Patents

Literature

365results about How to "Easy to pick and place" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

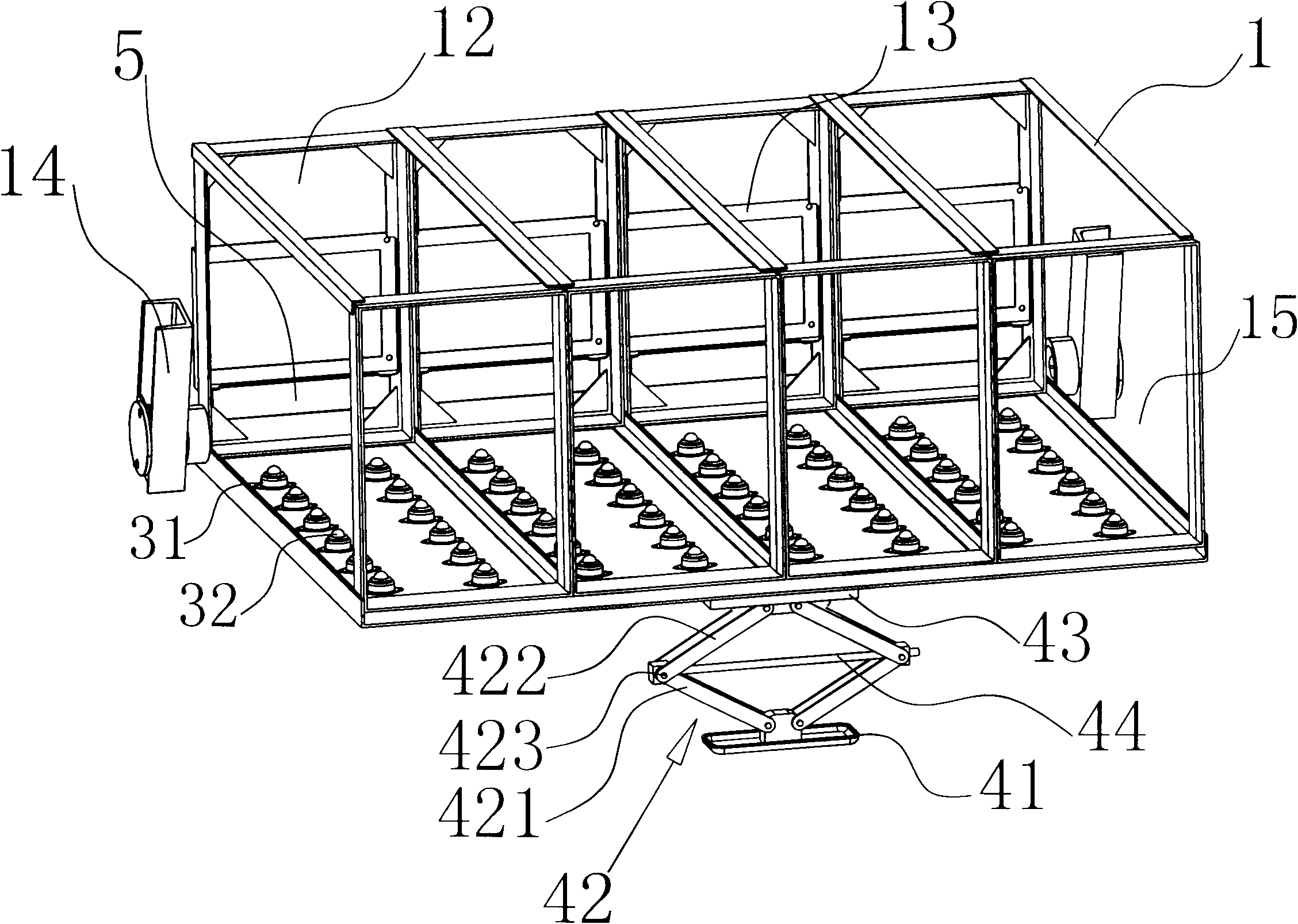

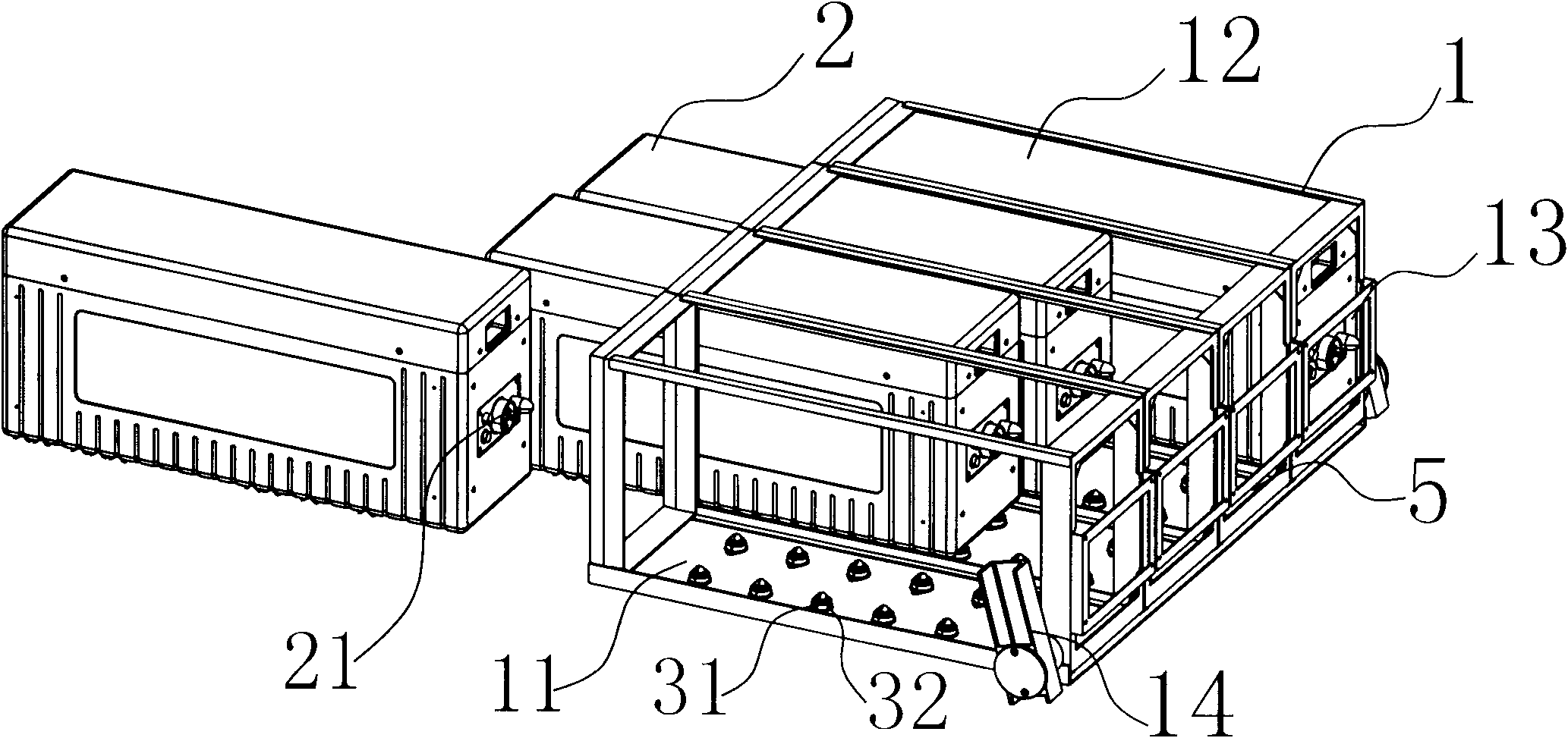

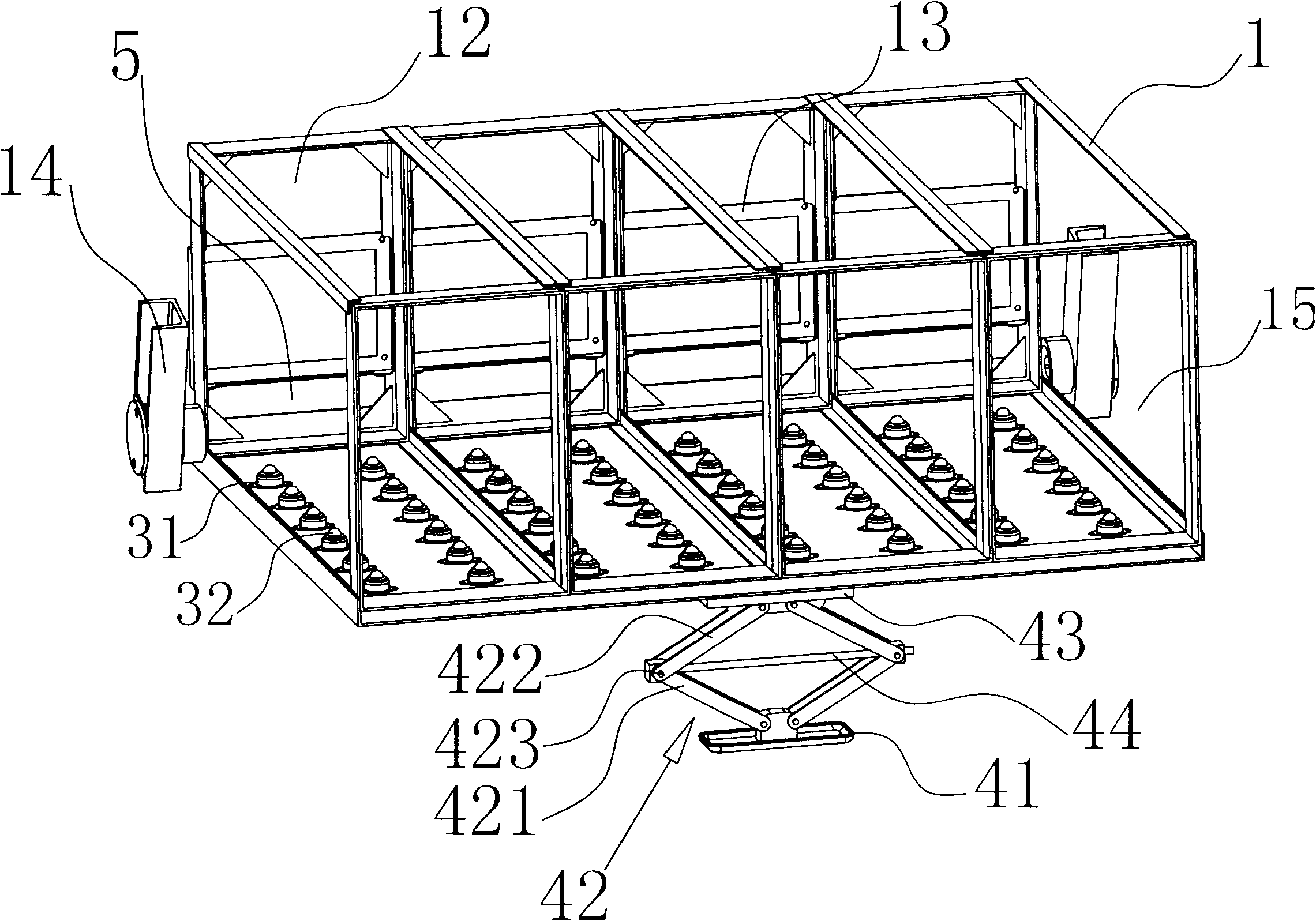

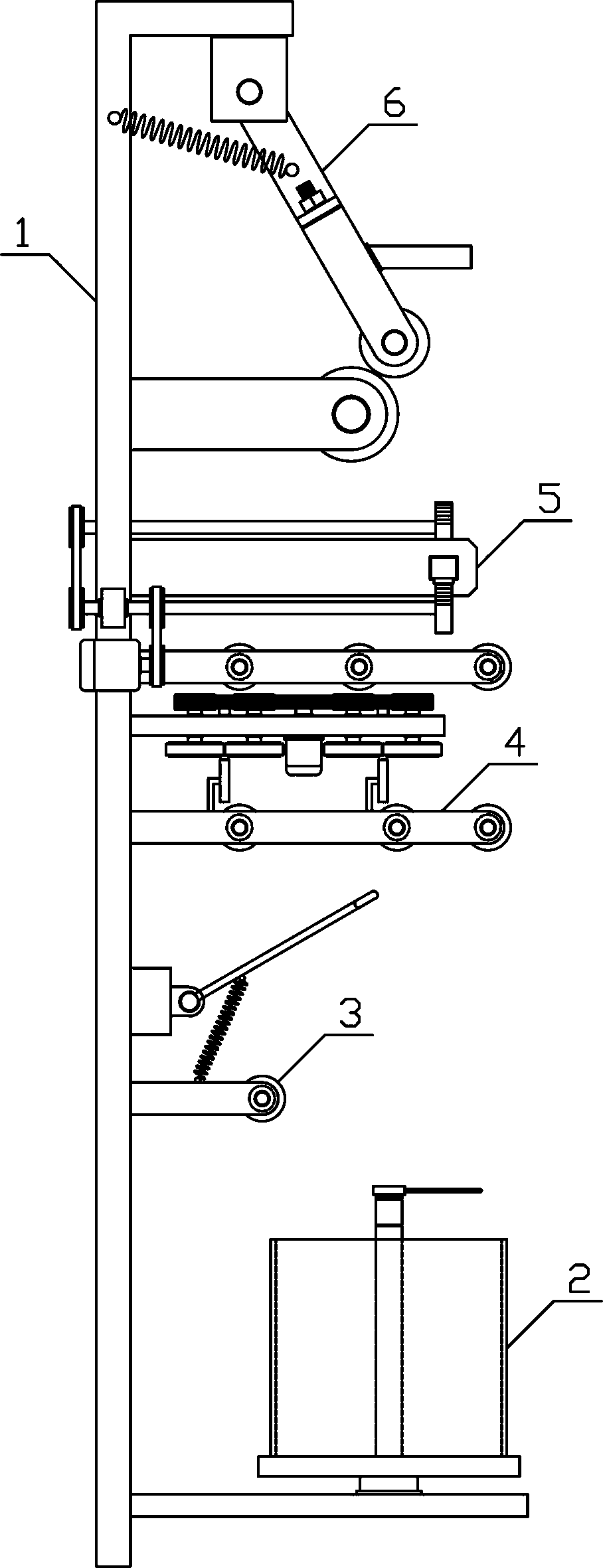

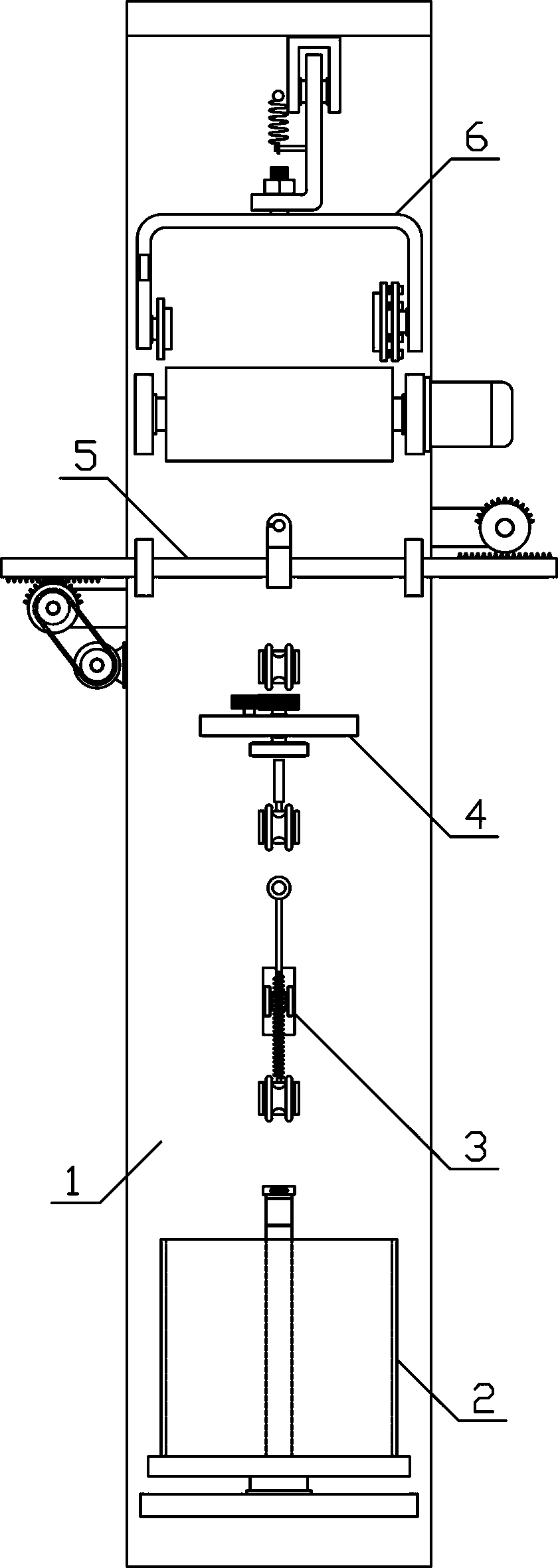

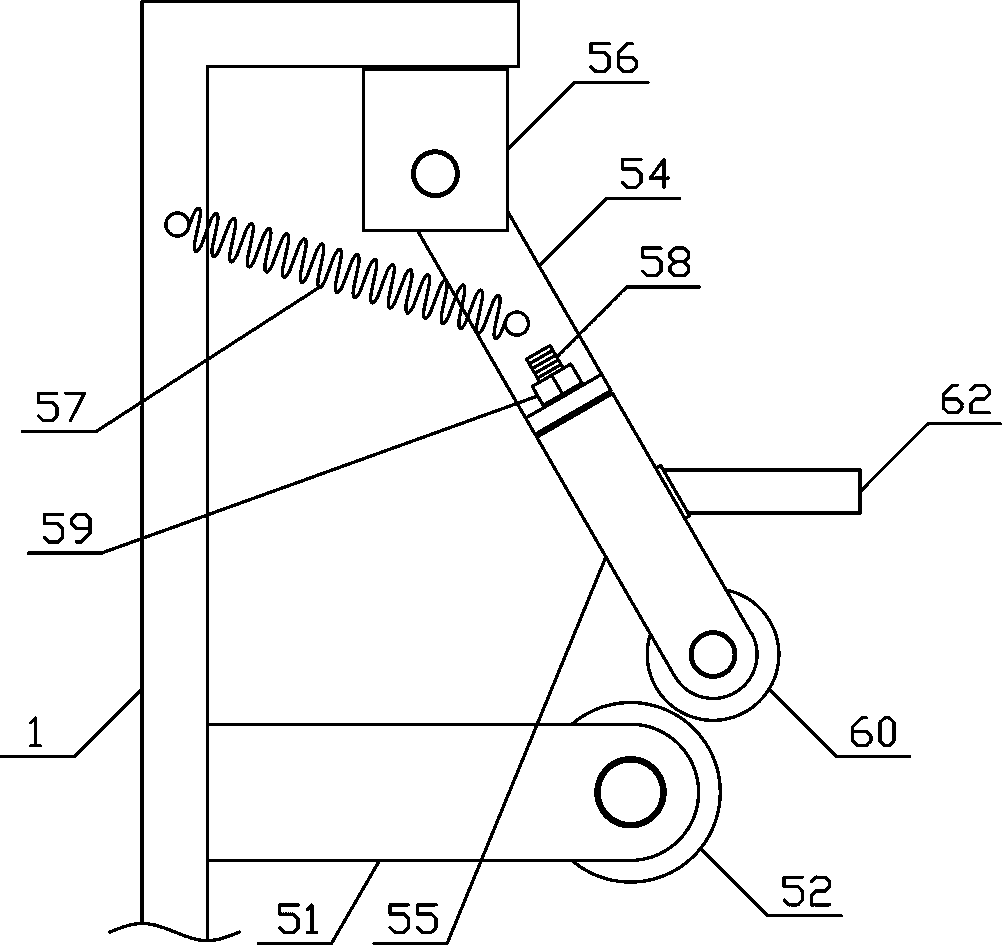

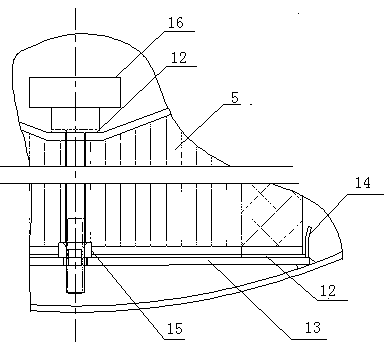

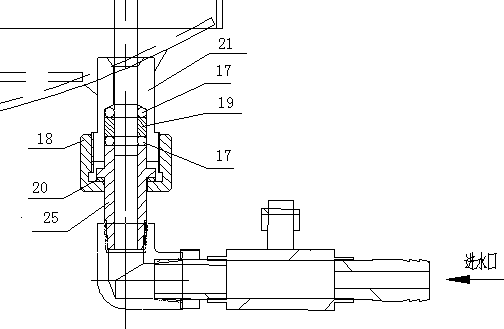

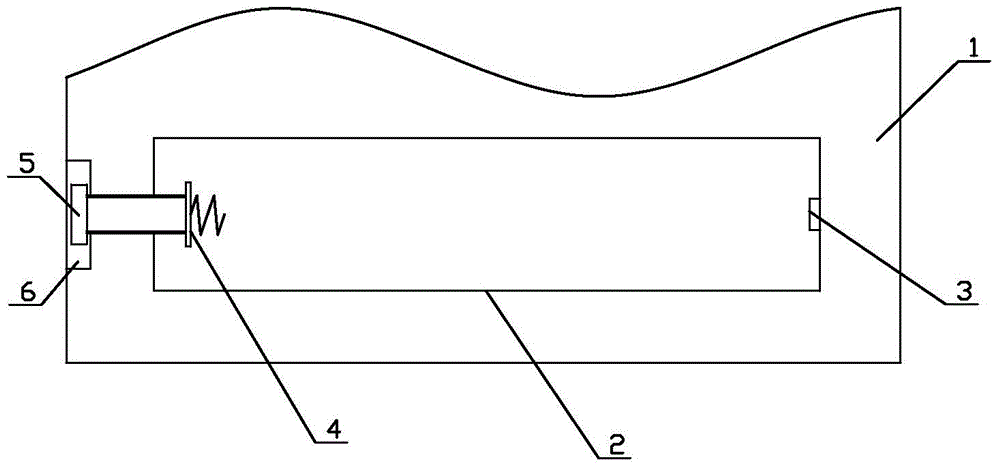

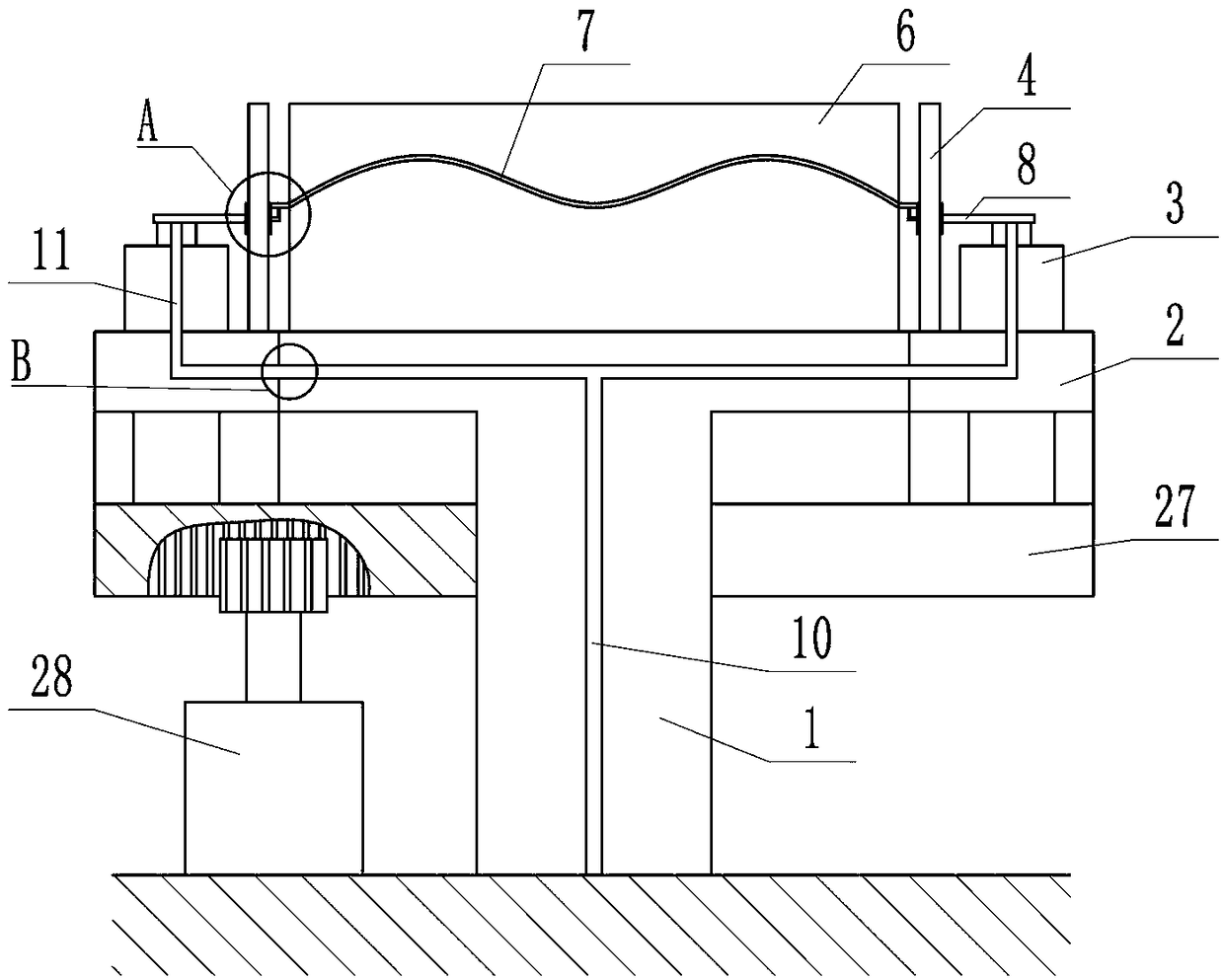

Electric automobile power battery quick-change mechanism

InactiveCN101890901AEasy to pick and placePrevent rush outElectric propulsion mountingCell component detailsPower batteryWorkload

