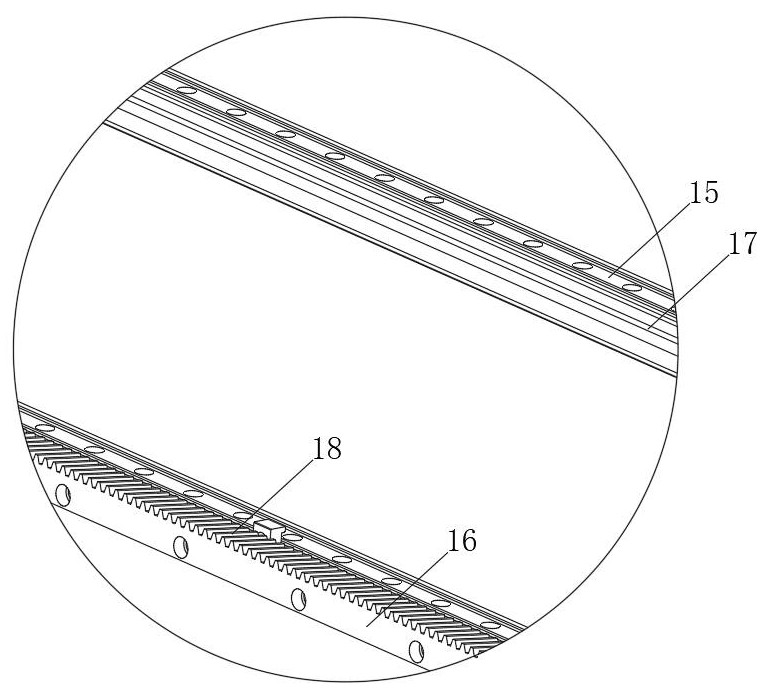

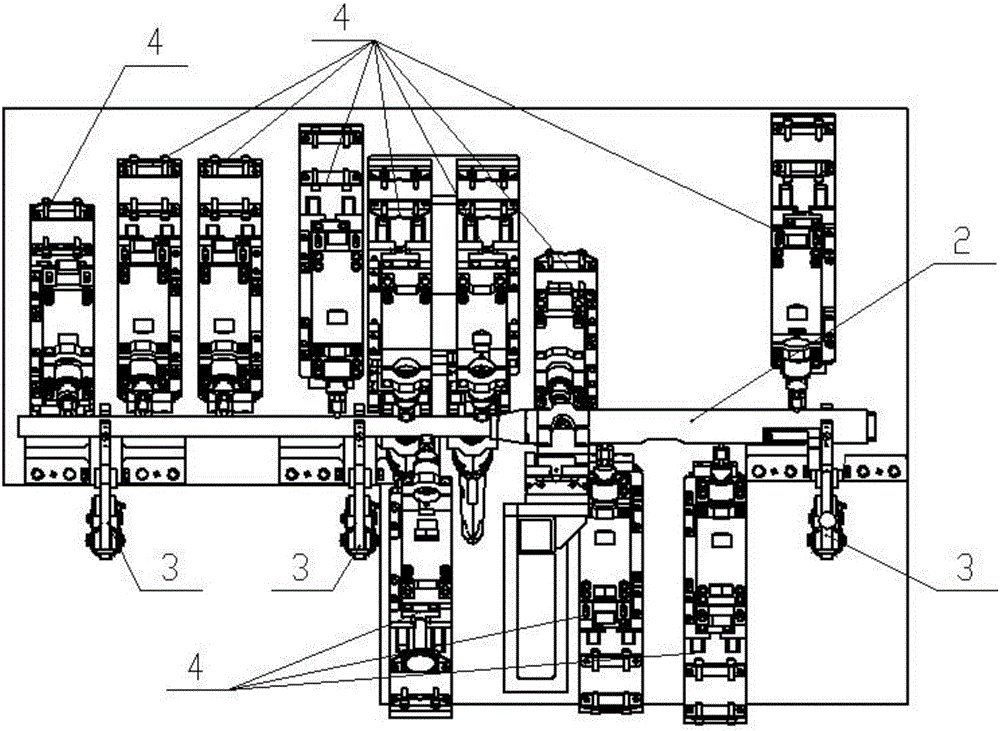

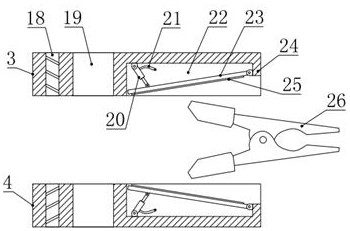

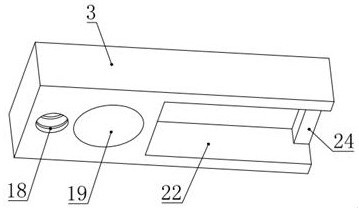

Automatic grafting device

The invention belongs to the technical field of agricultural machinery, and relates to an automatic grafting device. The automatic grafting device includes a stock clamping and transporting mechanicalarm, a scion clamping and transporting mechanical arm, a seedling cutting device, an automatic clip providing device, a rack and a grafting-clip automatic arranging and transporting device; the seedling cutting device and the automatic clip providing device are correspondingly arranged at the front and middle of the rack respectively; the stock clamping and transporting mechanical arm and the scion clamping and transporting mechanical arm are correspondingly arranged at the left and right sides of the rack respectively; the grafting-clip automatic arranging and transporting device is arrangedon the rear of the rack and is used for sequentially transporting grafting clips to the automatic clip providing device. The automatic grafting device is simple in structure, high in grafting speed and precision, and reliable and convenient in seedling providing, seedling clamping damage is reduced, regarding stock and scion seedlings, not only seedling providing positioning but also seedling cutting pivoting can be achieved, shifting the seedlings into the clips during grafting can also be achieved, and transporting and clamping of the grafting clips are reliable.

Owner:张铁中

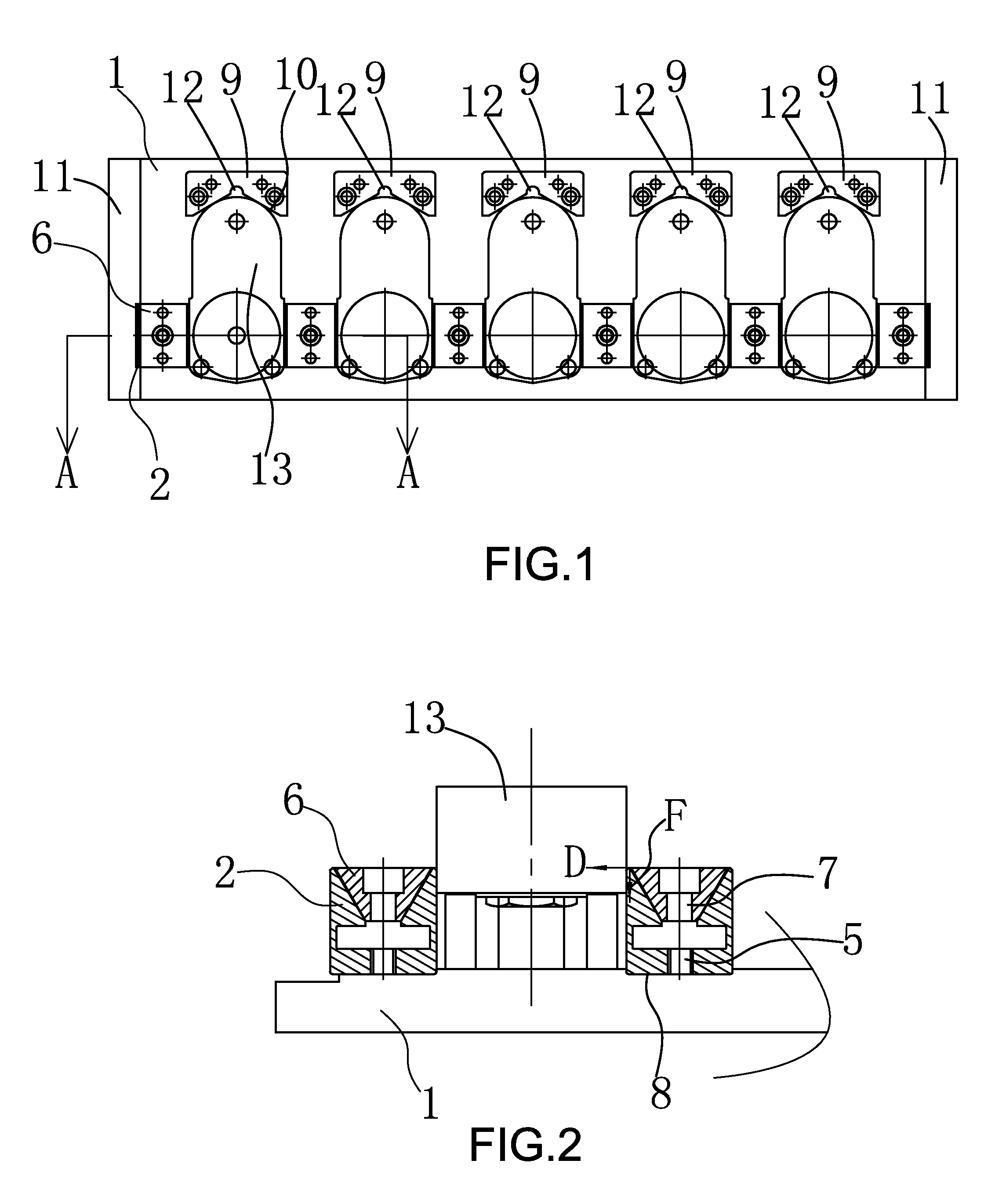

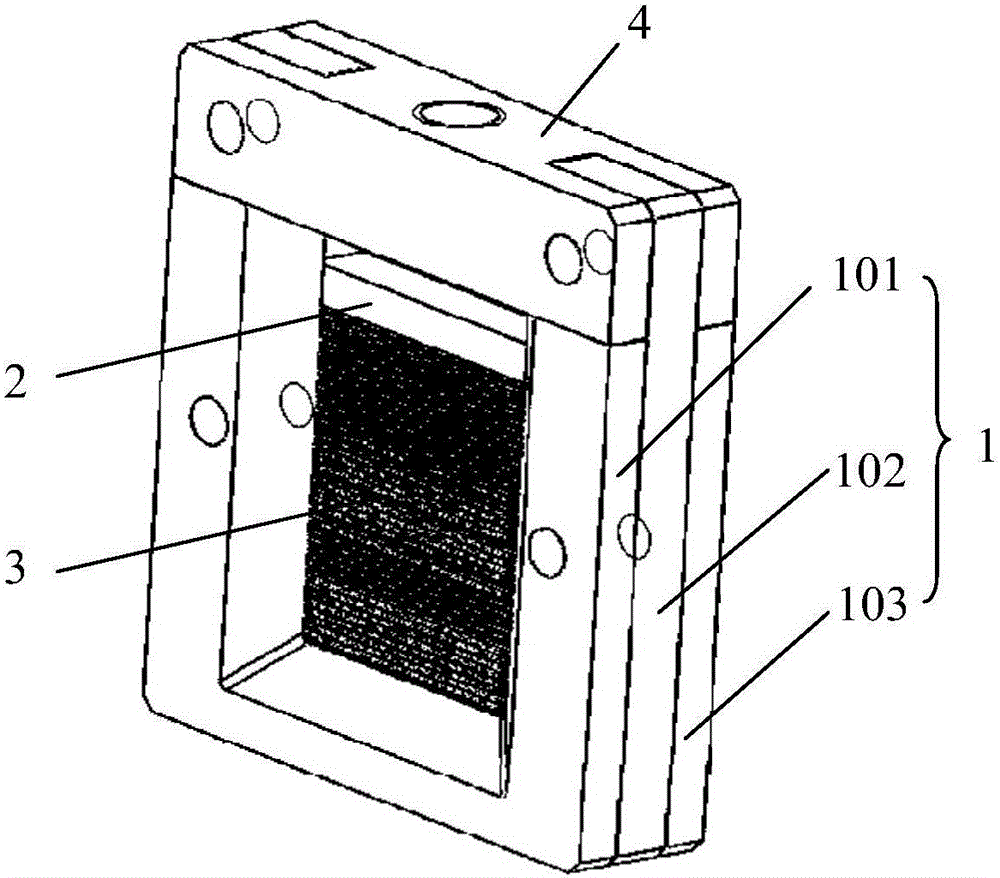

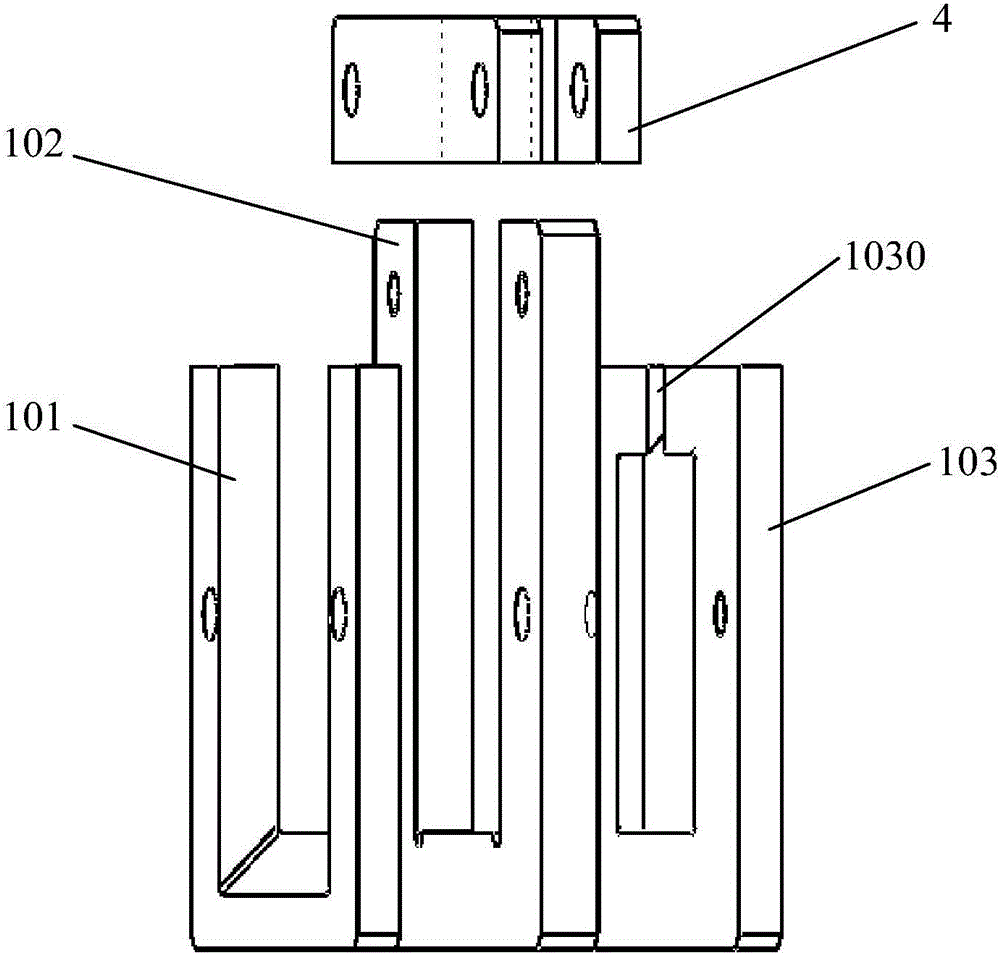

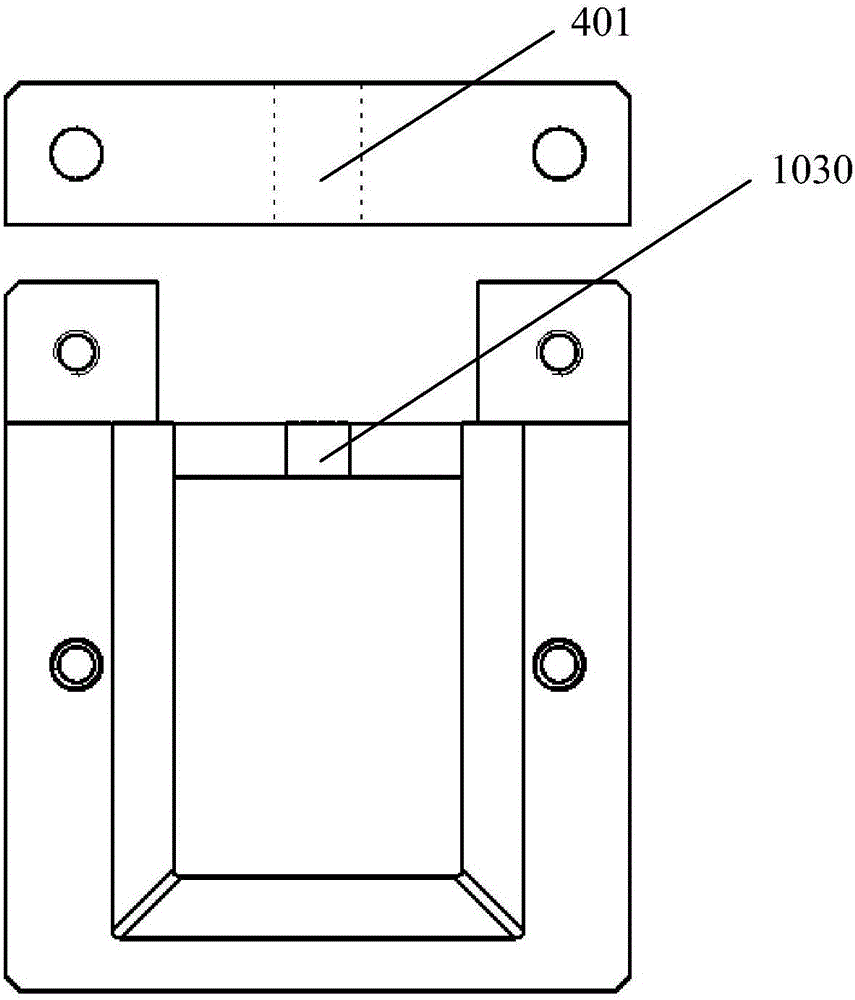

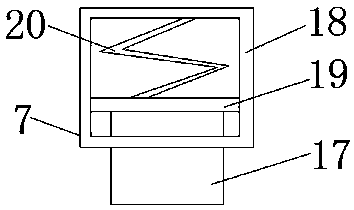

Facet film-plating clamp for semiconductor laser chip

InactiveCN106025789AEasy to processHigh precisionLaser detailsSemiconductor lasersEngineeringMechanical engineering

