Electric automobile power battery quick-change mechanism

A technology for power batteries and electric vehicles. It is applied in the direction of electric power devices, power devices, and battery pack components. It can solve the problems of time-consuming, cumbersome procedures, and heavy workload for battery disassembly and replacement, and achieve easy and labor-saving pick-and-place processes. , The effect of saving time and effort and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

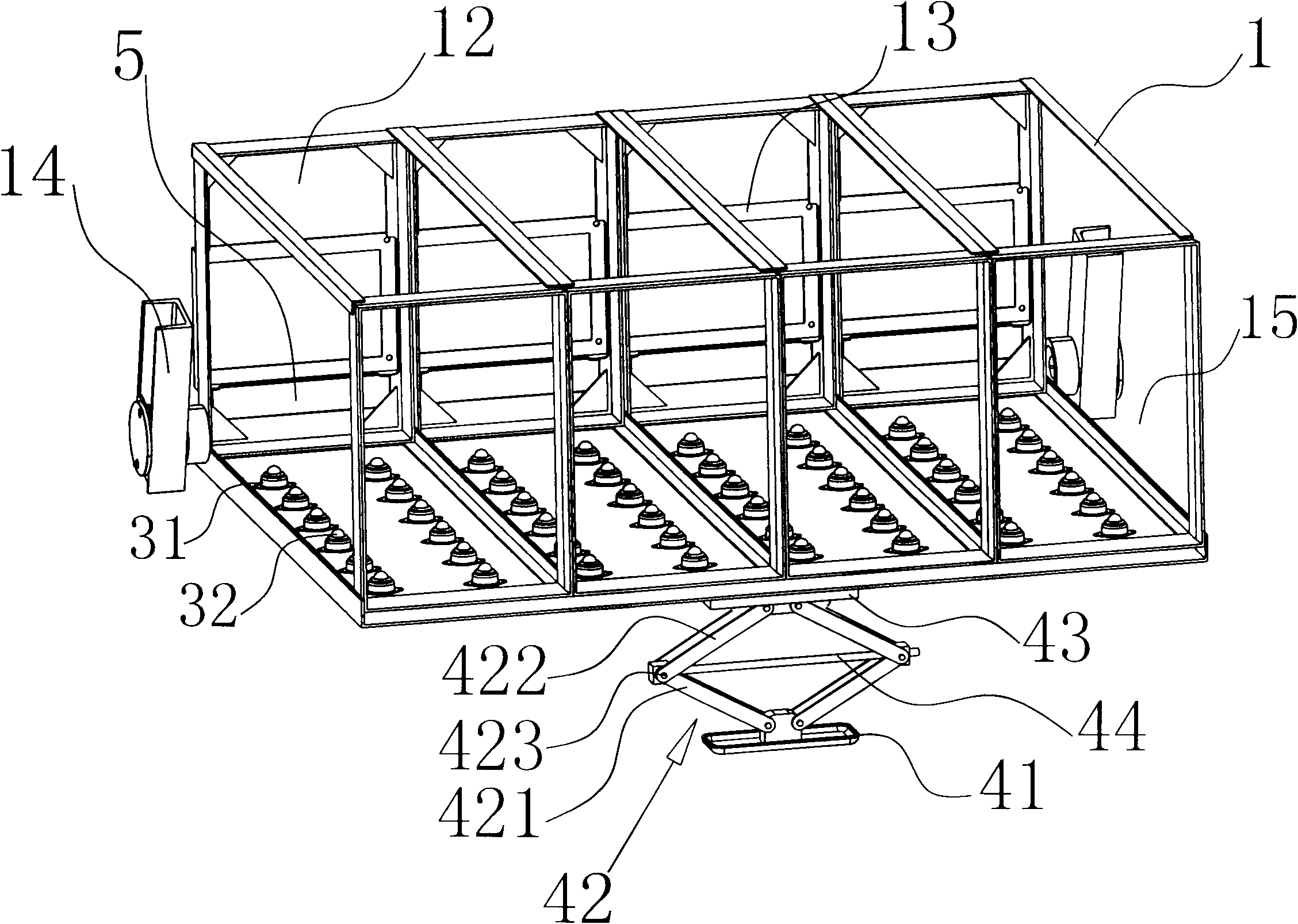

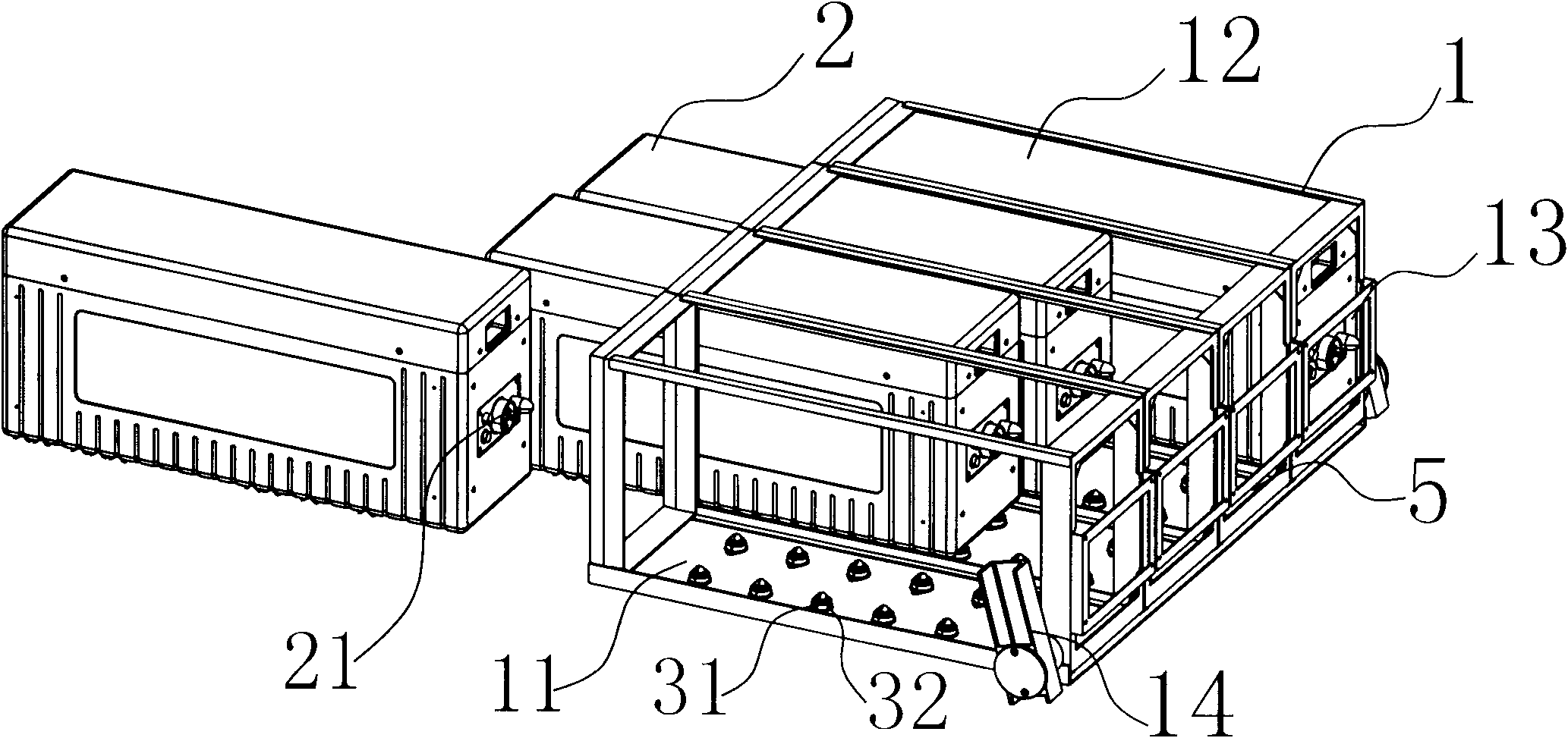

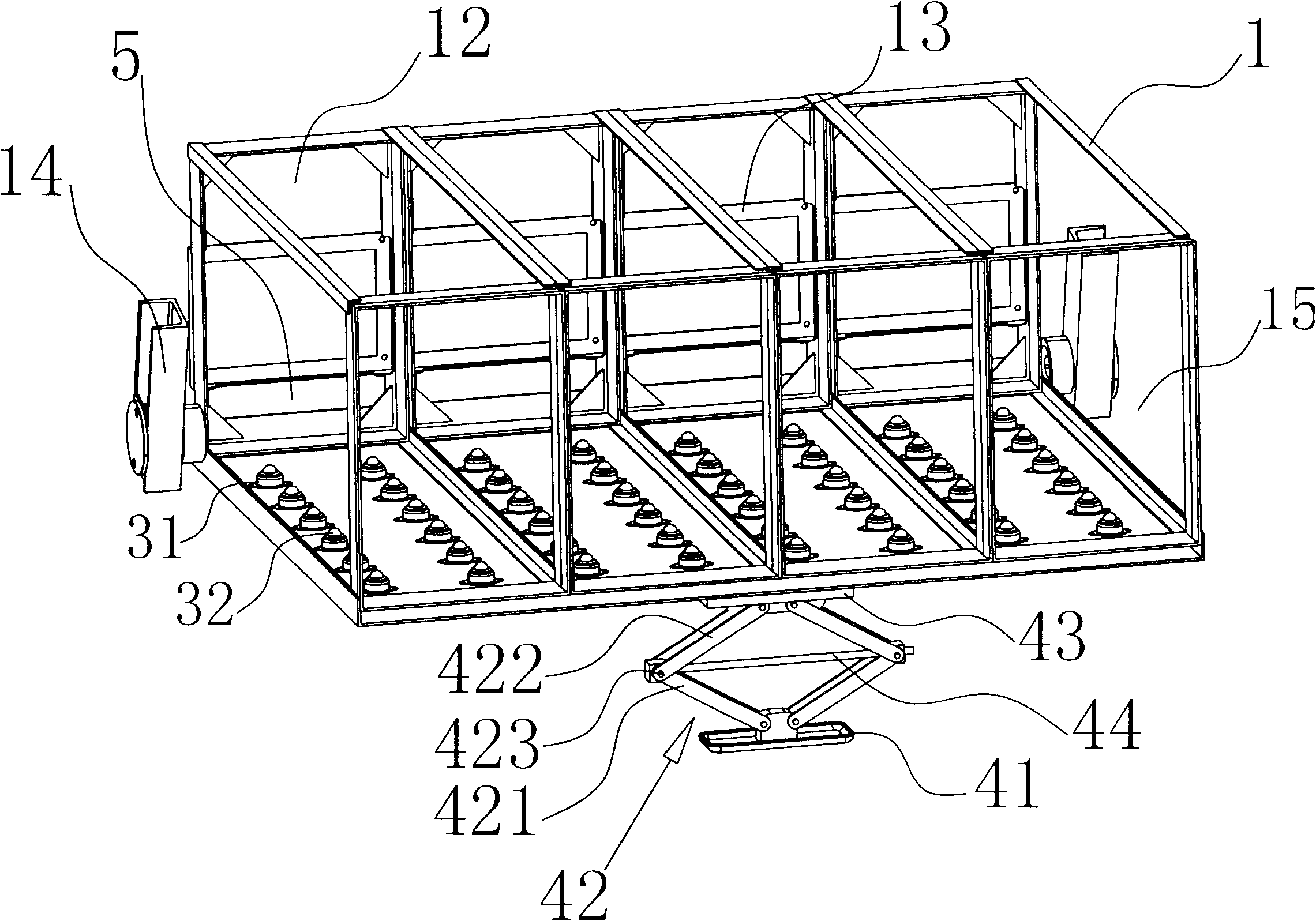

[0020] like figure 2As shown, in the electric vehicle power battery quick-change mechanism of the present invention, in order to save cost and reduce weight, the battery installation frame 1 in the electric