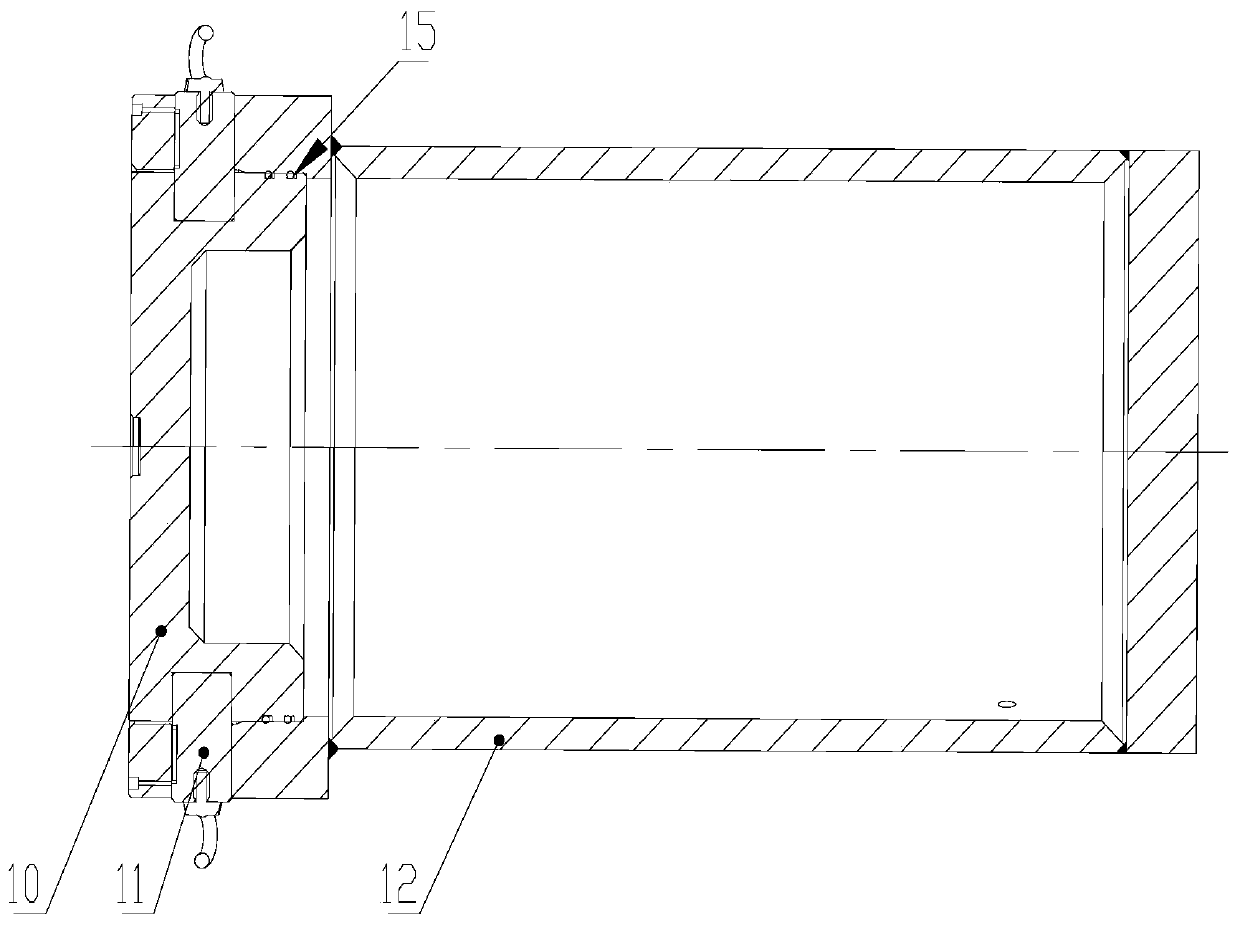

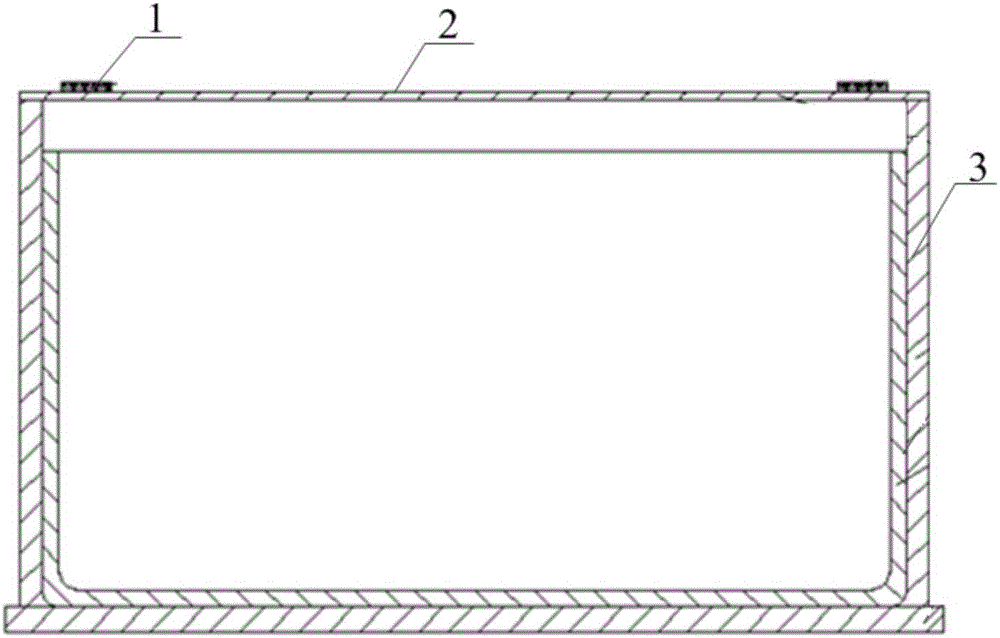

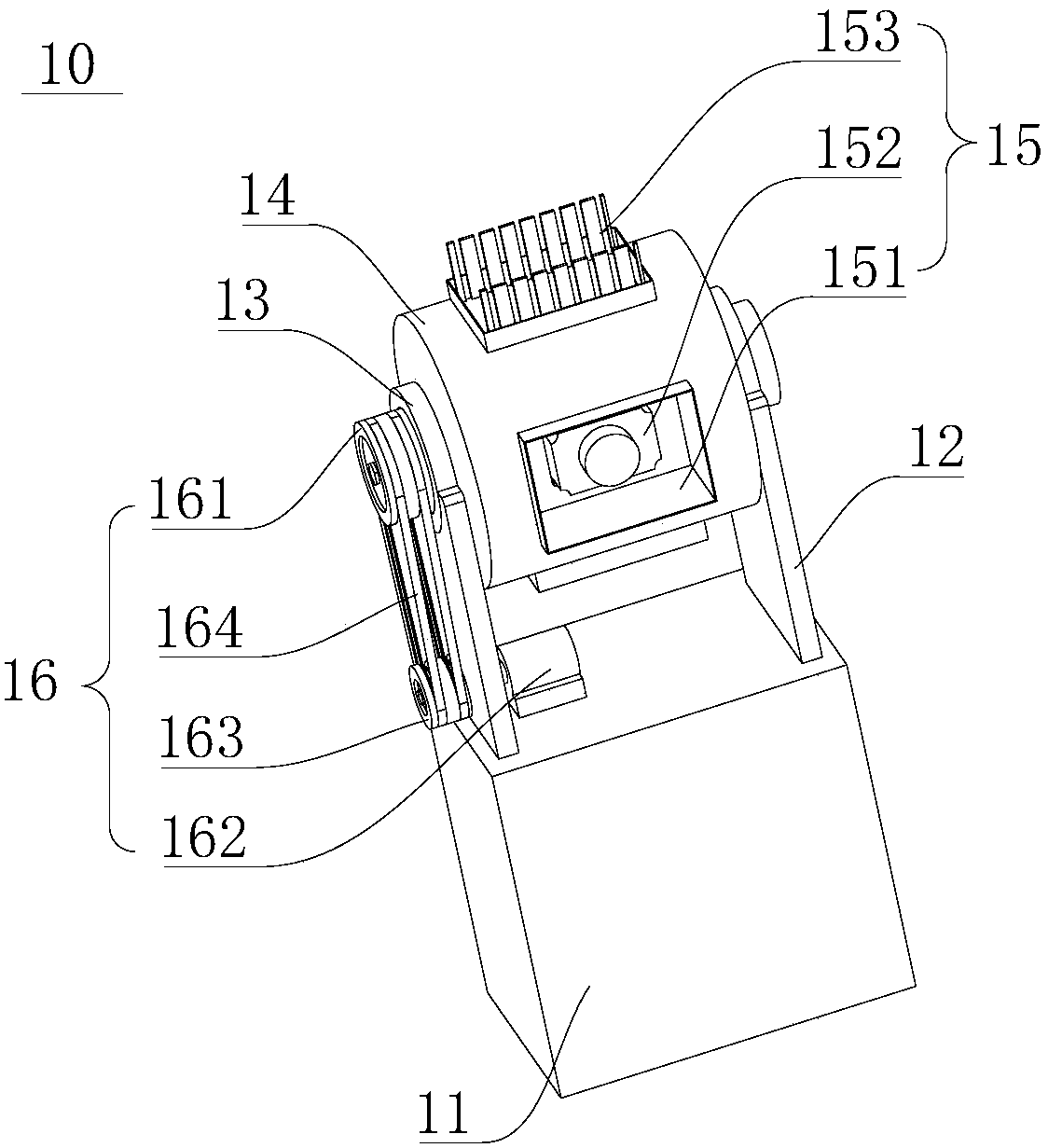

The invention discloses an electric automobile power battery quick-change mechanism which has simple structure, time-saving and labor-saving operations and use and convenient and quick battery change. The technical problems of time consumption, labor consumption, troublesome procedures, low efficiency, heavy workload and the like during battery removal, installation and change in the prior art is solved. The mechanism comprises a battery installing frame fixed on an automobile chassis and a battery pack arranged on the battery installing frame. One side of the battery installing frame is pivoted on the automobile chassis through a horizontal connecting shaft, the bottom of the battery installing frame is provided with a lifting mechanism which can drive the battery installing frame to rotate around the horizontal connecting shaft, and the other side of the battery installing frame opposite to the horizontal connecting shaft is provided with a battery pack inlet. The battery pack passing through the battery pack inlet is loaded to and unloaded from the battery installing frame through a sliding mechanism between a bottom board of the battery installing frame and the bottom surface of the battery pack, and a sliding stop mechanism capable of stopping the sliding of the battery pack is arranged in the battery installing frame corresponding to the battery pack inlet.

Owner:纽贝耳文化创意(杭州)有限公司

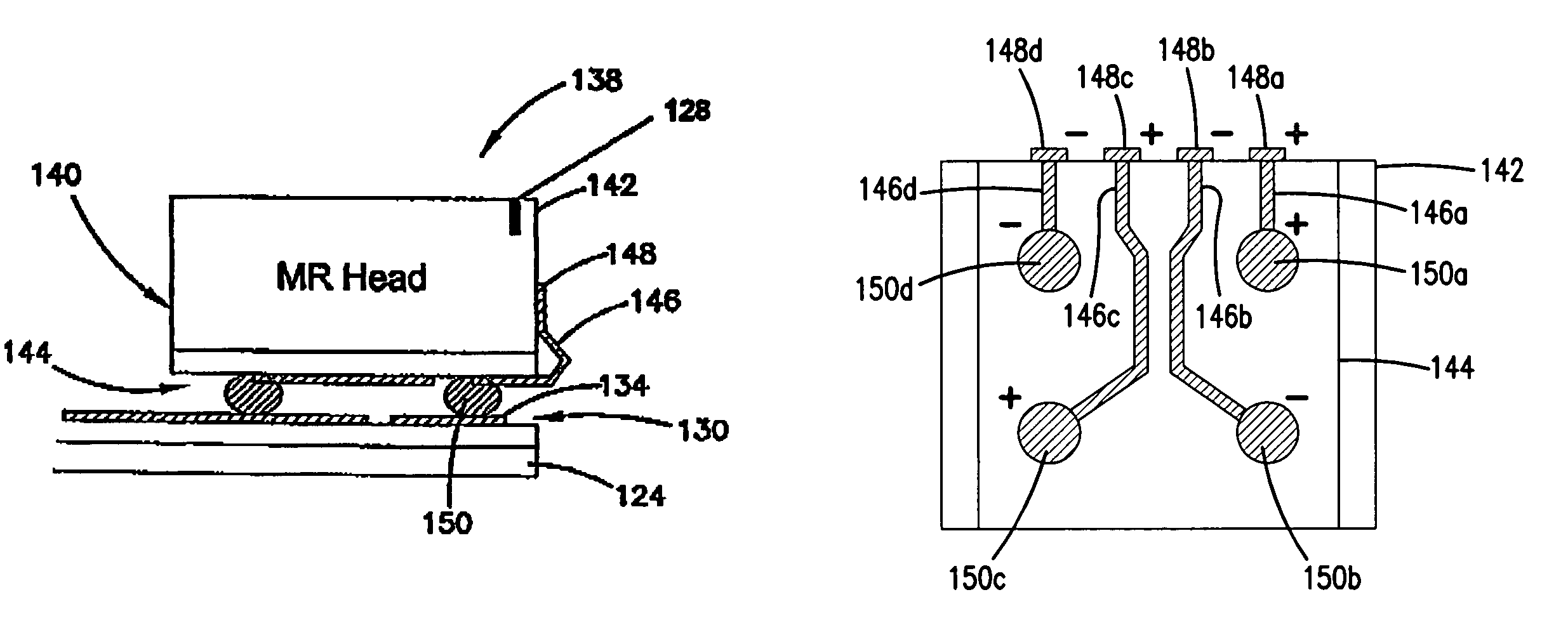

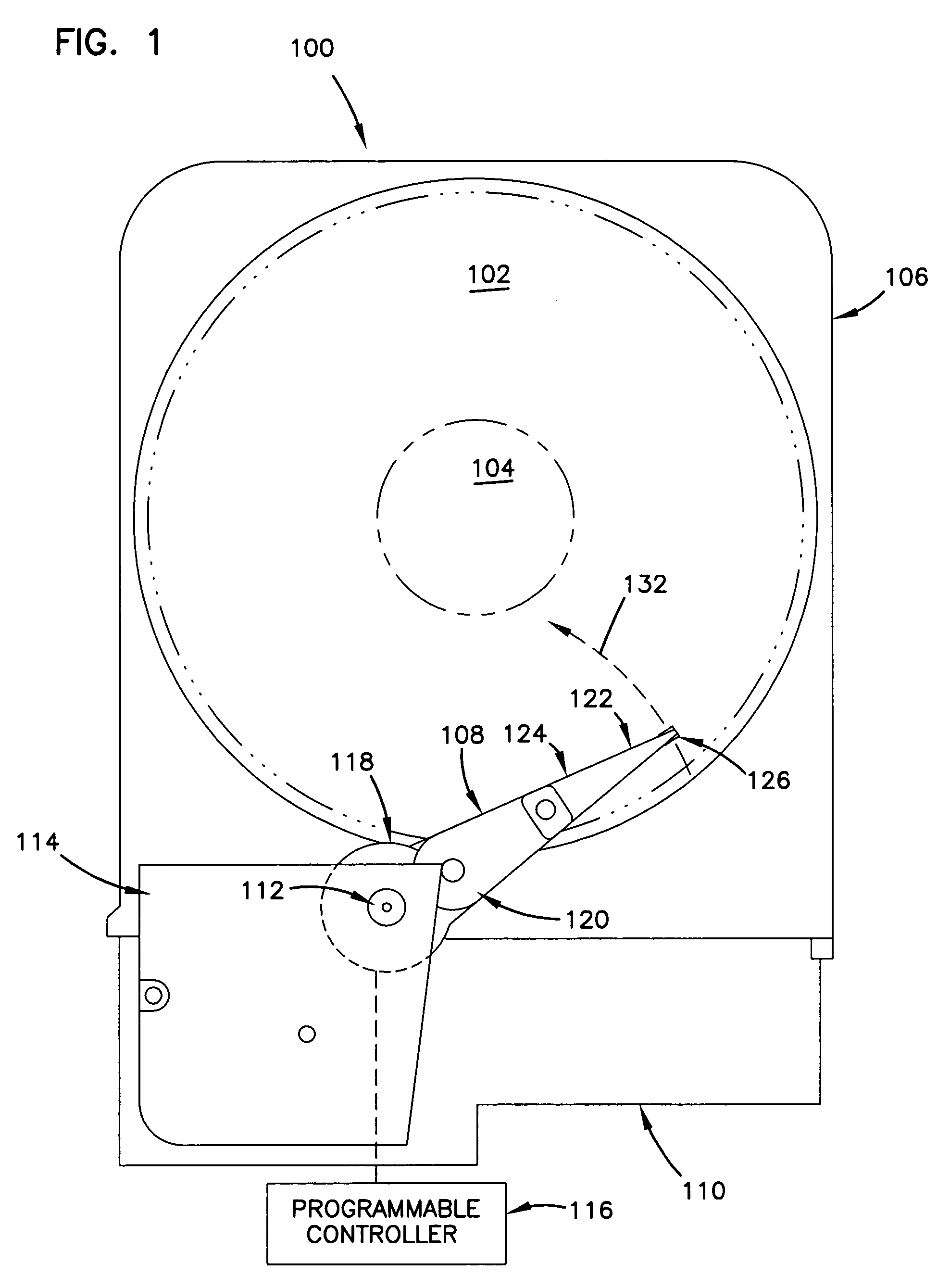

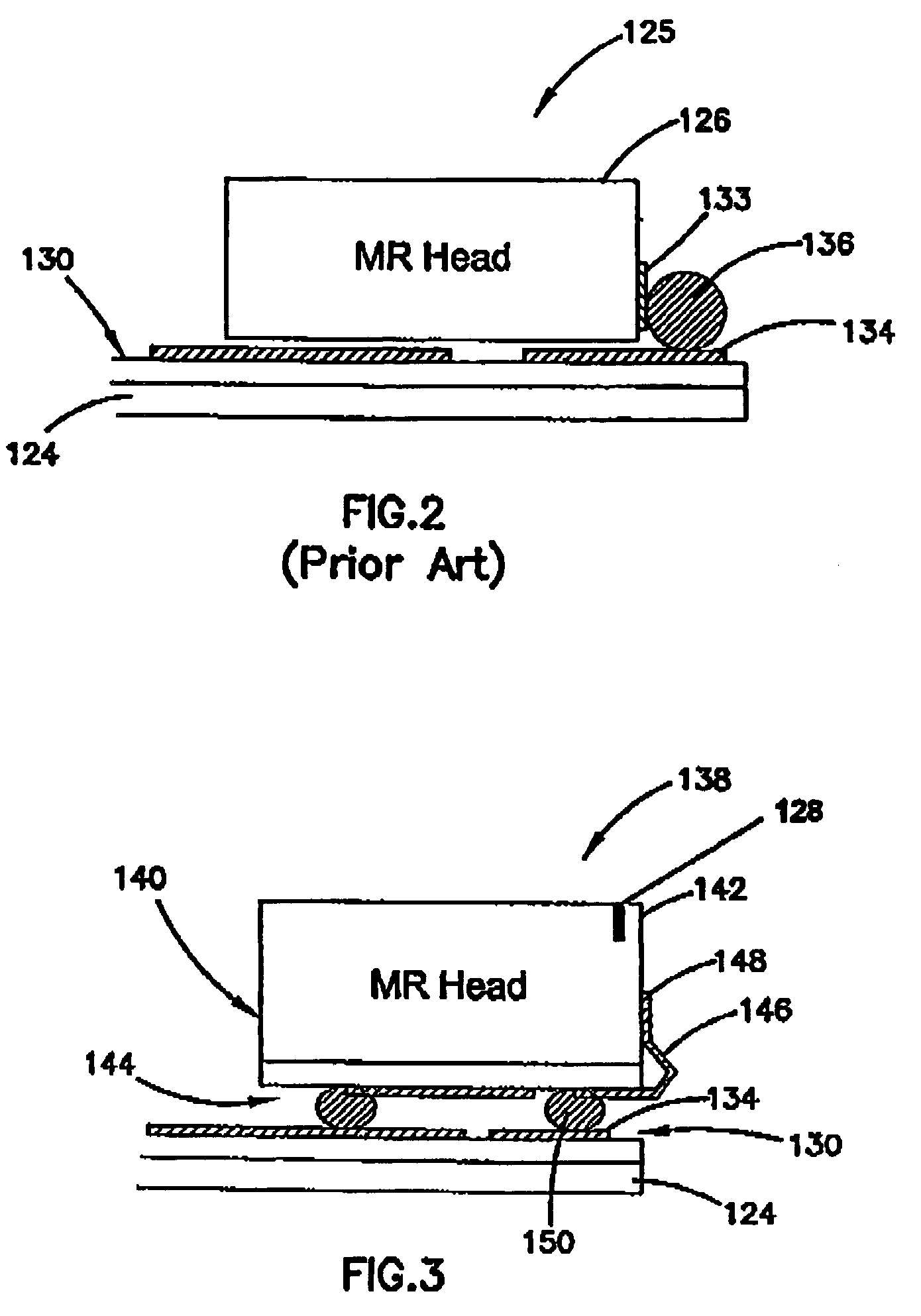

Head gimbal assembly with flex circuit arrangement between slider and head interconnect assembly

InactiveUS6985332B1Simple pickImprove adhesionElectrical connection between head and armFluid-dynamic spacing of headsFlexible circuitsEngineering

A slider scale package assembly in a head gimbal assembly (HGA) for electrically coupling a slider / magnetic recording (MR) head to a head interconnect circuit in a disc drive includes a flex circuit attached to the back of the slider / MR head which turns the slider / MR head into the slider scale package with at least one repositioned interconnect pad disposed at the back of the slider / MR head. The flex circuit further includes a conductive material, one end of which is electrically bonded to a bond pad of the slider / MR head, and the other end is electrically bonded to a conductive material of the head interconnect circuit via the interconnect pad. A plurality of flex circuits can be made in a sheet format and dividable into a plurality of individual flex circuits to be attached to a plurality of slider / MR heads. The bonding of the conductive material of the flex circuit to the slider / MR head and the bonding of the interconnect pad of the flex circuit to the conductive material of the head interconnect circuit can be done in a separate automated process.

Owner:SEAGATE TECH LLC

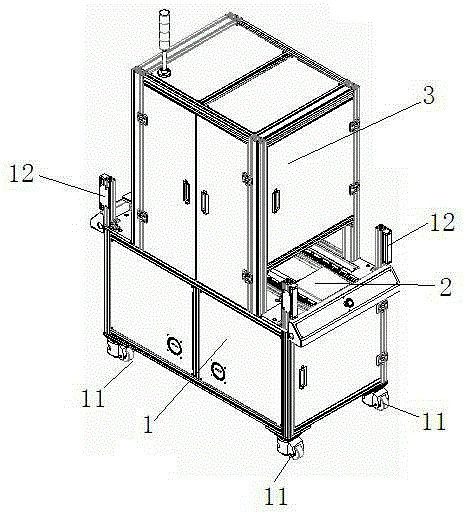

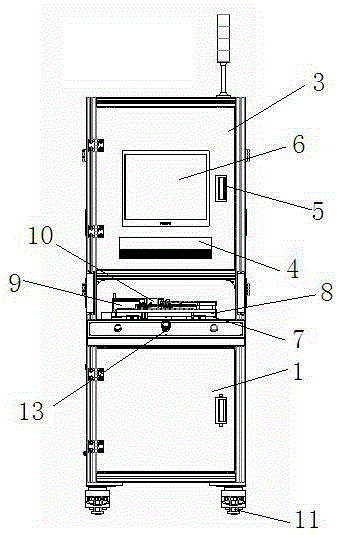

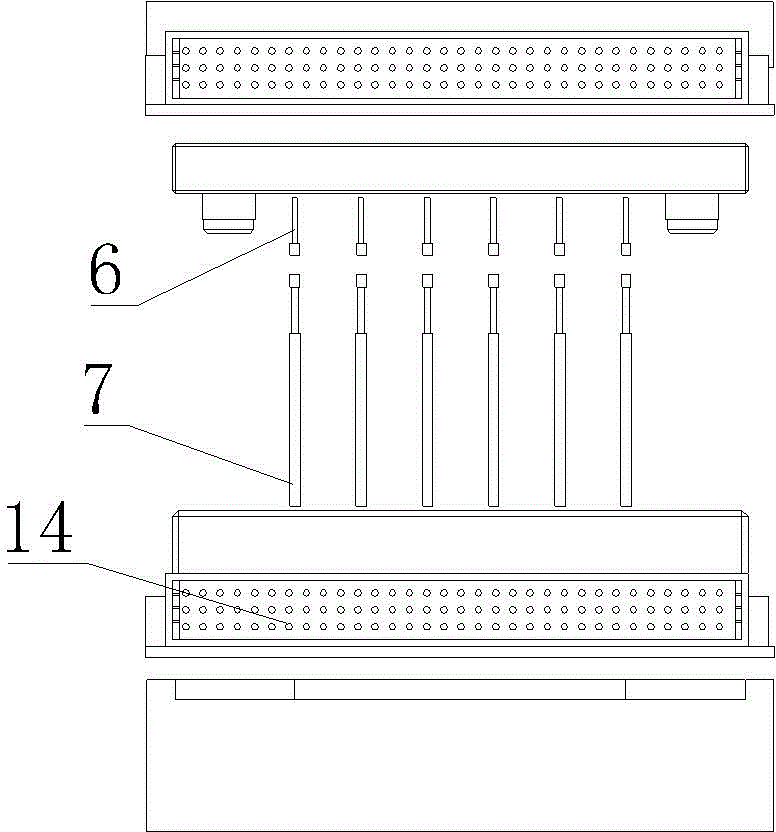

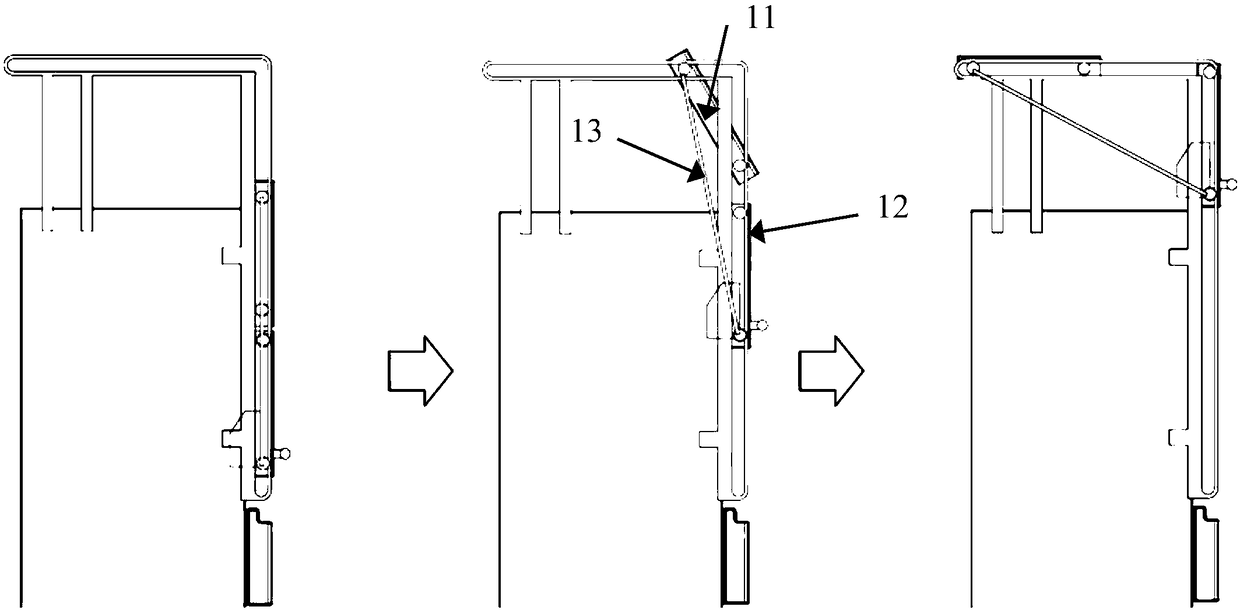

AOI vision detection device with automatic overturning function

InactiveCN105259182AFlipEasy flipOptically investigating flaws/contaminationEngineeringMechanical engineering

The invention discloses an AOI vision detection device with an automatic overturning function. The AOI vision detection device comprises a bearing machine box, the bearing machine box is provided with a conveying belt for conveying PCBs to be detected, a detection machine box is further arranged above the bearing machine box, and the detection machine box is internally provided with an automatic shooting camera, a processing terminal and a display panel. One side of an inlet of the conveying belt is fixedly provided with a PCB bearing mechanism, and the PCB bearing mechanism comprises a foundation support, a vacuum sucking disc plate, an overturning motor and a grab handle, the foundation support is fixed to the conveying belt, the vacuum sucking disc plate is fixed to the foundation support, the upper surface of the vacuum sucking disc plate is used for absorbing the PCBs to be detected, the overturning motor is arranged on one side of the foundation support, and the output end of the overturning motor is connected with the grab handle to drive the grab handle to grab and turn over the PCBs to be detected at the center of the conveying belt. By means of the AOI vision detection device, two faces can be detected at the same time through one-time conveying, a sucking disc is adopted for adsorption, taking, placing and fixing are facilitated, and detection efficiency is greatly improved.

Owner:KUNSHAN HONGZHIXI AUTOMATION EQUIP

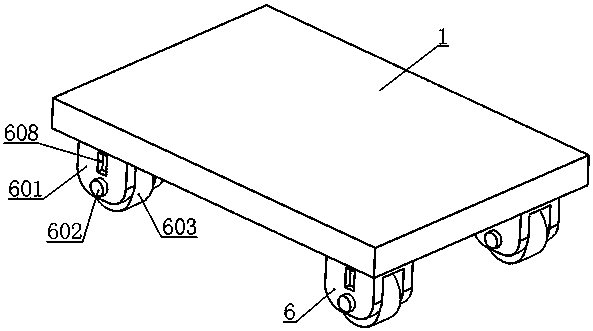

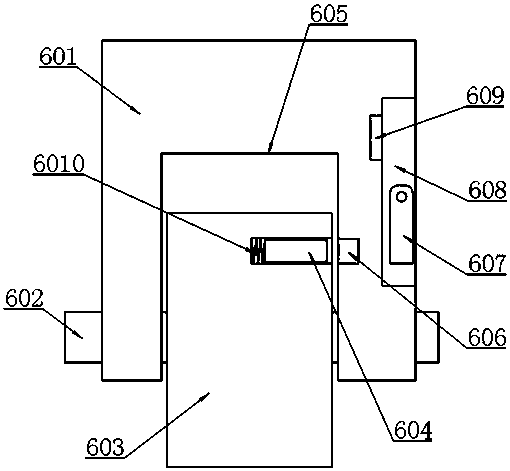

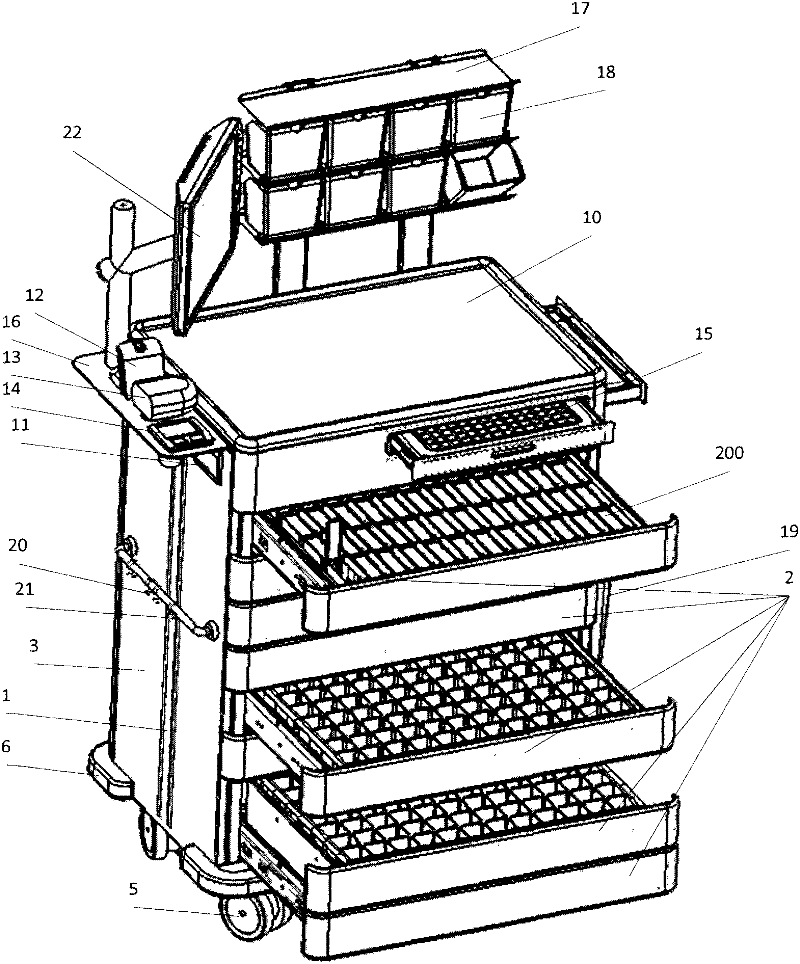

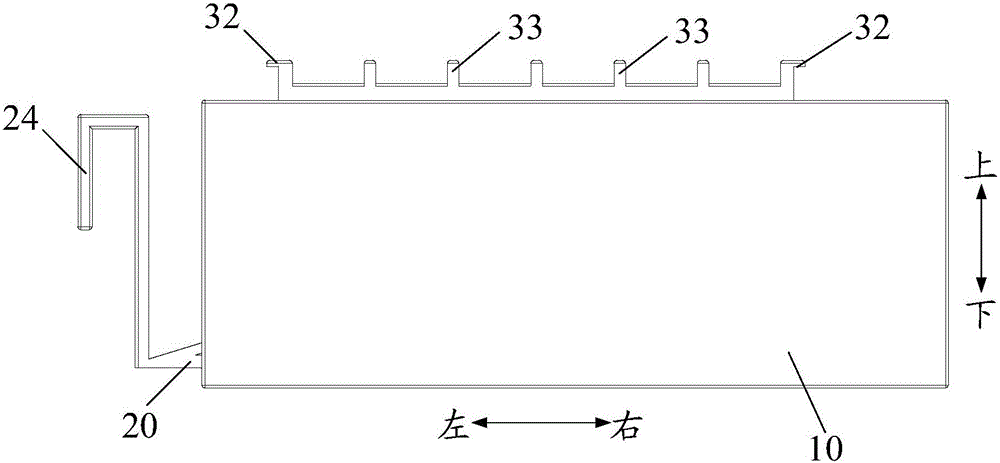

Movable placement frame for discarded printed circuit boards

PendingCN107826155AEasy to pick and placeImprove placement stabilitySupporting partsHand carts with multiple axesAgricultural engineeringUnit structure