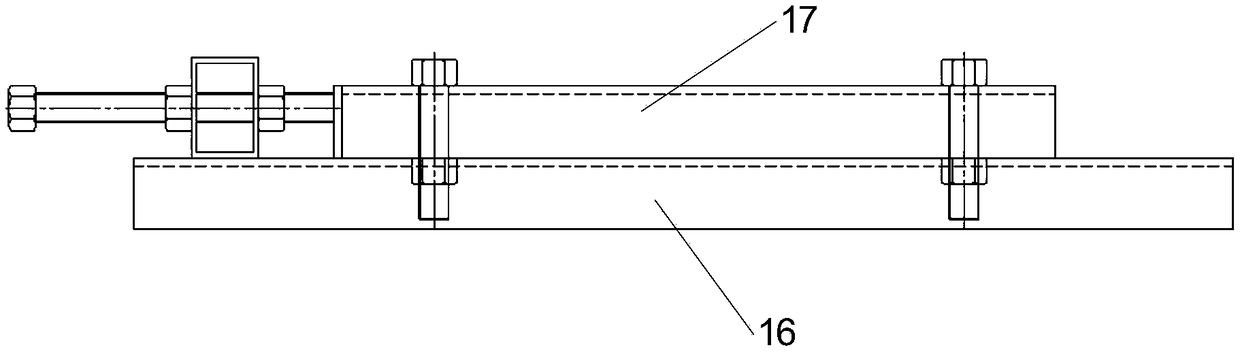

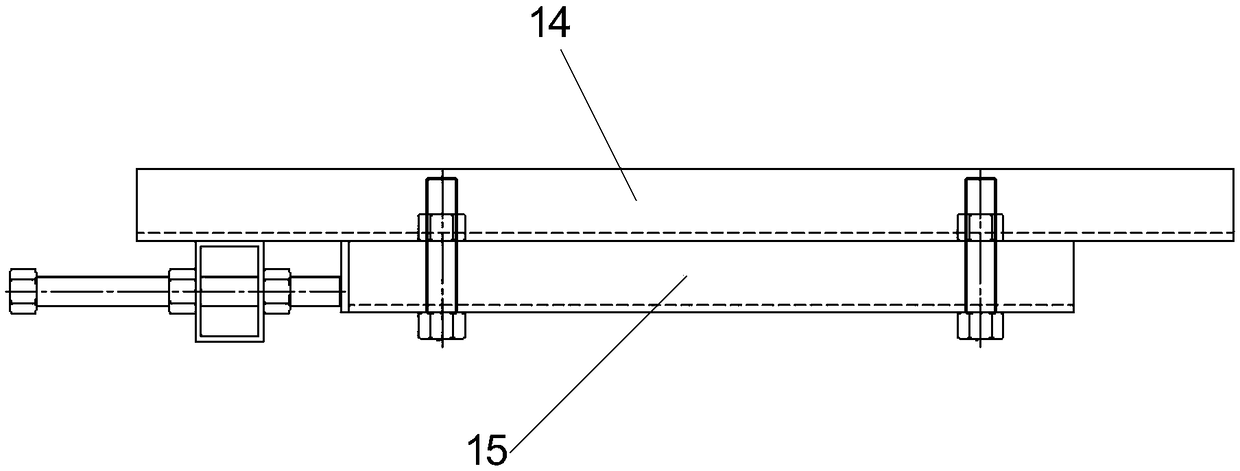

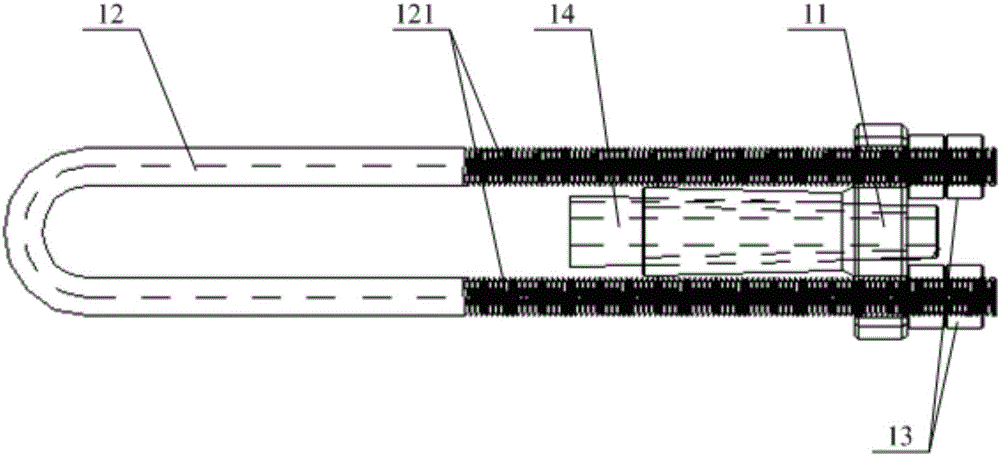

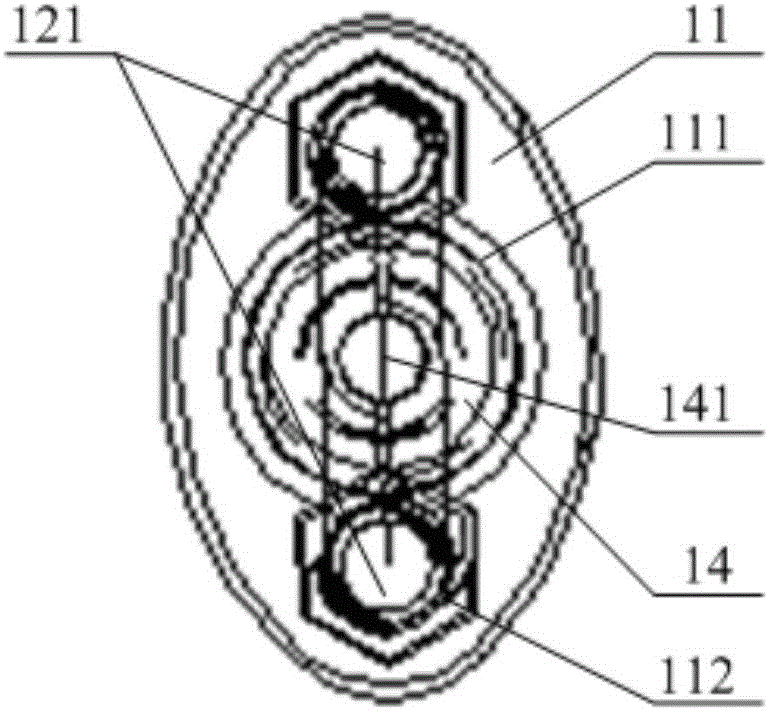

The invention provides a novel facet film-plating clamp for a semiconductor laser chip. The clamp has advantages of stable clamping, simple structure, convenient operation, and easy processing; and film plating can be carried out products in batches and the plated film quality can be improved effectively. The clamp comprises a flat-panel U-shaped frame assembly and a choke plug assembly arranged at a U-shaped opening end; and a plurality of bars are stacked successively from a U-shaped closing end to the U-shaped opening end in a planar closing area encircled by the flat-panel U-shaped frame assembly and the choke plug assembly. The inner side width of a U-shaped middle plate of the flat-panel U-shaped frame assembly is larger than inner side widths of a lower plate and a U-shaped upper plate, so that side cavity parts at the two ends of the multiple bars are supported on a rail surface reserved by the lower plate, are pressed and covered by a rail surface reserved by the U-shaped upper plate, and are limited by the U-shaped middle plate in a horizontal direction. The choke plug assembly applies tightening pressures on the multiple bars from the U-shaped opening end to the U-shaped closing end.

Owner:XIAN LIXIN PHOTOELECTRIC SCI & TECH

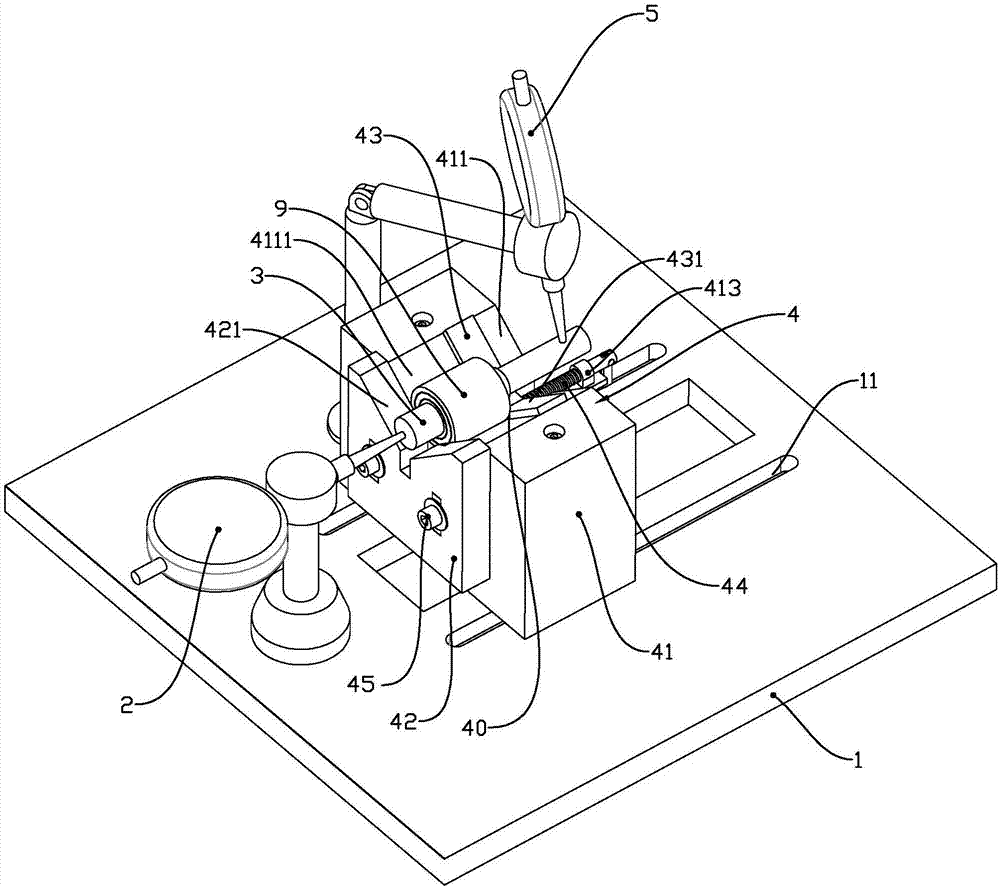

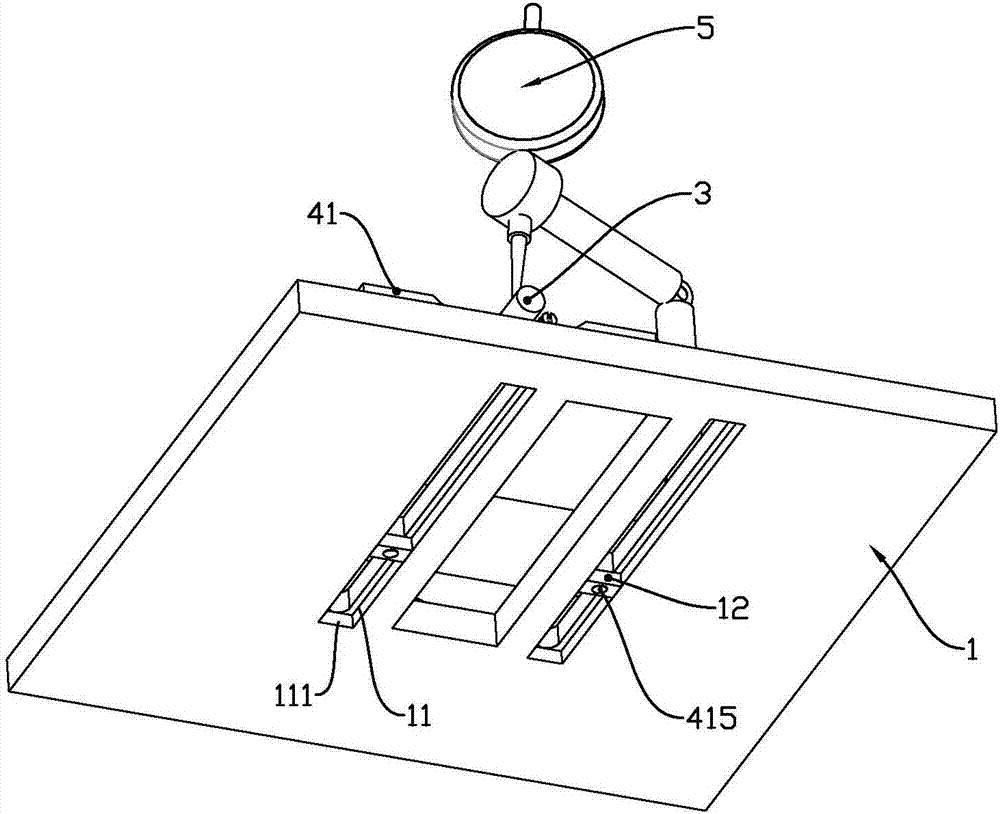

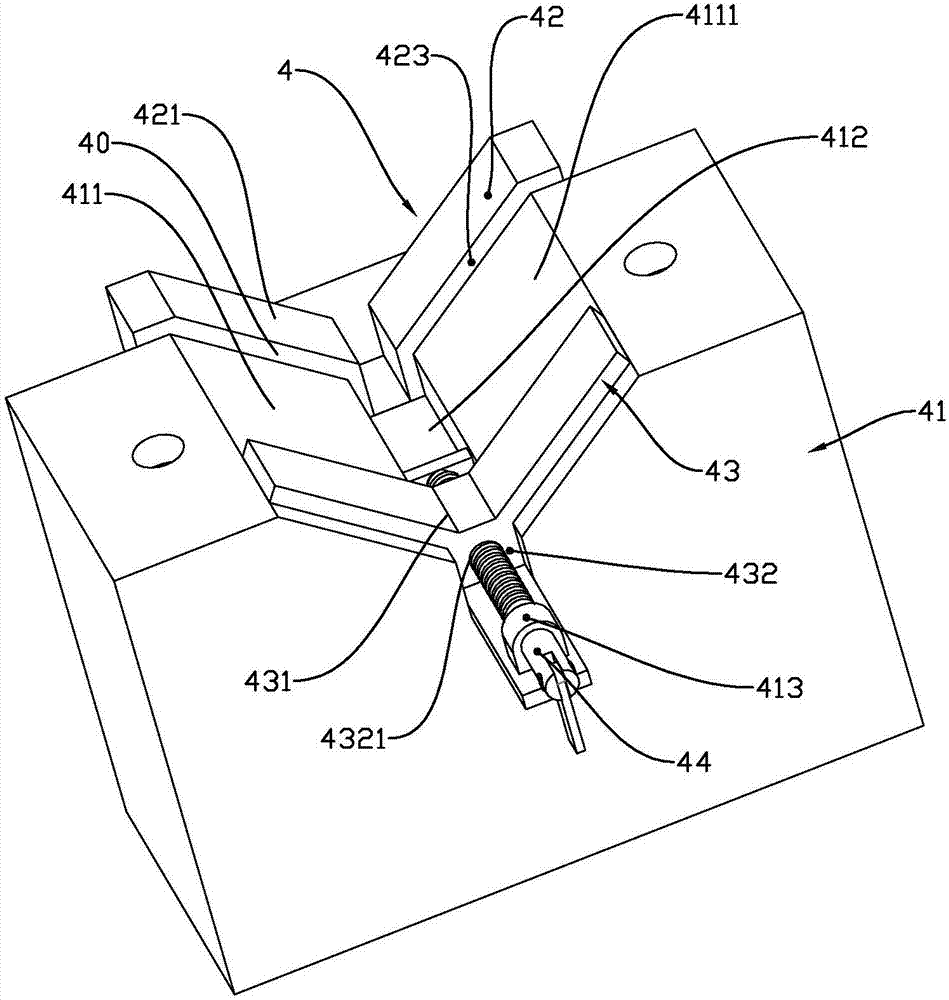

Bearing clearance detector

ActiveCN106907980AReasonable structural designEasy clampingMechanical clearance measurementsMechanical engineering

The invention relates to a bearing clearance detector comprising a substrate, an axial clearance detection meter, a mandrel and a bearing fixing tool, wherein a meter head of the axial clearance detection meter is in an abutting fit relation with an axial end of the mandrel, the bearing fixing tool comprises a support seat fixed on the substrate, a clamping mechanism used for firmly fixing an outer ring of a bearing to be detected is arranged on the support seat, a top part of the support seat is provided with a V-shaped groove, the clamping mechanism comprises a first clamping block and a second clamping block that are arranged along a length direction of the V-shaped groove at an interval, a clamping cavity used for axially clamping the outer ring of the bearing to be detected is formed in the interval between the first clamping block and the second clamping block, the V-shaped groove is at least partially positioned in the clamping cavity and forms a V-shaped positioning groove body, and each of top parts of the first clamping block and the second clamping block is provided with a V-shaped opening; an angle clearance detection meter is correspondingly matched on the other end of the mandrel of which one end is matched with the axial clearance detection meter, and a meter head of the angle clearance detection meter is in the abutting fit relation with a circumferential surface of the mandrel. The bearing clearance detector is reasonable in structure design, and the bearing to be detected is convenient to install, clamp and dismount.

