Noodle wrapping machine with "8" wrapping

A noodle wrapping and noodle feeding technology, which is applied in the fields of dough processing, baking, food science, etc., can solve the problems such as the pulling force is not too large, the noodle blank is easy to slip, and the noodle blank is inconvenient to pull and operate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

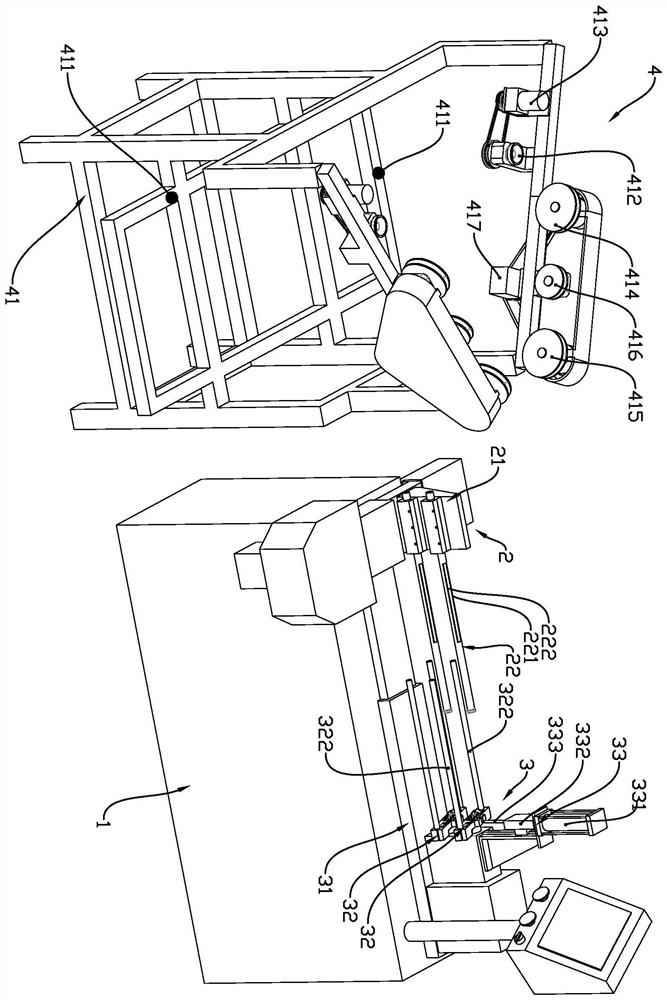

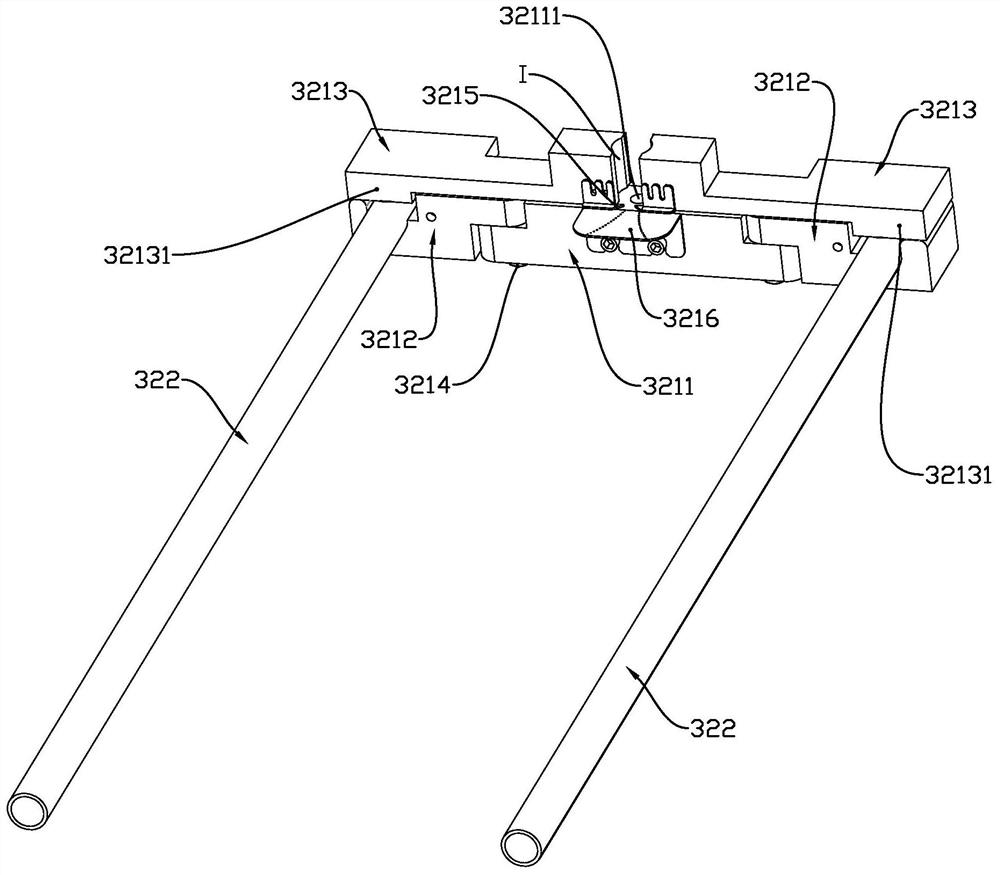

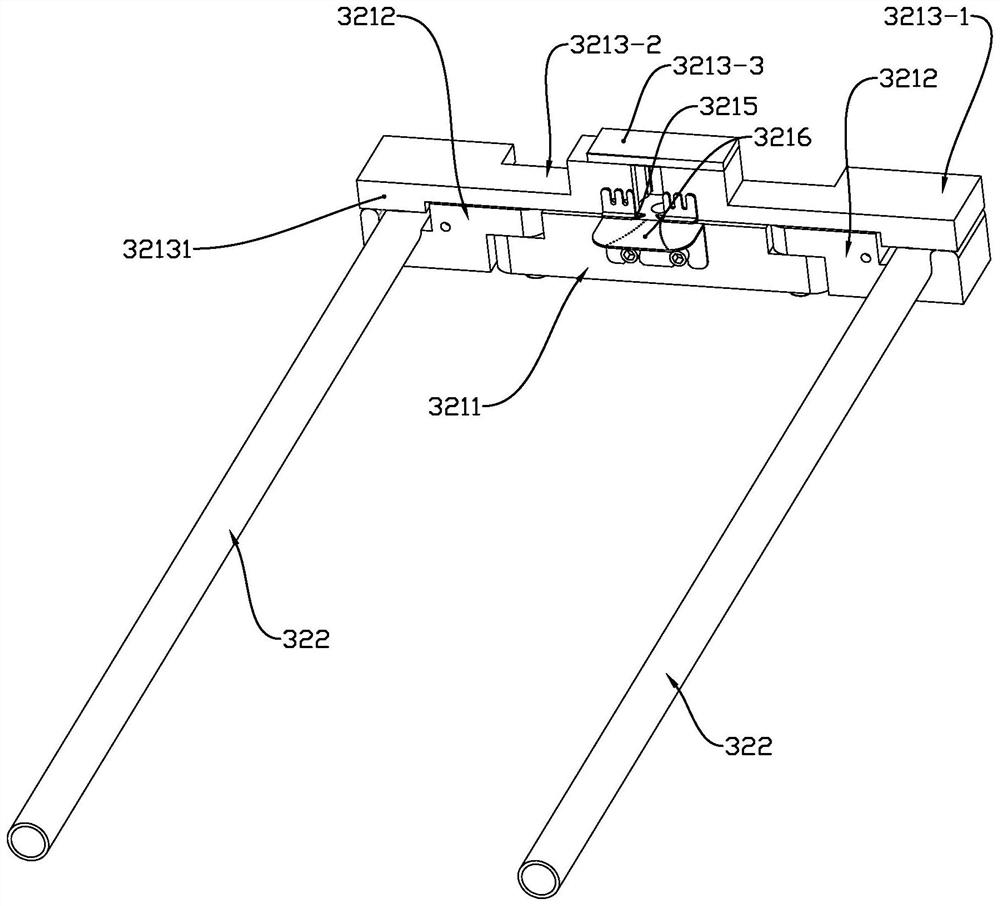

[0022] see attached Figures 1 to 5 , the present invention discloses a "8" wrapping machine for wrapping the surface, including a machine base 1, a horizontal reciprocating surface feeding device 2 and a wrapping receiving device 3. The transverse sliding seat 21 on the seat 1, the reciprocating driving mechanism for driving the transverse sliding seat 21 to reciprocate laterally, and the hollow noodle feeding tube 22 fixed on the transverse sliding seat 21, the reciprocating driving mechanism can be realized by a motor combined with a crank-slider mechanism, The push drive of a cylinder can also be used, etc. The axial direction of the hollow dough feeding tube 22 is perpendicular to the sliding direction of the lateral slide 21, and the surface wrapping receiving device 3 includes a sliding fit on the machine base along the axial direction of the hollow dough feeding tube 22. The longitudinal slide 31 on High, the longitudinal sliding drive mechanism is preferably realized...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com