Owner:福建志坤能源科技开发有限公司

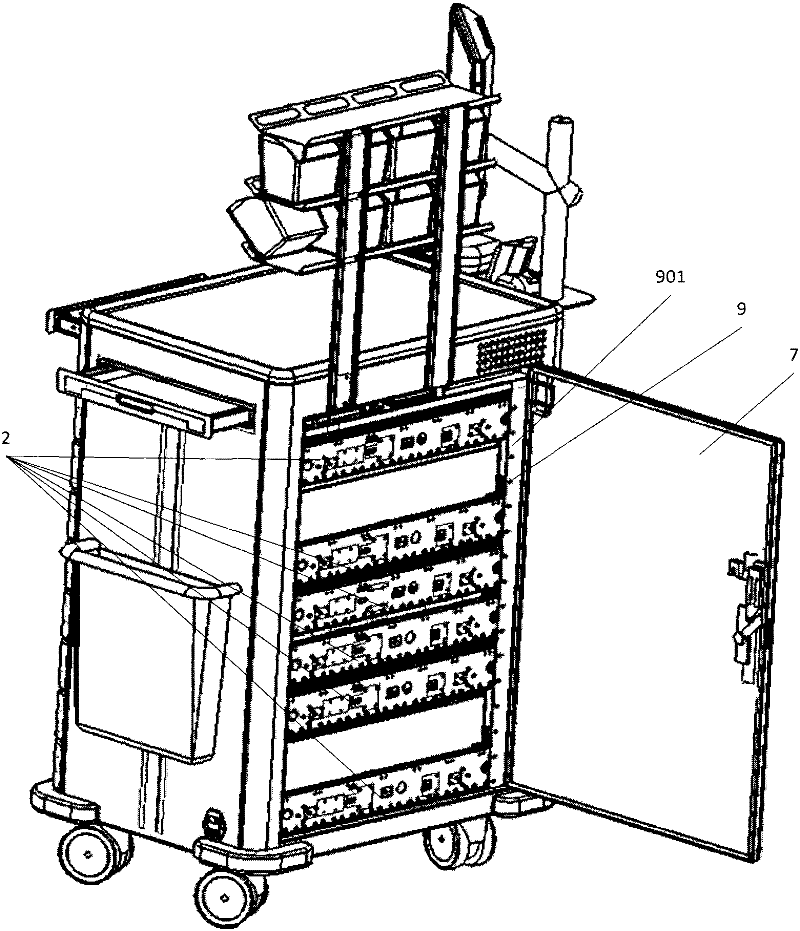

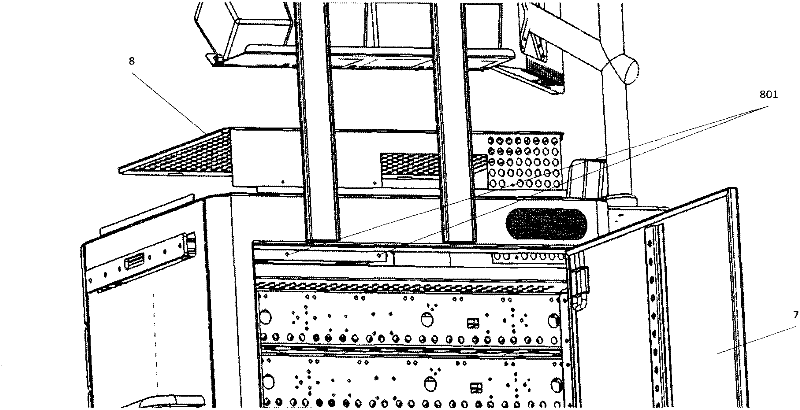

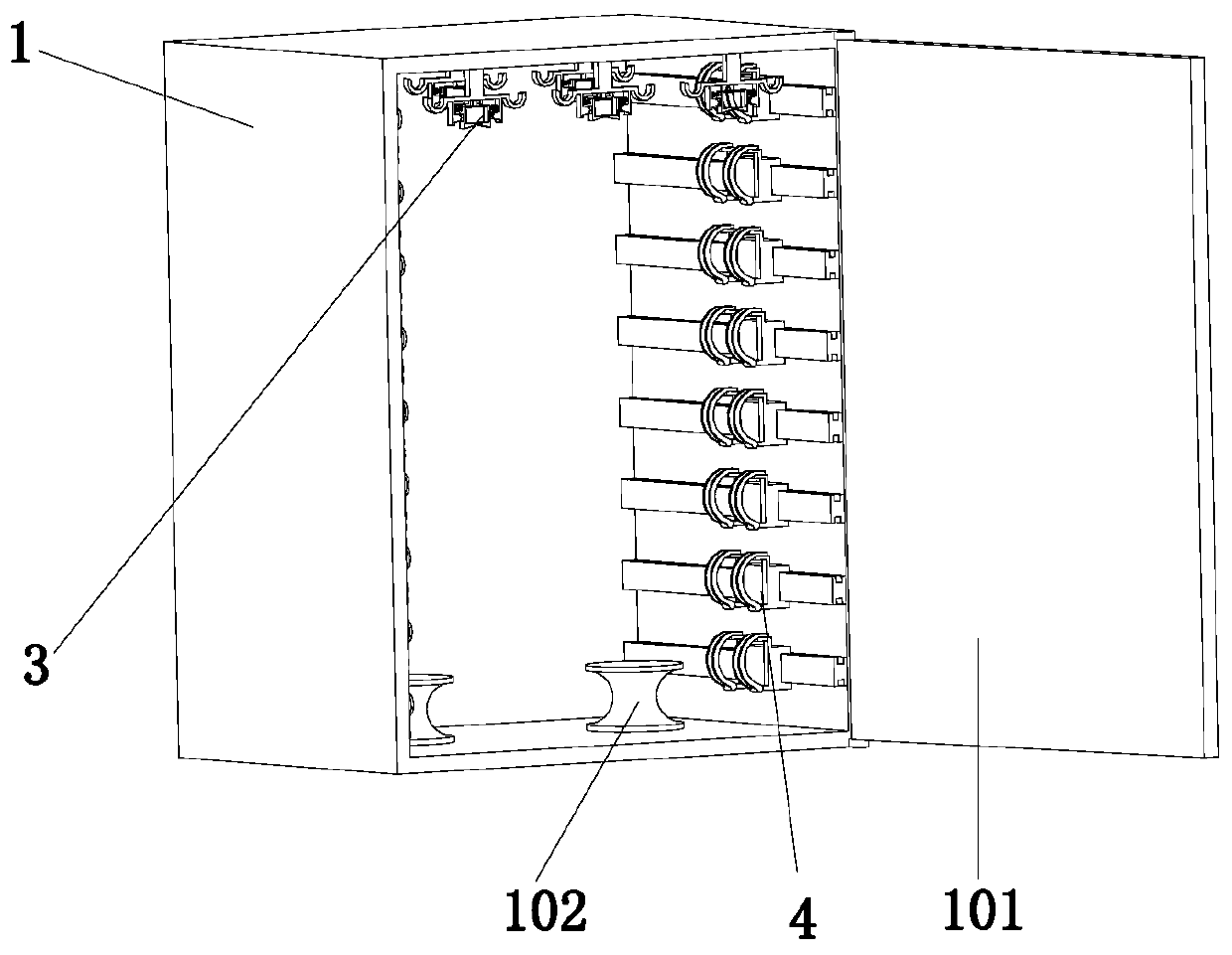

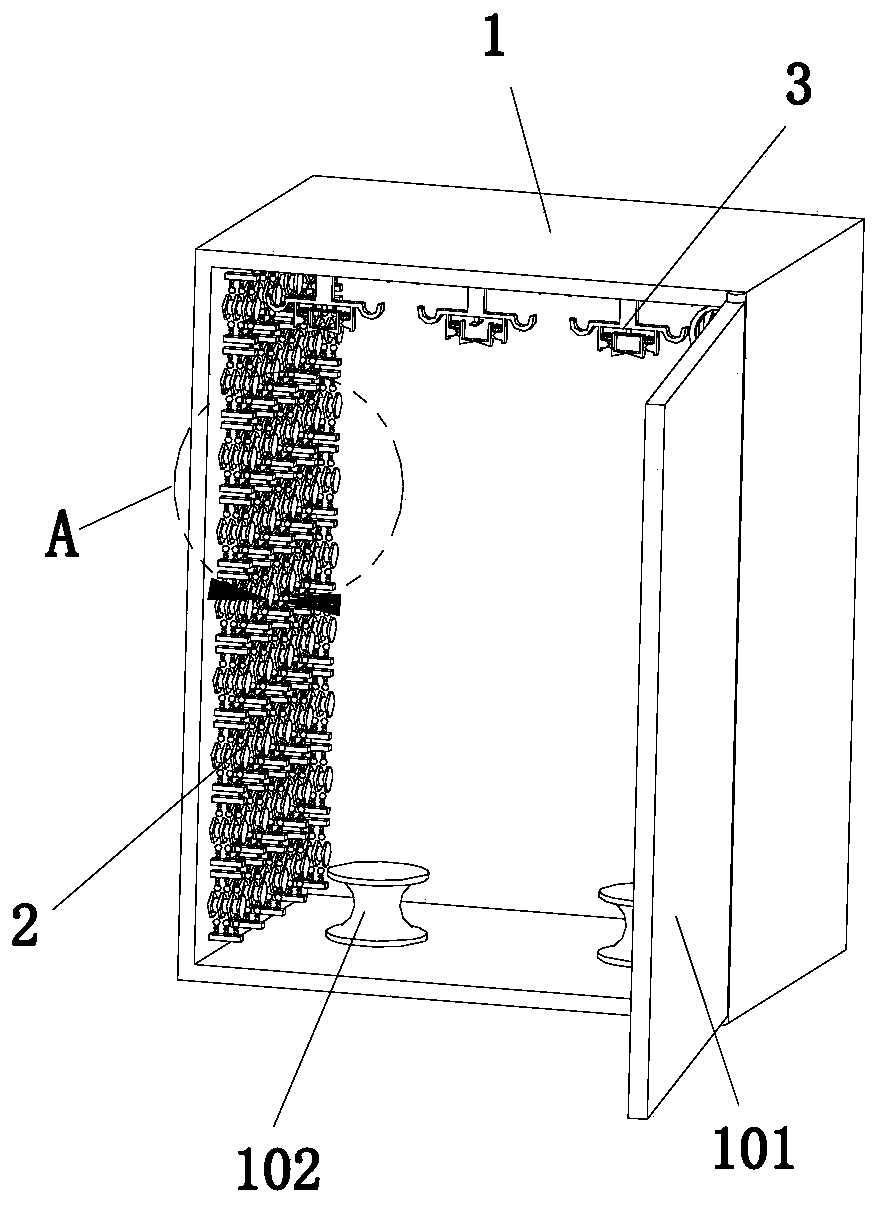

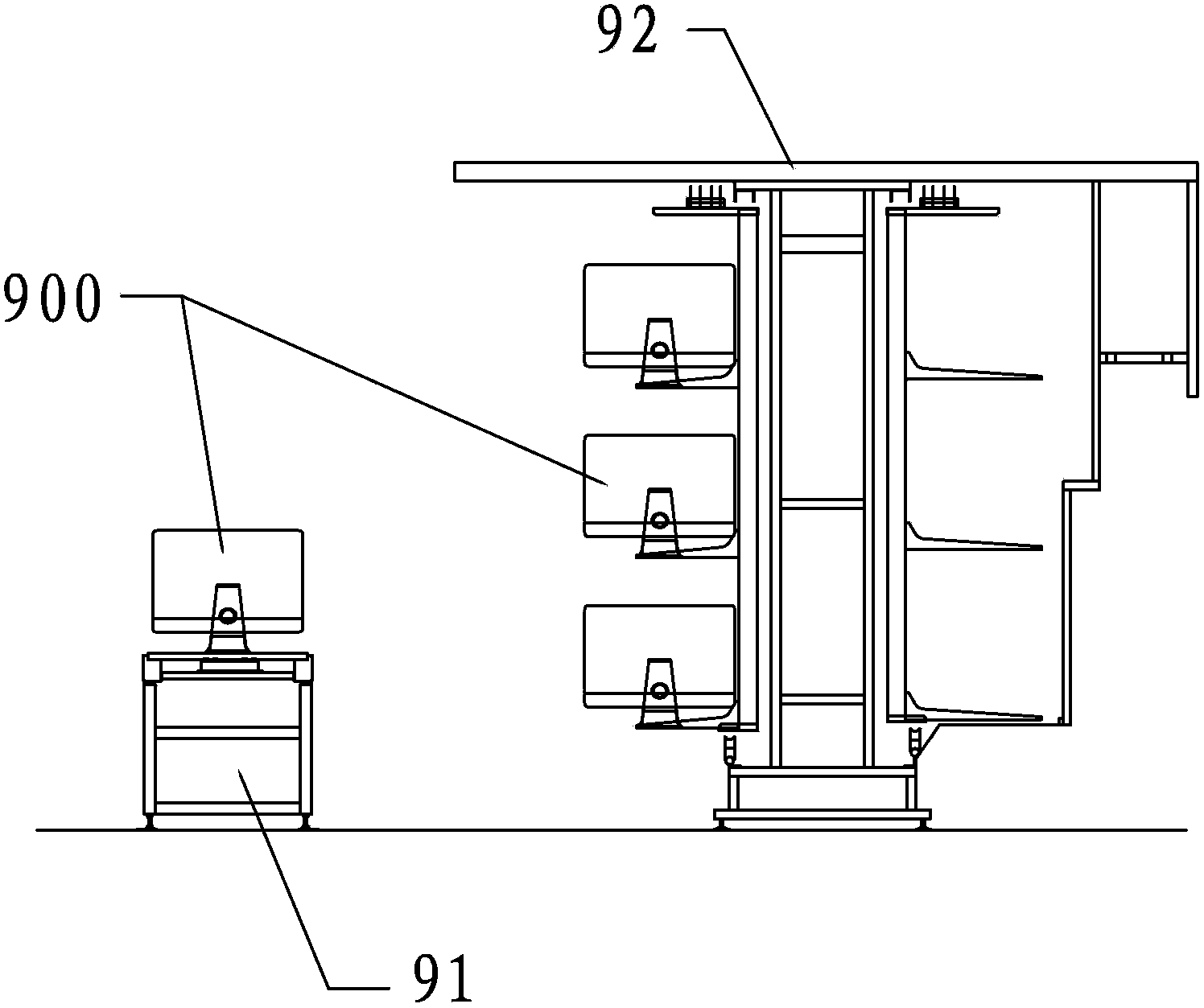

A drug access system

ActiveCN102259744AImprove efficiency and accuracyEasy to assemble and repairStorage devicesDrug accessBiomedical engineering

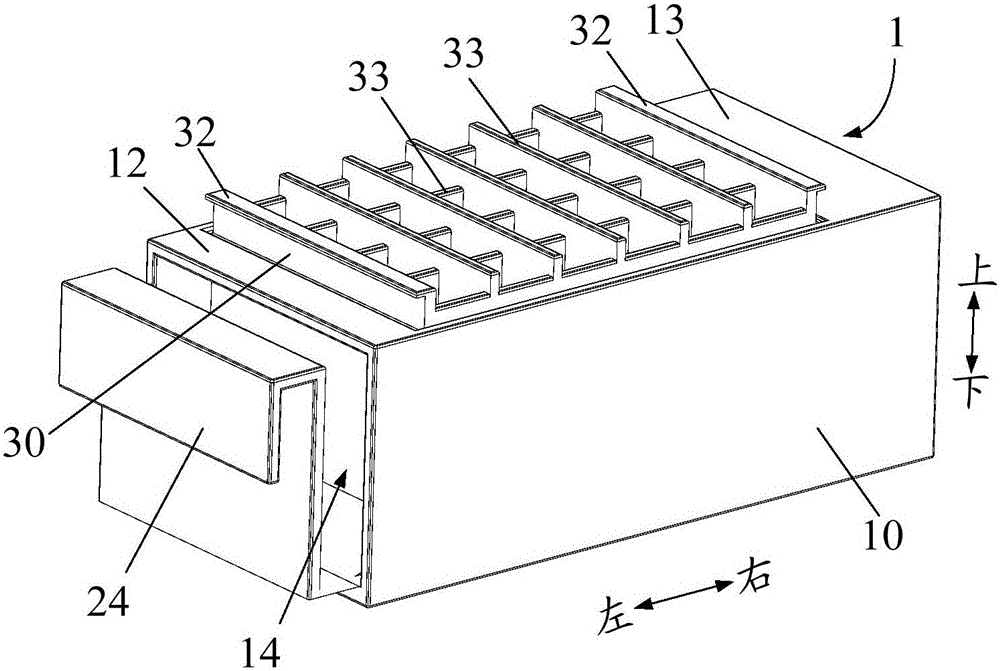

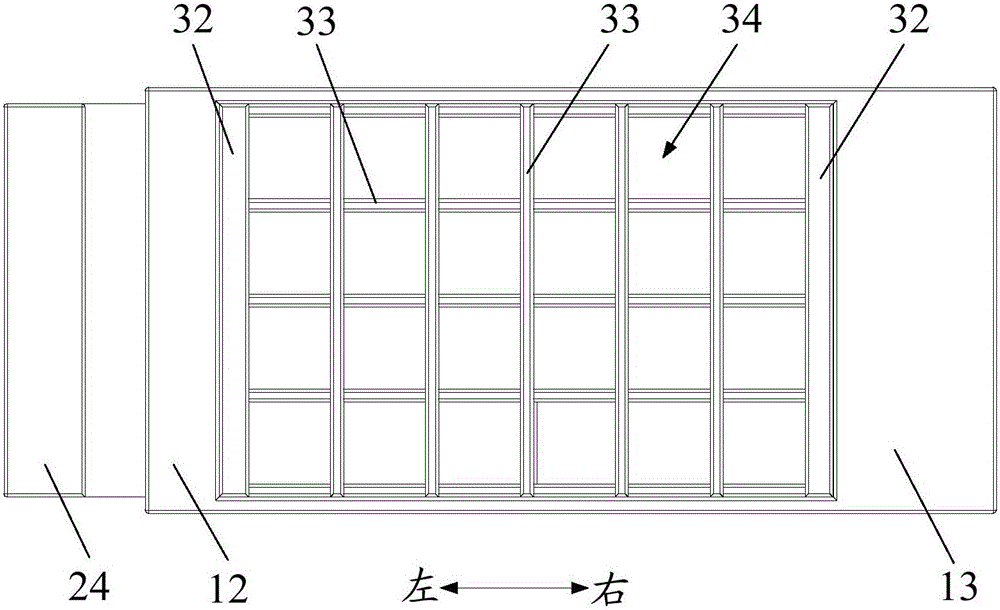

The invention relates to a medicine access system for hospitals, in particular to a medicine workstation of medicines and consumables in operating rooms. The medicine access system can be used for realizing automatic medicine access registration and effective data tracking; in addition, based on the design of a single access door, all drawers, medicine boxes and internal equipment can be maintained and changed only after a rear cabinet door is opened, moreover the cabinet door has a function of state memory and can record the open state of the cabinet without being electrified, therefore the safety of medicine and equipment management and convenience of equipment maintenance can be improved.

Owner:HUAXING RONGTAI

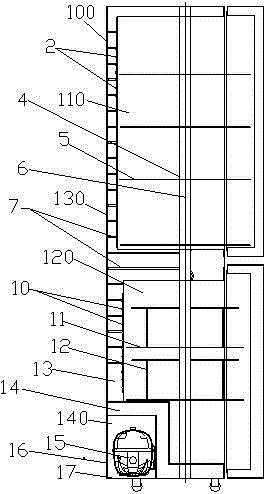

Yarn continuous twisting device

ActiveCN109137153AEfficient and accurate twisting processingEasy accessTextile disintegration and recoveryContinuous wound-up machinesYarnEngineering

The invention discloses a yarn continuous twisting device and belongs to the weaving processing machinery equipment field. A yarn winding mechanism, a yarn guiding mechanism, a twisting mechanism, a yarn drawing mechanism, and a yarn releasing mechanism of the invention are successively and fixedly arranged on one side of a fixing support from top to bottom. The central section of the lower side of a rotation disc is rotatably connected to a yarn bearing support. A drawing spring is arranged between a yarn drawing pull rod and a yarn wheel support. The upper yarn guide support, the twisting support and the lower yarn guide support of the twisting mechanism are successively, horizontally and fixedly arranged on one side of the fixing support from top to bottom. A reciprocating connection rod is slidably arranged on a reciprocating support along a horizontal direction. A yarn winding roller is horizontally and rotatably connected to a yarn winding support. A yarn winding spring is arranged between a rotation support and the fixing support in an inclined mode. A locking screw rod is arranged between the central section of the upper side of a yarn winding placing rack and the rotationsupport. The structure is designed reasonably, yarns can be high-efficiently and accurately twisted and processed continuously, the twisting degree of the yarns can be increased and a production and usage demand is satisfied.

Owner:浙江新景和纺织科技有限公司

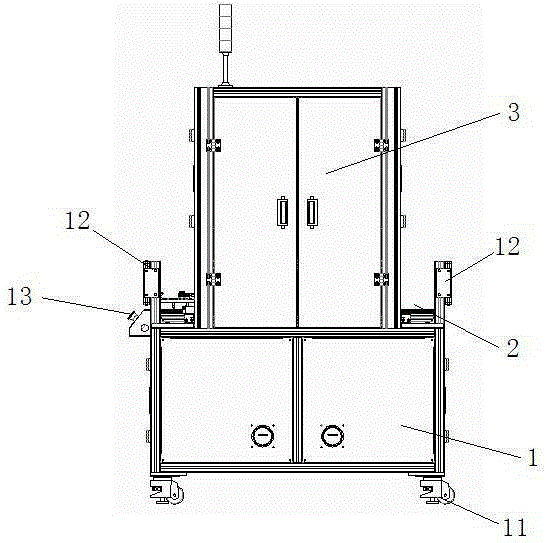

Power distribution cabinet with cable arrangement function

ActiveCN110380343AInhibit sheddingEasy to fixBus-bar/wiring layoutsSubstation/switching arrangement casingsConductor CoilElectrical and Electronics engineering

The invention discloses a power distribution cabinet with a cable arranging function, and relates to the technical field of power distribution equipment. The cabinet comprises a box body, wire arranging mechanisms, hanging mechanisms and bundling mechanisms. The box body is provided with a box door which is opened towards the outer side; the wire arranging mechanisms are mounted on the inner sidewall of the box body; the plurality of wire arranging mechanisms are arranged in a matrix manner; the hanging mechanisms are installed at the top of the inner side of the box body, and the hanging mechanisms are arranged in a matrix mode; the bundling mechanisms are arranged on the inner side wall of the other side of the box body, the bundling mechanisms are installed on the box body in a slidingmode, and the bundling mechanisms are arranged on the inner side wall of the box body at equal intervals in the vertical direction. The power distribution cabinet has the advantages that the wire arranging mechanisms, the hanging mechanisms and the bundling mechanisms are arranged; different cables can be arranged in different modes through the three mechanisms; the situation that the cables arearranged disorderly in the power distribution cabinet, circuits are inconvenient to maintain is avoided, and meanwhile, the potential safety hazards caused by mutual winding of the cables are reduced.

Owner:常德三欣电力电子科技有限公司

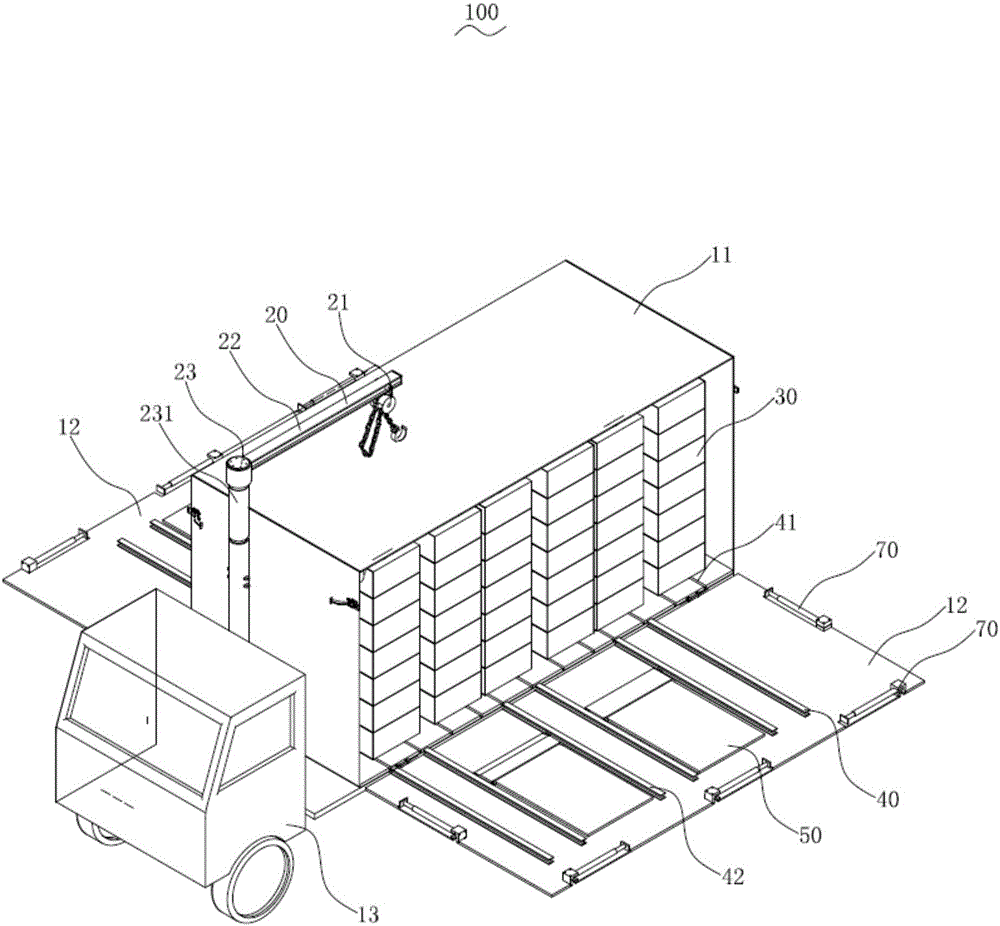

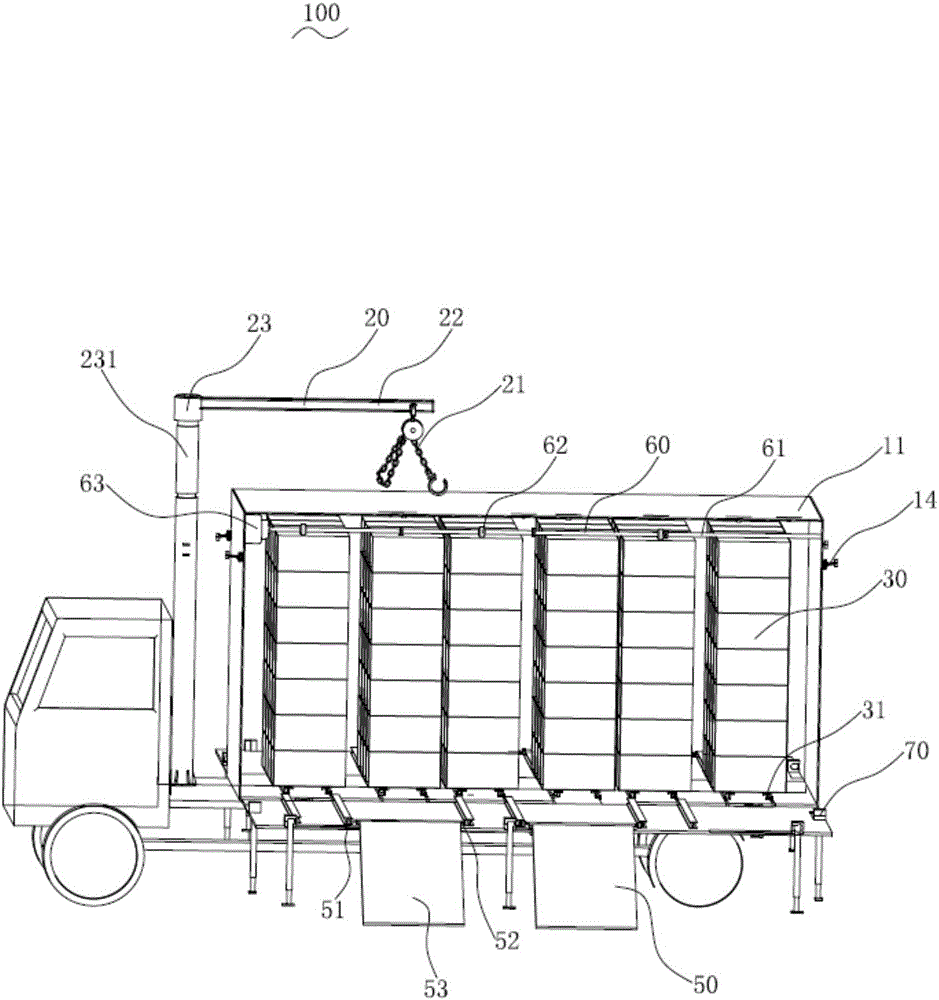

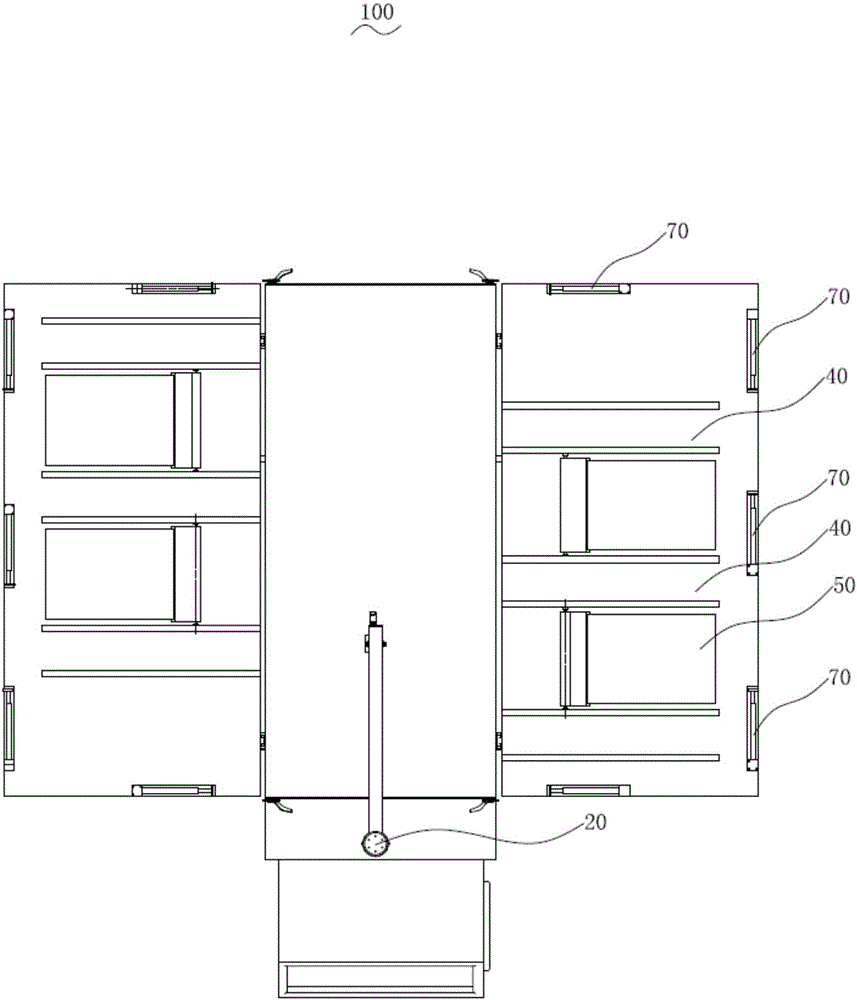

Multifunctional express carrying car

InactiveCN105691471AReduce work intensityPut in orderItem transportation vehiclesLoading-carrying vehicle superstructuresEngineeringPulley

A multi-functional express delivery vehicle, comprising a compartment, the side of the compartment is provided with a side door, and also includes a bird box, a guide rail and a friction wheel device, the bird box is movably arranged in the compartment, and the guide rail is arranged in the compartment On the bottom surface and the inner side of the side door, the bottom of the side door is movably linked with the bottom surface of the carriage, and the side door can be opened downward to be flush with the bottom surface of the carriage. The friction wheel device is arranged above the bird box, which drives the bird box along the The guide rail moves to the outside of the compartment or to the interior of the compartment. In the present invention, by setting the bird box, the courier can divide the objects into the bird box according to the needs, and the objects are placed in an orderly manner, which is convenient for management, and the work efficiency is greatly improved. A bird box with pulleys and a guide rail are also provided, so that the bird box can move out of the compartment or into the compartment along the guide rail, which is convenient for the courier to pick and place objects, and has the advantages of fast and easy access. And by setting the friction wheel device, it is used to drive the movement of the bird box, without manual pushing, reducing the work intensity of the courier.