Owner:C&U CO LTD +1

Robot part processing clamp with multi-angle fixing function

InactiveCN110065048AEasy to processThe processing position is accurateProgramme-controlled manipulatorGripping headsMotor driveIndustrial engineering

The invention discloses a robot part processing clamp with a multi-angle fixing function. The robot part processing clamp comprises an installing platform, a movable disc and a clamping seat, the movable disc is arranged above the installing platform, the clamping seat is arranged below one end of the movable disc, and a bottom support plate is horizontally arranged below the movable disc. The robot part processing clamp has the beneficial effects that robot parts are clamped and fixed through a plurality of equally-spaced clamping jaws, it is ensured that the robot parts can be processed by aprocessing instrument more conveniently, efficiently and stably; a transferring and connecting seat drives the clamping seat to move front and back on the installing platform to adjust the position,on one hand, the position of processing of the robot parts by the processing instrument is more precise and adjustable, on the other hand, it is ensured that after the robot parts are processed, and the robot parts can be quickly and conveniently transferred and put to the specific position to be arranged; and a first motor drives the clamping seat to rotate by 360 degrees to ensure that the moving, transferring and putting efficiency of the robot parts is high and the scope is wider.

Owner:XUZHOU COLLEGE OF INDAL TECH

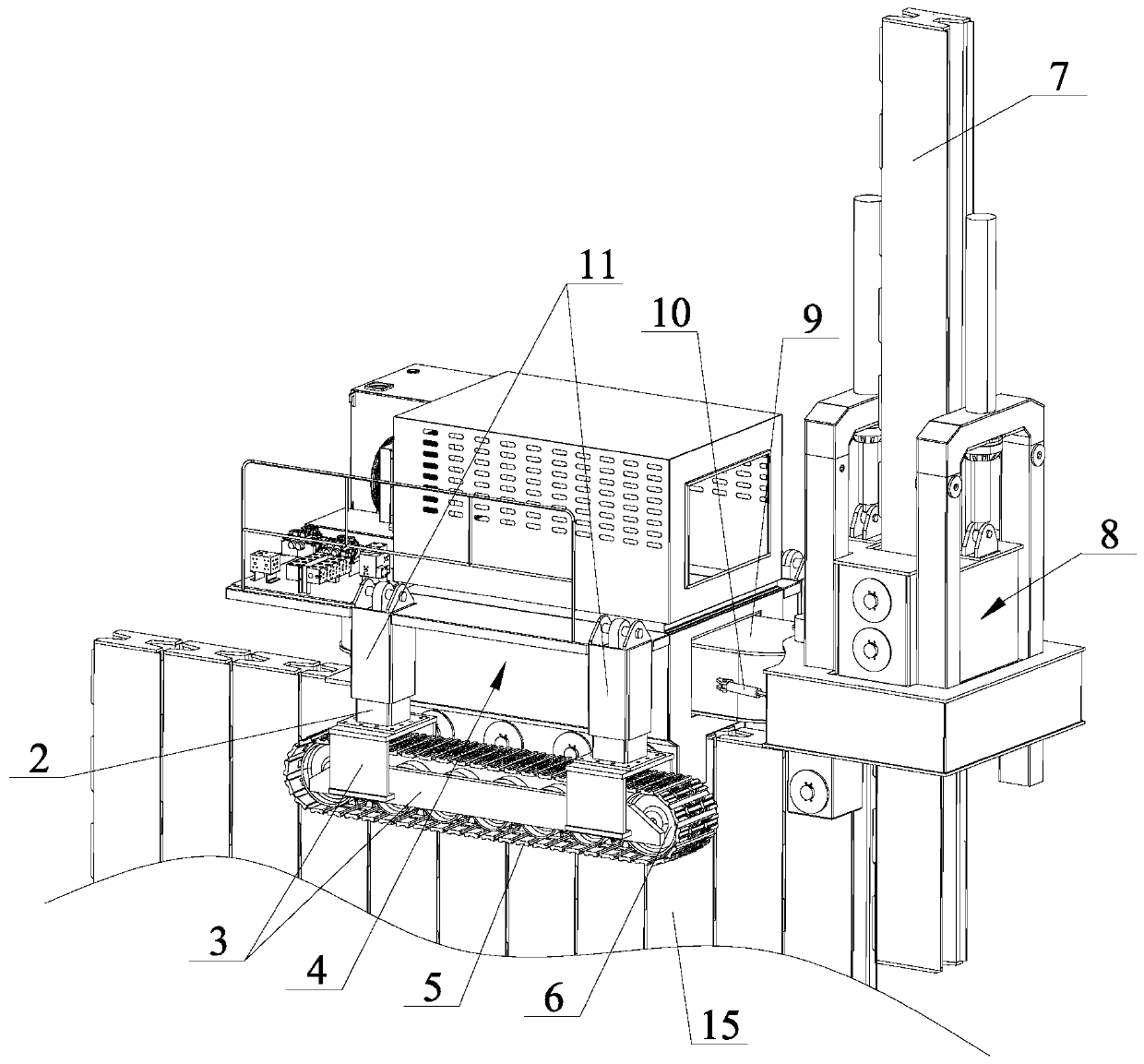

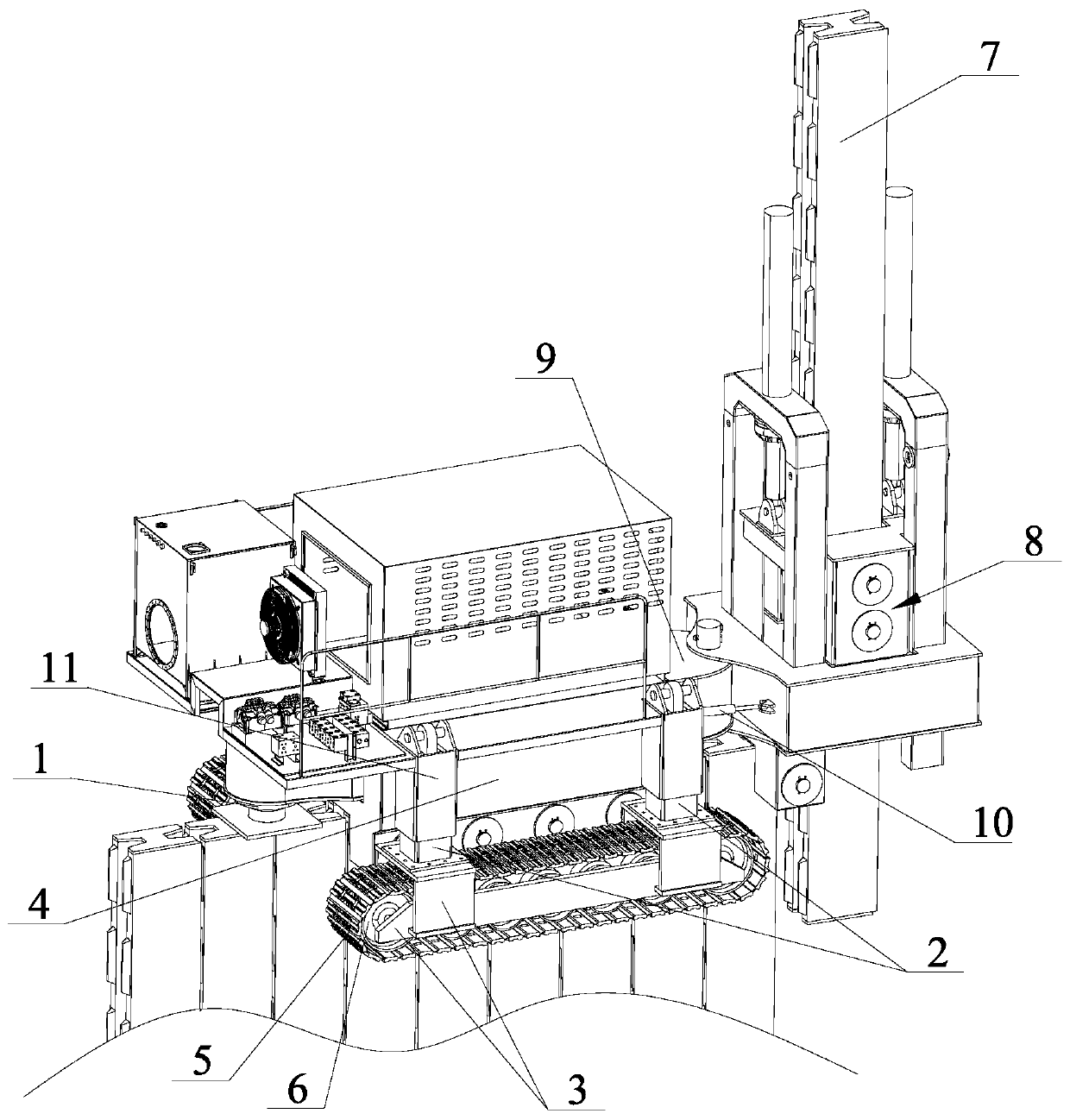

Pile pressing equipment

PendingCN110424389AQuality improvementFlexible and convenient horizontal turningBulkheads/pilesArchitectural engineeringDrilling machines

The invention discloses pile pressing equipment. The equipment comprises a base, first clamping mechanisms fixed to the two sides of the bottom of the base correspondingly, a first lifting oil cylinder fixed to the rear end of the base, a guide rail closed into a middle hole of the base in a sliding sleeving mode, and a horizontal moving oil cylinder which is arranged on the guide rail and the base and used for moving the base or the guide rail front and back. The equipment further comprises a pile pressing device arranged at the front end of the guide rail, and second clamping mechanisms arearranged on the two sides of the bottom of the pile pressing device. The equipment further comprises a crawler device and a lifting device which enable the base and the pile pressing device to be placed at the top of a planted pile. The front end of the guide rail is in the shape of an arc, the rear end of the pile pressing device is hinged to the front end of the guide rail, and turning oil cylinders used for enabling the pile pressing device to turn horizontally are arranged on the two sides of the front end of the guide rail; fixing blocks used for fixing lifting oil cylinders are hinged tothe rear end of the guide rail; and a rotary drilling machine is mounted on the pile pressing device. The pile pressing equipment can travel to the top end of the planted pile and is positioned or moved, and in addition, the pile pressing device can horizontally turn.

Owner:浙江万坚建设有限公司

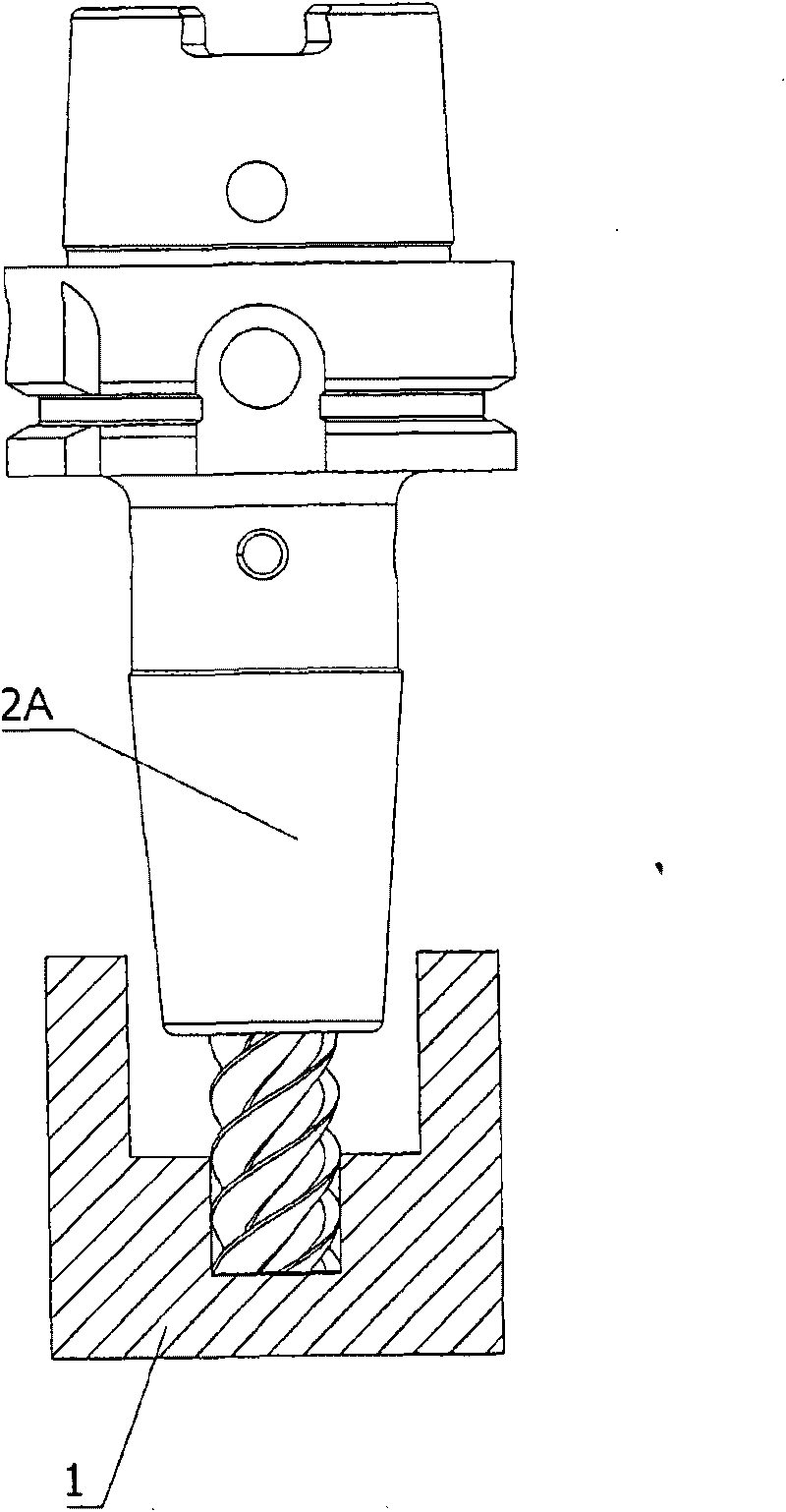

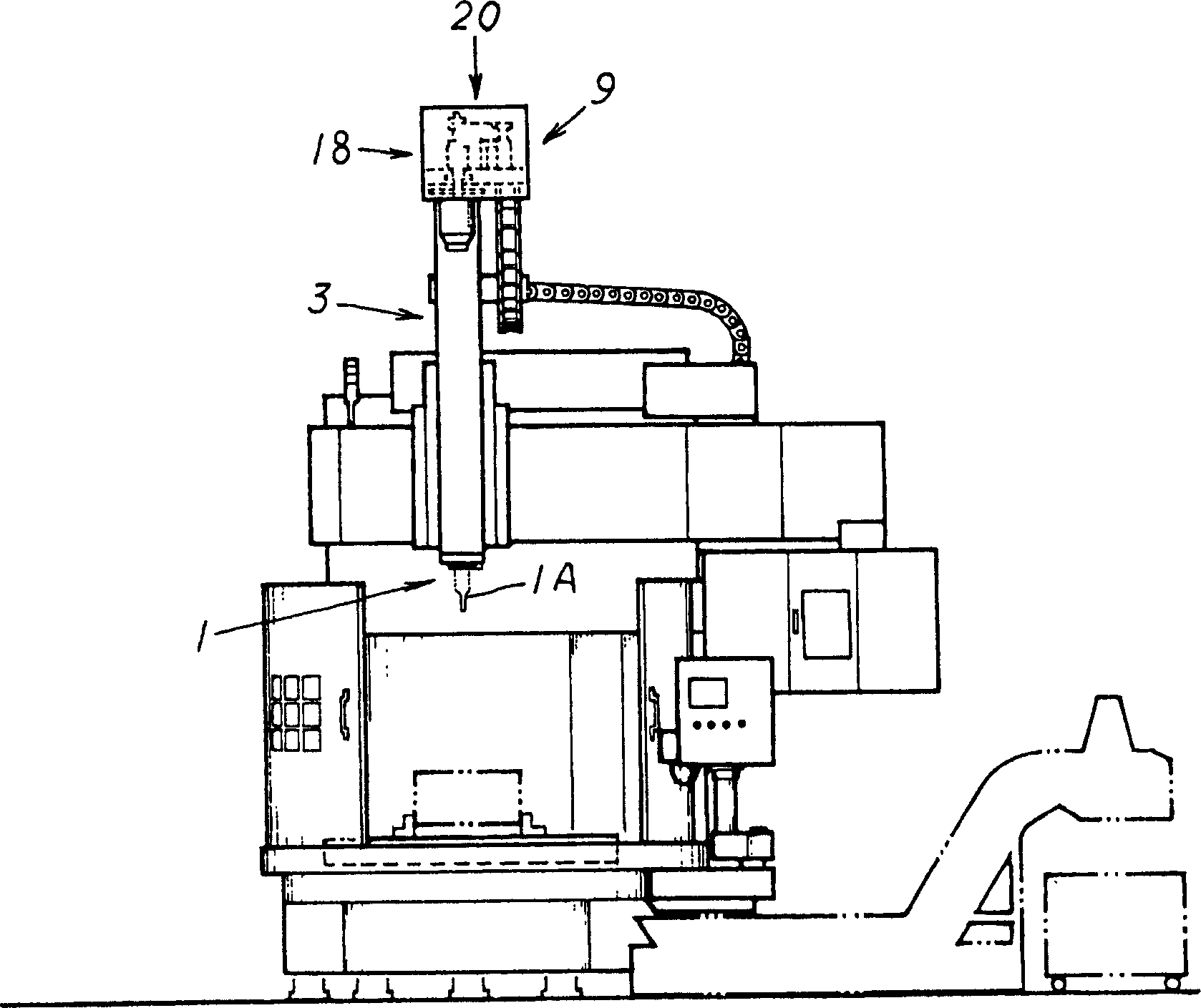

Tool mounting device for turning center

InactiveCN1824441ASave resourcesFully withstand heavy loadsLathesTool holdersEngineeringElectrical and Electronics engineering

