Noodle winding machine capable of winding noodles in shape of 8

A technology of wrapping and feeding noodles, applied in the fields of dough processing, baking, food science, etc., can solve the problems of inconvenient pulling operation of noodle blanks, easy slipping of noodle blanks, and difficulty in pulling too much.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

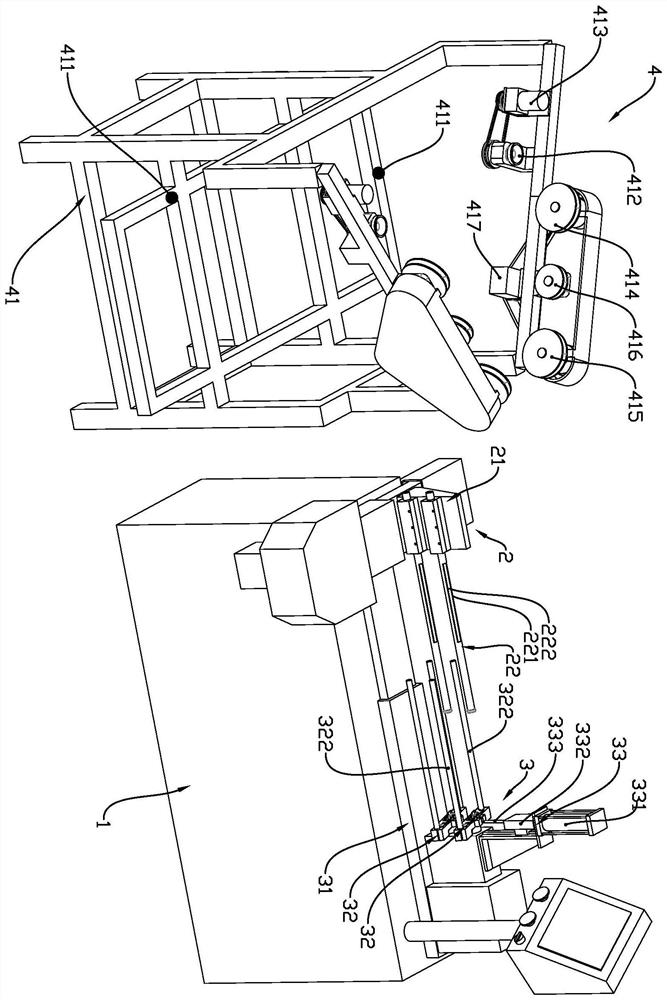

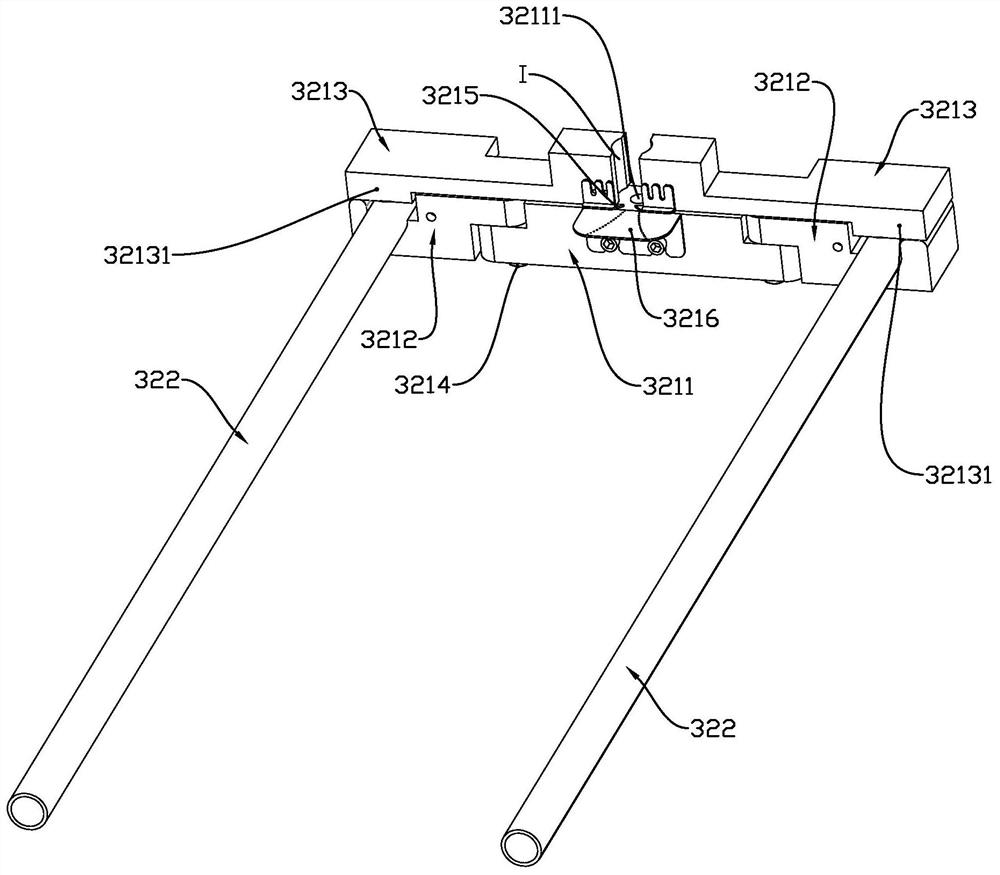

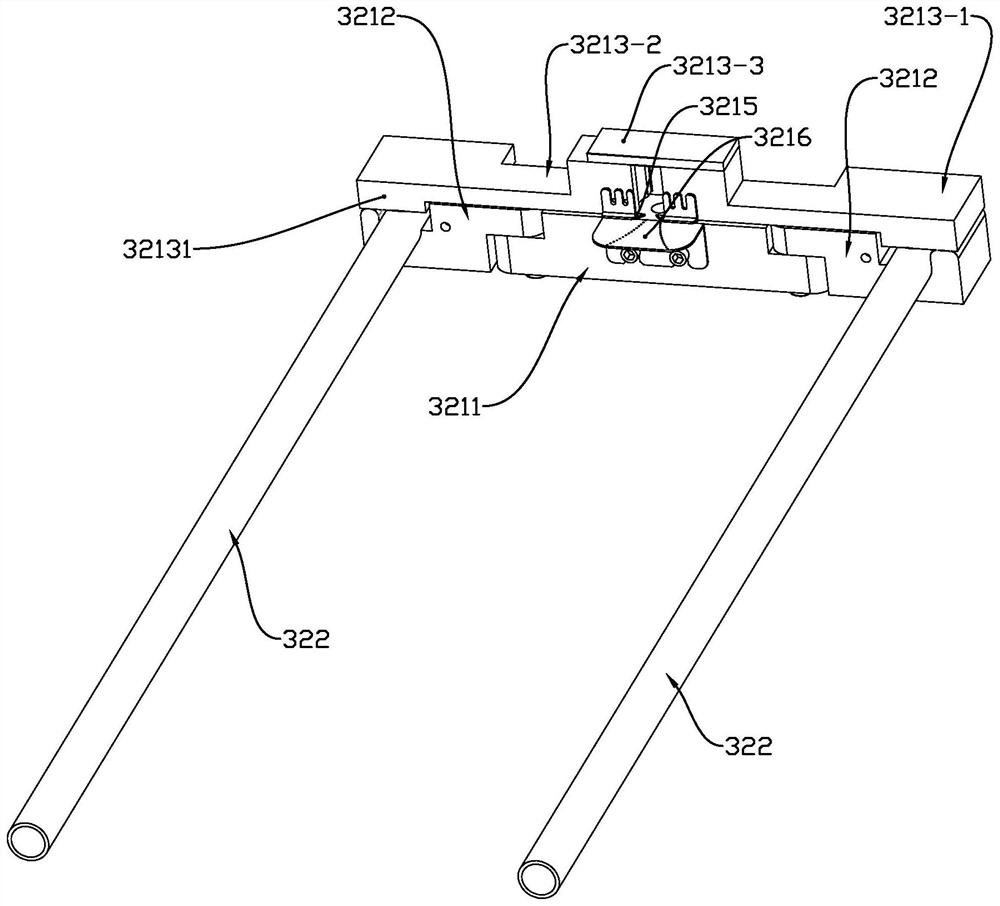

[0022] See attached Figure 1~5 , a noodle wrapping machine in the form of an "8" shape disclosed in the present invention, comprising an organic base 1, a horizontal reciprocating noodle feeding device 2 and a noodle wrapping receiving device 3, the horizontal reciprocating noodle feeding device 2 includes a horizontal and lateral sliding fit on the machine The horizontal sliding seat 21 on the seat 1, the reciprocating drive mechanism that drives the horizontal sliding seat 21 to reciprocate laterally, and the hollow noodle feeding tube 22 fixed on the horizontal sliding seat 21, the reciprocating driving mechanism can be realized by using a motor with a crank slider mechanism, The push drive of the cylinder can also be used, and the axial direction of the hollow noodle feeding pipe 22 is perpendicular to the sliding direction of the transverse sliding seat 21. 1, the longitudinal slide driving mechanism that drives the longitudinal slide 31 to slide longitudinally, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com