Owner:XIAMEN UNIV OF TECH

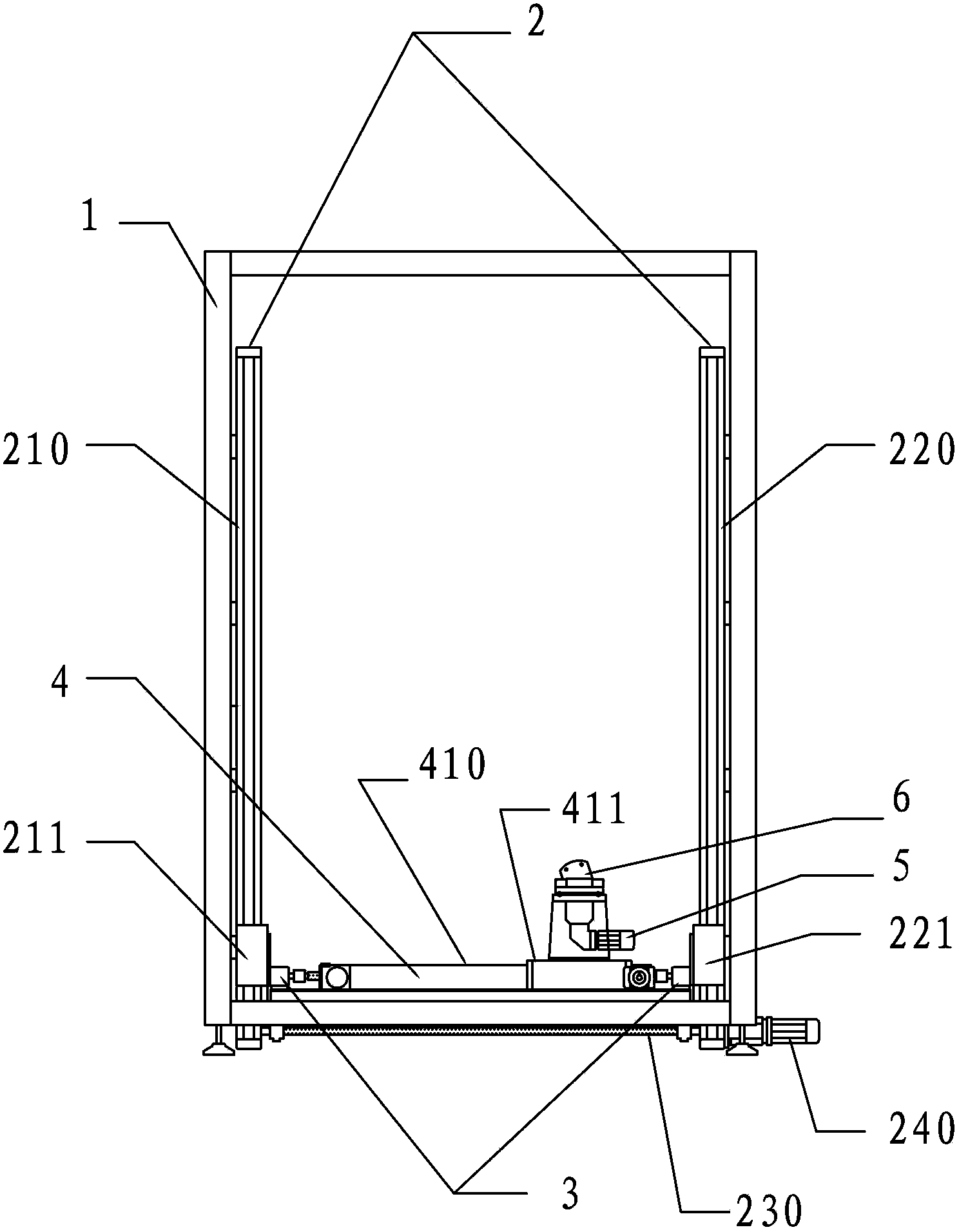

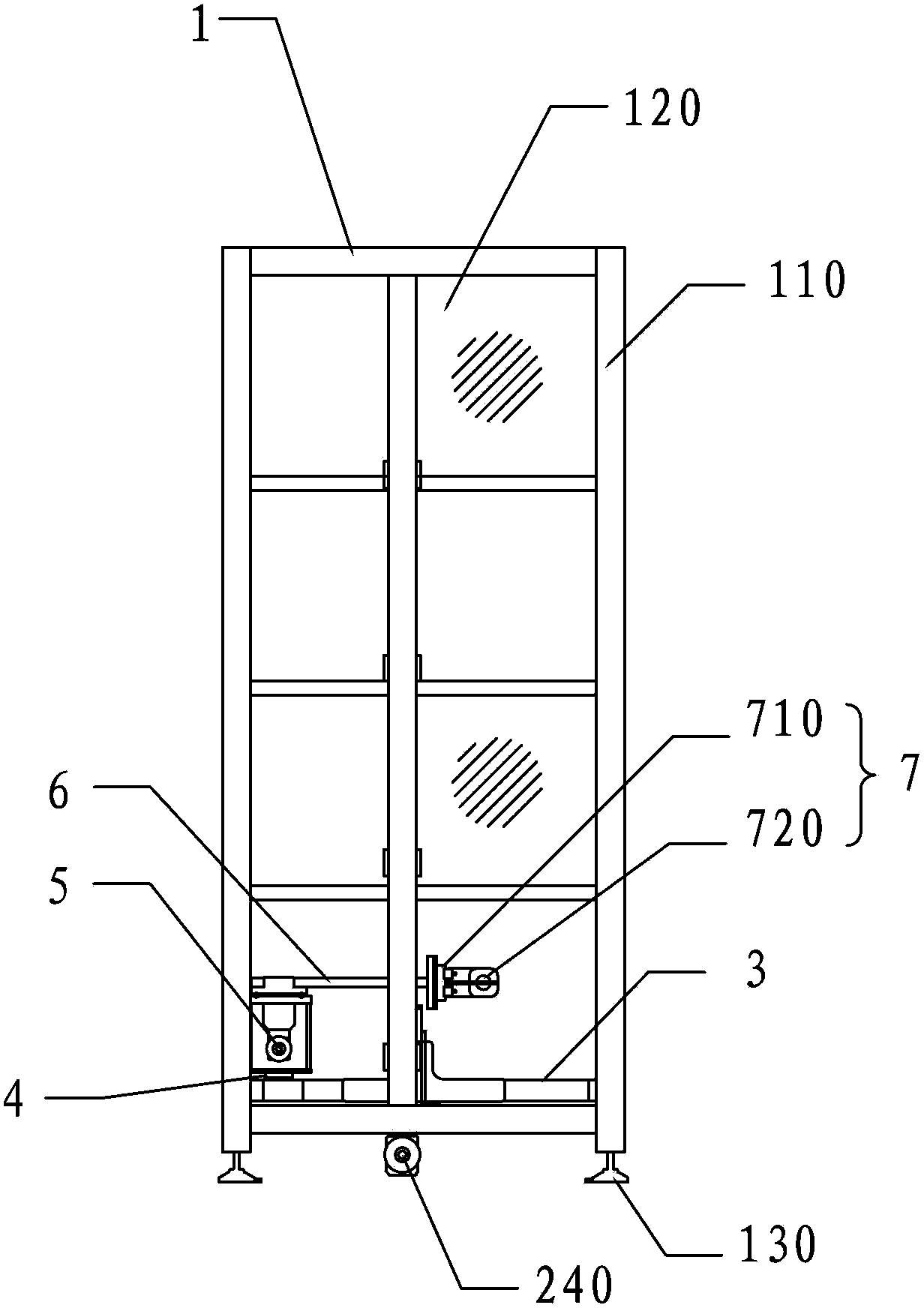

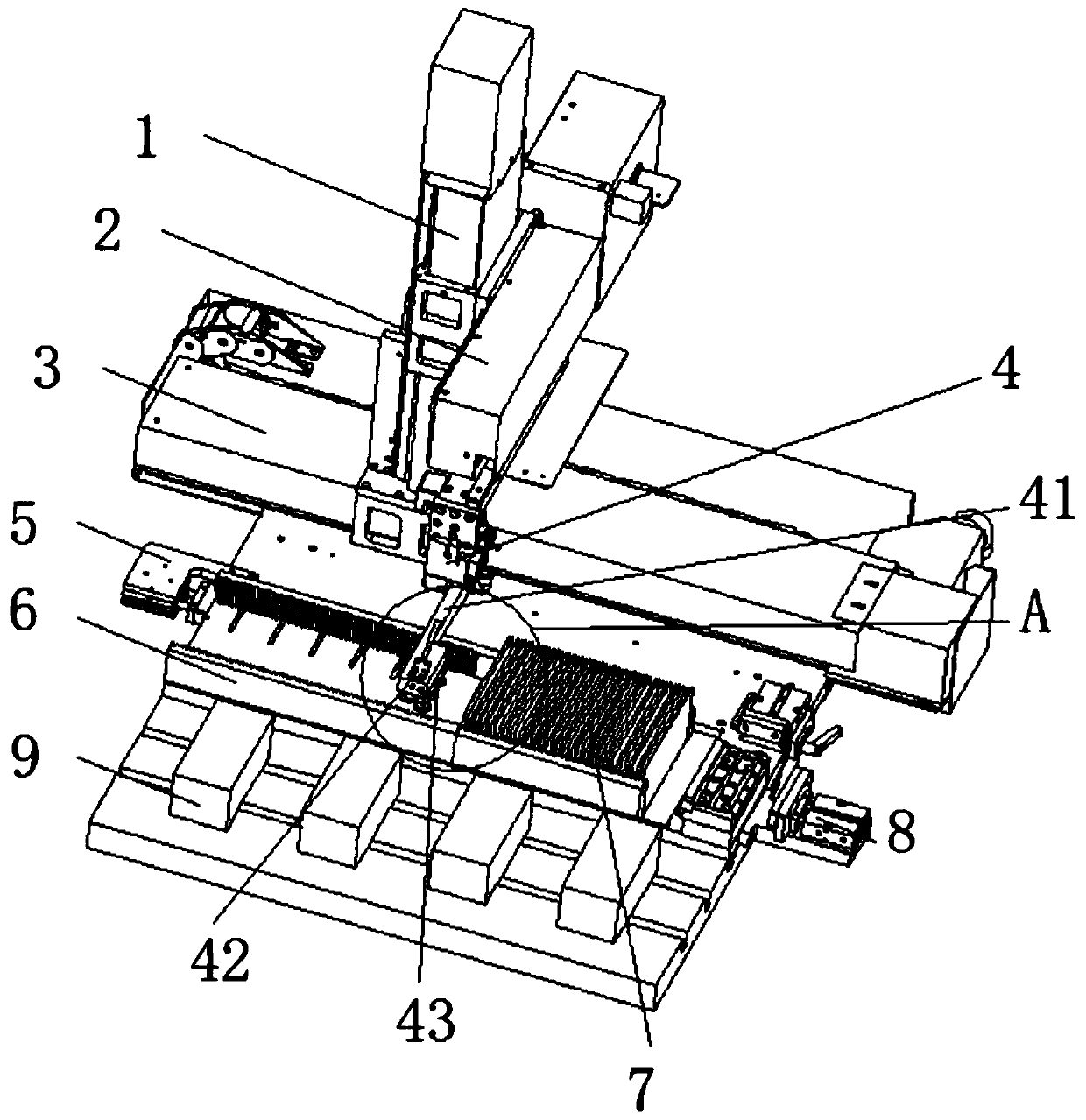

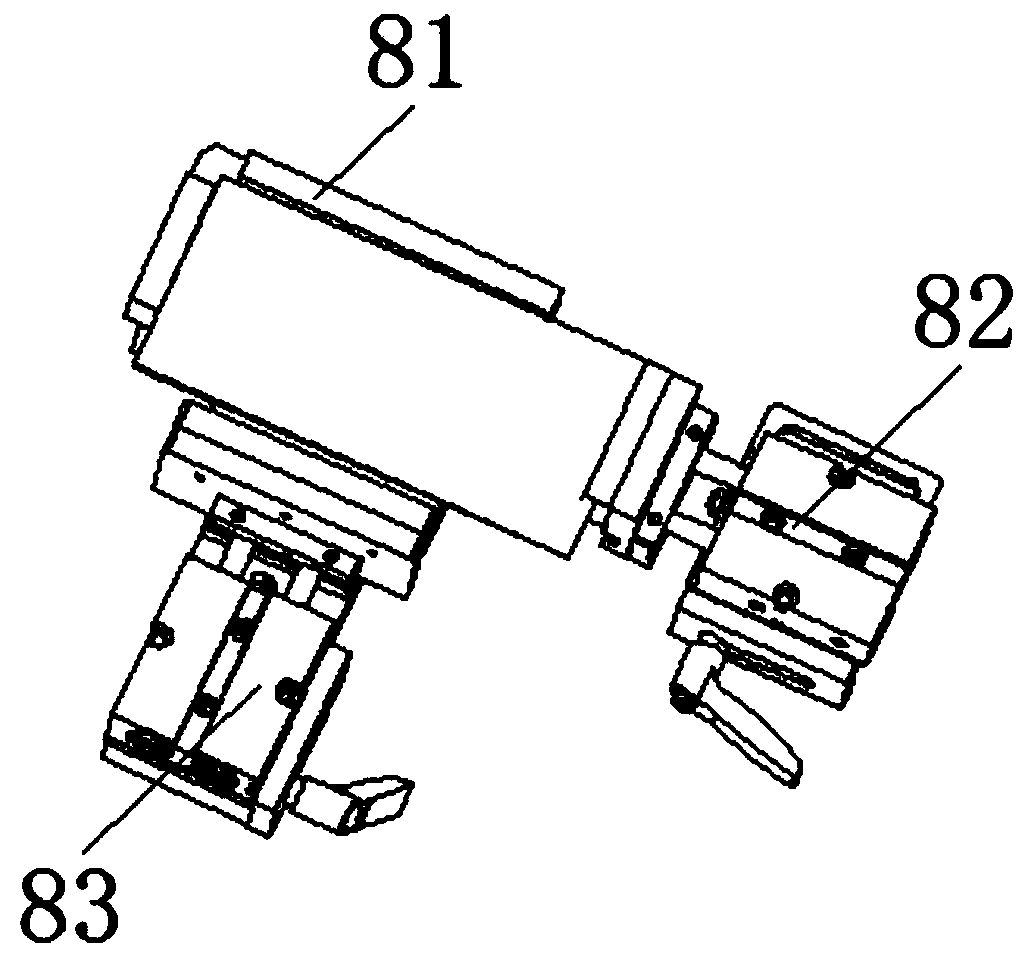

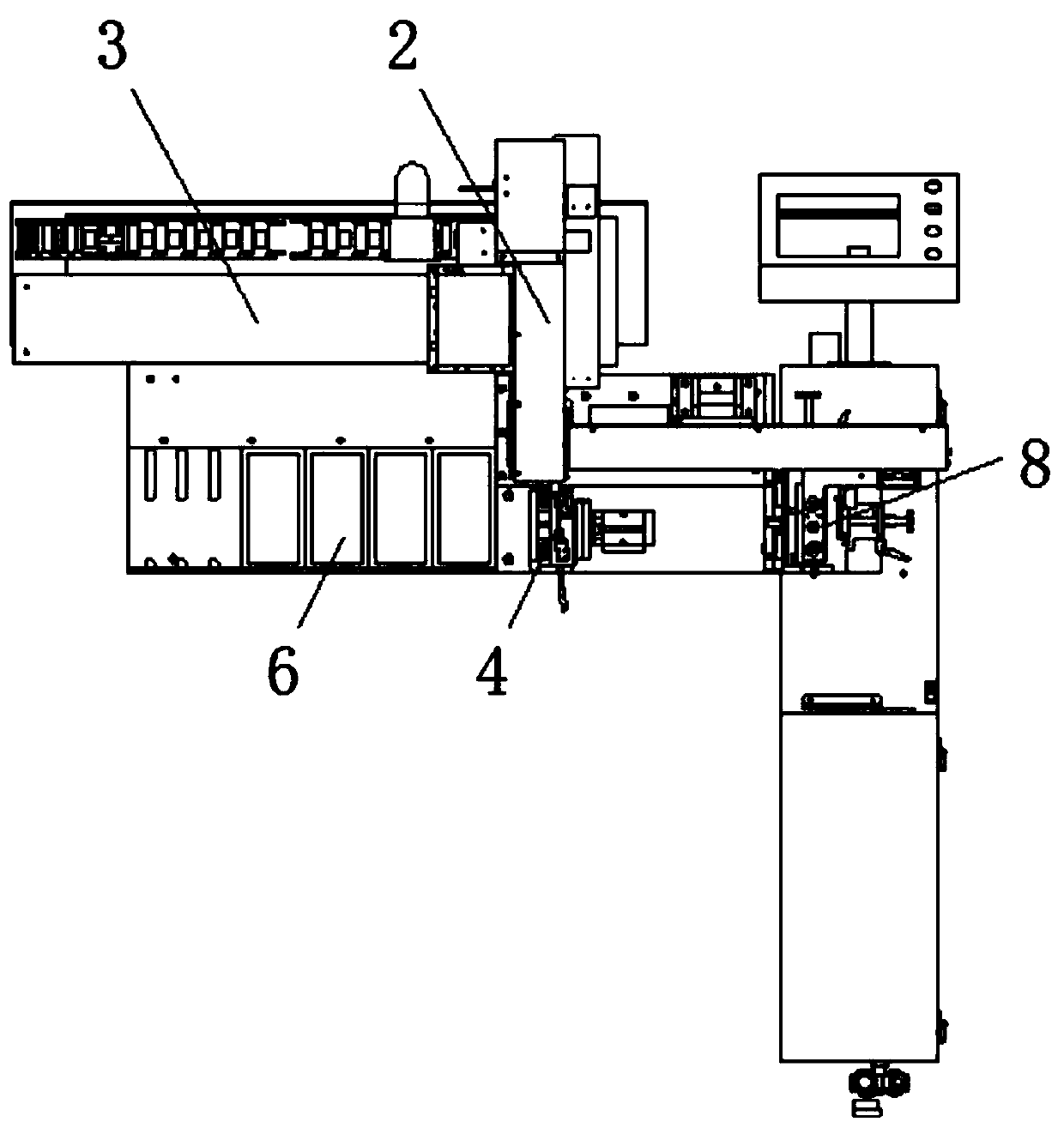

Mechanical arm clamping machine

The invention discloses a mechanical arm clamping machine which comprises a rack, a Z-direction linear sliding rail set, a Y-direction linear sliding rail set, an X-direction linear sliding rail, a rotation driving device, a rotating arm and a clamping jaw mechanism. The Z-direction linear sliding rail set is arranged on the rack; the Y-direction linear sliding rail set is connected to the inner sides of first and second Z-direction sliding bases on first and second Z-direction guide rails of the Z-direction linear sliding rail set; the X-direction linear sliding rail is connected between first and second Y-direction sliding bases on first and second Y-direction guide rails of the Y-direction linear sliding rail set; the rotation driving device is fixedly arranged on an X-direction sliding base of the X-direction linear sliding rail; one end of the rotating arm is connected to an output shaft of the rotation driving device in the radial direction, and the other end of the rotating arm is fixedly connected with the clamping jaw mechanism. The mechanical arm clamping machine can carry out three-dimensional and high-speed spatial motion and revolving location within a certain range to carry, pick and place products, is suitable for carrying out the operations of carrying, picking and placing in a narrow operating space and among a plurality of operating platforms, and has the advantages of being good in applicability, high in efficiency and low in cost.

Owner:KUNSHAN HANWEI AUTOMATION EQUIP

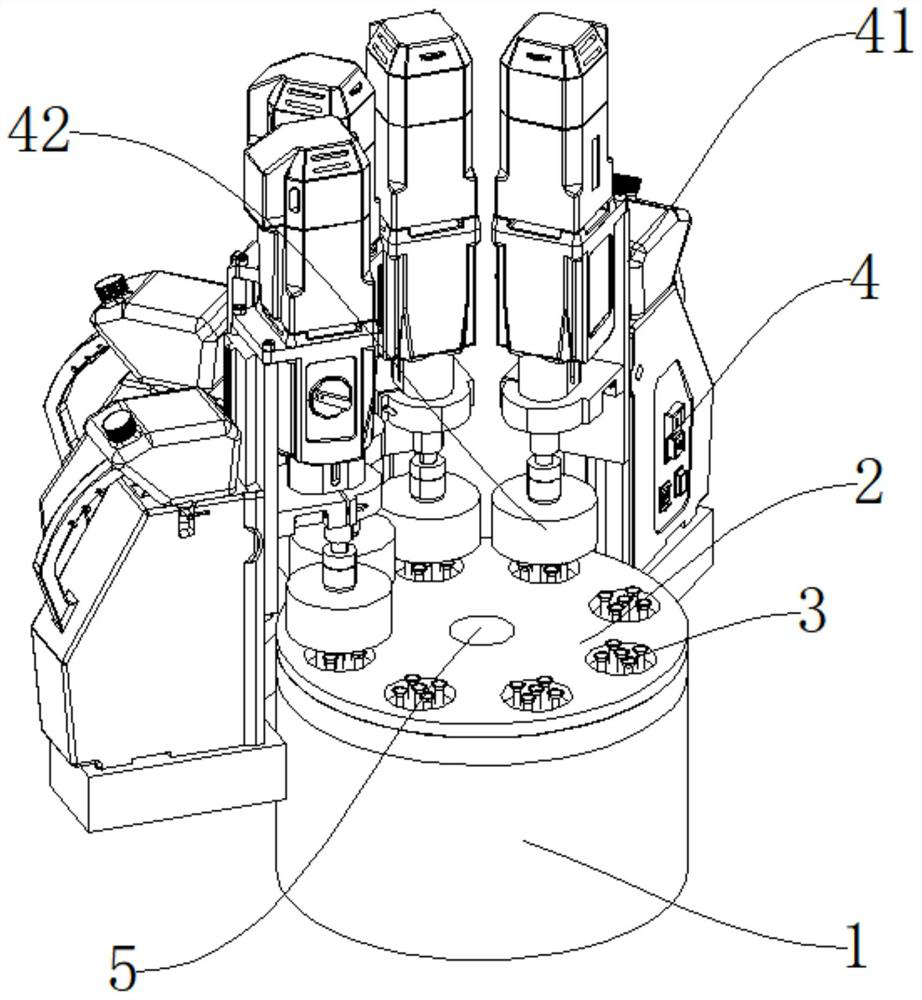

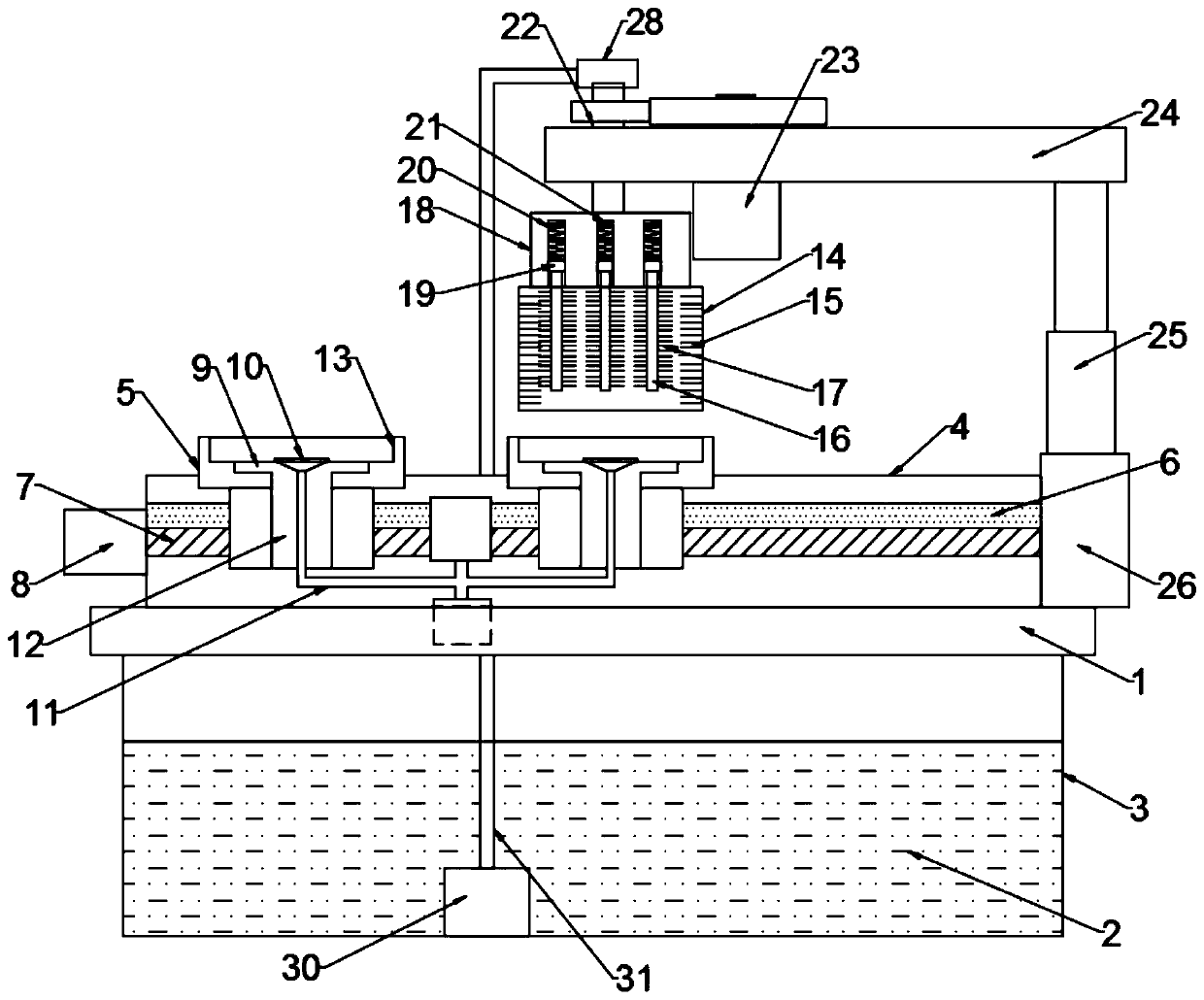

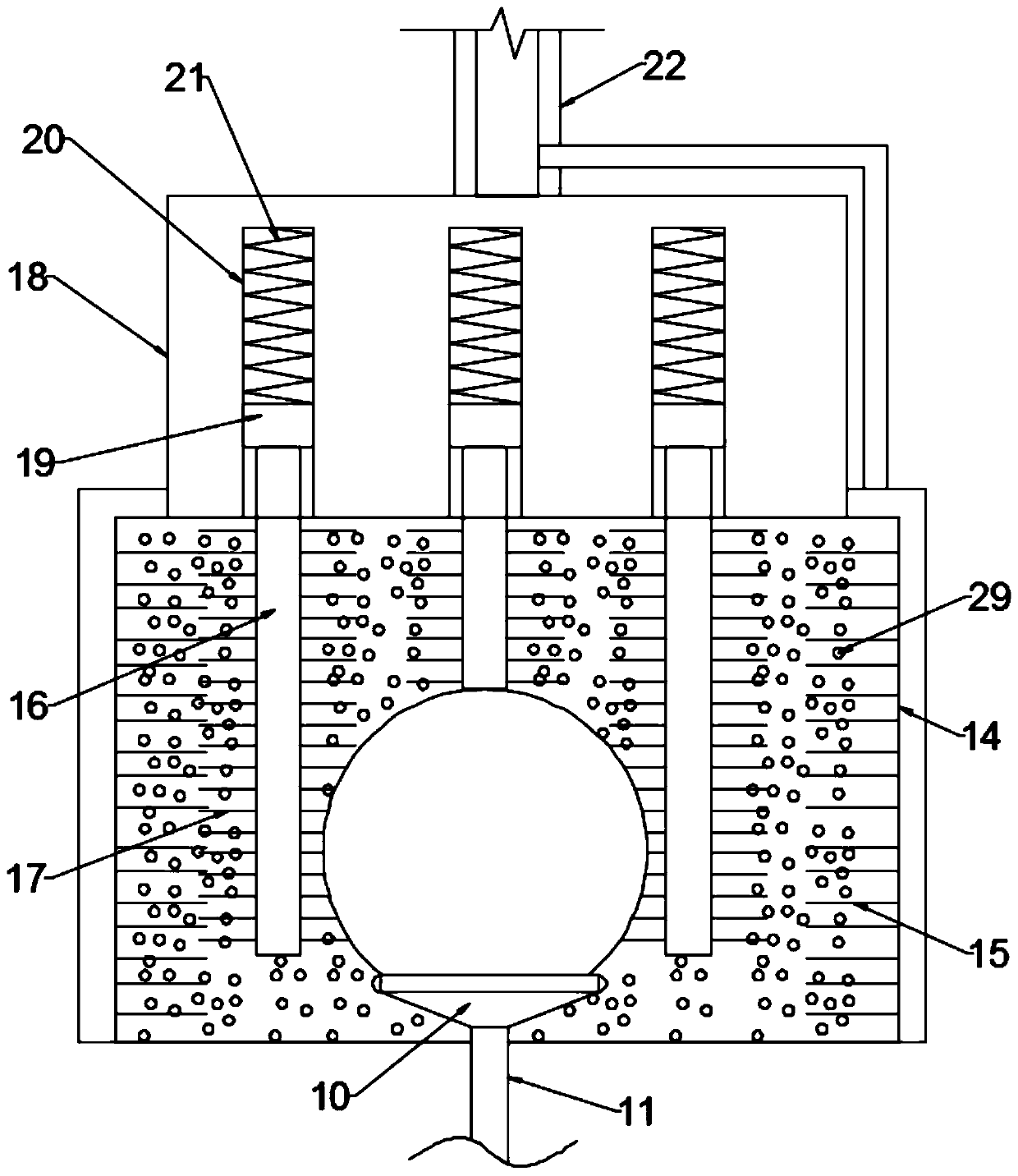

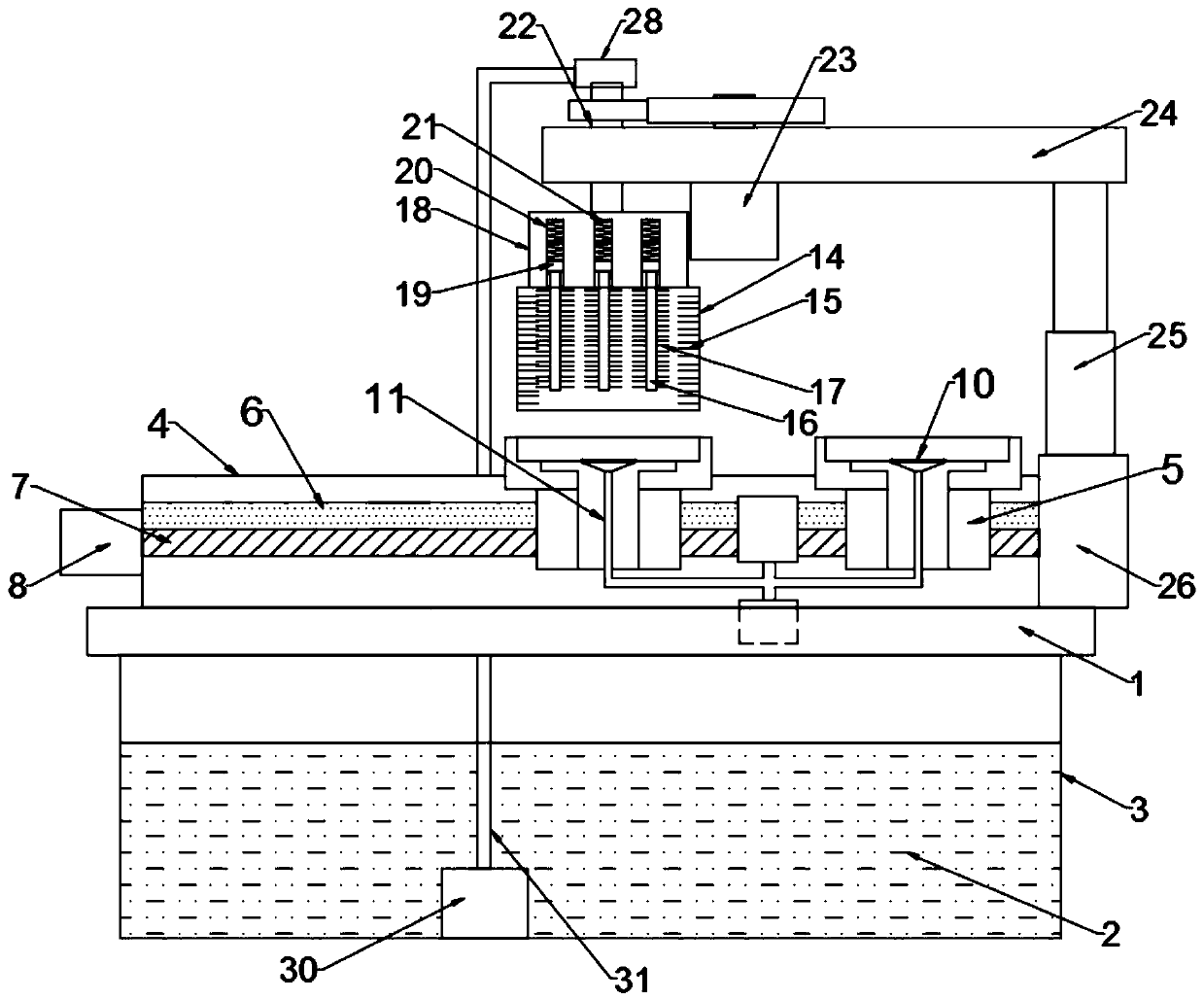

Surface polishing device for high-refractive-index lens processing and using method of surface polishing device