Owner:OM MFG CO LTD

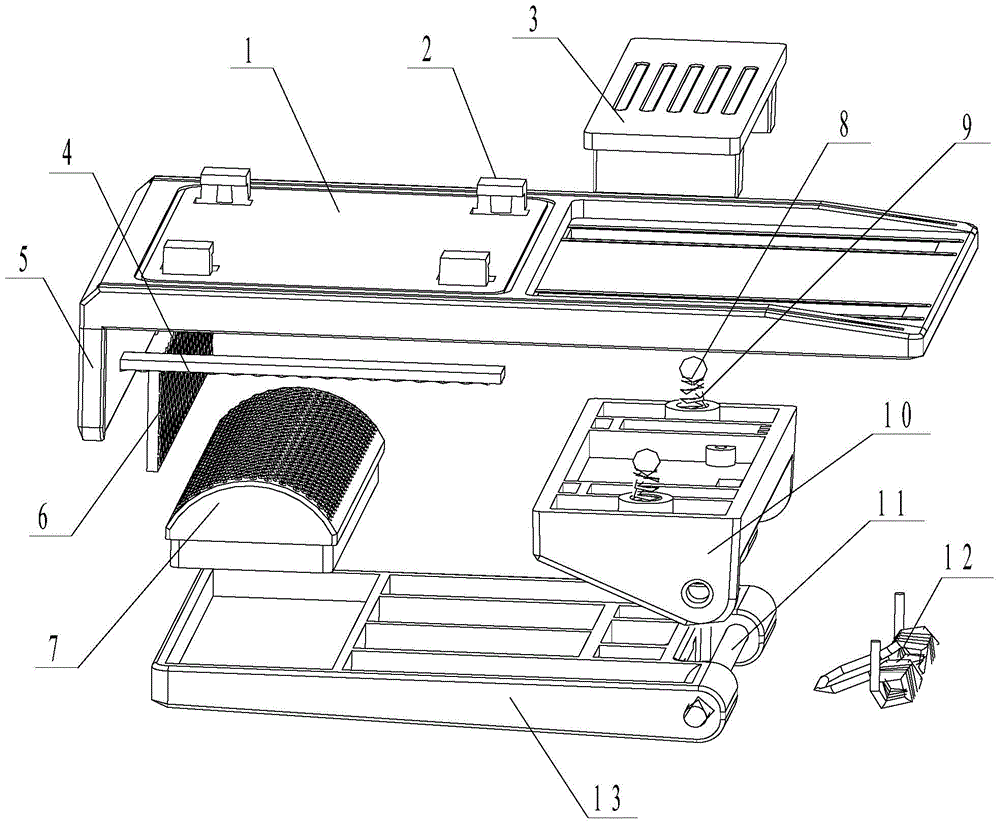

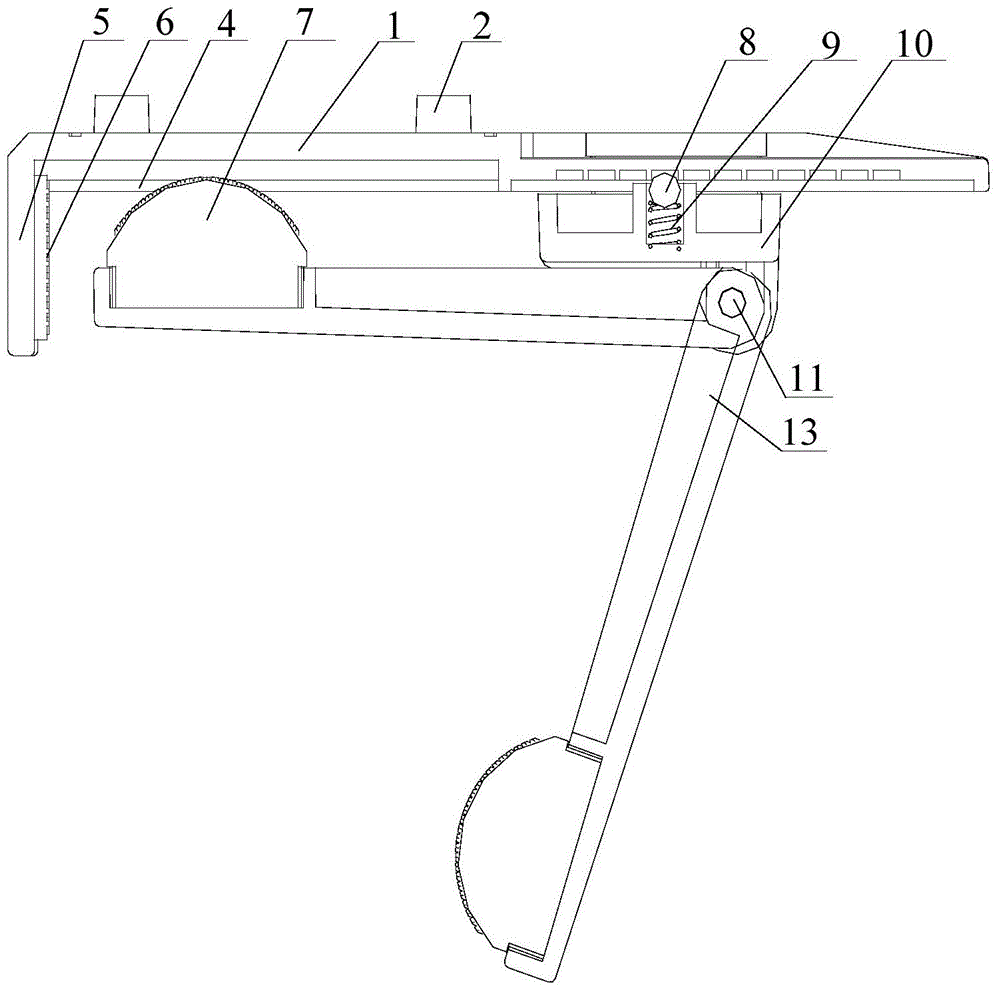

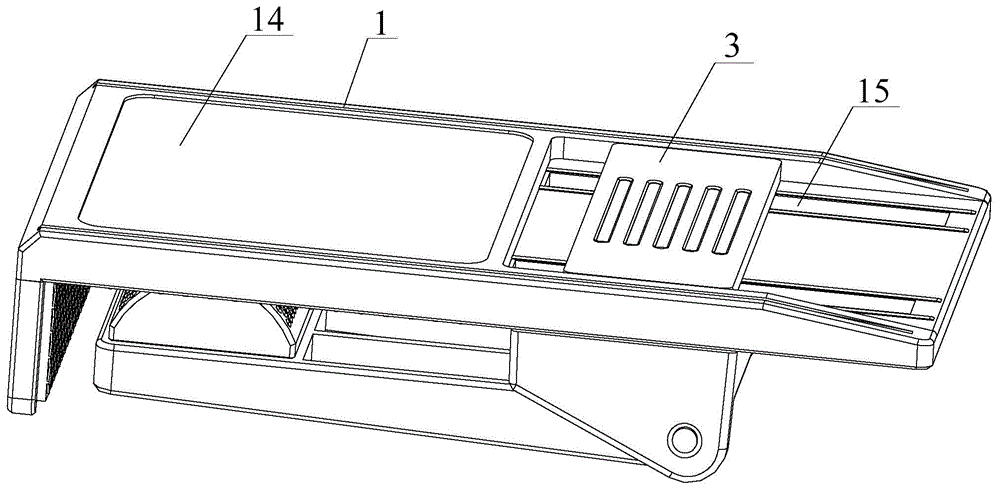

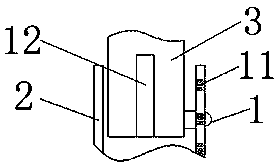

Machine box support

The invention discloses a machine box support. The machine box support is characterized by comprising a supporting plate (1), an adjustment base (10) and a clamping plate (13), the adjustment base (10) is connected to the lower surface of the supporting plate (1) and can move leftwards and rightwards along the supporting plate (1), the clamping plate (13) is connected to the adjustment base (10) through a rotating shaft (11), a tornsional spring (12) matched with the clamping plate (13) is arranged on the rotating shaft (11), and the clamping plate (13) can be clamped on the supporting plate (1) through the torsional spring (12). The support is simple in structure and low in cost, various traditional interwoven power lines are replaced, a traditional wall-mounted installation mode that holes are drilled in a wall is replaced, the problems that a machine box is complex to install and use and is not attractive in appearance is solved, the integrity of home decoration is kept, space can be saved, and the machine box support is suitable for application and popularization.

Owner:SICHUAN JINWANGTONG ELECTRONICS SCI & TECH

Ramie peeling device and feeding mechanism thereof

PendingCN109355712AReliable clamping and fixingAvoid the phenomenon of being directly exportedMechanical fibre separationEngineeringChain link

The invention discloses a ramie peeling device and a feeding mechanism thereof. The ramie peeling device comprises an upper clamping assembly and a lower clamping assembly, wherein the upper clampingassembly comprises an upper clamping chain and an upper driving mechanism for driving the upper clamping chain to move; the lower clamping assembly comprises a lower clamping chain and a lower drivingmechanism for driving the lower clamping chain to move; the upper clamping chain and the lower clamping chain are always in a parallel opposite clamping states on a conveying line corresponding to ramie; the upper clamping chain and the lower clamping chain have the same linear speeds on the conveying line; an elastic pressure bar is fixedly arranged on the clamping surface of the upper clampingchain; and a concave clamping plate matched with the elastic pressure bar is arranged on the clamping surface of each chain link of the lower clamping chain. The feeding mechanism transversely pressesthe ramie into the concave clamping plates through the elastic pressure bar, and then the ramie can be clamped and fixed more stably and reliably, so that the phenomenon of different cleanness degrees of peeling of the ramie in the same batch is avoided.

Owner:INST OF BAST FIBER CROPS CHINESE ACADEMY OF AGRI SCI

Cable clamp

InactiveCN106786276AImprove efficiency and operational effectivenessGuarantee the construction qualityOverhead installationTowersEngineeringMechanical engineering

The invention discloses a cable clamp, which comprises a base and a U-shaped adjusting part. The U-shaped adjusting part comprises two parallel rod bodies, the base is slidably arranged on the rod bodies in a sleeving mode in the axial direction, and locking devices matched with the base are arranged on the rod bodies; a clamping hole is formed in the middle of the base, the hole diameter of the clamping hole gradually reduces from the outer end portion to the inner end portion, a clamping block is inserted into the clamping hole, and a cable hole matched with a cable penetrates through the middle of the clamping block in the axial direction. The cable clamp is convenient to operate, high in efficiency and not prone to damaging cables.

Owner:STATE GRID ZHEJIANG YUYAO POWER SUPPLY +2

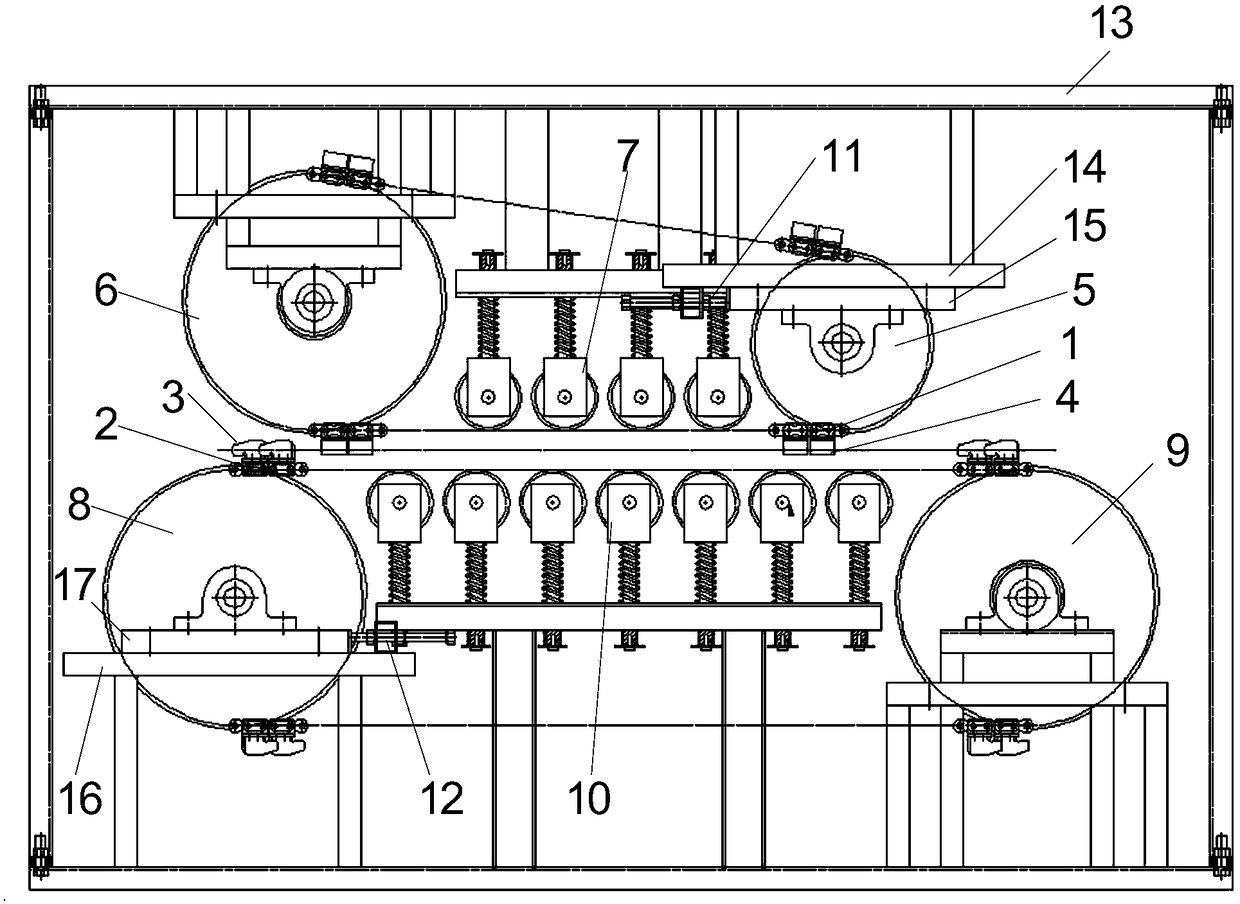

Noodle winding machine capable of winding noodles in shape of 8

ActiveCN113396947AStable and reliable around the surfaceWon't fallDough processingWinding machineReciprocating motion

The invention discloses a noodle winding machine capable of winding noodles in shape of 8. The noodle winding machine comprises a machine base, a horizontal reciprocating noodle feeding device and a wound noodle receiving device, wherein the transverse sliding base of the horizontal reciprocating noodle feeding device is driven by a reciprocating driving mechanism to carry out horizontal and transverse reciprocating motion; the axial direction of a hollow noodle feeding pipe on the transverse sliding base is perpendicular to the slippage direction of the transverse sliding base; the longitudinal sliding base of the wound noodle receiving device is driven by a longitudinal sliding driving mechanism to slide along the longitudinal direction; a noodle winding frame is arranged on the longitudinal sliding base and comprises a swinging base rotatably matched with the longitudinal sliding base; two noodle winding rods are arranged on the swinging base and extend along the longitudinal direction; and the swinging base is matched with a swinging driving mechanism. When the swinging base transversely swings, left and right swinging inclination angles are the same, the hollow noodle feeding pipe is correspondingly arranged on the rotating central axis of the swinging base, and the longitudinal sliding base has a noodle winding stroke forming relative displacement of a noodle outlet port of the hollow noodle feeding pipe from one end of the noodle winding rod to the other end of the noodle winding rod. The noodle winding machine is suitable for winding the coarse materials of the noodles in the shape of 8 and has the advantage of being stable and reliable in noodle winding.