vehicle power battery sliding assembly mechanism of the present invention is welded by square tube profiles, which includes rectangular battery The installation frame 1 and the battery pack 2 installed in the battery installation frame 1 are pivotally connected to the side of the long side of the battery installation frame 1 through the horizontal connecting shaft 5 in the sinking groove of the automobile chassis, and on the side corresponding to the short side of the battery installation frame 1 A pair of connection plates 14 are symmetrically welded on the top, and the two ends of the horizontal connection shaft 5 pass through the connection plate 14 and are welded symmetrically on the connection plate 14. On the battery installation frame 1, four parallel partitions are ...

Embodiment 2

[0023] The lifting mechanism is a vertical screw rod and a vertical screw nut screwed on the vertical screw rod. The nut is welded and fixed on the chassis of the car, and the lower end of the vertical screw rod is connected with a geared motor through a coupling. The sliding mechanism includes a pair of slide rail grooves on the inner bottom plate 11 corresponding to the positioning groove 12 and a pair of sliders on the bottom surface of the battery pack 2 that match with the slide rail grooves. The slide rail grooves are symmetrically distributed relative to the battery pack inlet 15, and the battery pack 2 Sliding connection is maintained with the bottom plate 11 through the sliding blocks and the sliding rail grooves which are matched with each other. All the other parts are identical with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com