ActiveCN111906629AGuaranteed stabilityImprove machining accuracyOptical surface grinding machinesGrinding drivesRefractive indexMechanical engineering

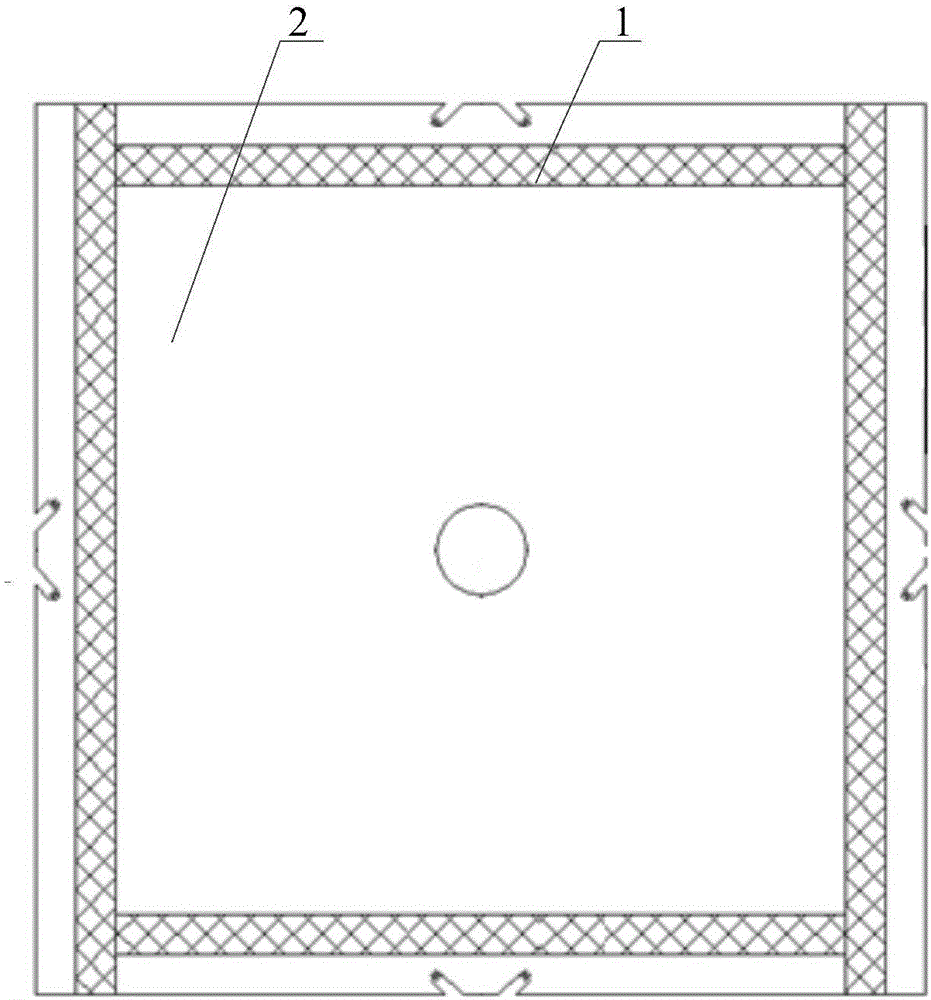

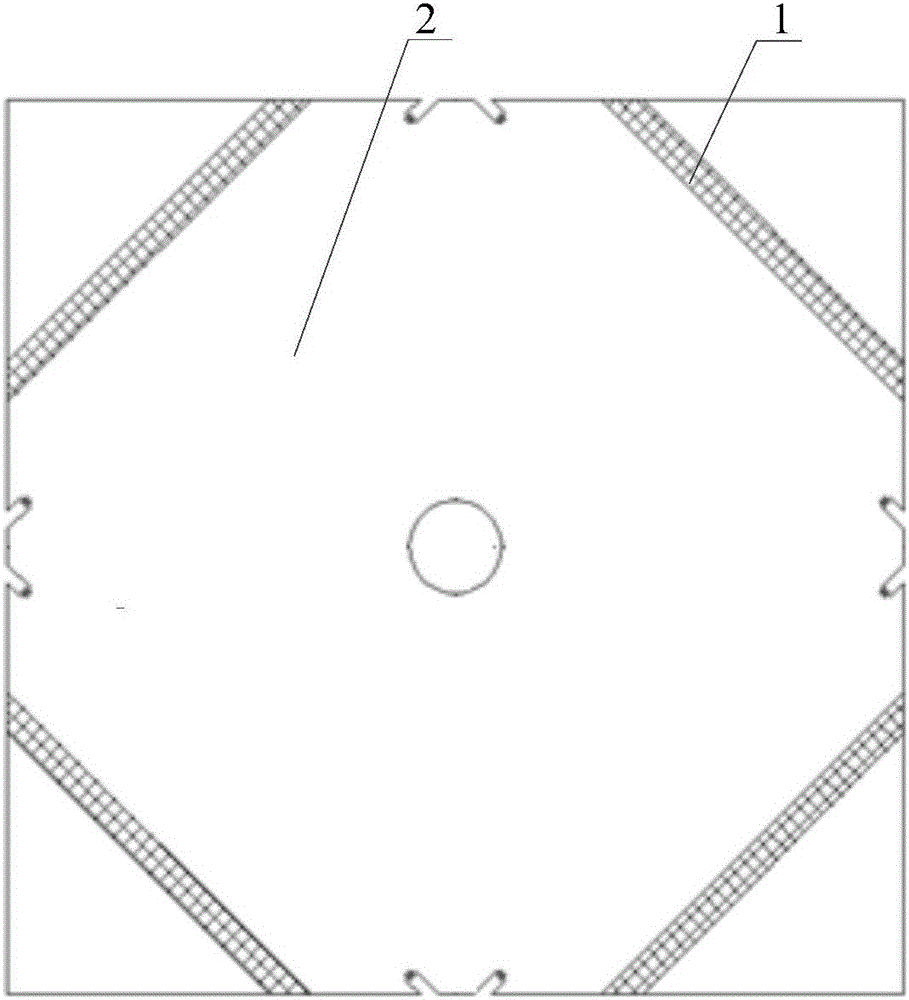

The invention discloses a surface polishing device for high-refractive-index lens processing. The surface polishing device comprises a rotating mechanism for driving a to-be-processed lens to rotate,an adsorption mechanism for fixing the to-be-processed lens and a limiting mechanism for limiting the adsorption mechanism, and the adsorption mechanism is arranged on the inner side of the rotating mechanism; and a base is arranged at the lower end of the rotating mechanism, a power mechanism is connected to the power end of the rotating mechanism, the limiting mechanism is arranged on the innerside of the adsorption mechanism, four polishing mechanisms are arranged on the upper side of the rotating mechanism, and the power mechanism is arranged in the base. The adsorption mechanism is driven by the limiting mechanism, so that the adsorption mechanism forms the negative pressure for adsorbing the lens, the stability of the lens is guaranteed, the machining precision is improved, taking and placing are convenient, the precision during lens placing can be guaranteed through cooperation of the rotating mechanism and the adsorption mechanism, and thus the processing efficiency is improved while the processing precision is improved.

Owner:AZURE PHOTONICS

Mobile phone screen detection device

ActiveCN106534441ASimple structureFlexible and stable movementSubstation equipmentEngineeringMobile phone

The invention relates to the field of a mobile phone detection device and especially relates to a mobile phone screen detection device. The mobile phone screen detection device comprises a first guide rail and a second guide rail, which are arranged vertically. The first guide rail is equipped with a first driving mechanism for driving the first guide rail to move along the second guide rail; the first guide rail is provided with a base and a second driving mechanism for driving the base to move along the first guide rail; the base is equipped with a touch screen mechanism and a third driving mechanism for driving the touch screen mechanism to move up and down; the touch screen mechanism is provided with an adjusting member for adjusting force applied to the touch screen mechanism; and a fixation mechanism for installing a mobile phone is arranged under the touch screen mechanism. The beneficial effects are that the mobile phone screen detection device is simple in structure and flexible and stable to move; through the two guide rails, omni-directional movement of the detection device is realized, so that click and scribing detection of different positions of the mobile phone is realized, and detection efficiency is high; and through arrangement of the adjusting member, click and scribing strength on the mobile phone screen can be adjusted conveniently, thereby meeting a plurality of test requirements.

Owner:重庆哈迪斯科技有限公司

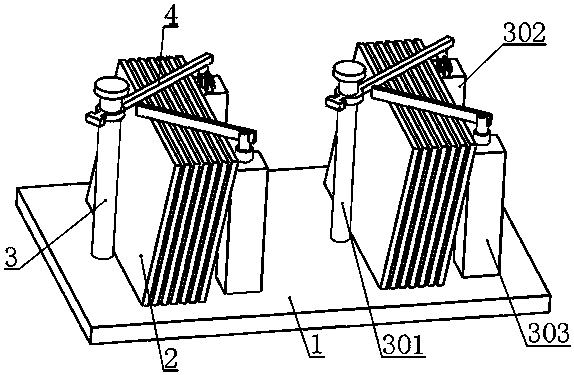

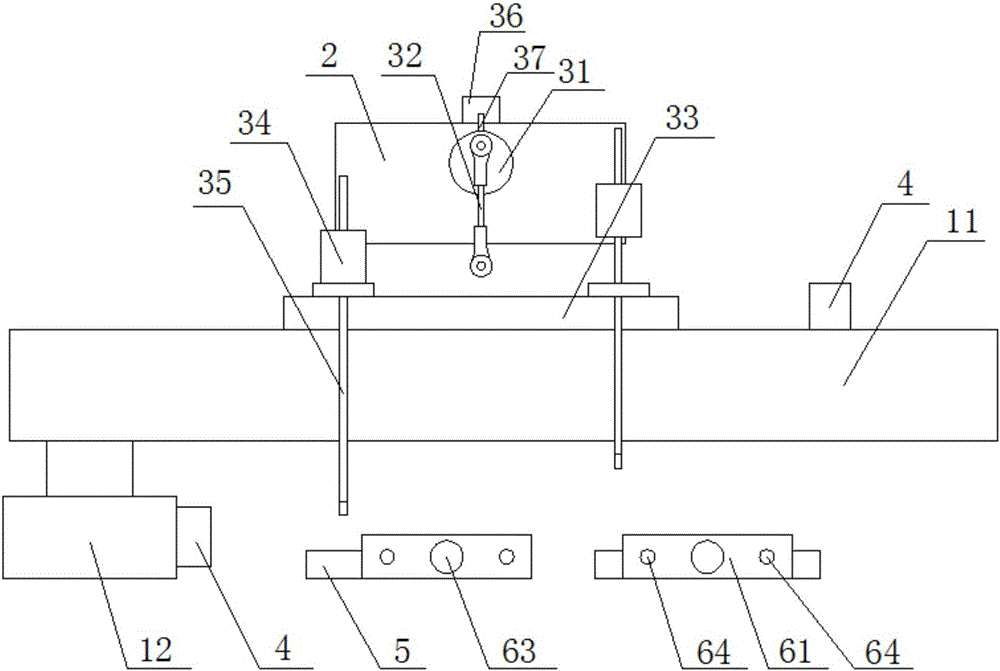

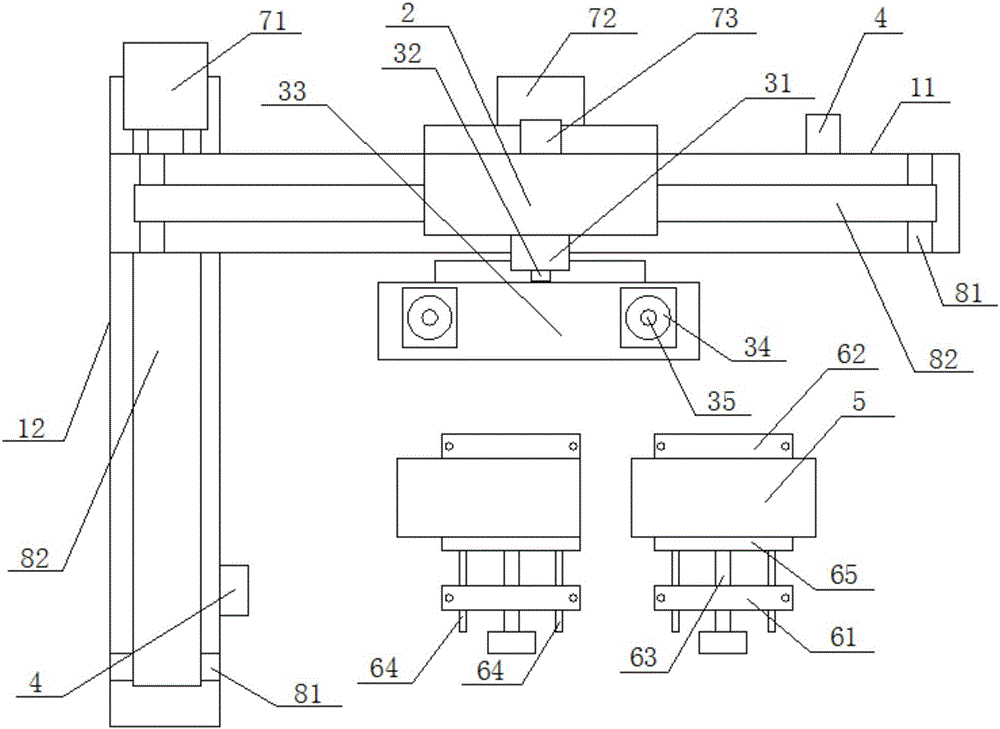

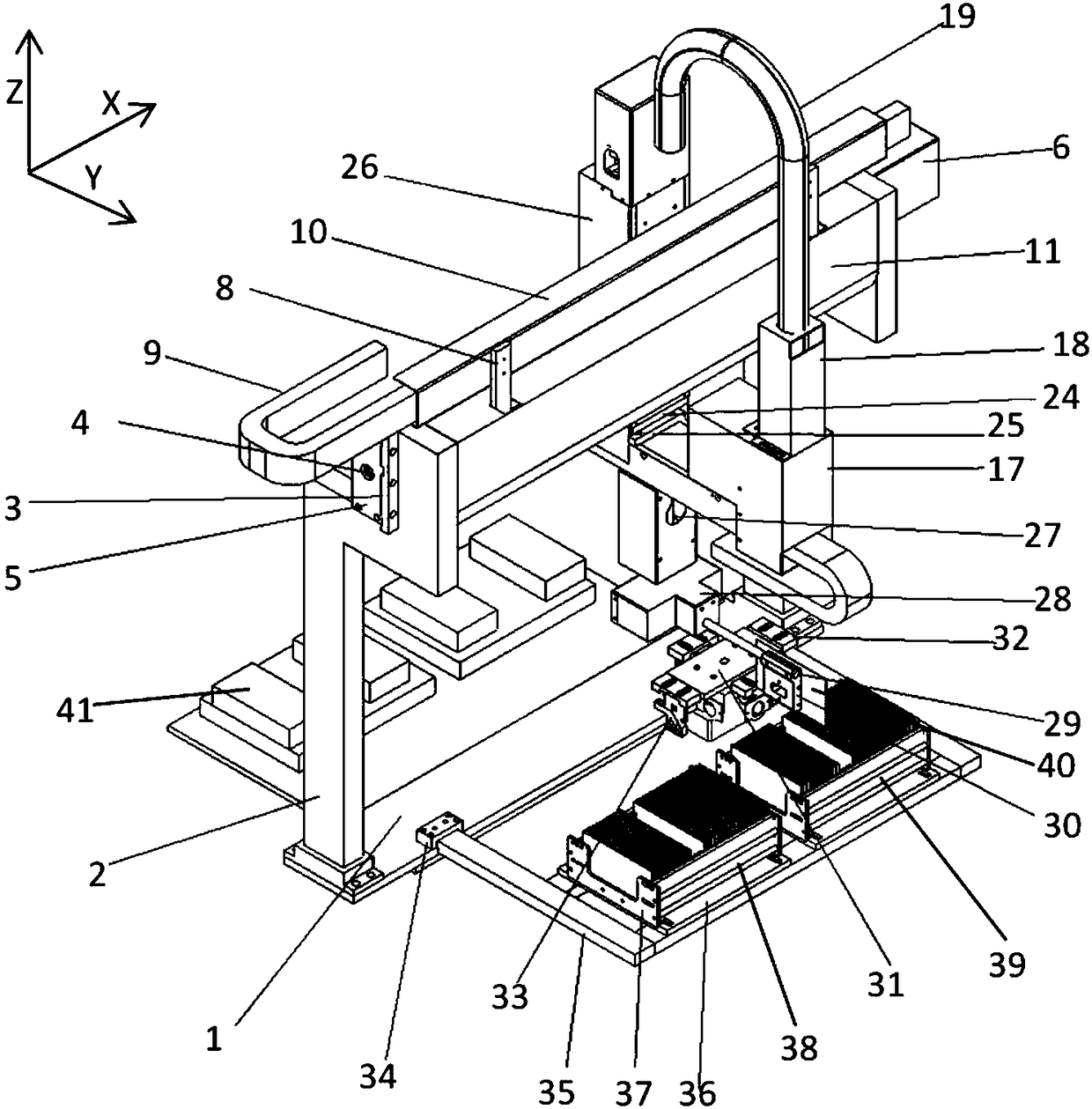

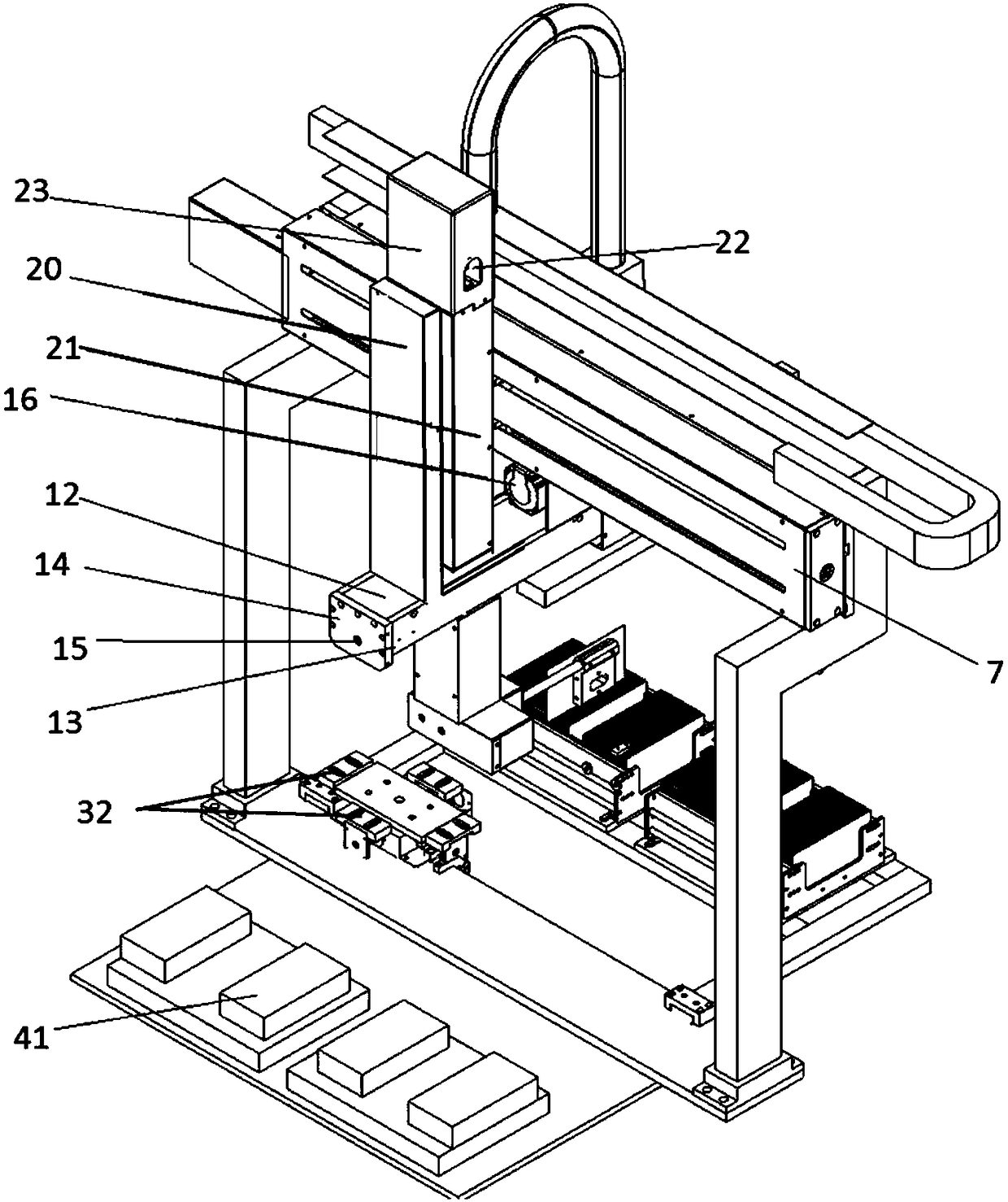

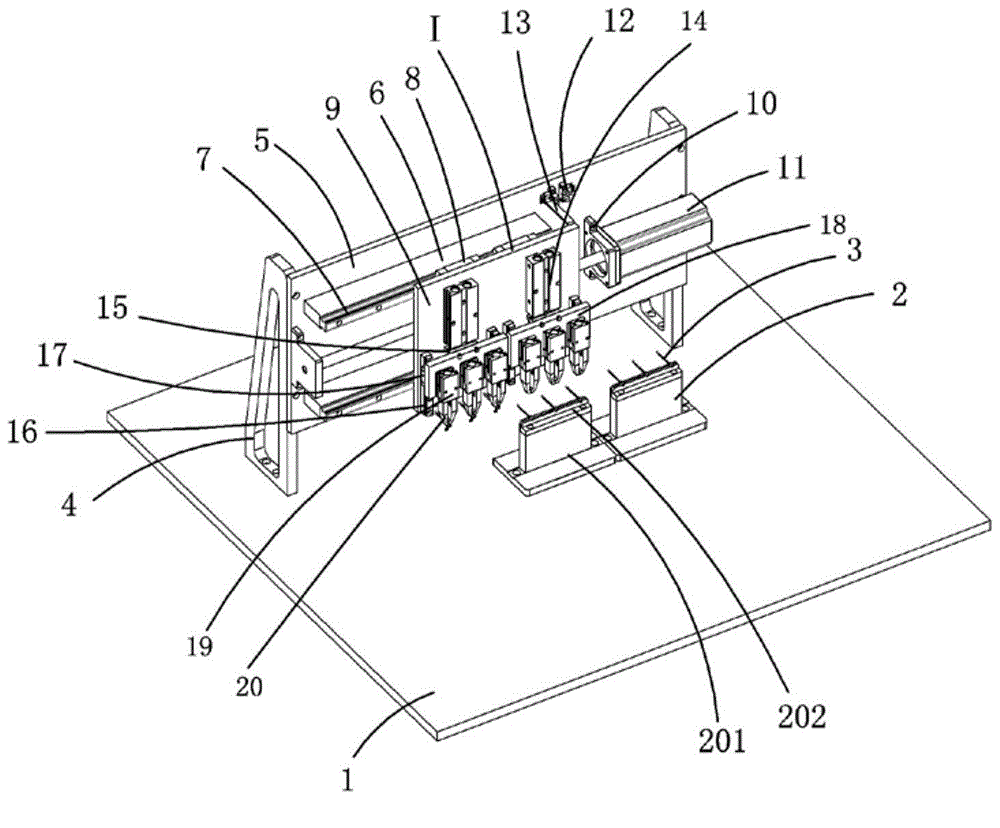

Glass precise-engraving mechanical arm device and glass sheet processing method

ActiveCN108583111AHigh precisionImprove efficiencyProgramme-controlled manipulatorGripping headsManipulatorEngineering

The invention provides a glass precise-engraving mechanical arm device and a glass sheet processing method. The glass precise-engraving mechanical arm device comprises a large supporting base plate, aportal bearing frame, an X-axis moving system, a Y-axis moving system, a Z-axis moving system, an R-axis rotating system, a vacuum suction cup, a locating system, a material frame system and machining carriers. The portal bearing frame is arranged on the large supporting base plate. The X-axis moving system is arranged on the portal bearing frame. The Z-axis moving system is connected to the X-axis moving system. The Y-axis moving system is connected to the Z-axis moving system. The R-axis rotating system is connected to the Y-axis moving system. The R-axis rotating system can provide independently controlled 360-degree rotation and 90-degree turning rotation. The vacuum suction cup is connected to the R-axis rotating system. The locating system is arranged on the large supporting base plate. The material frame system and the processing carrier are arranged on the two sides of the portal bearing frame. The glass precise-engraving mechanical arm device can provide X / Y / Z / R five-axis control at the same time, the precision is higher, five-axis integrated arrangement and control are achieved, operation and assembly are convenient, and the work efficiency is high.

Owner:姜杰勇

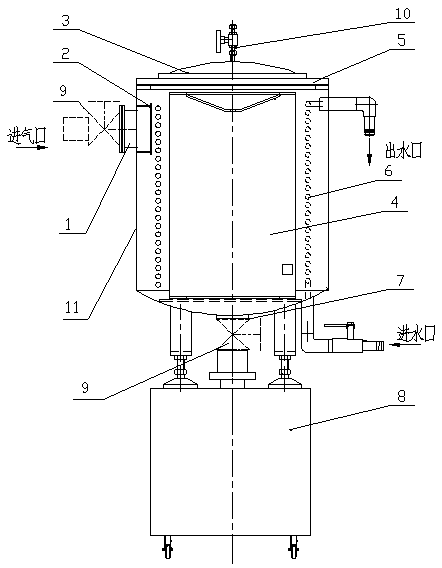

Vacuum filter

InactiveCN105498380AOptimize the installation structureQuick and easy installationHuman health protectionDispersed particle filtrationFiltrationUpstream downstream

The invention discloses a vacuum filter, and belongs to the field of filtration, which is used for solving the problems of cooling and dedusting of high-temperature and dust-contained gas in a vacuum working system. The vacuum filter comprises a cavity body, a diffuser and a filter element, wherein the cavity body is provided with a gas inlet connected with a specific gas pipeline and a gas outlet connected with a vacuum pump; the top end of the cavity body is provided with a top cover connected with the cavity body in a sealed mode; the cavity body is internally provided with the diffuser at the gas inlet; the filter element is installed at the center in the cavity body; the side wall of the filter element is provided with filter holes; the bottom surface of the filter element is provided with an opening leading to the gas outlet of the cavity body, thereby preventing the vacuum pump and an upstream-downstream system from being damaged by high-temperature, corrosive and dangerous dust particles, and solving the problem of too complex and frequent maintaining frequency of the vacuum pump of the vacuum filtration system. From the aspect of environment protection, gas in pipelines can be further cooled down and purified, and air pollution can be reduced.