Owner:ZHEJIANG IND & TRADE VACATIONAL COLLEGE

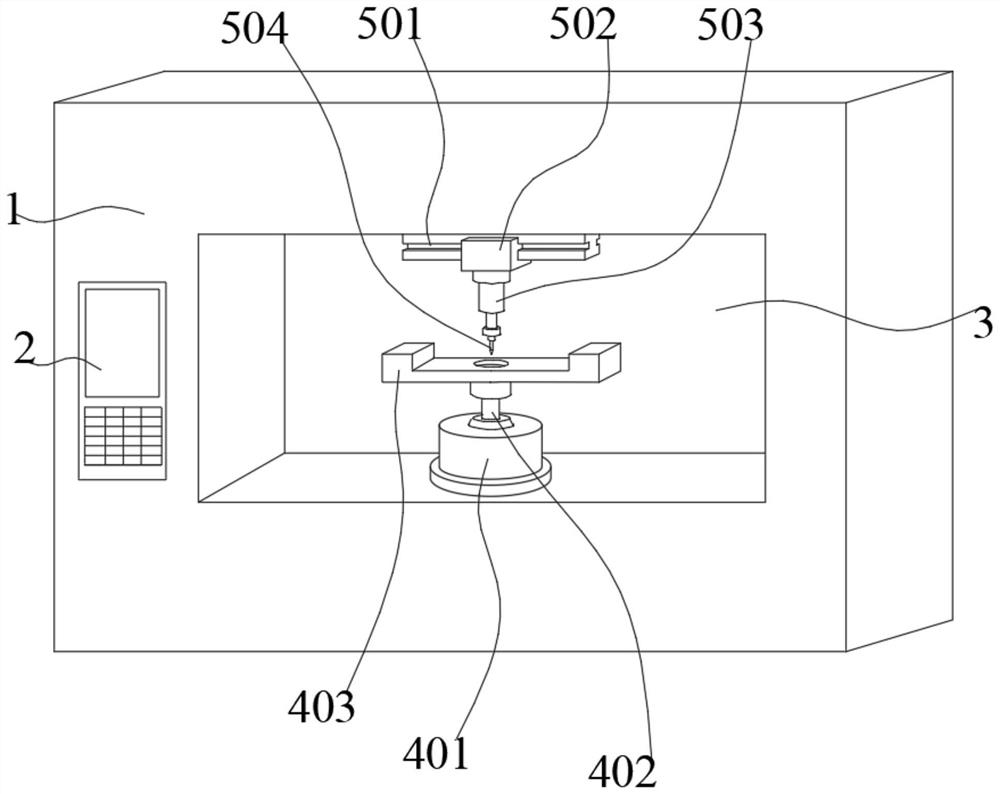

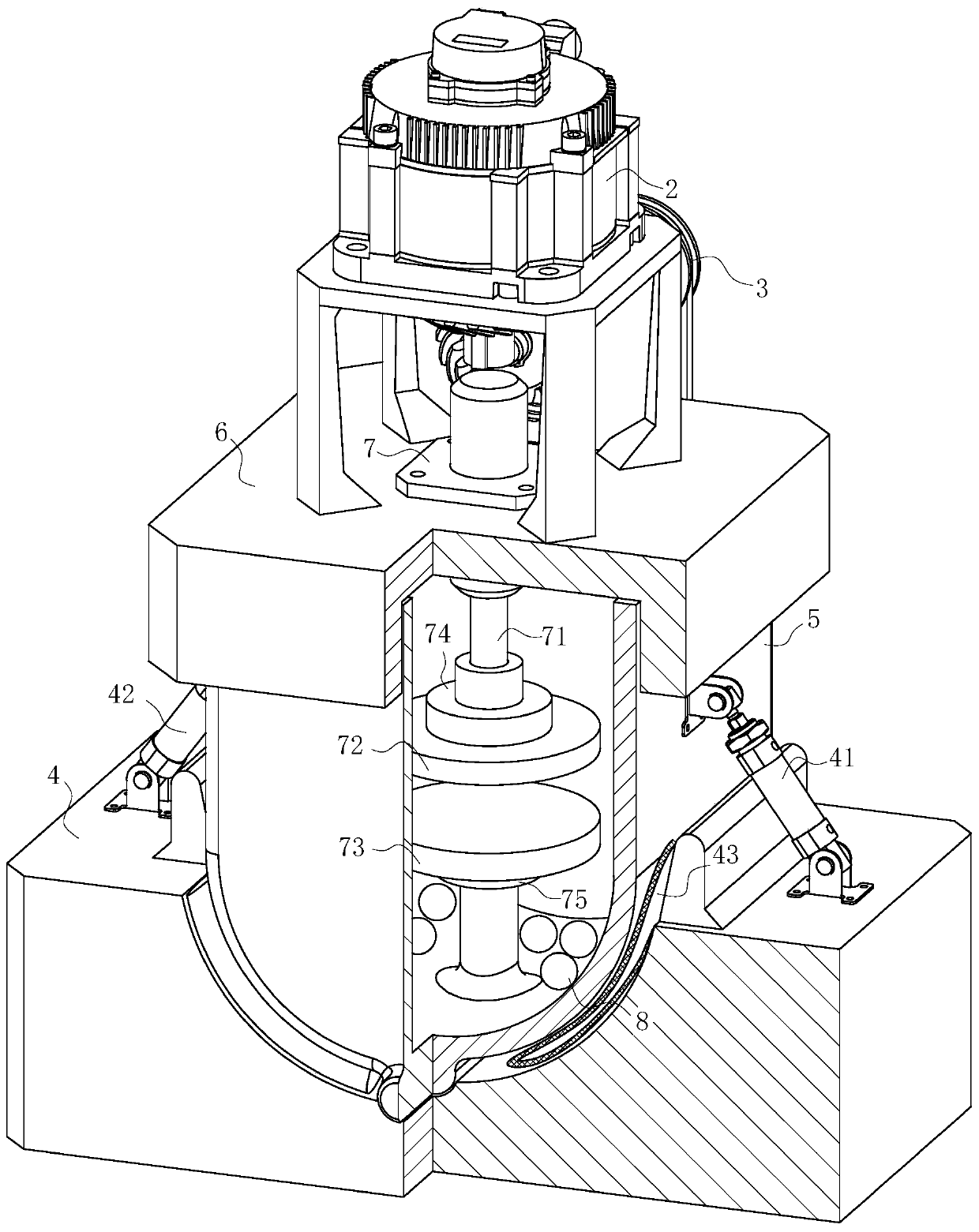

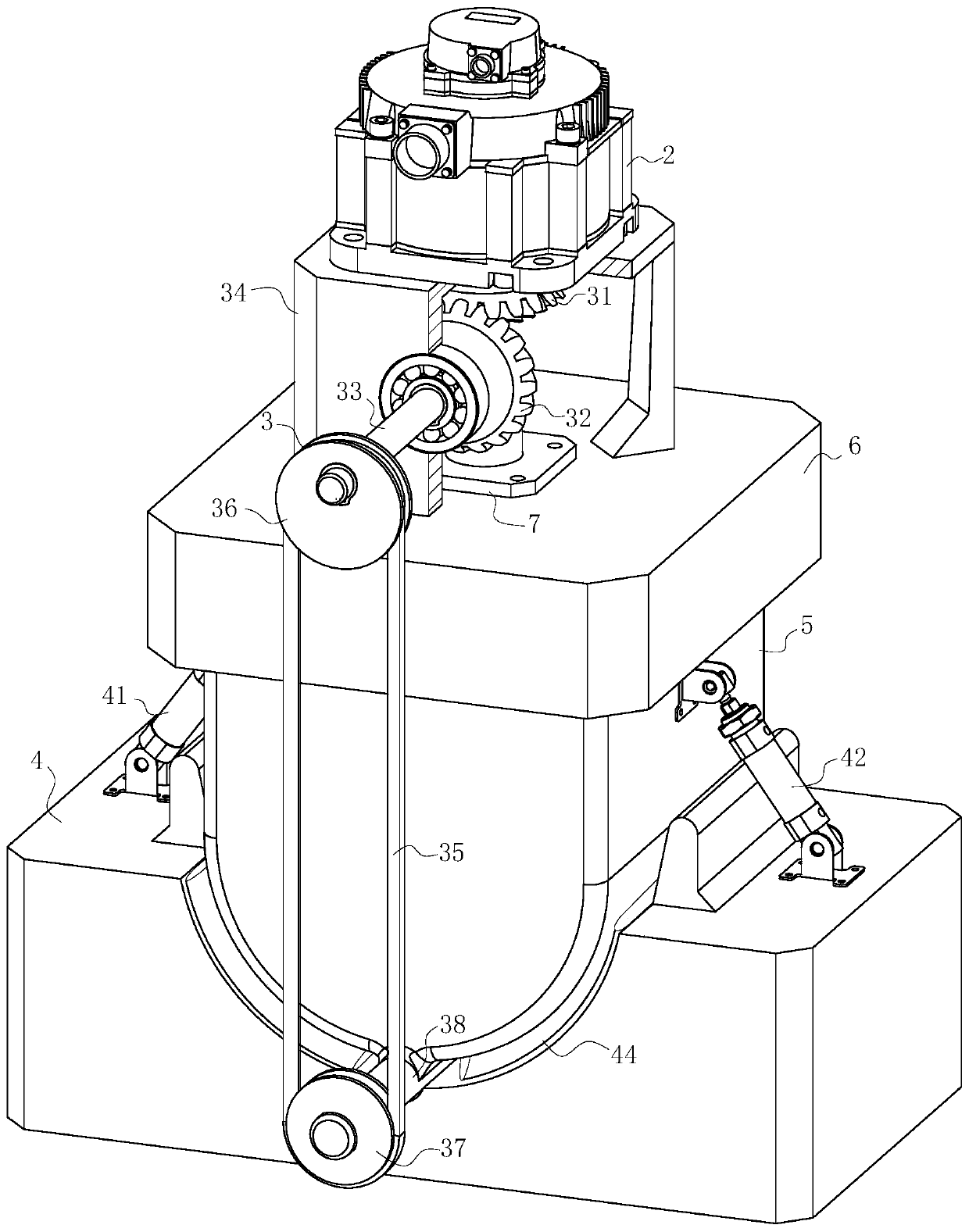

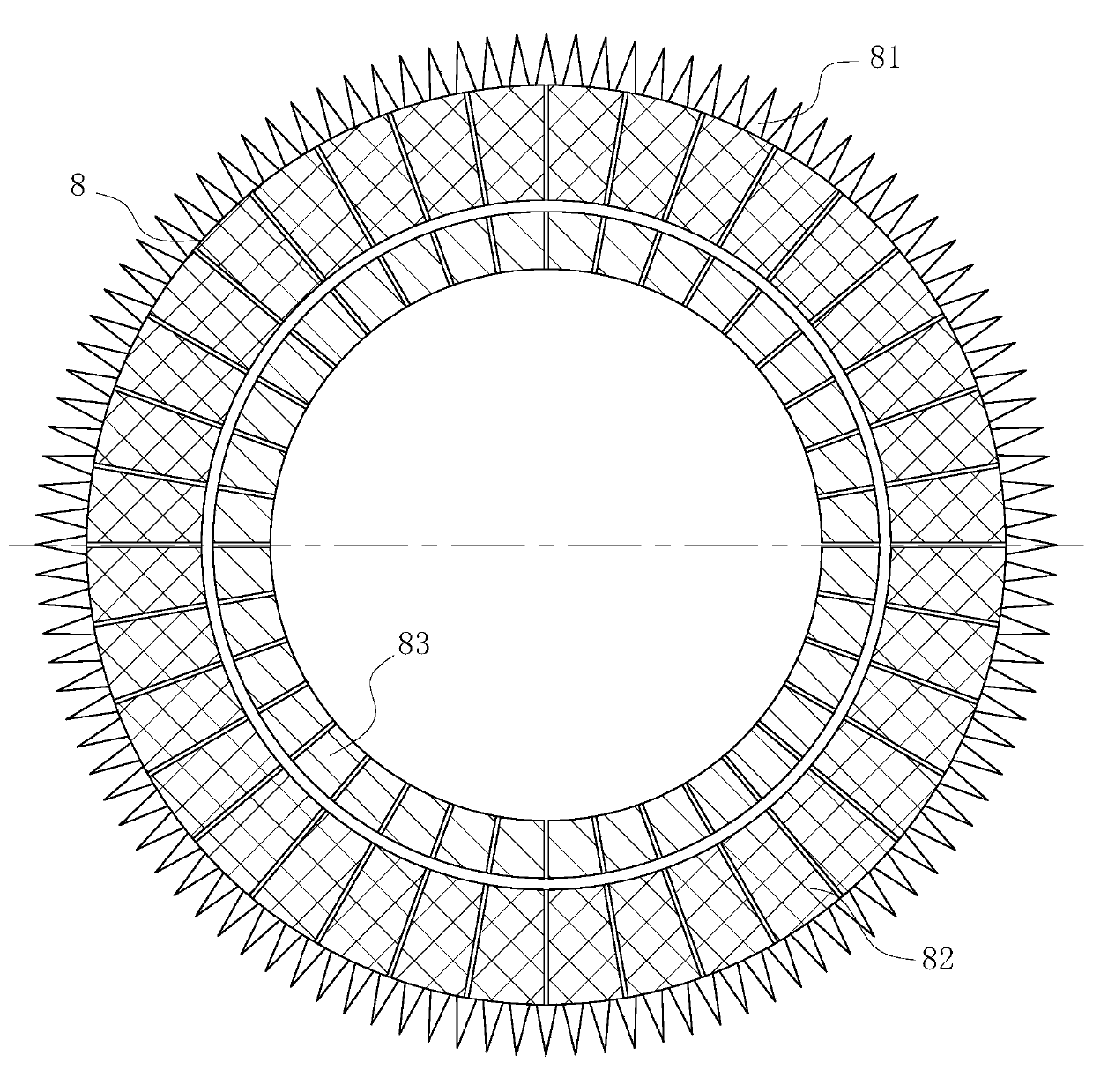

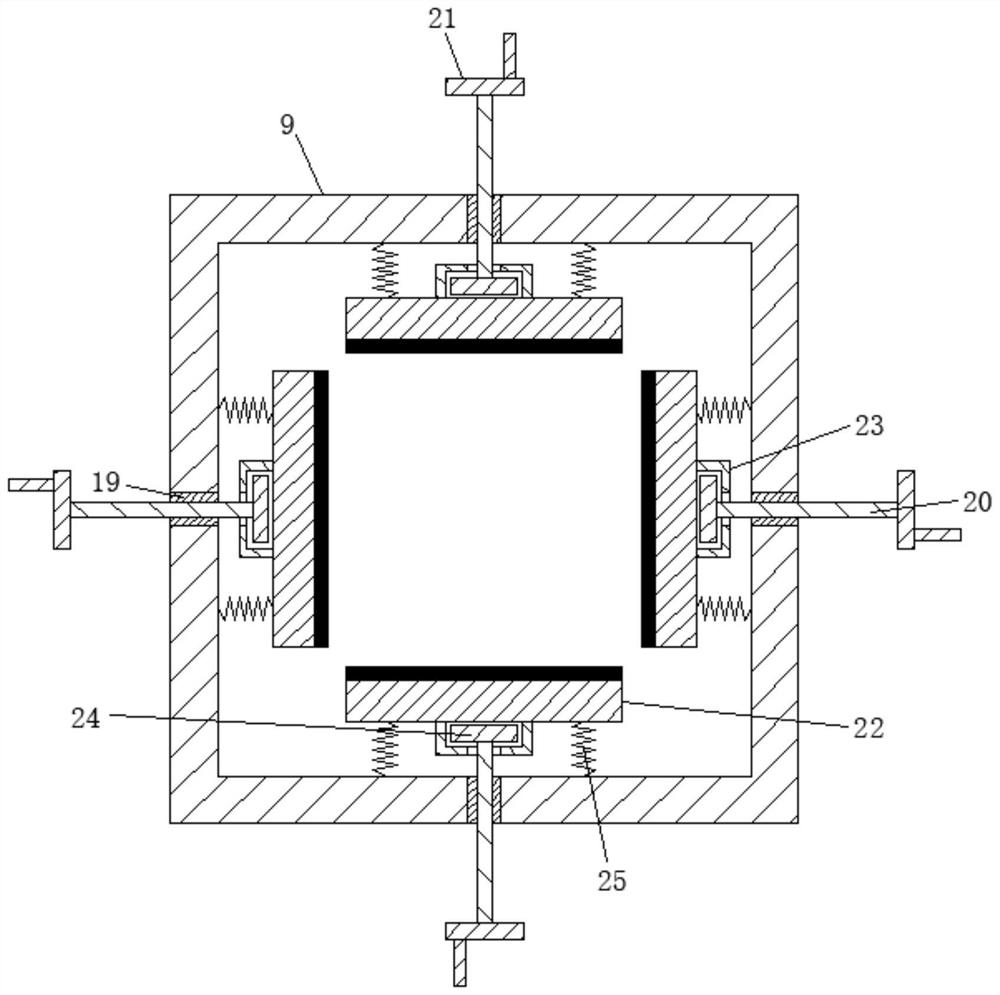

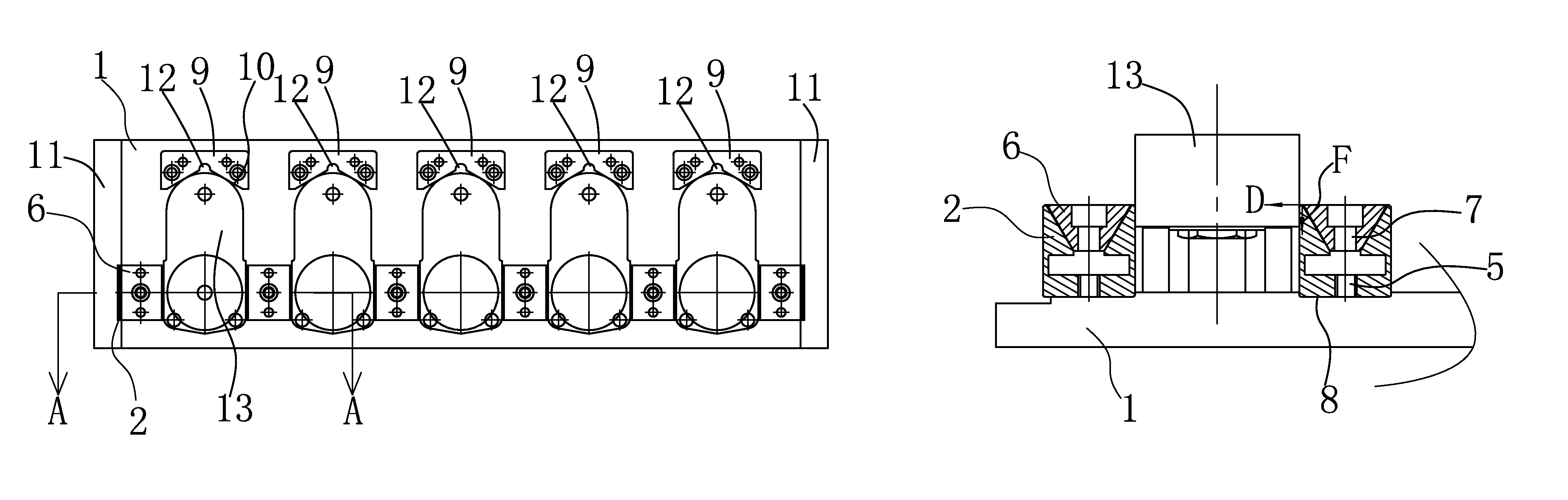

Thrust cylindrical roller bearing outer ring inner raceway machining device and using method thereof

PendingCN113441768AAchieve clamping and fixingReliable clamping and fixingMilling equipment detailsPositioning apparatusStructural engineeringMachining

The invention discloses a thrust cylindrical roller bearing outer ring inner raceway machining device and a using method thereof. The thrust cylindrical roller bearing outer ring inner raceway machining device comprises a base, a supporting mechanism, a machining mechanism and a clamping mechanism, wherein a machining groove with a forward opening end is formed in the outer surface of the base, a controller is arranged on the outer wall of the opening end of the machining groove, the supporting mechanism is installed on the inner wall of the bottom face of the machining groove, the clamping mechanism is arranged on the upper surface of the supporting mechanism, and the machining mechanism is installed on the inner wall of the top face of the machining groove. Through the clamping mechanism, a thrust cylindrical roller bearing outer ring is clamped and fixed in the mode that limiting is conducted firstly and then magnetic attraction fixing is conducted, and the device is suitable for stably and reliably clamping and fixing bearing outer rings of various different sizes; and through the supporting mechanism, the thrust cylindrical roller bearing outer ring can be conveniently put in and taken out before and after machining operation of the device, potential safety hazards are eliminated, machining chippings in a storage groove can be timely cleaned, and thus the device is suitable for being widely used and popularized.

Owner:JIANGSU QIANCHAO BEARING

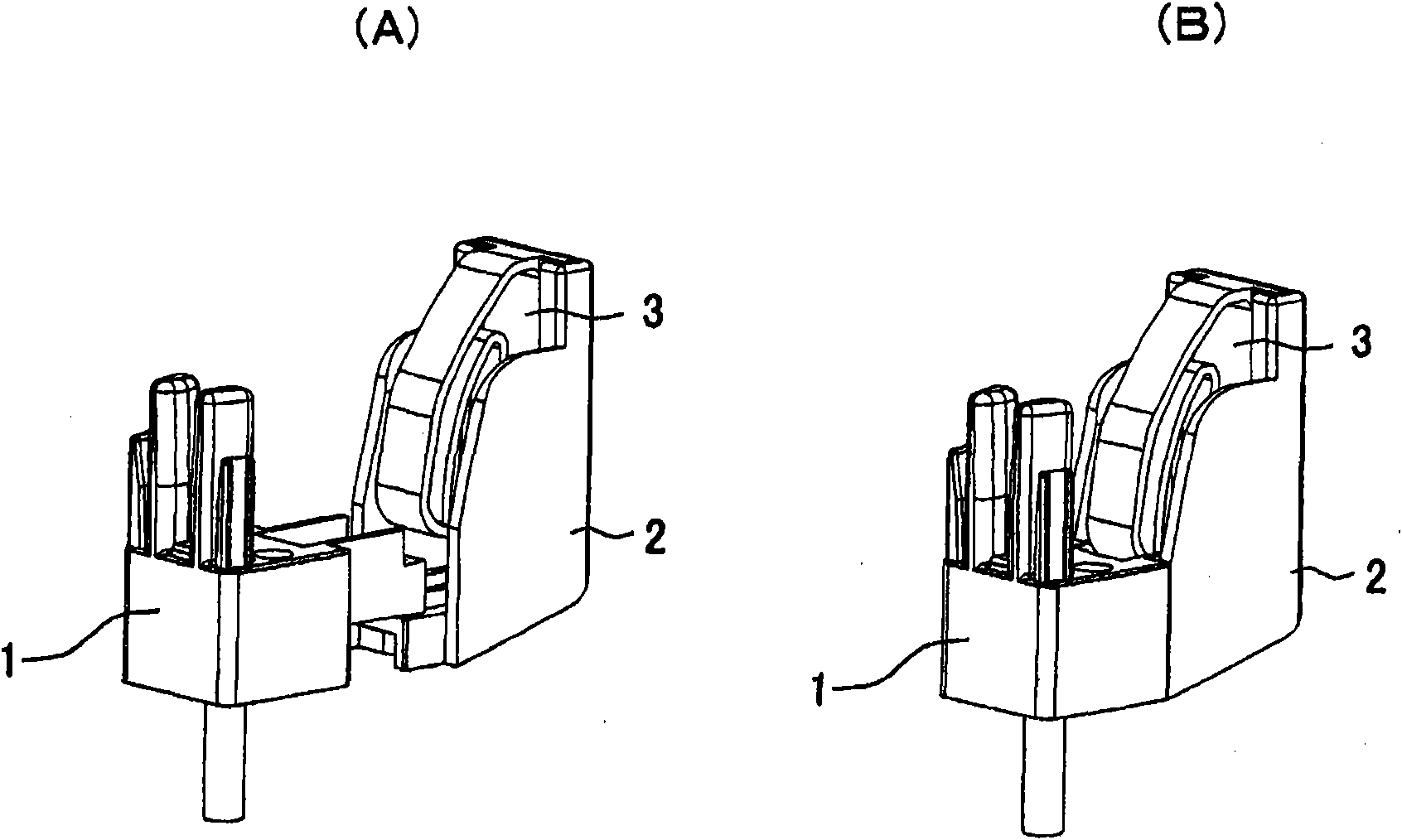

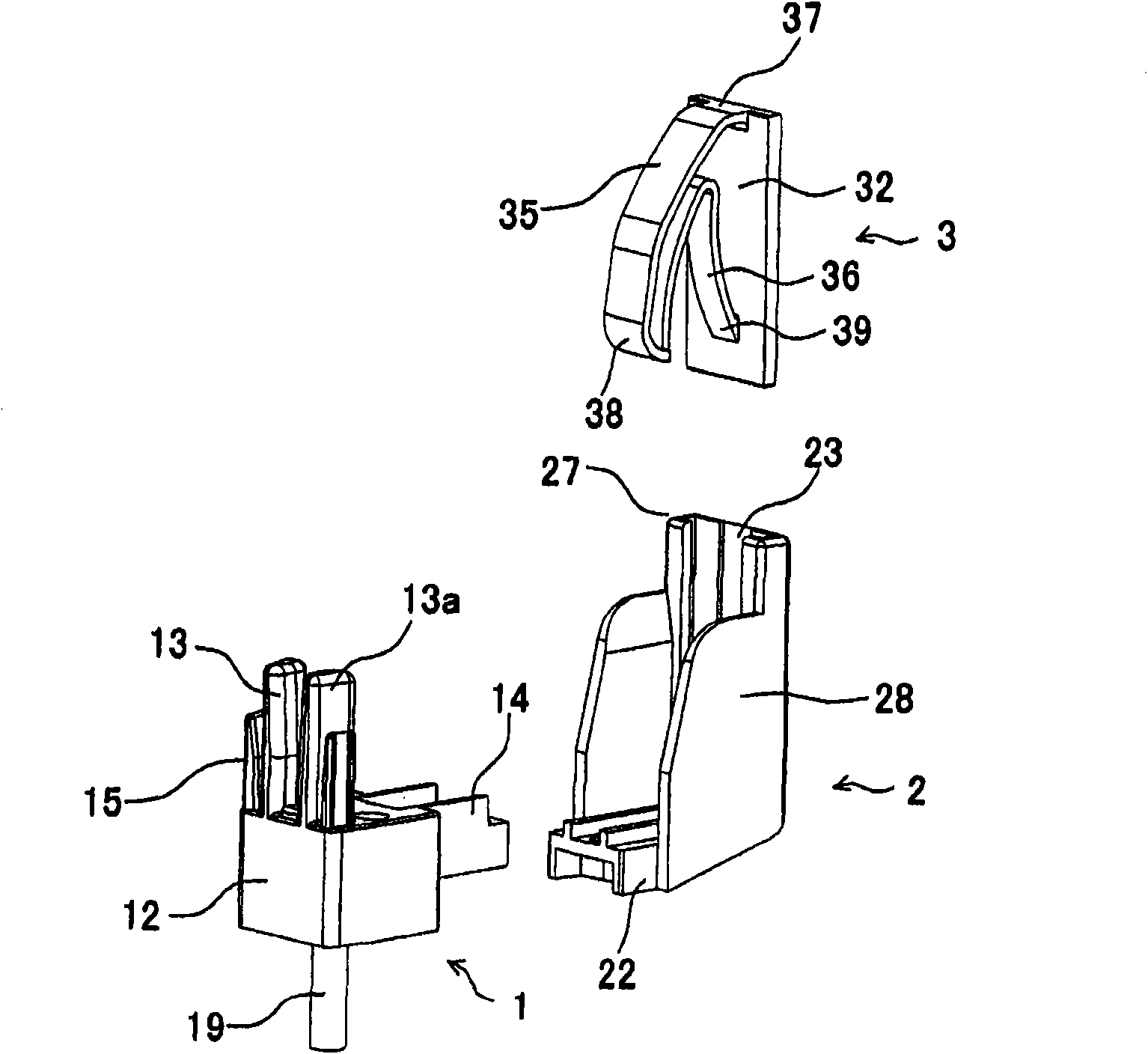

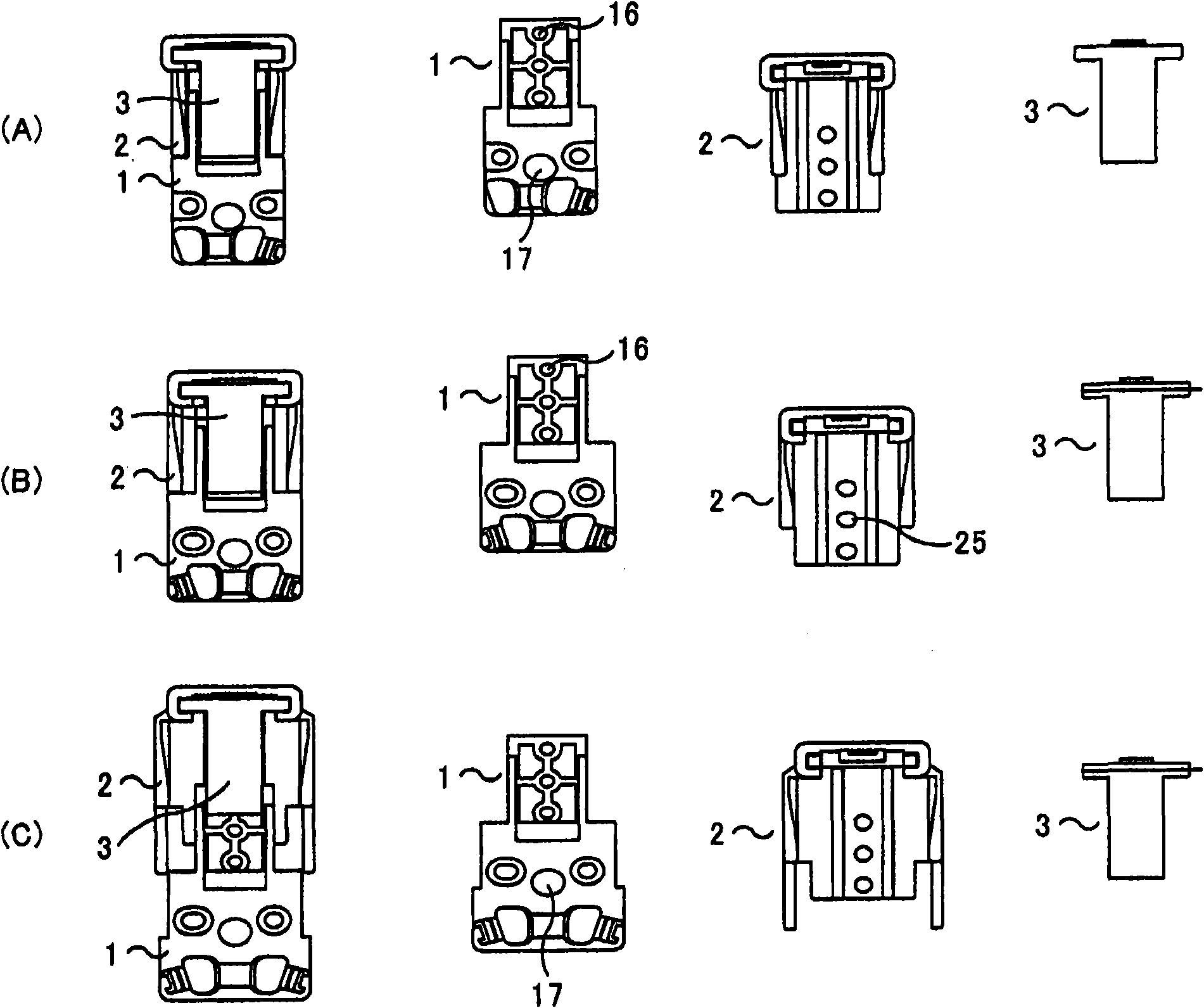

Connector holder, assembled drawing board and spring component

InactiveCN101944699AEasy to fixOptimize the extraction processElectrically conductive connectionsContact member assembly/disassemblyEngineeringBackplane

The invention provides a connector holder, an assembled drawing board and a spring component. The connector holder can correspond to the connectors having various widths and depths with fewer tools, by correctly arranging the tools relative to the connectors on a wiring plate dispensing with time and assembling skills. The connector holder of the invention comprises a holder main body, a spring component supporter fixed on the holder main body and the spring component mounted on the spring component supporter, wherein the holder main body comprises a comb toothed connector supporter and a connecting part connected to the spring component supporter; the spring component supporter comprises a connected part connected to the holder main body and a rear panel; the spring component comprises a spring part which is freely detachably mounted on the rear panel for supplying an elastic force on the direction of the comb toothed connector supporter; and a connector receiving part is formed between the comb toothed connector supporter and the spring part.

Owner:RIC TOKIOTOKYO

Clamping and perforating equipment for circuit breaker processing and using method of clamping and perforating equipment

ActiveCN113084223AHigh degree of automationImprove the fit rangeWork clamping meansLarge fixed membersDrill holeDrill bit

The invention discloses clamping and perforating equipment for circuit breaker processing and a using method of the clamping and perforating equipment. The clamping and perforating equipment comprises a lower rotary table, a workbench, two clamping piece seats and a perforating mechanism, wherein the workbench is located above the lower rotary table, two welding rods are vertically arranged at the two ends of the workbench, and a mounting plate is welded to the lower portion of one side of each of the two welding rods. The clamping and perforating equipment has the beneficial effects that the automation degree of the equipment for circuit breaker perforating treatment work is high, the time and labor are saved during use, the equipment can clamp and fix circuit breakers with different sizes for drilling treatment, and the working adaptation range is enlarged; a sixth motor drives the lower rotary seat to rotate, the working height and the inclination angle of a drill bit are adjusted, a third motor on the perforating mechanism drives a second lead screw to rotate, and the second lead screw drives a second nut, a sliding plate and the drill bit to move forwards and backwards for adjustment through the thread effect; and on one hand, the equipment can rapidly carry out perforating treatment on different positions of the circuit breaker, and on the other hand, the perforating precision of the equipment on the circuit breaker is greatly improved.

Owner:安徽淮光智能科技有限公司

Aluminum-magnesium alloy die casting surface treatment device and treatment method

ActiveCN110181385AIncrease swingClamping and fixing firmlyEdge grinding machinesPolishing machinesPulleyMagnesium alloy

The invention belongs to the technical field of aluminum-magnesium alloy treatment, and particularly relates to an aluminum-magnesium alloy die casting surface treatment device and a treatment method.The device comprises a controller, a motor, a belt pulley, a base, an air cylinder, an air bag, a box body, an end cover, a clamping unit and grinding balls; the belt pulley is positioned behind thebase; the box body is positioned above the base; the end cover is arranged above the box body; the motor is fixedly arranged at the top of the end cover; the clamping unit is positioned inside the boxbody; and the grinding balls are uniformly distributed at the bottom of the inner side of the box body. The box body is driven by an eccentric belt pulley to intermittently swing forwards and backwards, so that the swinging of the box body is increased; an electric push rod is arranged to push a clamping table, so that the clamping and fixing of the clamping unit are more firm, a plurality of layers of aluminum-magnesium alloy die castings are able to be superposed, the clamping quantity is increased, and the grinding efficiency is further improved; and the flexible grinding balls with through holes are arranged, so that a surface to be treated is not damaged when the grinding balls directly knock the surface of the casting on the premise of no influence to the grinding efficiency.

Owner:上饶市鸿创新材料有限公司

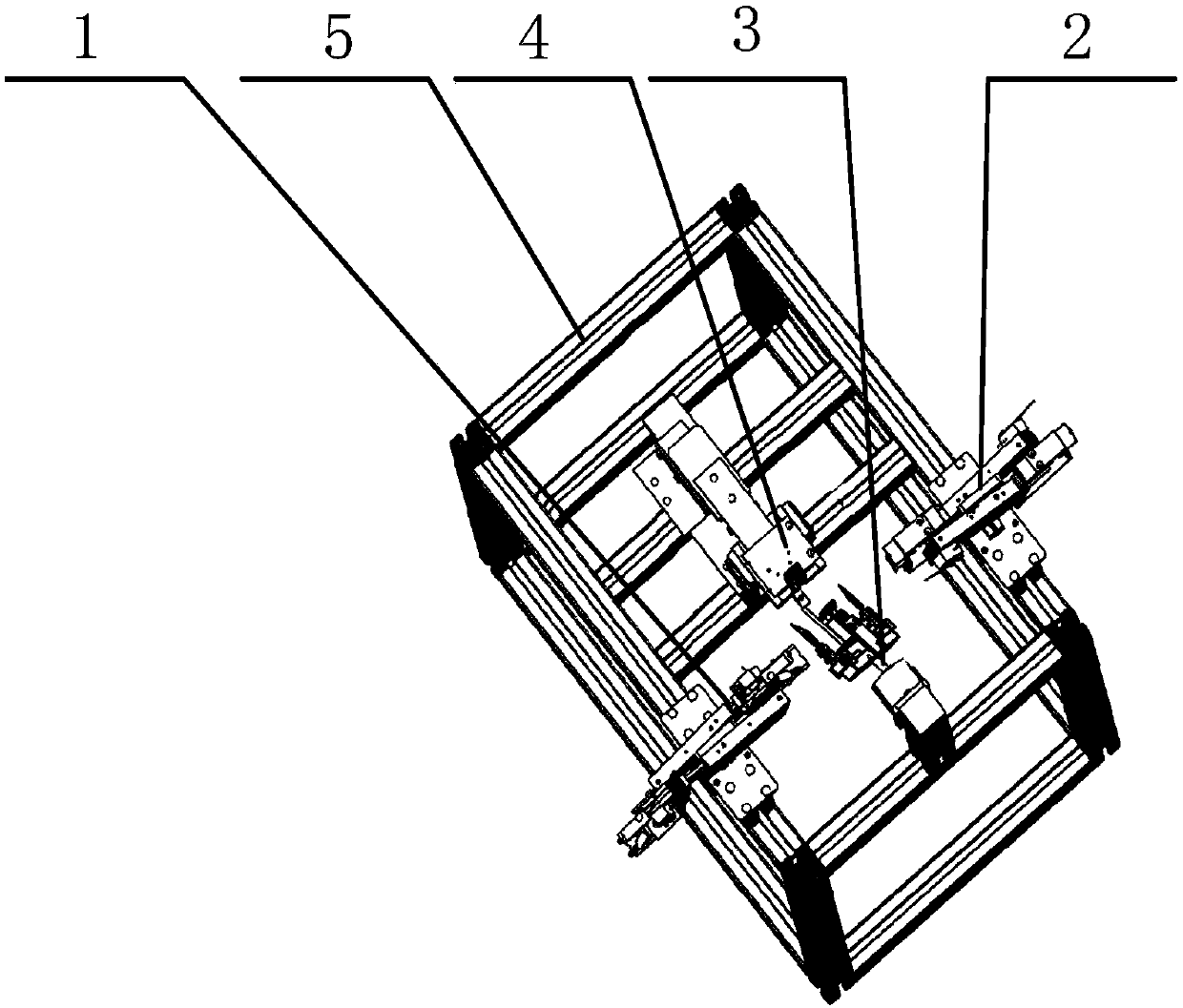

Special drilling equipment for porous long shaft

ActiveCN106392135ACompact structureEasy to manufacture and installPositioning apparatusBoring/drilling componentsLong axisEngineering

The invention discloses special drilling equipment for a porous long shaft. The special drilling equipment comprises a machine base, clamps and gun drilling modules, wherein each clamp comprises a supporting frame; each supporting frame comprises a pair of L-shaped steel plates which clamp a supporting plate with a notch; a Z-shaped pressure plate is arranged above the opening of each notch; a lower horizontal plate of each Z-shaped plate is hinged with the corresponding supporting plate; the tail end of each lower horizontal plate is hinged with a first hydraulic rod; and each gun drilling module comprises a gun drill, a gun drill mounting base and second hydraulic rods, wherein the second hydraulic rods are hinged with a clamp mounting base, and a fastening nut and a supporting screw of a supporting barrel which is fixedly equipped with a supporting shaft are sequentially arranged between the two second hydraulic rods. The gun drill mounting base comprises a clamp base, a tail base and a jacket which comprises an upper blocking base and a lower blocking base; the clamp base moves under the action of a third hydraulic rod; the clamps are arranged in one side of the machine base; notches of all clamps are on the same horizontal straight line; and the gun drilling modules are separately arranged at the two sides of the long shaft. The special drilling equipment is simple in structure, is convenient to mount and manufacture, is flexible and various in drilling performance, and is strong in adaptation.