Owner:青岛赛瑞达电子科技有限公司

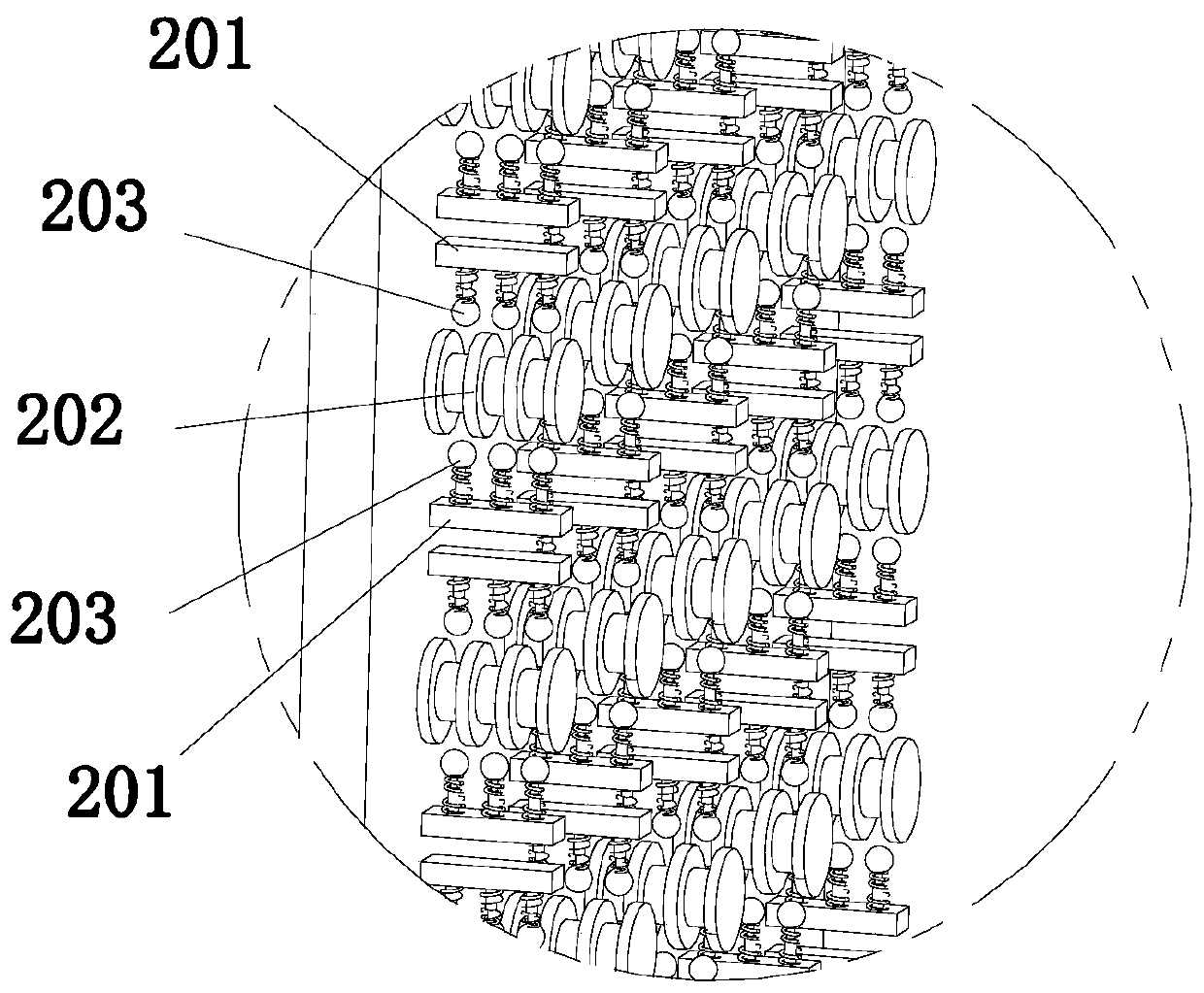

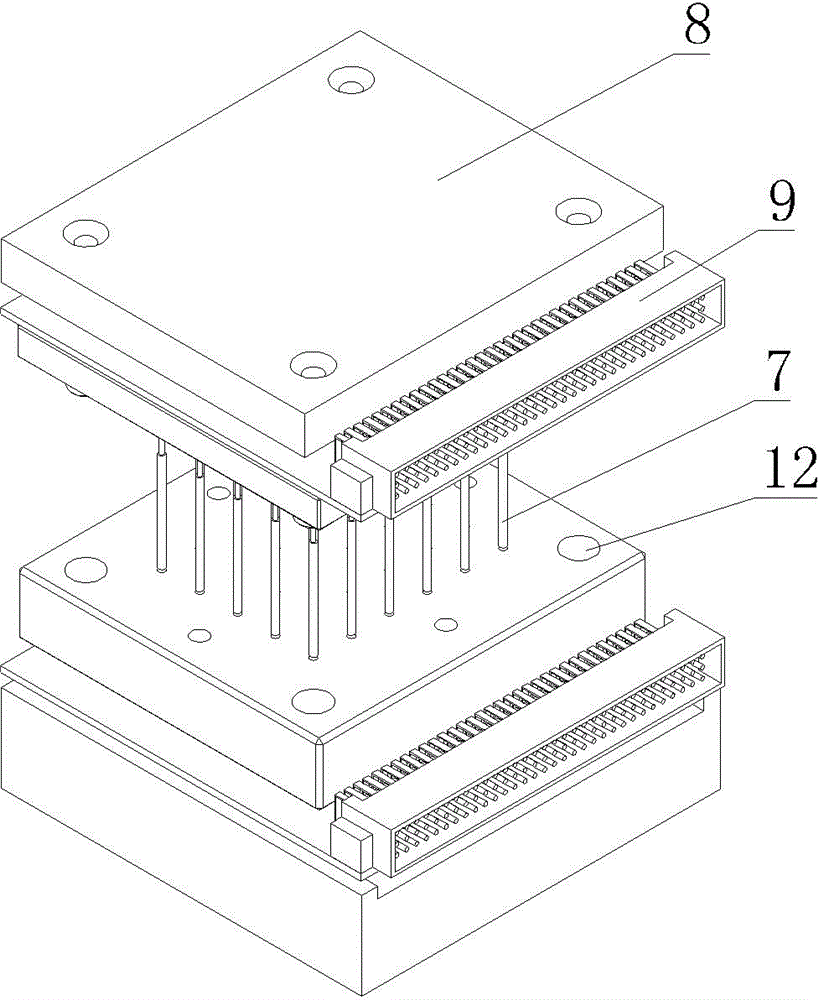

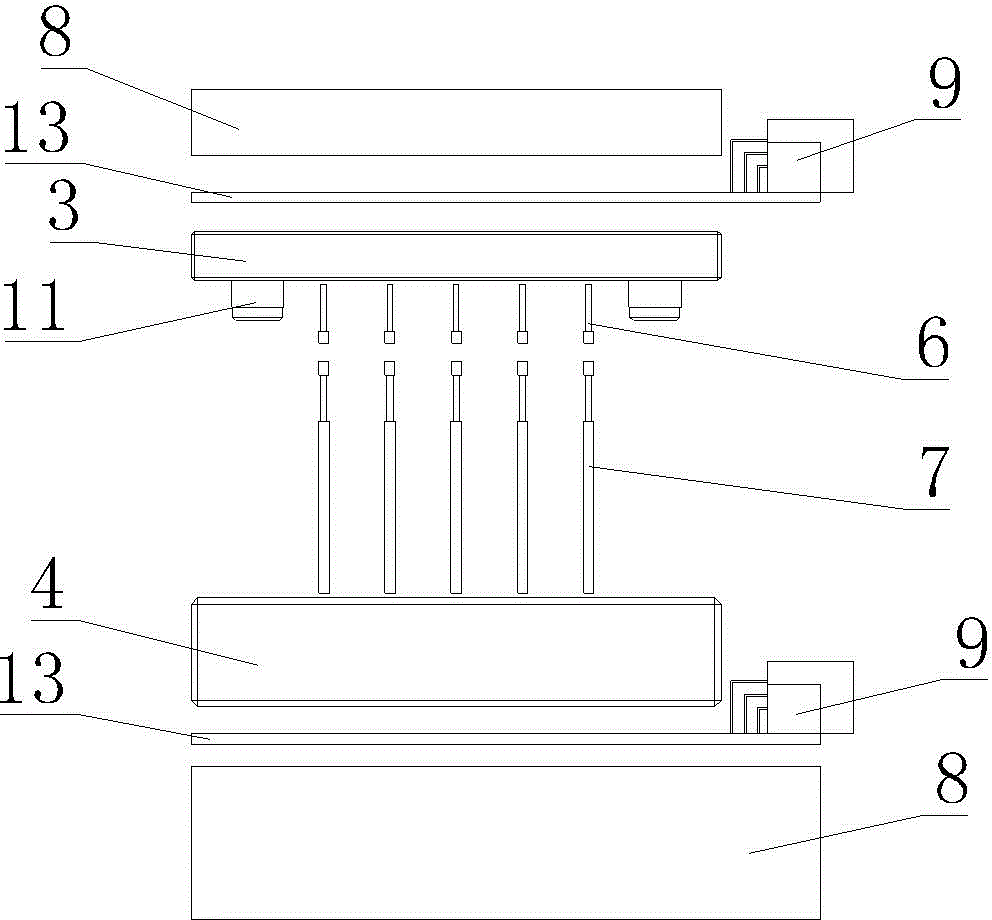

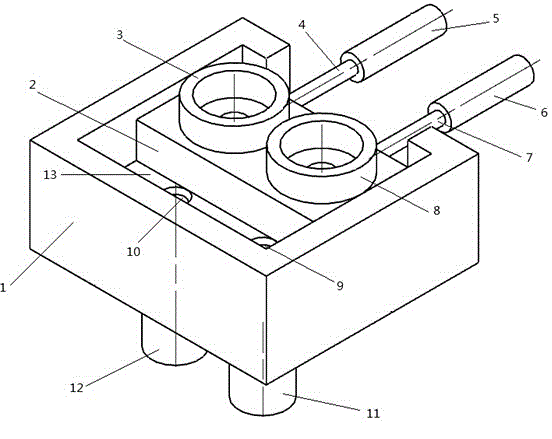

Test fixture for single layer capacitor

ActiveCN104914278AAchieve non-destructive testingAchieve agingMeasurement instrument housingTest efficiencyCapacitance

The invention provides a test fixture for a single layer capacitor, so as to effectively solve problems that the prior fixture causes damages to a capacitor electrode and the test efficiency is low, realize undamaged test and aging on the single layer capacitor, simplify taking and placing operation during the test and aging steps of the single layer capacitor, improve the production efficiency and reduce equipment cost. The test fixture for the single layer capacitor comprises two electrode plates arranged in a mutually parallel mode, and is characterized in that probes are relatively arranged between the electrode plates respectively, the probes clamp the single layer capacitor in a vertical matching mode, and the plane contact area of probe ends of the probes is larger than the electrode area of the single layer capacitor.

Owner:江苏伊施德创新科技有限公司

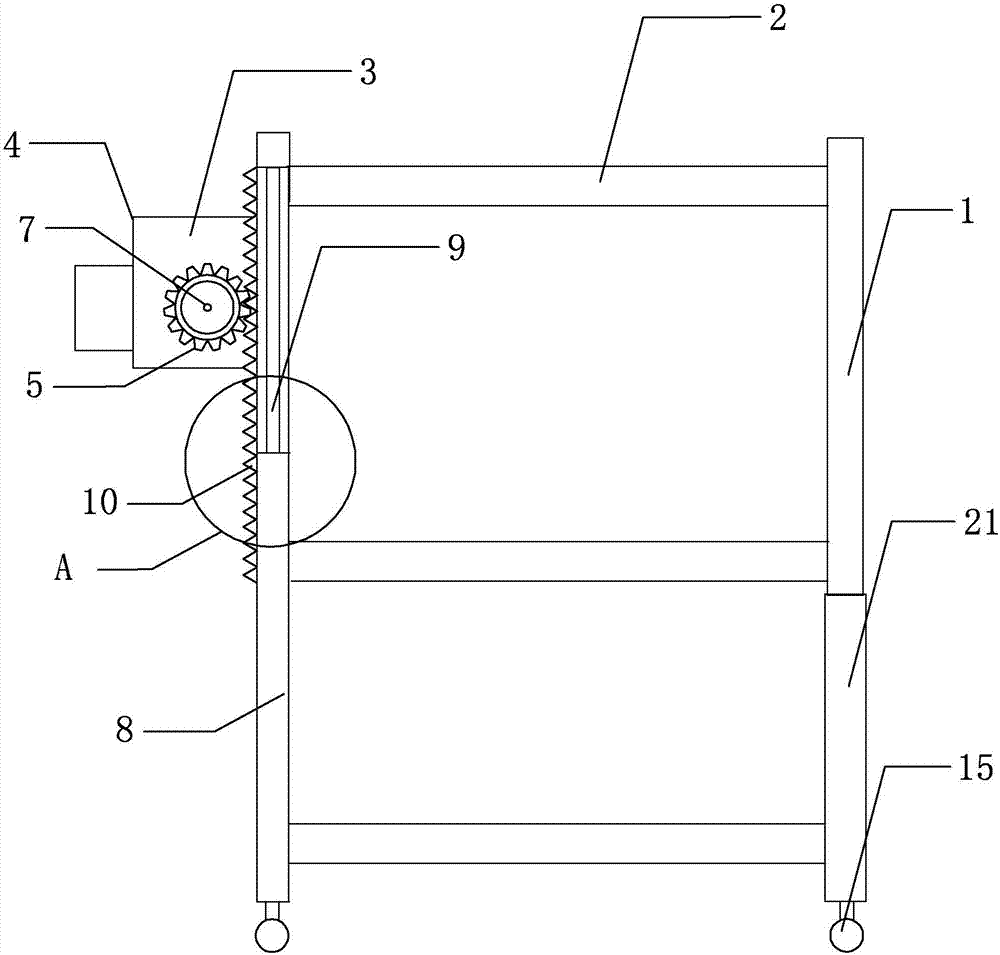

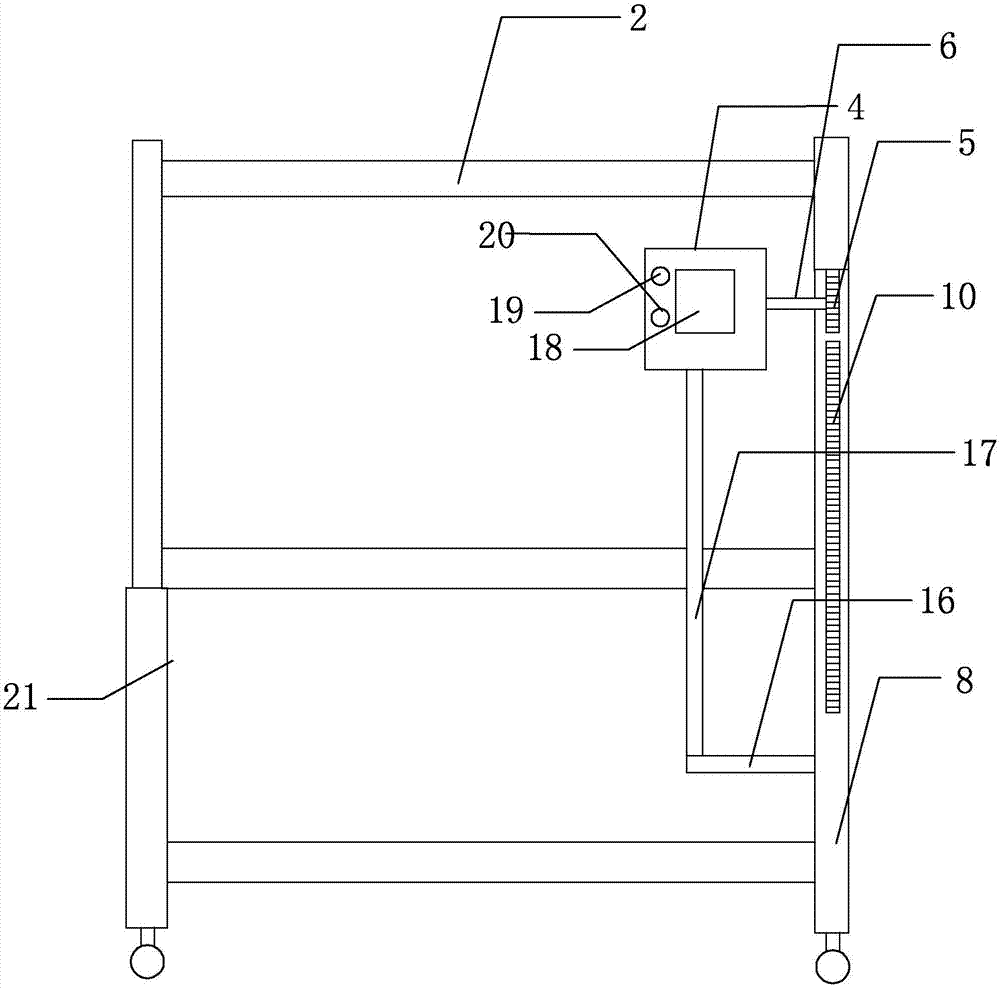

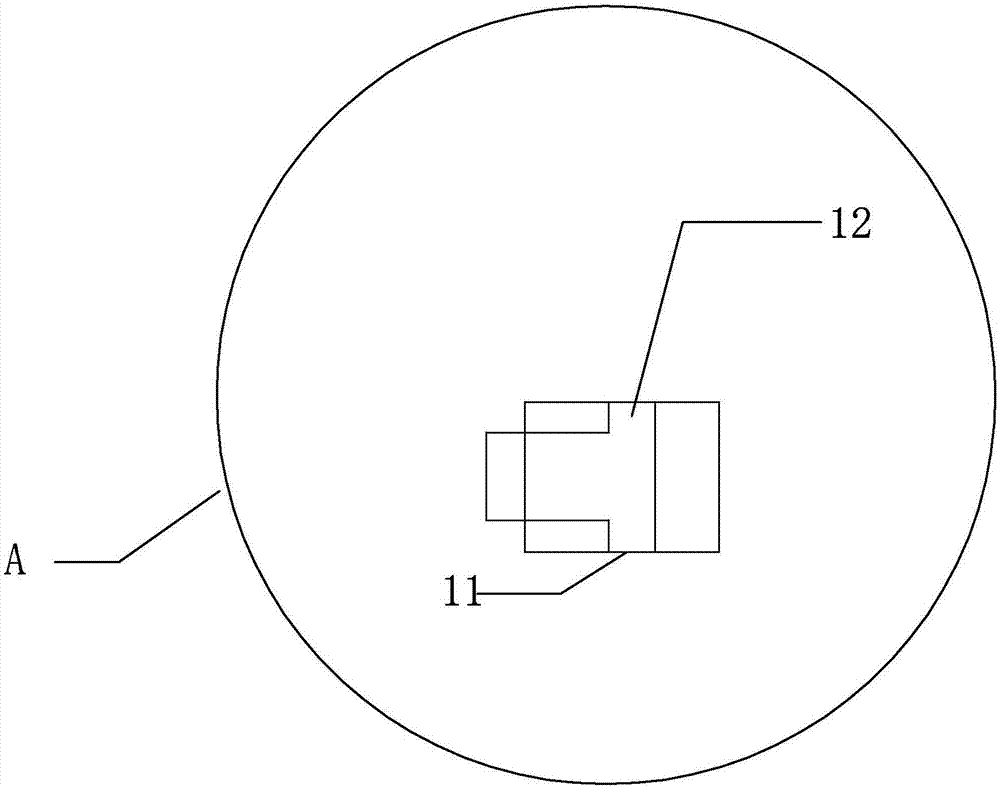

Liftable goods shelf

InactiveCN107456003AEasy to pick and placeEasy to moveShow shelvesShow hangersTransverse planeMotor control

The invention relates to a liftable goods shelf and solves the problem that goods shelves in the prior art are low in space utilization rate. The liftable goods shelf comprises a frame, transverse plates and a lifting mechanism and is characterized in that the transverse plates are arranged on the frame; the lifting mechanism comprises a motor and a gear, the gear is arranged at the tail end of the output shaft of the motor, the tail end of the output shaft of the motor is connected with the axis of the gear, a lifting tube is arranged on the lower portion of the left side of the frame, a rack column is slidably arranged in the lifting tube, a rack is fixedly arranged on the outer side of the rack column, a motor shell is provided with a controller unit, and the controller unit is connected with the motor; the frame is used for fixing and supporting the transverse plates, the transverse plates are used for placing goods, the gear is matched with the rack to achieve shelf lifting, the motor controls the gear to rotate to drive the rack to rotate, and the rack column moves to drive the shelf to move upwards and downwards. The liftable goods shelf is high in automation level, convenient in goods taking and placing, high in space utilization rate, simple to operate, convenient to move and high in applicability.

Owner:ZHEJIANG HANQIANG AUTOMATION EQUIP

Automatic product taking and placing device

ActiveCN104150218AEasy to pick and placeImprove efficiencyConveyor partsMotor driveElectric machinery

The invention relates to an automatic product taking and placing device. Two sets of carriers are mounted on a bottom plate, a product is arranged on each carrier, two supporting plates are arranged on the bottom plate, and a vertical plate is mounted on the two supporting plate. The vertical plate is provided with two sets of booster blocks which are respectively provided with a sliding rail, sliding blocks are arranged on the sliding rails in a matched mode, and a movable plate is mounted on the sliding blocks. A motor fixing seat is fixed on the vertical plate, a servo motor is mounted on the motor fixing seat, and the servo motor drives the movable plate to move along the sliding rail. A material taking air cylinder is mounted on the movable plate, the lower end of a piston of the material taking air cylinder is connected with a material taking push plate, two sets of material taking sliding rails are mounted on the movable plate and are respectively provided with one set of material taking sliding blocks in a matched mode, and a material taking lifting plate is mounted on the two sets of material taking sliding blocks. A clamping jaw air cylinder is mounted on the material taking lifting plate, and a material taking clamping jaw is mounted below the clamping jaw air cylinder. The automatic product taking and placing device is capable of achieving the continuous operation process, materials are conveniently and rapidly taken, efficiency is high, and the utilization rate of equipment is high.

Owner:BOZHON PRECISION IND TECH CO LTD

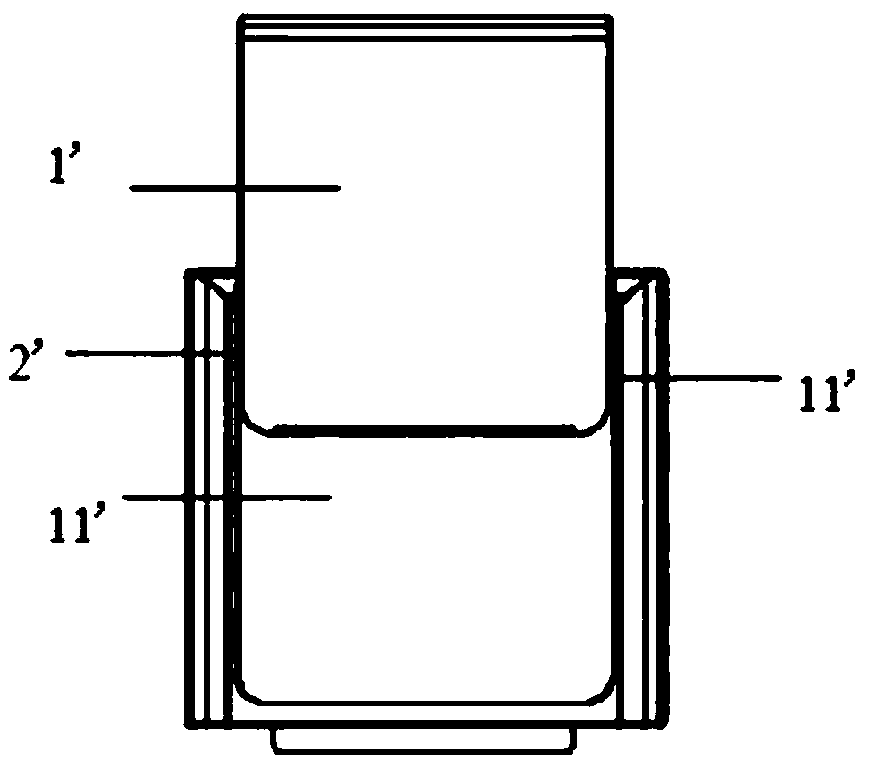

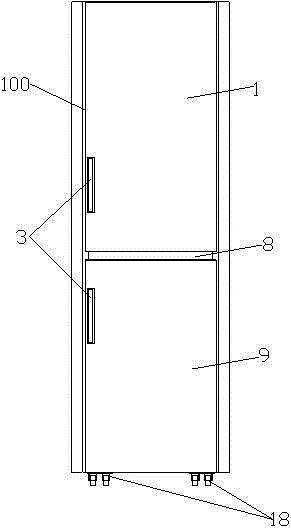

Refrigerator door

InactiveCN109425183ALower the altitudeAchieve storageDomestic cooling apparatusLighting and heating apparatusRefrigerator carRefrigerated temperature

Owner:SUZHOU SAMSUNG ELECTRONICS CO LTD +1

Cosmetic storage box

ActiveCN106564705AEasy to pick and placeNot easy to flow outDispensing apparatusSealingEngineeringBottle

The invention discloses a cosmetic storage box. The cosmetic storage box comprises a box body, a box cover, storage bottles, movable pipes and a plurality of fixing holes. A fixed block is fixed inside the box body. The fixed block is provided with the fixing holes. The storage bottles stretch into the fixing holes to be fixed to the fixed block. A stopping plate is arranged below the bottle opening of each storage bottle, and a through hole is formed in the center of each stopping plate. Each stopping plate is provided with a plurality of positioning grooves and a plurality of through grooves penetrating through the corresponding stopping plate. Each movable pipe is made of an outer pipe body and a push-pull rod located inside the outer pipe body. A plurality of bosses matched with both the positioning grooves and the through grooves are arranged on the outer wall of each outer pipe body. The outside of each outer pipe body is sleeved with a sealing disk capable of moving along the outer pipe body. The top of each push-pull rod is provided with a round cake-shaped fixed disk, and each sealing disk and the corresponding fixed disk are connected through a plurality of first springs. The sealing disks are tightly pressed onto the corresponding stopping plates. The box cover covers the box body. A compression plate is arranged at the bottom of the box cover. According to the cosmetic storage box, the storage bottles are arranged inside the box body, different sorts of cosmetics can be placed into the storage box, and thus carrying is made convenient.

Owner:HUBEI GUANGHUA PACKING CO LTD

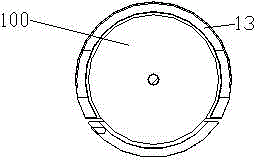

Cylindrical refrigerator

ActiveCN105004124ANew and exquisite appearanceOptimizationLighting and heating apparatusDomestic refrigeratorsEngineeringRefrigeration

The invention discloses a cylindrical refrigerator which comprises a refrigerator body. The refrigerator body is of a cylindrical structure. Movable or fixed universal wheels are arranged at the bottom of the refrigerator body. The refrigerator body comprises an arc foaming box, a foaming center separation plate, a foaming base, a refrigeration door and a freezing door. A box component is formed by the arc foaming box, the foaming center separation plate and the foaming base. The refrigerator body is divided into a refrigeration chamber and a freezing chamber by the foaming center separation plate, then the refrigeration door and the freezing door are assembled through hinges, and the refrigerator body is formed. The cylindrical refrigerator is large in space utilization rate, and the space usage ratio can be effectively improved; assembling is easy and convenient, packing is simpler, and cost is low.

Owner:ANHUI KONKA TONGCHUANG HOUSEHOLD APPLIANCES

Die holder device capable of sliding

ActiveCN104438602AEasy to pick and place materials and stamping operationsShorten the timeShaping toolsEjection devicesSlide plateIndustrial engineering

The invention discloses a die holder device capable of sliding. The die holder device includes a cuboid die holder. A cuboid groove is formed in the center of the upper portion of the die holder. A sliding plate which slides left and right in the cuboid groove is arranged in the cuboid groove. A first outer die sleeve and a second outer die sleeve are arranged in parallel in the front-back direction on the surface of the sliding plate. Punching dies are placed in the first outer die sleeve and the second outer die sleeve. A notch is formed in the right side face of the cuboid groove. A first drive mechanism and a second drive mechanism are arranged in parallel in the front-back direction on the right side face of the die holder. Two vertical through holes are formed in parallel in the front-back direction in the bottom surface of the left of the die holder, and a first ejector beam and a second ejector beam are arranged in the two through holes respectively. According to the die holder device, the sliding plate provided with multi-station dies is moved out of the position underneath a slide block through an air cylinder so that the working procedures of feeding and discharging can be performed; meanwhile, a hydraulic cylinder ejecting device is arranged underneath the die holder; accordingly, quick, safe and efficient punching production can be achieved.