Owner:重庆鑫宝田冶金工业有限责任公司

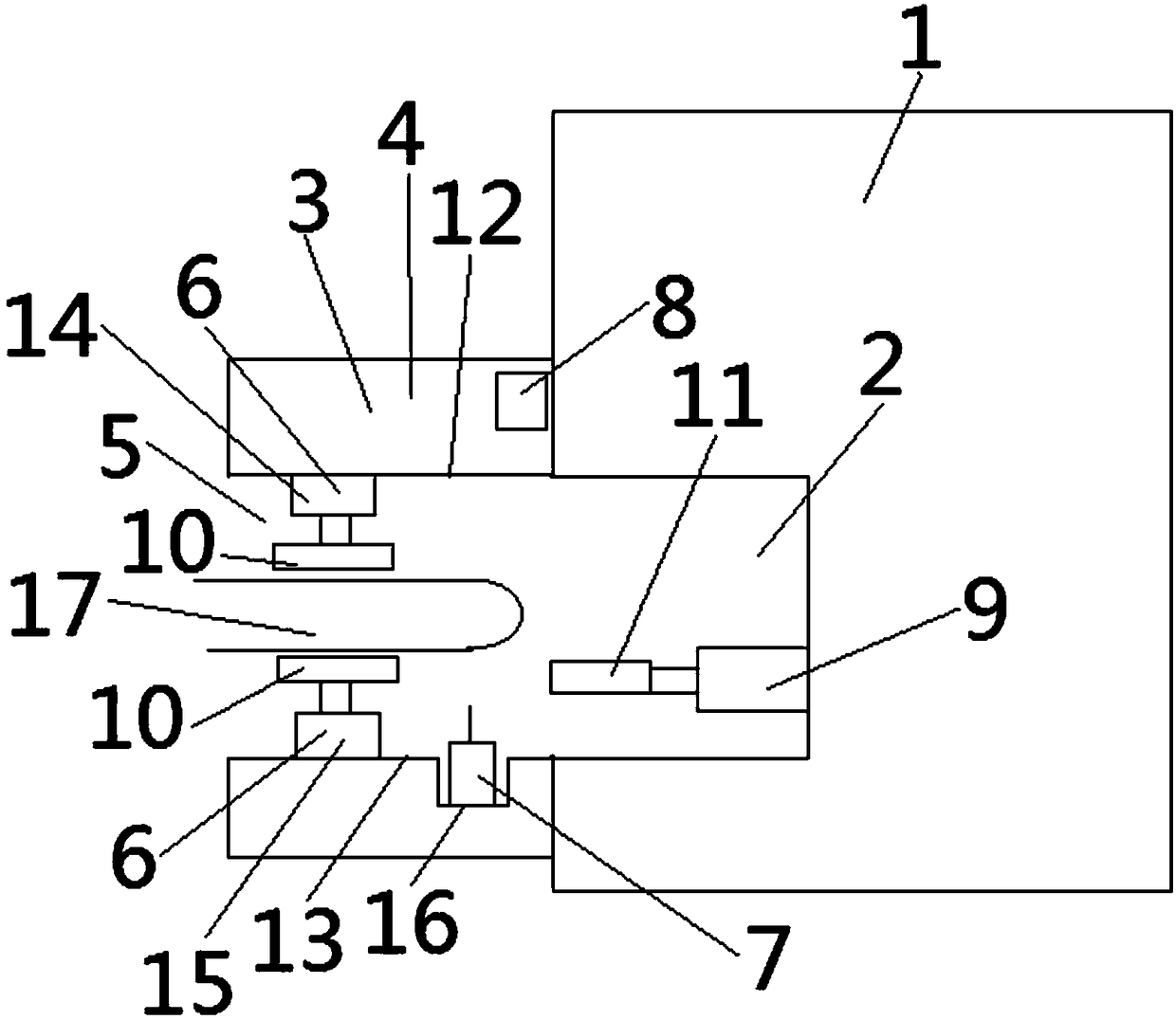

Blood analyzer

InactiveCN108375671AQuick analysisImprove analysis convenienceSensorsBiological testingBlood collectionBlood gas analysis

The invention provides a blood analyzer applied in the technical field of medical instruments. A blood analysis port (2) is arranged on the side face of an analyzer body (1) of the blood analyzer, a blood collection part (3) is arranged on the side face of the analyzer body (1) close to one side of the blood analysis port (2), a placement cavity (5) is arranged on a collection part body (4) of theblood collection part (3), an extensible part I (6) is arranged in the placement cavity (5), an extensible needle (7) is arranged in the placement cavity (5), and an extensible part II (9) in the blood analysis port (2) is connected with a control part (8). The blood analyzer can reliably clamp and fix a finger for the convenience of blood collecting, collected blood can be accurately and efficiently delivered into the analyzer body for blood analysis, automatic control on blood collection and analysis is realized, and convenience for blood collection and analysis is improved comprehensively.

Owner:ANHUI GUOKE BIOTECH CO LTD

Fixed pouring device for planting seedlings of nursery stock

InactiveCN108112421APrevent blown offReliable clamping and fixingBatteries circuit arrangementsWatering devicesCulture vesselEngineering

The invention relates to a fixed pouring device for planting seedlings of nursery stock, comprising a support and a culture vessel which is arranged in the bottom of the support, wherein a threaded rod is further horizontally arranged in the support and a clamping plate is in rotary connection with the threaded rod through screw. A lifting device is connected to the two sides of the support, and the two ends of the threaded rod are respectively connected with the lifting device. The pouring tube is obliquely connected in the support above the threaded rod, wherein the bottom of the pouring tube is provided with a liquid outlet hole. The liquid outlet hole is positioned right above the culture vessel, and the connection positions of the two ends of the pouring tube and the two sides of thesupport are respectively provided with a liquid inlet and a liquid outlet. The top of the support is provided with an illumination bulb, which is connected with the solar power generation device. Theinvention can not only fix the trunk of the nursery stock preventing the seedlings of the nursery stock from being blown off under the action of strong wind, but also can adjust the height of the fixing device according to different tree ages, thereby enabling the clamping plate to be more firmly clamped and fixed on the trunk of the nursery stock.

Owner:丹阳市宏光机械有限公司

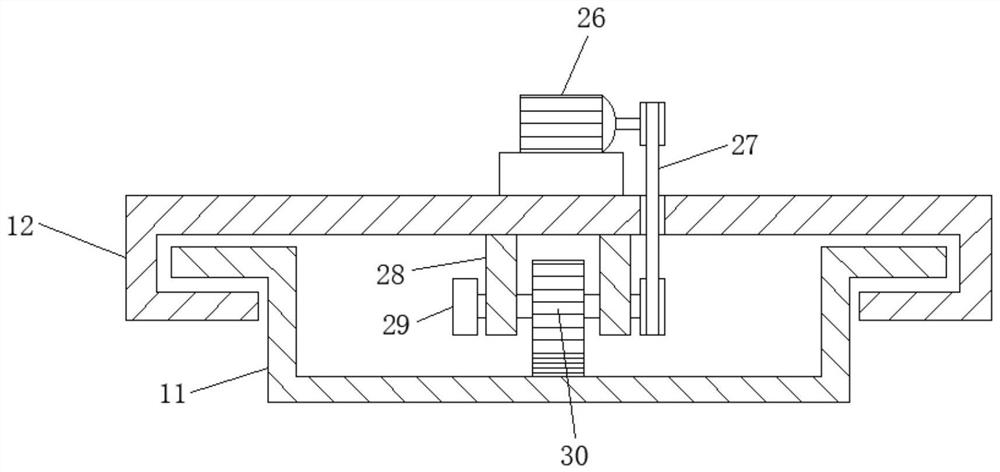

Twisting machine for processing square profile

The invention relates to a twisting machine for processing a square profile. The twisting machine comprises a processing table, wherein a plurality of supporting legs are fixedly connected to the bottom of the processing table, a bracket is fixedly connected to the top of the processing table, a limiting pipe is fixedly connected to the top end of the bracket, a first motor is mounted on one sideof the bracket, a driving gear is fixedly connected to the tail end of an output shaft of the first motor, a transmission shaft is inserted into the limiting pipe, one end of the transmission shaft isfixedly connected to a transmission gear engaged to the driving gear, a clamping rack is fixedly connected to the other end of the transmission shaft, two limiting blocks are fixedly connected to a shaft body of the transmission shaft, the two limiting blocks are located at two ends of the limiting pipe, a slide rail is mounted on the processing table, a movable table is arranged on the slide rail in a sleeving manner, a supporting rod is fixedly connected to the top of the movable table, the top end of the supporting rod is fixedly connected to a fixed table, a limiting groove is formed in the fixed table, a fixed rack is fixedly connected to the top and bottom of the fixed table, an air cylinder is mounted on the fixed rack, and a pressing plate is fixedly connected to the tail end of an output shaft of the air cylinder.

Owner:TIANJIN SHENGFA IND & TRADE

Metal hose fixing device

The invention provides a metal hose fixing device and relates to the technical field of metal hoses. The metal hose fixing device includes a base, the top of the base is welded with a bottom tube, the top of the bottom tube is inserted into a top frame, the side wall of the top frame is welded with a clip and a limit rod, and the clip passes through the side of the bottom tube. The slot hole opened on the wall runs through the inner wall of the bottom cylinder and extends to the outer wall of the bottom cylinder. The bottom of the top frame is provided with a top clamp, and the bottom of the top clamp is provided with a bottom clamp. The fixing device of the metal hose is to place the metal hose between the top clamp and the bottom clamp, press down the top frame, make the top clamp and the bottom clamp close to each other and clamp the metal hose, and at the same time, the clamps welded on the side wall of the top frame It is fixed together with the slot hole opened on the side wall of the bottom tube. When removing it, you only need to press the clip to the inside of the slot hole to separate the top frame and the bottom tube, which reduces the time spent on fixing the metal hose and is convenient. fast.

Owner:无锡华利达金属制品有限公司

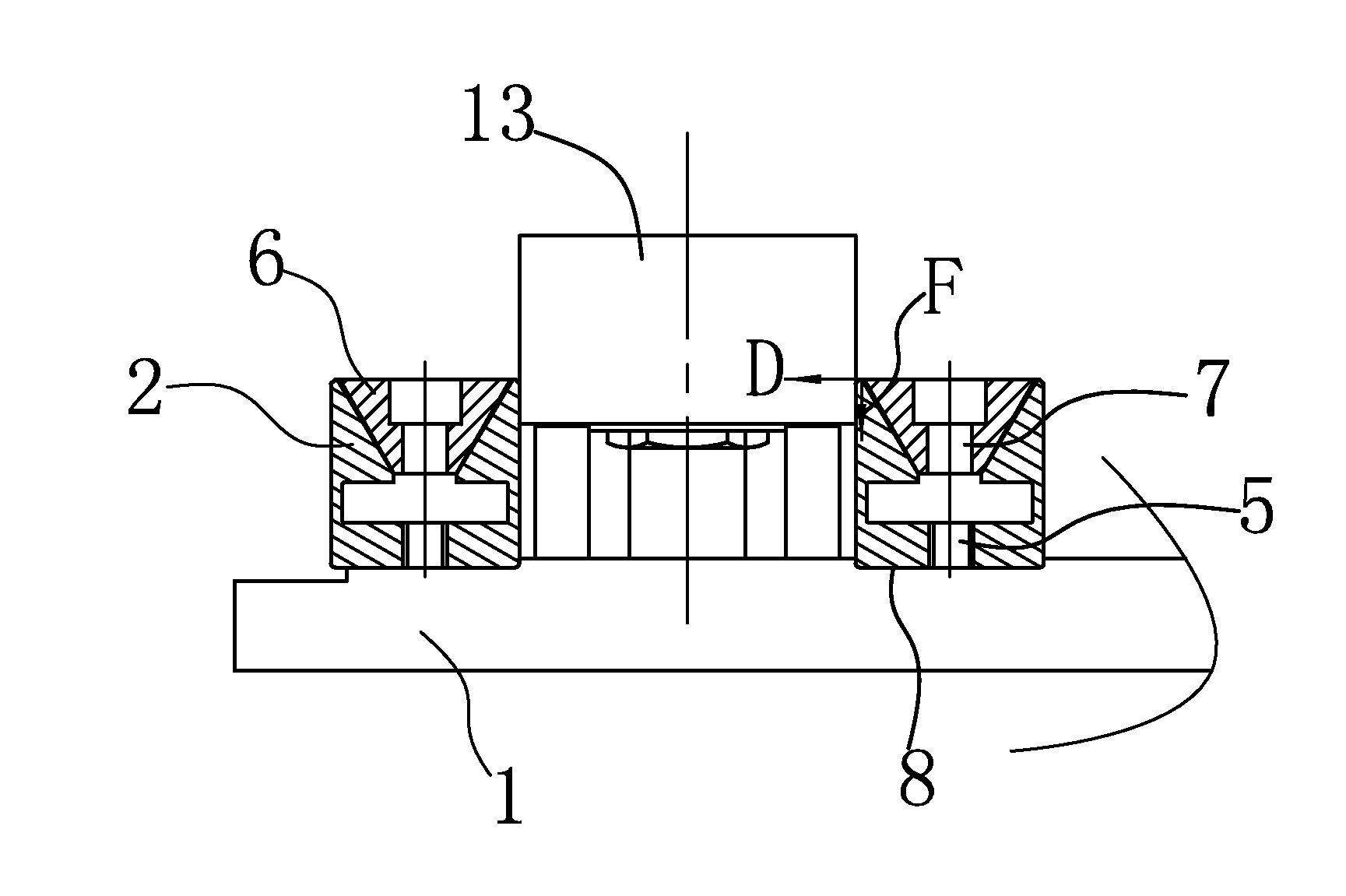

Tool for clamping using sides of workpieces

InactiveUS9050694B2Easy clampingReliable clamping and fixingTool holdersPositioning apparatusEngineering

The invention relates to a tool for clamping using sides of workpieces, in particular to a tool for clamping and processing workpieces like boxes using sides of the box workpieces, belonging to the technical field of tools for clamping used in the processing center to process workpieces. The tool for clamping using sides of workpieces comprises a soleplate, wherein one side of the soleplate is fixed with multiple elastic seats arranged at interval, the elastic seats are provided with vertical V-shaped grooves, the bottom of each vertical V-shaped groove is provided with a rectangle groove, the bottom of the rectangle groove is provided with a threaded hole, a V-shaped pressing block is fitted in the vertical V-shaped groove, a through hole which is coaxial with the threaded hole on the bottom of the rectangle groove is formed on the V-shaped pressing block, and a bolt passes through the through hole on the V-shaped pressing block to fit with the threaded hole on the bottom of the rectangle groove; and, the other side of the soleplate opposite to the elastic seats is provided with multiple V-shaped locating blocks arranged at interval, the gap between each two adjacent elastic seats corresponds to one V-shaped locating block, and each V-shaped locating block is provided with a horizontal V-shaped groove, the opening of which faces the gap between two adjacent elastic seats.

Owner:ZHEJIANG LINIX MOTOR

A manipulator device for power equipment maintenance

InactiveCN113043299BReliable clamping and fixingEasy to clamp and fixGearingManipulatorRobot handElectric power equipment

The invention relates to the field of power equipment maintenance, in particular to a manipulator device for power equipment maintenance, including an insulating rod, the upper part of the insulating rod is provided with an upper splint and a lower splint for sliding cooperation, and the opposite side of the upper splint and the lower splint A set of pneumatic adjustment splint assemblies are respectively installed inside, and a control assembly for simultaneous control of the two sets of pneumatic adjustment splint assemblies is installed on the lower part of the insulating rod. The side of the upper splint and the lower splint away from the pneumatic adjustment splint assembly is connected with a screw thread. The positive and negative threaded rods are also mounted on the insulating rods for driving the rotation of the positive and negative threaded rods. The invention can reliably clamp and fix the test clip, is beneficial to stably sending the test clip to a high place and clamping the electric equipment, and can adapt to the use of test clips of different working conditions and types, and is worthy of popularization.