Owner:泰州浙华机械精锻有限公司

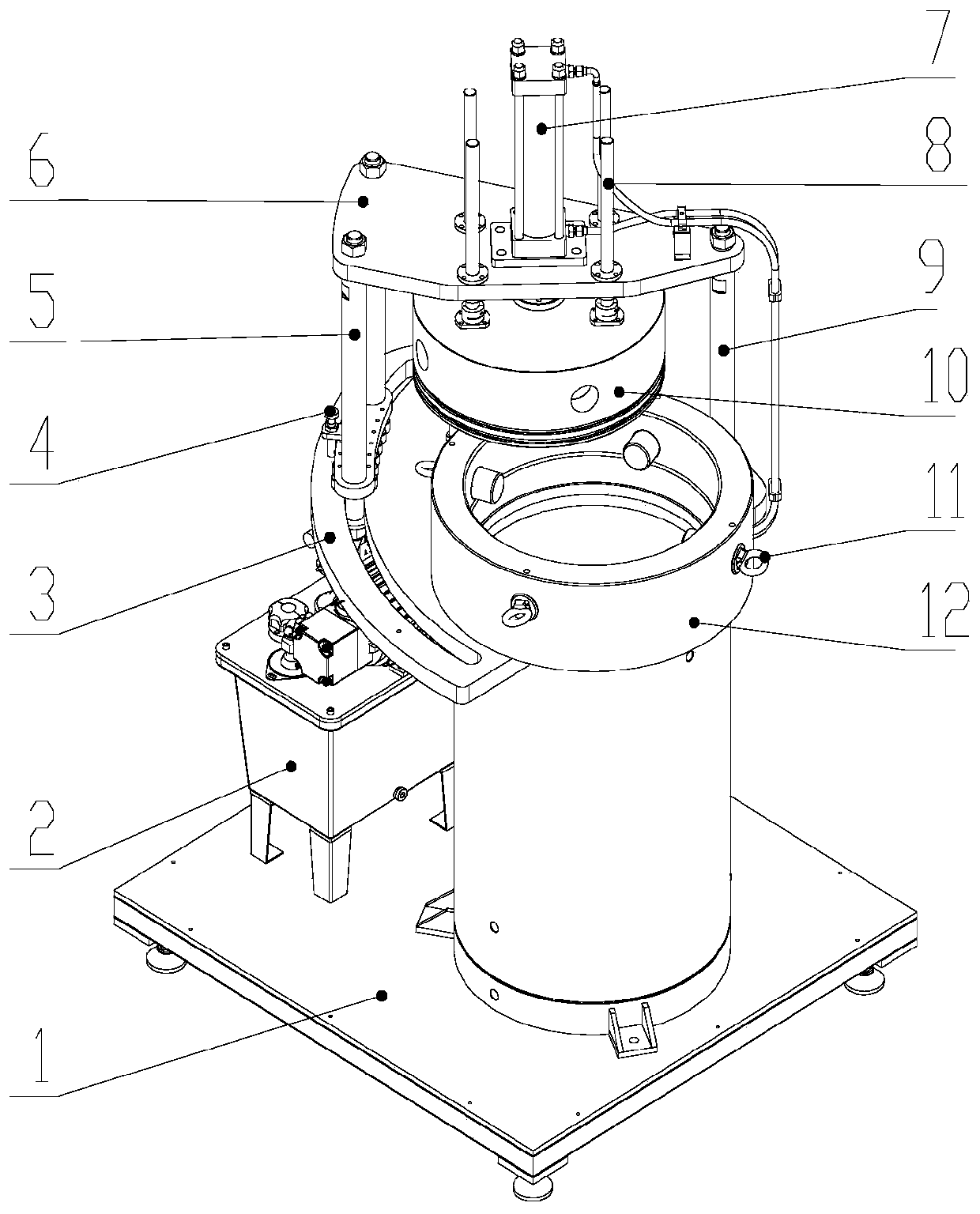

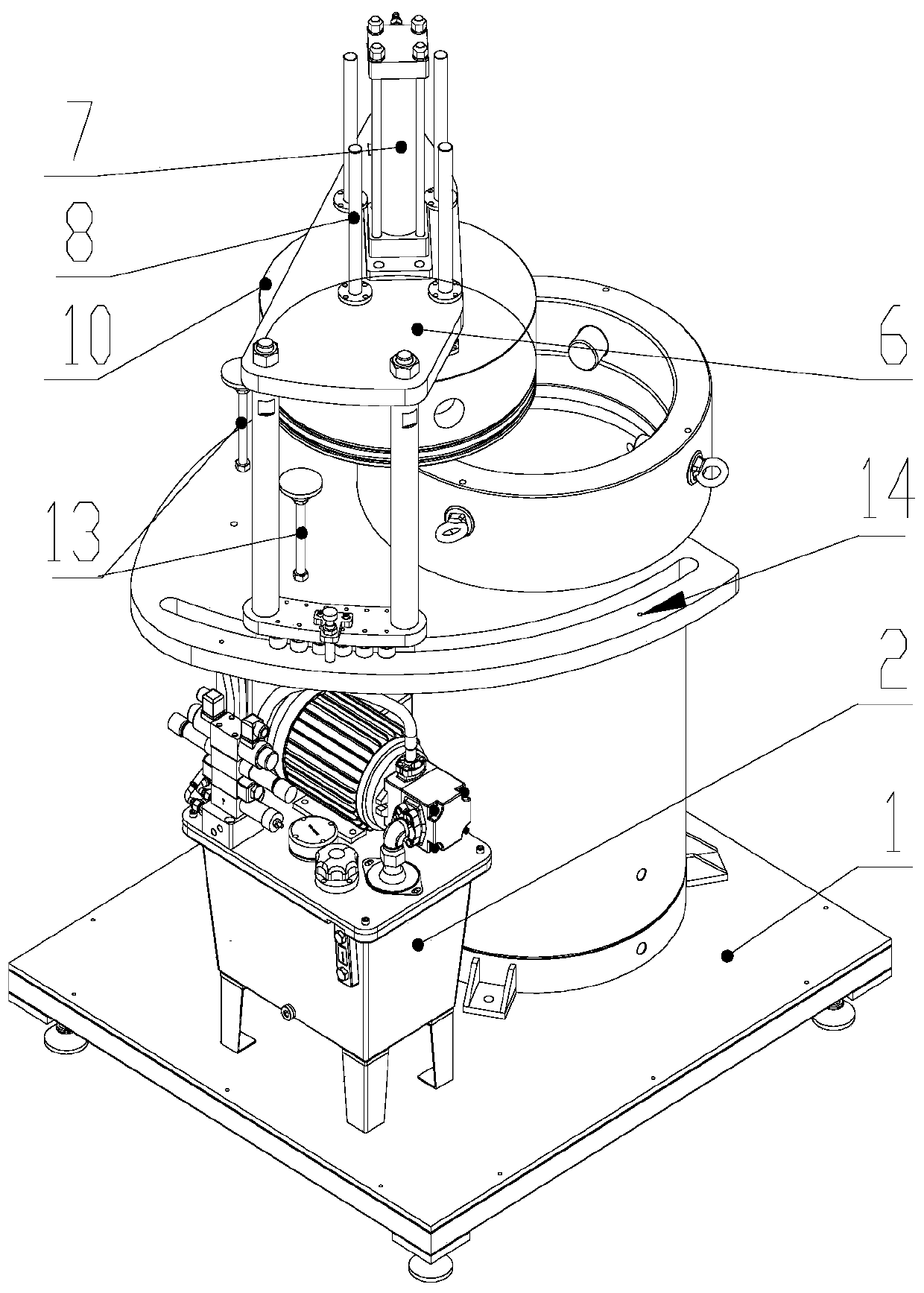

Pressure tank device for simulating deep oversea external pressure test

PendingCN110274832AEasy to moveEasy accessMachine part testingMaterial strength using tensile/compressive forcesUltimate tensile strengthExternal pressure

The invention provides a pressure tank device for simulating a deep oversea external pressure test. The pressure tank device for simulating the deep oversea external pressure test comprises a pressure tank body, a pressure tank top cover, a guide plate and a fixing plate; the filling opening of the pressure tank body faces upwards; the pressure tank top cover is downwards inserted into the filling opening of the pressure tank body and seals the pressure tank body; the fixing plate is located above the filling opening of the pressure tank body; a driving mechanism is arranged on the fixing plate; the pressure tank top cover is connected below the fixing plate through a driving mechanism; and the driving mechanism is used for driving the pressure tank top cover to vertically move so as to insert the pressure tank top cover into the pressure tank body or take out the pressure tank top cover from the tank body. According to the pressure tank device for simulating the deep oversea external pressure test of the invention, a rotary stand column is connected with the fixing plate, so that a rotary structure can be formed, so that the pressure tank top cover can be conveniently driven to move above the pressure tank body, and therefore, test personnel can conveniently, rapidly and safely pick a part under test from the pressure tank and place the part under test into the pressure tank; the driving mechanism can automatically lift and lower the pressure tank top cover, and insert the pressure tank top cover into the pressure tank body or take out the pressure tank top cover from the pressure tank body, and thus, the labor intensity of operators is greatly reduced.

Owner:深圳万测试验设备有限公司

Roller-type drying device for astragalus membranaceus

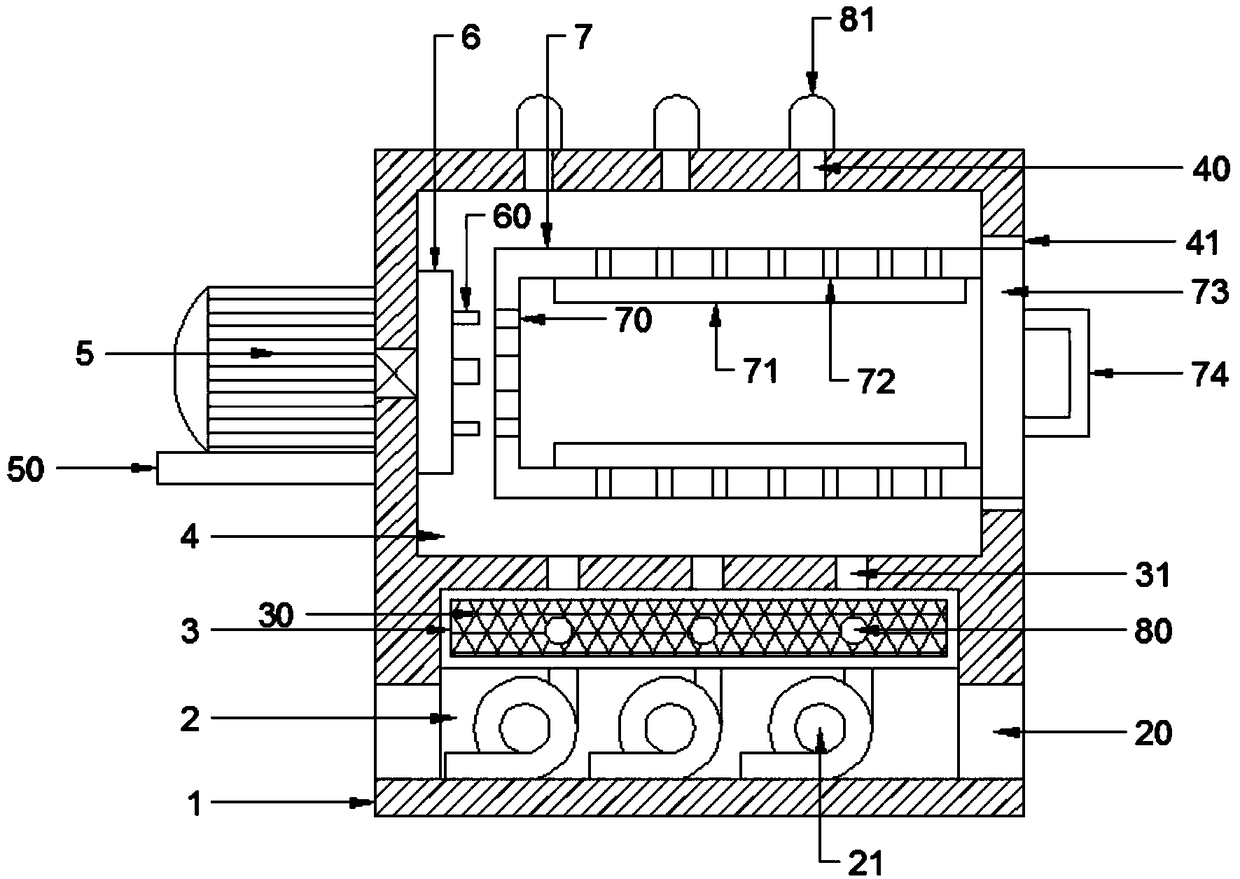

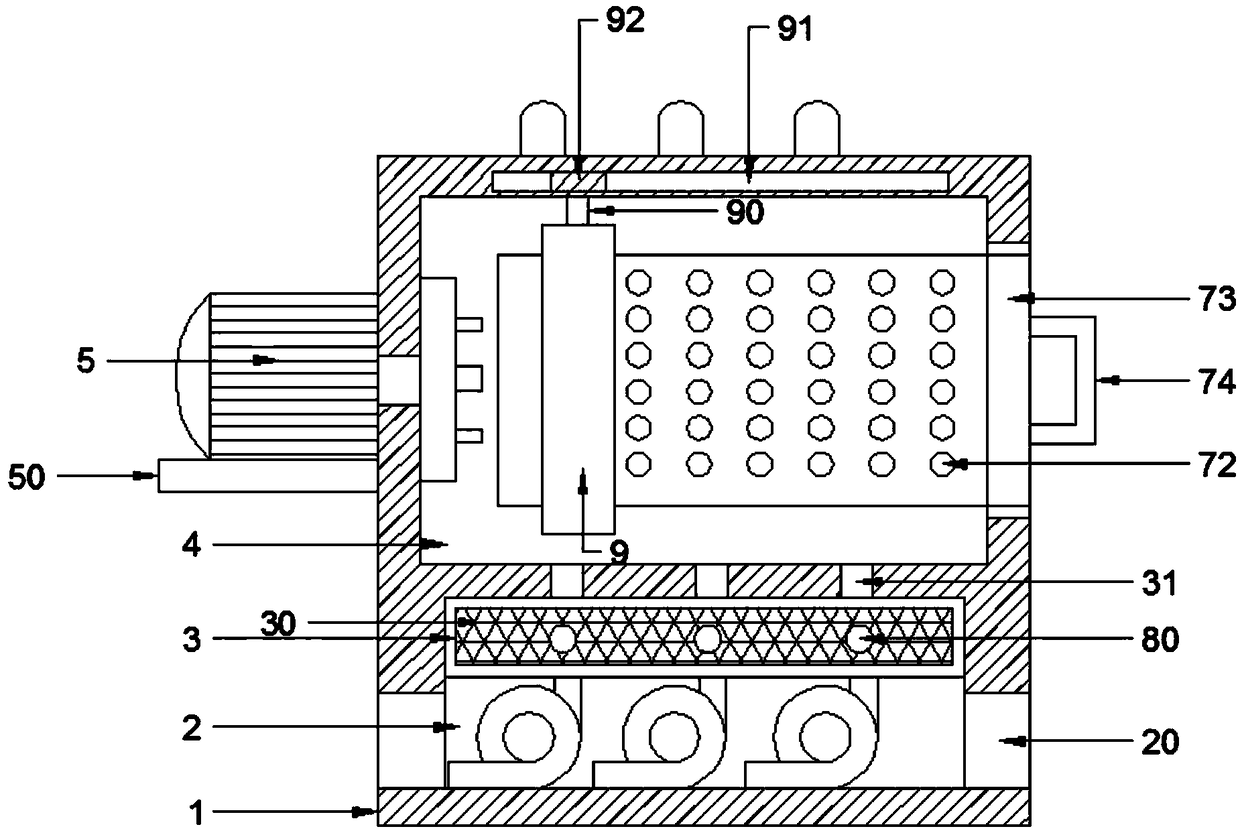

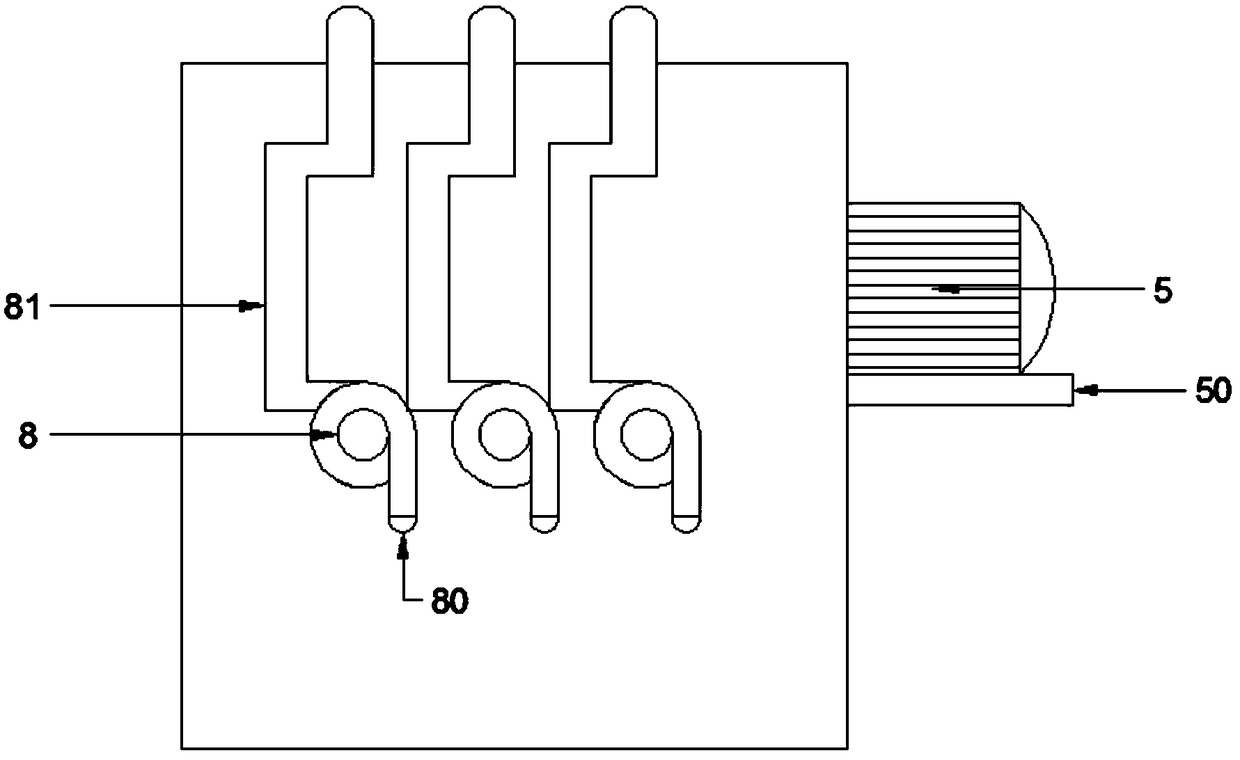

InactiveCN109000457AEasy to pick and placeIncrease flipping frequencyDrying gas arrangementsDrying chambers/containersDrive motorEngineering

The invention discloses a roller-type drying device for astragalus membranaceus. The roller-type drying device comprises a drying box, an air blowing chamber and a drying chamber are formed in the drying box, a plurality of air blowers are fixed to the inner bottom face of the air blowing chamber, a heating box is fixed to the inner top face of the air blowing chamber, a plurality of layers of heating electric resistance wires are laid in the heating box, a driving motor is fixed to the left side wall of the drying box through a motor base, and a position clamping disc is fixed to the right end of a motor shaft of the driving motor; and a drying roller is arranged in the drying chamber, a hanging bearing ring is arranged on the left side cylinder wall of the drying roller in a sleeving mode, the hanging bearing ring is arranged in a hanging sliding groove through a hanging rod and a hanging sliding block in a clamped mode, the hanging sliding groove is formed in the inner top face of the drying chamber, a plurality of scraping plates are transversely fixed to the inner cylinder wall of the drying roller, and a plurality of clamping grooves are formed in the left side wall of the drying roller. According to the roller-type drying device, through the drawing roller design, the turning frequency of the astragalus membranaceus is increased while taking and placing of the astragalusmembranaceus are facilitated, and the consistency of drying effects of all parts of the astragalus membranaceus is improved.

Owner:ANHUI HUARUI PHARMA TECH DEV CO LTD

Crucible cover plate

InactiveCN105821475AImprove flexural strengthExtended service lifeAfter-treatment apparatusPolycrystalline material growthEngineeringUltimate tensile strength

The invention discloses a crucible cover plate. The crucible cover plate comprises a cover plate body used for being arranged on the top of a quartz crucible, and strengthening ribs used for improving the bending strength of the cover plate body are arranged on all corners of the top wall of the cover plate body. According to the crucible cover plate, due to the fact that each corner of the cover plate body is provided with one strengthening rib, the bending strength of the cover plate body can be improved, buckling deformation of the corners is prevented, and the probability of arcing sparking caused by corner buckling of the cover plate body is reduced; in addition, by means of the strengthening ribs, the overall strength of the cover plate body is improved, and prolonging of the service life of the crucible cover plate is promoted; furthermore, after the strengthening ribs are arranged, the bending strength can be improved without increasing the thickness of the cover plate body and reducing the width-to-thickness ratio of the cover plate body, reduction of the material cost and the production cost is promoted, the weight of the whole plate is reduced, and pick-and-place operation of an operator is convenient.

Owner:JINKO SOLAR CO LTD +1

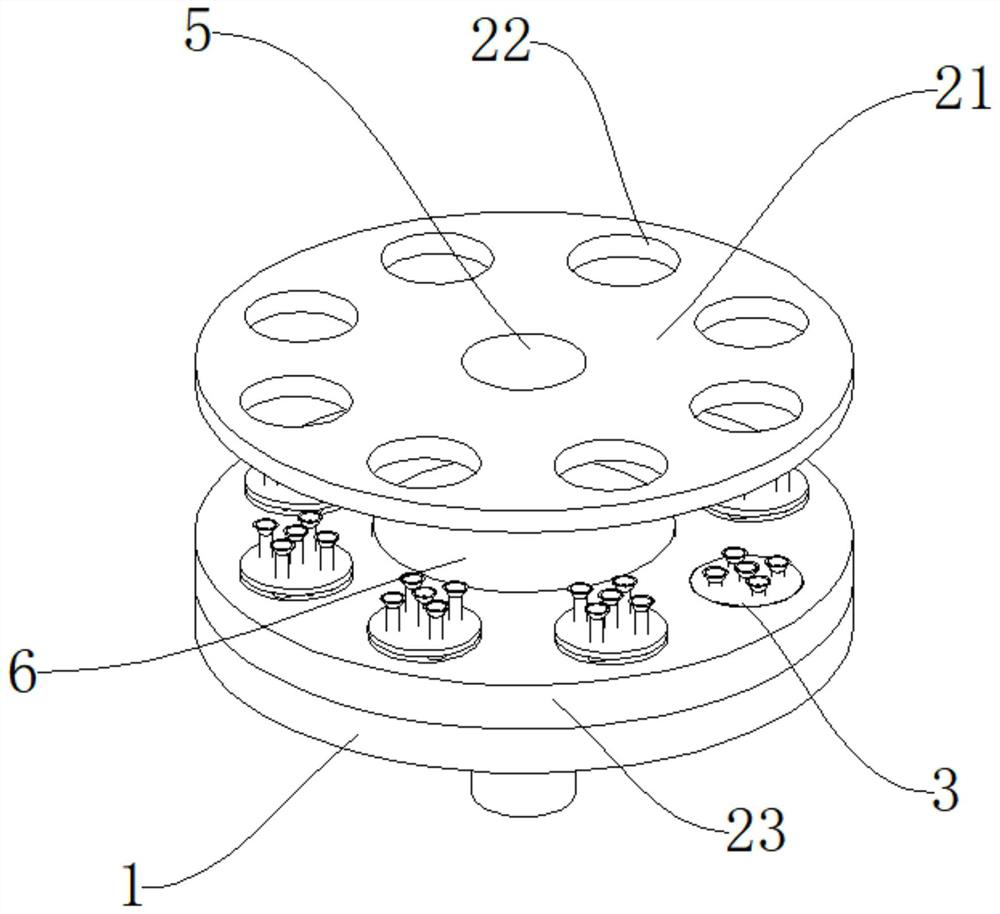

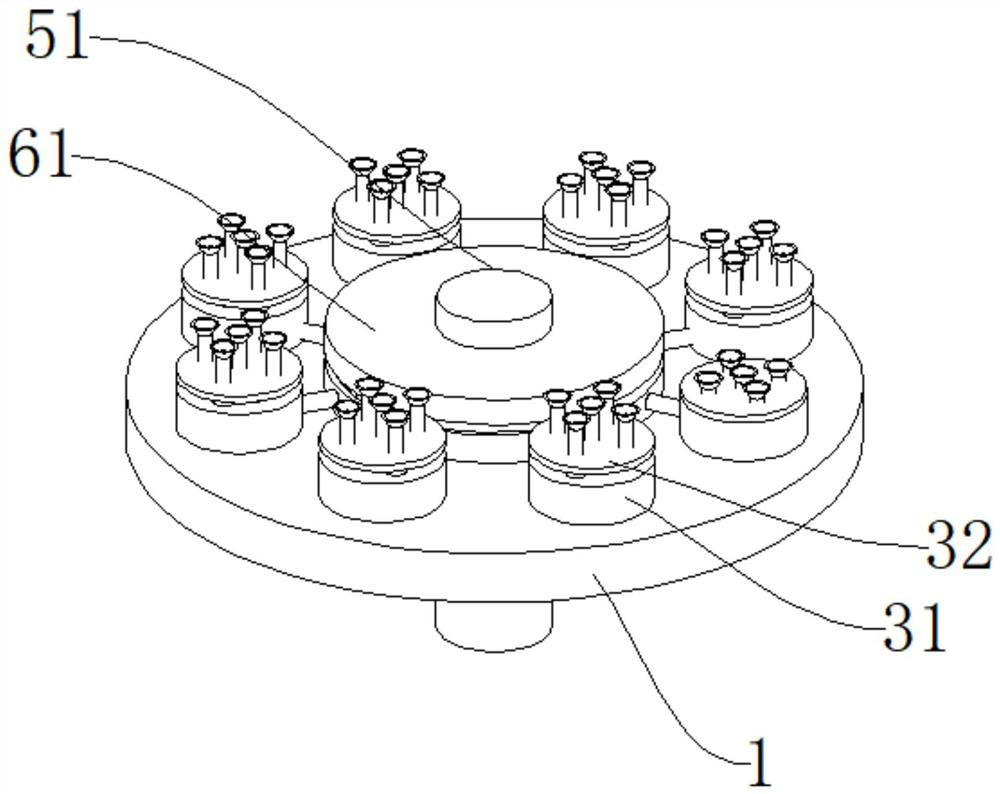

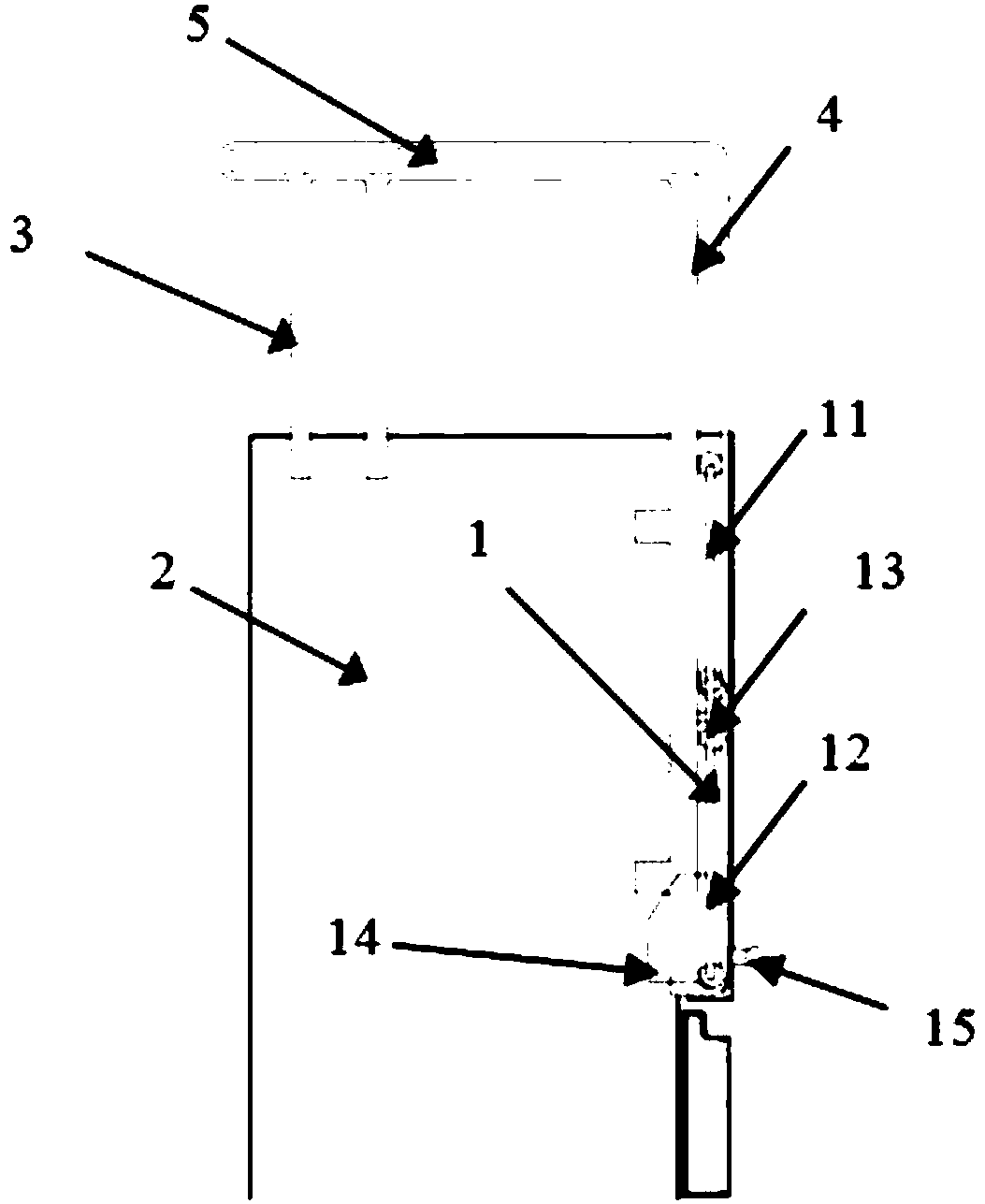

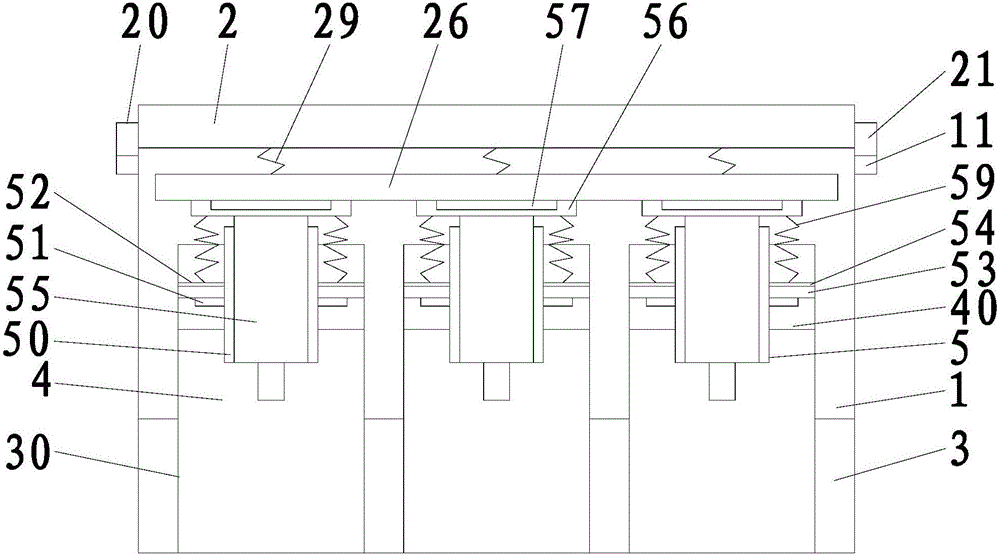

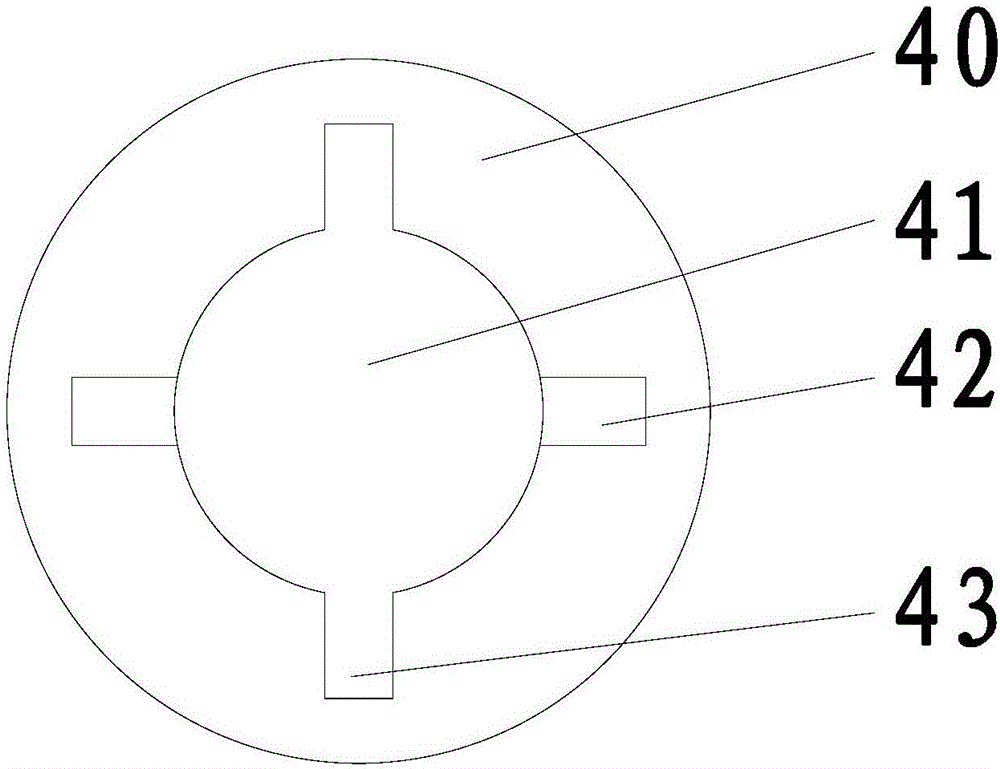

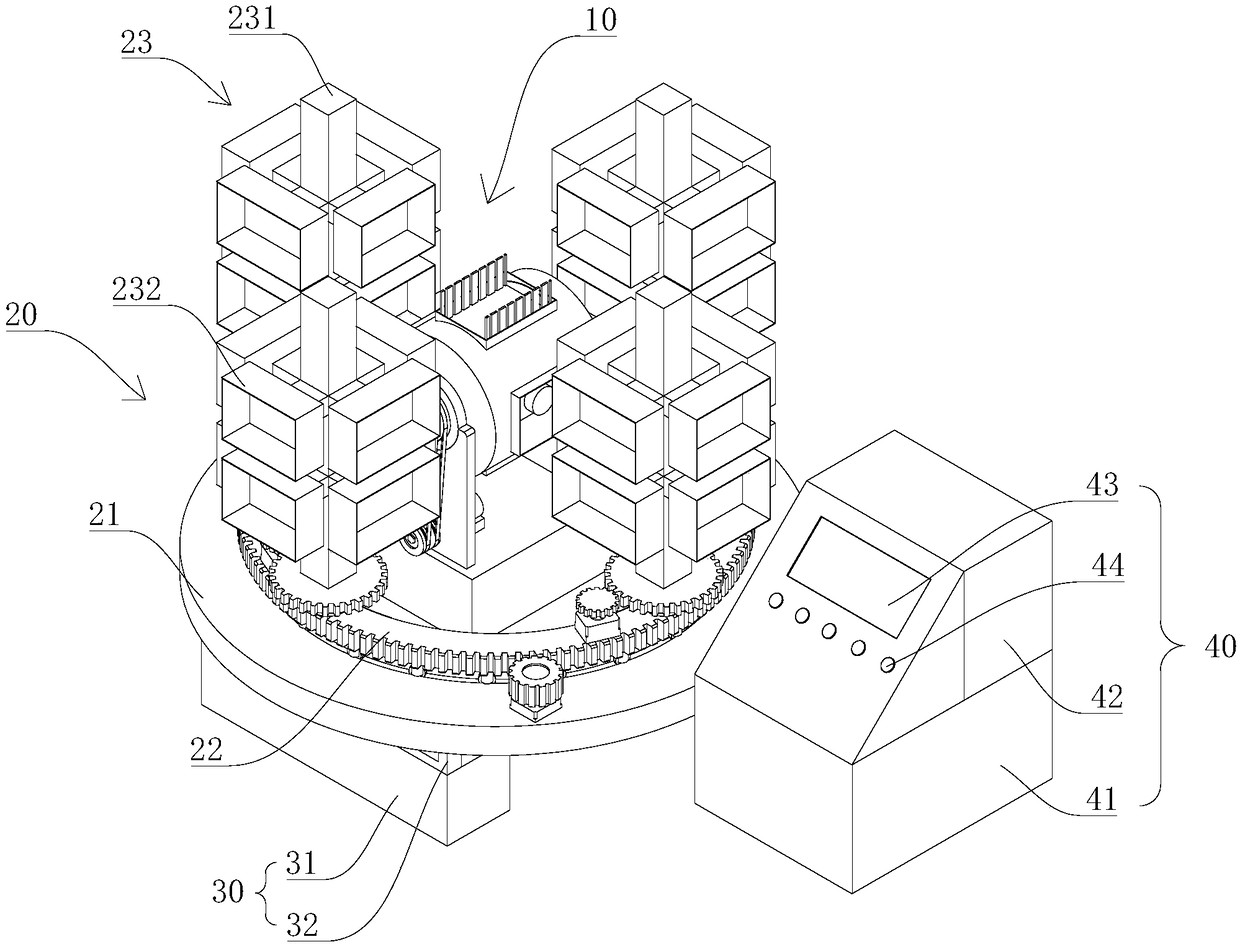

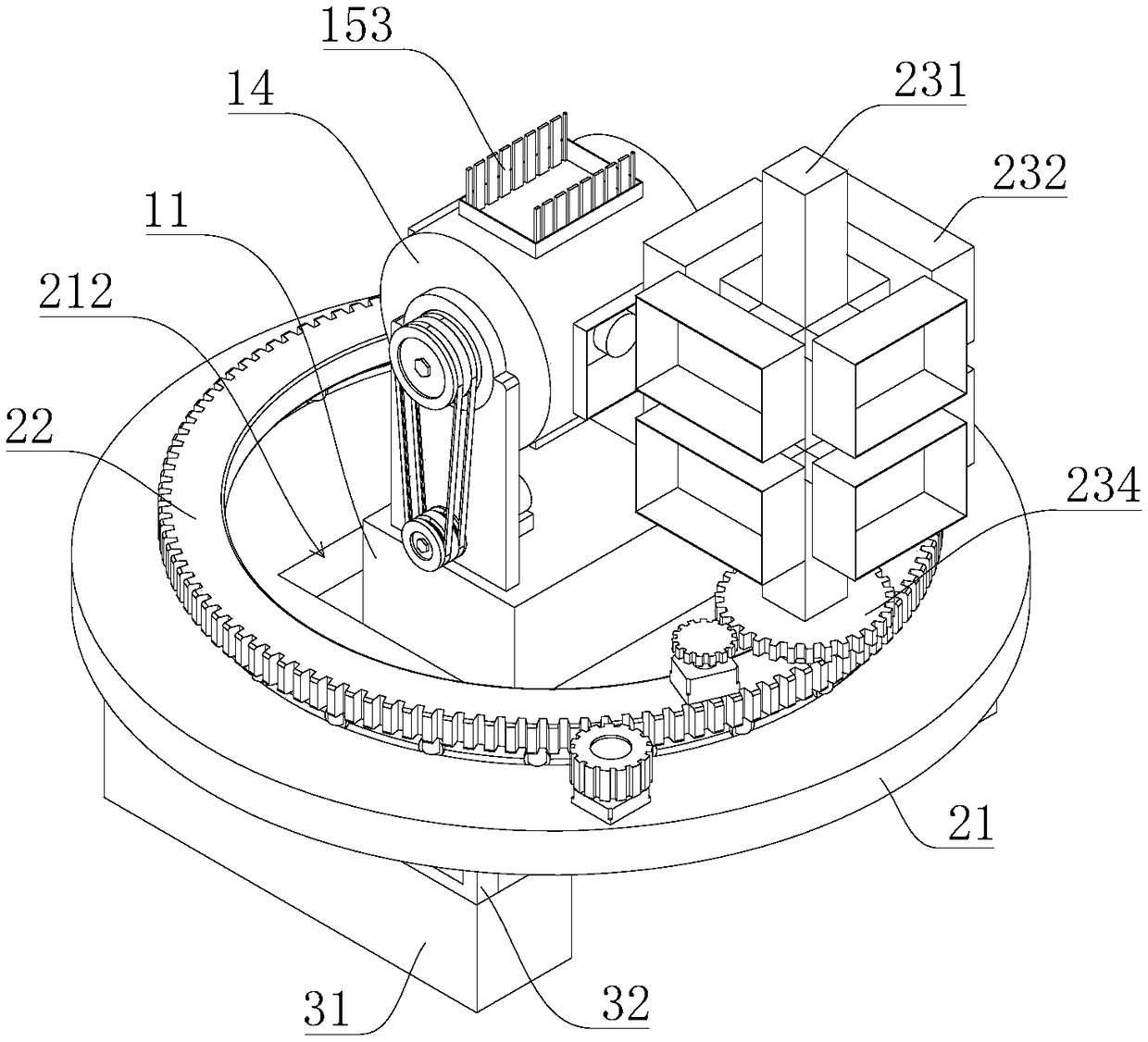

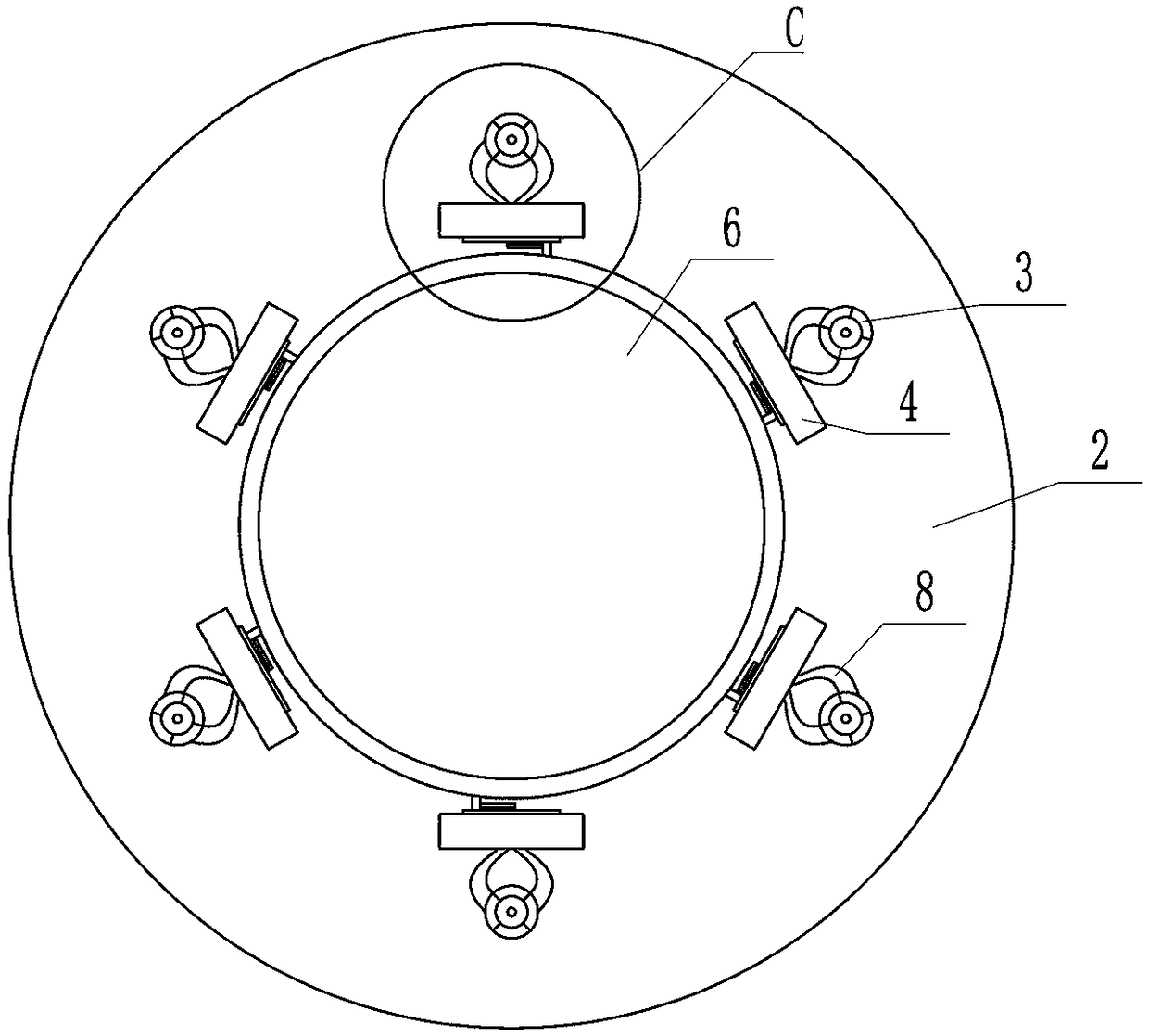

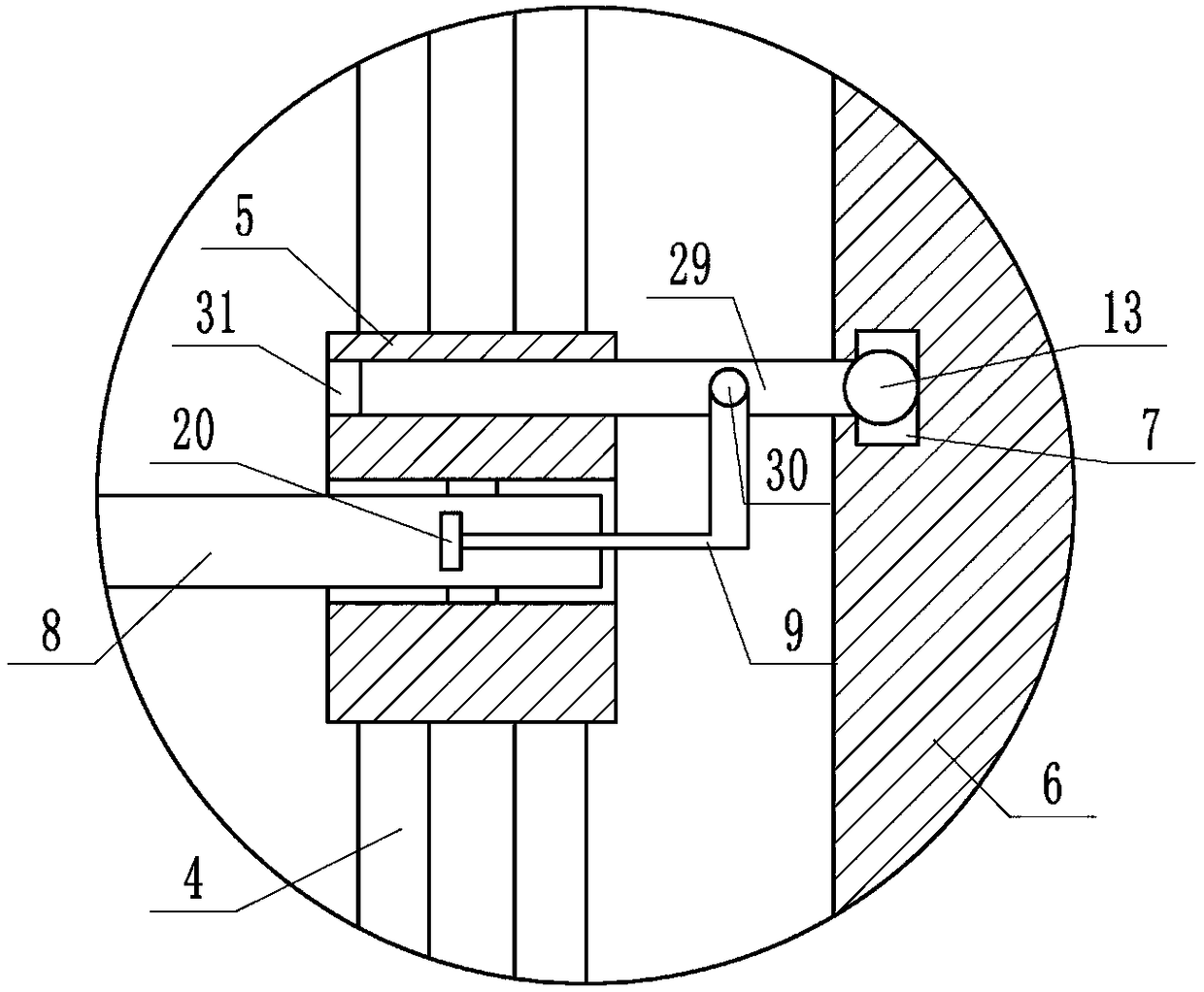

Battery replacing mechanism of shared automobile chassis

ActiveCN108275127AReduce energy consumptionEasy to pick and placeCharging stationsElectric propulsion mountingElectrical batteryElectricity

The invention belongs to the technical field of shared automobile battery replacing devices, and particularly relates to a battery replacing mechanism of a shared automobile chassis. The battery replacing mechanism is arranged below a battery replacing platform and comprises a battery replacing mechanism body, a stacking mechanism, a perpendicular lifting mechanism and a control center; the battery replacing mechanism body is arranged under a battery replacing opening in the battery replacing platform; the battery replacing mechanism body comprises a battery replacing roller, four or more battery replacing devices and a first driving room, wherein the battery replacing devices are arranged on the cylindrical face of the battery replacing roller, and the first driving room drives the battery replacing roller to rotate; the four battery replacing devices are evenly distributed on the cylindrical face of the battery replacing roller; the stacking mechanism is located on the periphery of the battery replacing mechanism body and used for containing to-be-charged batteries and storing fully-charged batteries. The battery replacing mechanism body with the roller is adopted, the battery replacing devices are arranged on the battery replacing roller, in this way, battery replacing, battery placing and battery taking can be completed at the same time in battery replacing, battery replacing time is shortened, and energy consumption of a transferring platform is saved.

Owner:SOUTHWEST JIAOTONG UNIV

Egg frame structure and refrigerator

ActiveCN105806030AEffective protectionEasy to installLighting and heating apparatusCooling fluid circulationReciprocating motionEngineering

The invention provides an egg frame structure and a refrigerator. The egg frame structure comprises a protection cover, a supporting frame and an egg storage box; a containing groove with an opening in the upper end is formed in the protection cover, and a limiting part is arranged in the containing groove; the supporting frame is arranged in the containing groove and can do reciprocating motion in the horizontal direction relative to the protection cover, and a lifting part is formed on the supporting frame; the egg storage box is located in the containing groove and supported by the lifting part, a limiting matching part is arranged on the egg storage box and matched with a limiting part, and the egg storage box can be limited to move in the horizontal direction relative to the protection cover; and when the supporting frame moves in the horizontal direction relative to the protection cover, the lifting part drives the egg storage box to move in the vertical direction. The egg frame structure has the beneficial effects of fool mounting and dismounting, complete and lossless eggs or other egg classes are guaranteed, economic losses are reduced, placement at will can be achieved, the space using rate of the refrigerator is increased, and the egg taking and placing processes are simple and practical.

Owner:HEFEI HUALING CO LTD +1

Multi-nozzle cleaning device of negative pressure adsorption type plastic products

InactiveCN110560401AImprove cleaning efficiencyEasy to pick and placeCleaning using toolsCleaning using liquidsBristleWater flow

The invention discloses a multi-nozzle cleaning device of negative pressure adsorption type plastic products, belongs to the technical field of cleaning equipment, and solves the problems that the existing spherical plastic products are inconvenient to fix and difficult to clean, and a cleaning device cannot be fully contacted with the surfaces of the plastic products to carry out cleaning. The technical point is that the multi-nozzle cleaning device comprises a cleaning bench frame, cleaning benches, suction cups, a cleaning cover, a buffer box and a circulating water pipe, wherein the suction cups are arranged on the cleaning benches to adsorb and fix the plastic products; the cleaning cover for covering the plastic products is arranged above the cleaning benches; lateral cleaning brushes, rubber rods and bristles are in contact with the plastic products; the efficiency of cleaning the plastic products is improved under the conditions that the cleaning cover rotates and sprays water,and cleaning water flow is convenient to collect for recycling; and the multi-nozzle cleaning device is suitable for full cleaning of the spherical plastic products one by one, the taking and placingoperation of the plastic products is convenient, and the plastic products do not need to be fixed by clamps and the like.

Owner:SUZHOU CHAOSHUOFAN PLASTIC PROD CO LTD

Novel material taking and placing mechanical arm for glass fine carving machine

PendingCN110217029AReduce weightReduce volumeProgramme-controlled manipulatorGripping headsEngineeringManipulator

The invention discloses a novel material taking and placing mechanical arm for a glass fine carving machine. The novel material taking and placing mechanical arm comprises a module assembly, a basketpositioning mechanism, a basket assembly, a glass positioning mechanism and a machining mold, wherein the module assembly and the machining mold are arranged on the front side and the rear side of thebasket assembly, and the basket positioning mechanism and the glass positioning mechanism are respectively arranged at the left end and the right end of the basket assembly; and the module assembly comprises a Z-axis module, a Y-axis module and an X-axis module, and one end of the Y-axis module is provided with a rotating mechanism. According to the novel material taking and placing mechanical arm, three modules are used for realizing the X-axis and Y-axis of the mechanical arm, the motion in the Z-axis three-dimensional direction is replaced, manual feeding and discharging are replaced, andpersonnel can be saved; the rotating mechanism is arranged in front of the Y-axis module, so that a sucker can rotate by 90 degrees; and by utilizing the adsorbability of the sucker, the material taking and placing can be conveniently carried out, the structure is optimized, the weight and the size of the mechanical arm are reduced, and the running speed and the efficiency of the device are improved.

Owner:SHENZHEN YANCHUANG PRECISION EQUIP MACHINERY

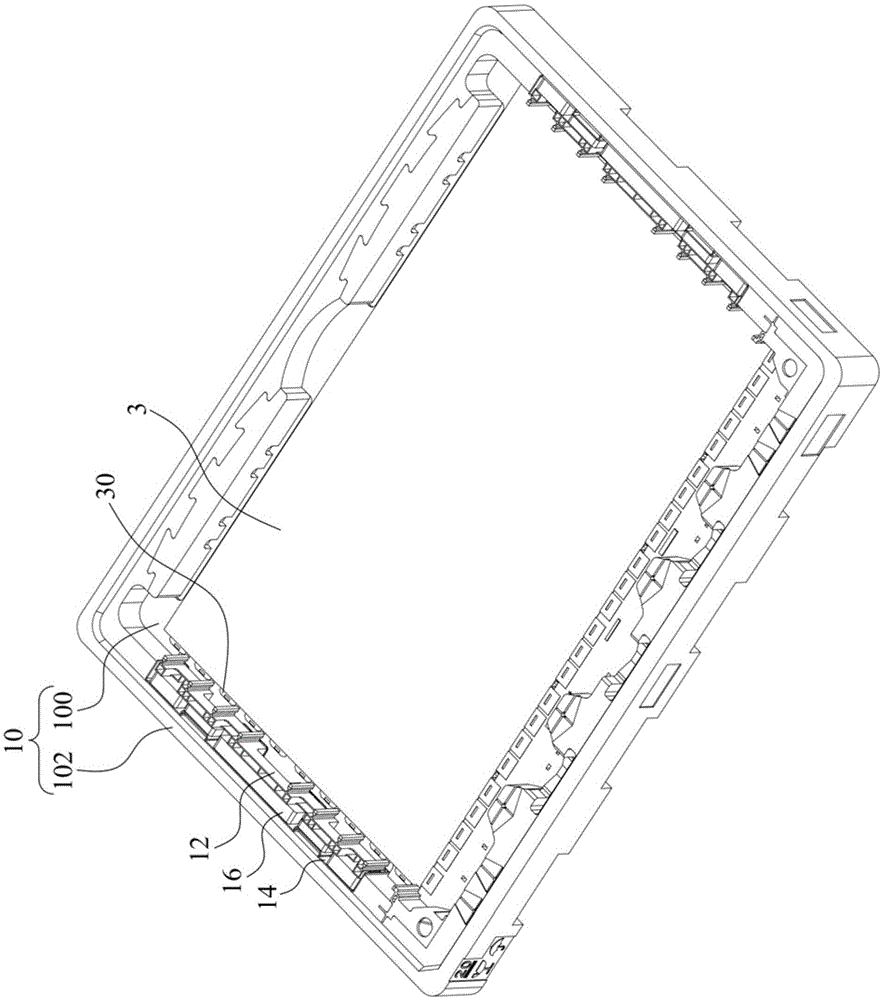

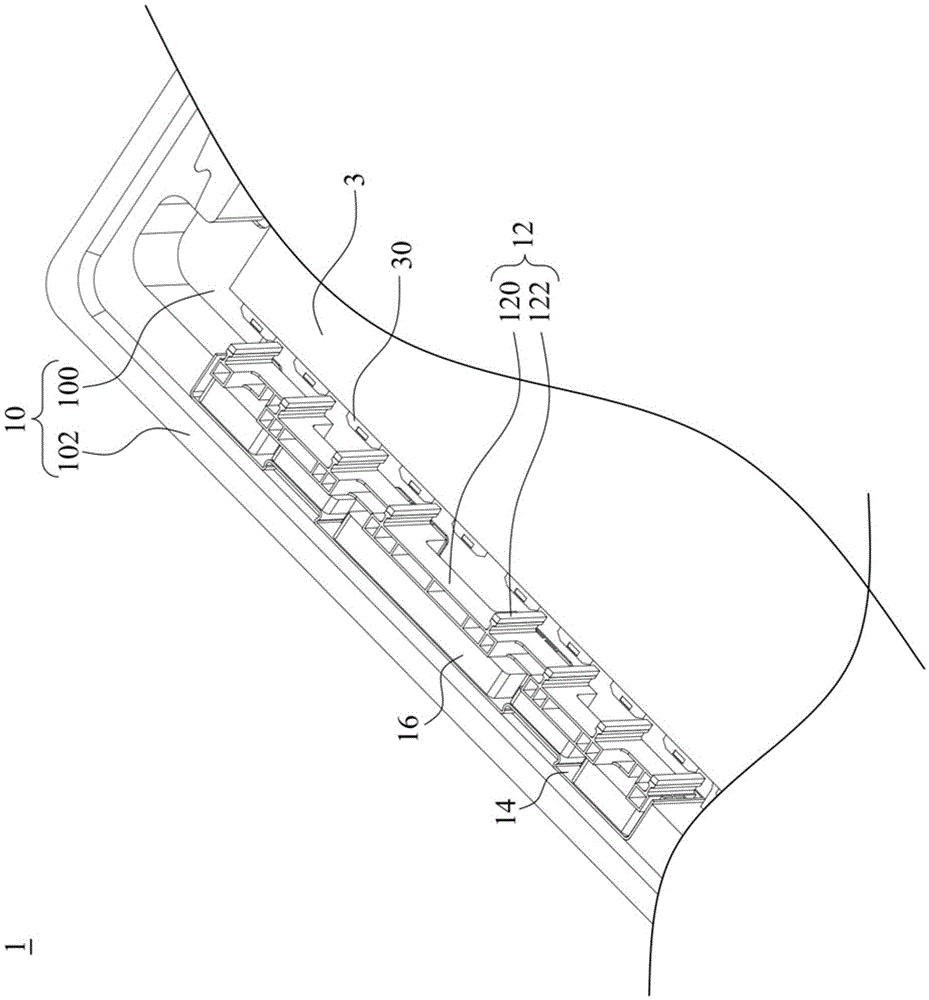

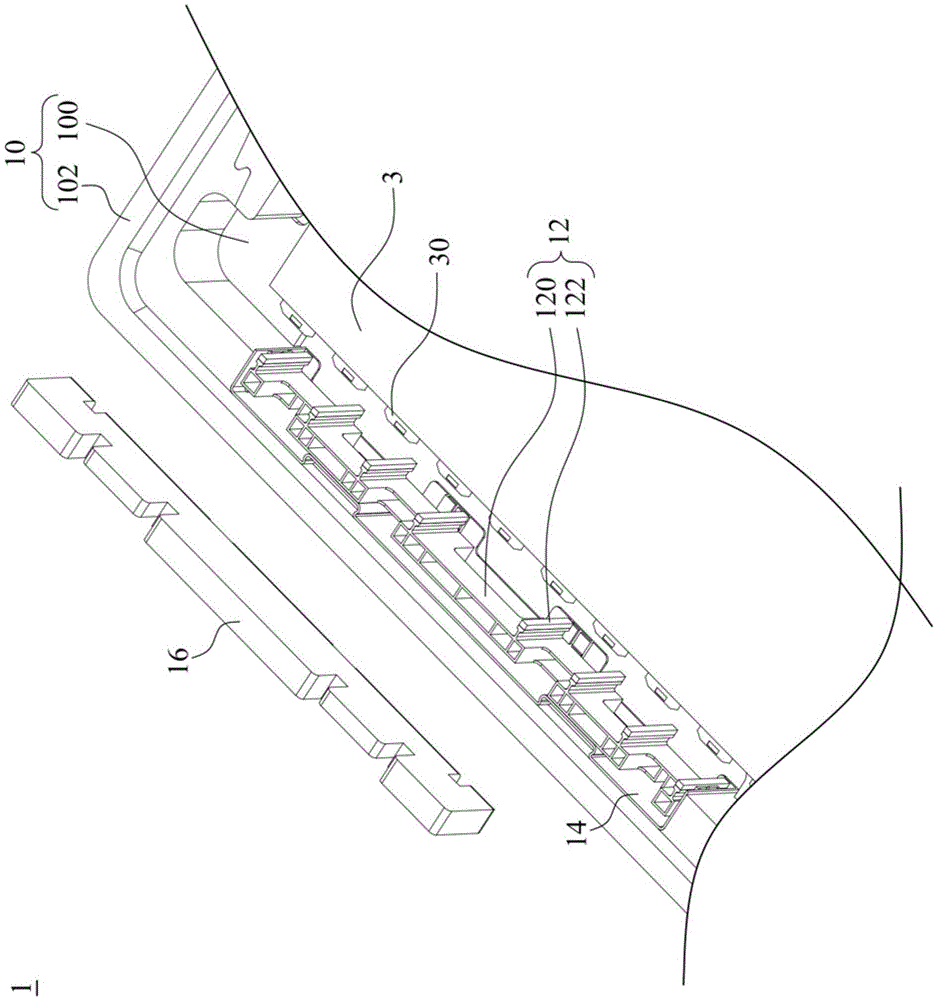

Battery holder

InactiveCN103560216AEasy pick and placeReliable clampingCell component detailsEngineeringThreaded rod

The invention discloses a battery holder. The battery holder comprises a battery holder body and a battery compartment in the battery holder body, wherein one end of the battery compartment is provided with a positive conducting plate, and the other end of the battery compartment is provided with a negative conducting plate. The battery holder is characterized in that one end with the negative conducting plate of the battery holder body is provided with a bolt, the threaded rod part of the bolt penetrates into the battery compartment from the outer side of the battery holder body, the end part of the threaded rod part of the bolt is fixedly connected with the negative conducting plate, and the bolt is connected with the battery holder body by threads. Through the adjustable bolt, the battery holder allows a battery to be easily taken and put and to be reliably clamped, thereby avoiding the poor contact between the battery and each conducting plate.

Owner:李刘睿

Packaging assembly

ActiveCN105564819AAvoid damageEasy to pick and placeContainers to prevent mechanical damageDamagable goods packagingEngineering

A packaging assembly is used for packaging an object. The packaging assembly comprises a box, a first check block, a guide structure and a second check block. The box comprises a base and a side wall which are connected. The base is arranged to bear the object. The first check block is arranged on the box. The guide structure is arranged on the box and matched with the first check block, and therefore the first check block is guided to move away from the side wall to the first position or to move towards the side wall to the second position. The first check block is arranged to bear and abut against the object at the first position. The second check block is arranged to be detachably plugged in the space between the side wall and the first check block when the first check block is located at the first position. After the second check block is removed, the first check block can move towards the side wall for avoiding, then an additional clearance is formed between the first check block and the object, and therefore the later taking and placing operation on the object can be facilitated, and the situation that a flexible object on the edge of the object collides with the first check block, so that damage is caused can be avoided.

Owner:AU OPTRONICS CORP

Detection device convenient for handling gloves

ActiveCN108956019AEasy to operateEasy access to glovesFluid-tightness measurement using fluid/vacuumEngineeringWorking hours

The invention discloses a detection device convenient for handling gloves and effectively solves problems of working-hour delay and damage to the gloves caused difficulty in handling the gloves existing in a device in the prior art. The detection device comprises a frame, wherein the frame is rotatably connected with a console, the frame and the console are in sealing connection, and the console is provided with multiple detection devices. The detection device is advantaged in that operation is simple, manually handling the gloves is more convenient, originally stretching the gloves is not needed, the gloves can be directly sleeved on hook claws, opening and closing actions are completed by the hook claws, the opening and closing angle is greatly reduced compared with an original angle, damage to the gloves is avoided, the structure is ingenious, the original console makes the process more reasonable, workers can complete multiple process tasks without moving the position, and work efficiency is greatly improved.

Owner:南通金斯顿防护用品有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com