Owner:PINGLIANG POWER SUPPLY CO STATE GRID GANSU ELECTRIC POWER CO LTD

Rapid cutting and separating device

InactiveCN112958822AEasy to cutReliable clamping and fixingDirt cleaningShearing machinesEngineeringKnife blades

The invention discloses a rapid cutting and separating device, and aims to provide a device capable of automatically and rapidly cutting workpieces. According to the technical scheme, the device is characterized by comprising a base and a workbench arranged on the base, wherein the bottom of the workbench is provided with a sliding groove fixedly mounted on the base, a sliding block is arranged at the bottom of the workbench and located in the sliding groove, a pushing air cylinder facing the workbench is arranged on one side of the base, a pushing rod is arranged on the pushing air cylinder and is connected one side of the workbench in a threaded mode, a supporting plate is arranged above the workbench, the periphery of the supporting plate is connected with the base through fixing rods, a vertically-downward lifting air cylinder is arranged on the supporting plate, a piston rod is arranged at the bottom of the lifting air cylinder, a connecting plate is mounted at the bottom of the piston rod, and a blade is arranged at the bottom of the connecting plate in a fixedly connected mode.

Owner:无锡美高帝机械有限公司

Blood analysis system

InactiveCN108254544AQuick analysisAffect the smooth collectionDiagnostic recording/measuringSensorsAutomatic controlCOMPONENT II

The invention provides to a blood analysis system applied to the technical field of medical instruments. A blood analysis opening (2) is formed in the side surface of an analysis meter body (1) of theblood analysis system; a blood collecting component (3) is also arranged on the side surface, which is close to one side of the blood analysis opening (2), of the analysis meter body (1); a placementcavity (5) is arranged on the blood collecting body (4) of the blood collecting component (3); a telescopic component I (6) is arranged in the placement cavity (5); a telescopic needle (7) is also arranged in the placement cavity (5); a telescopic component II (9) in the blood analysis opening (2) is connected with a control component (8). The blood analysis system provided by the invention is capable of reliably clamping and fixing fingers, is convenient to collect blood and is capable of accurately and efficiently feeding collected blood to the analysis meter body for carrying out blood analysis, automatic control of blood collection and analysis can be realized, and convenience of blood collection and analysis can be comprehensively increased.

Owner:ANHUI GUOKE BIOTECH CO LTD

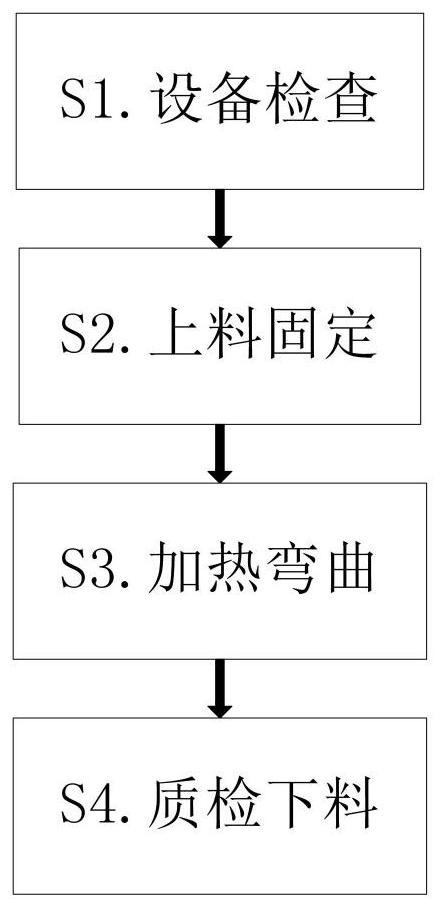

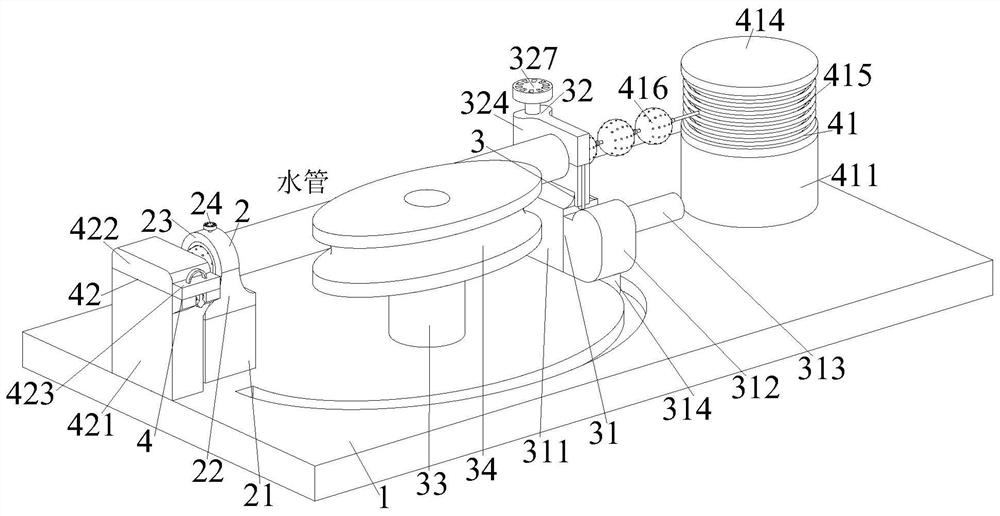

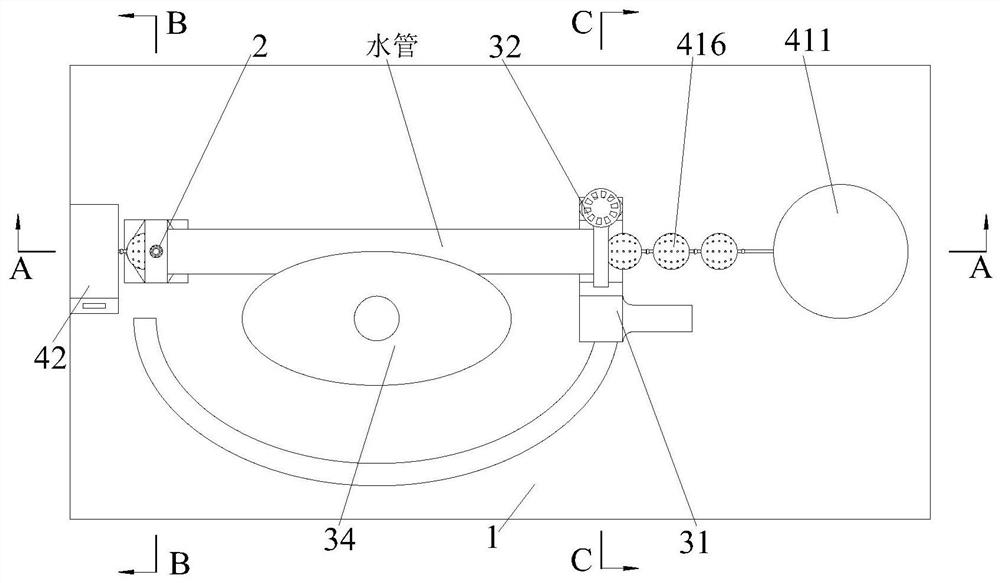

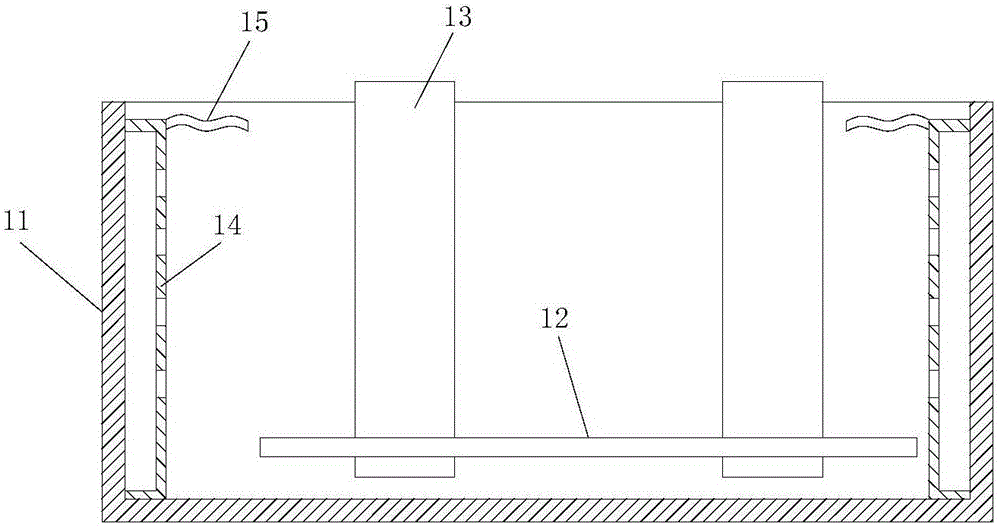

PPR water pipe bending machining process

InactiveCN111688173AReduce bend failuresImprove bending efficiencyStructural engineeringMachining process

The invention relates to a PPR water pipe bending machining process. A workbench, a clamping device, a bending device and a supporting device are included. The clamping device is mounted on the left side of the upper end of the workbench, the bending device is arranged on the right face of the clamping device, and the supporting device is arranged on the outer side of the clamping device and the bending device. According to the PPR water pipe bending machining process, the problems that during manual bending, firstly, a PPR water pipe is heated, then the PPR water pipe is bent, as the strengthof bending the PPR water pipe is hardly controlled manually, the bending angle of the PPR water pipe is disqualified, when existing PPR water pipe bending machining equipment carries out bending, firstly, the PPR water pipe is clamped and fixed, then the PPR water pipe is heated and then bent, as the interior of the PPR water pipe is not supported and fixed, the PPR water pipe is excessively bentor torn when bent, bending of the PPR water pipe is disqualified, and therefore the bending efficiency of the PPR water pipe is reduced can be solved.

Owner:许吉界

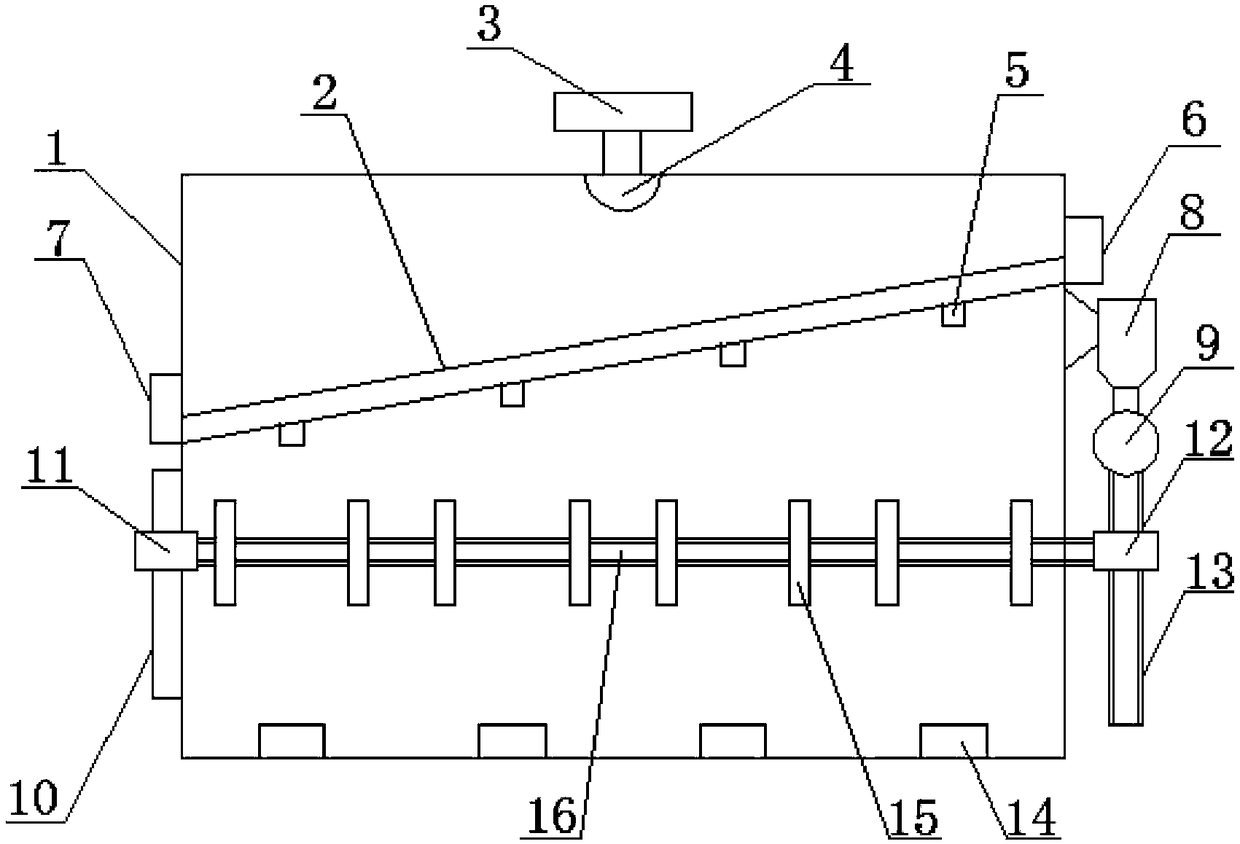

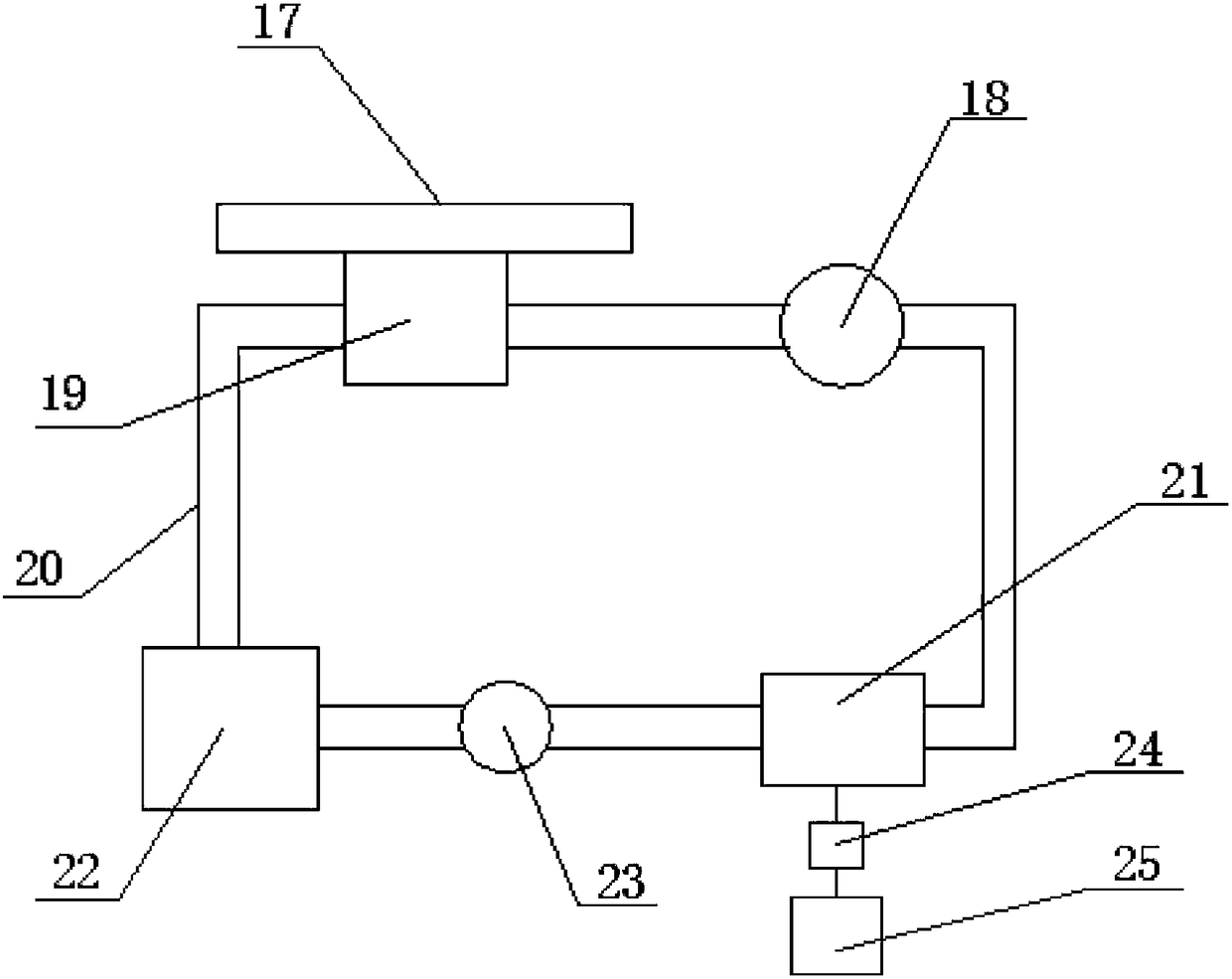

Reciprocating water-bathing constant temperature oscillator

ActiveCN106269003APrevent splashReliable clamping and fixingShaking/oscillating/vibrating mixersTransportation and packagingWater bathsReciprocating motion

The invention discloses a reciprocating water-bathing constant temperature oscillator which comprises a shell. A water bath is arranged on the shell. A supporting plate for supporting a reaction instrument is arranged inside the water bath. The supporting plate is composed of a mesh plate. The supporting plate is fixed to a movable support. The movable support is connected with a driving mechanism. The driving mechanism drives the supporting plate to reciprocate inside the water bath in the length direction of the water bath. The inner sides of the two bath walls, perpendicular to the motion direction of the supporting plate, of the water bath are each provided with a bath-shaped plate piece. The notch of each bath-shaped plate piece points to the wall of the water bath, and the two bath walls of each bath-shaped plate piece are arranged in the horizontal direction. The two bath walls of the bath-shaped plate pieces and the wall of the water bath are connected into a whole. The bottoms of the bath-shaped plate pieces are provided with through holes respectively. The sides, away from the wall of the water bath, of the side of the upper side of the bath-shaped plate pieces are provided with a corrugated plate. The reciprocating water-bathing constant temperature oscillator can effectively prevent water from being splashed and can reliably clamp and fix a test tube.

Owner:ANHUI XUANTONG IND DESIGN CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com