Movable placement frame for discarded printed circuit boards

A technology for discarding circuit boards and placing racks, which is used in motor vehicles, multi-axis trolleys, trolley accessories, etc., can solve the problems of complicated picking and placing operations, poor placement stability of the placing racks, etc. Switch between convenient effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

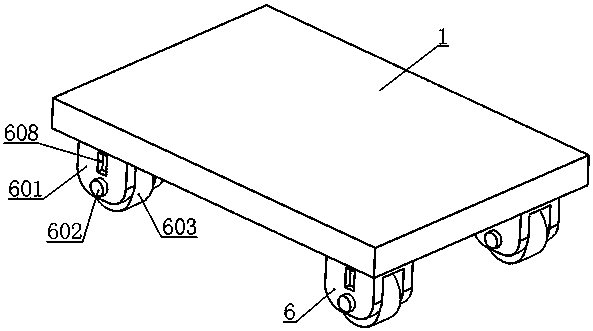

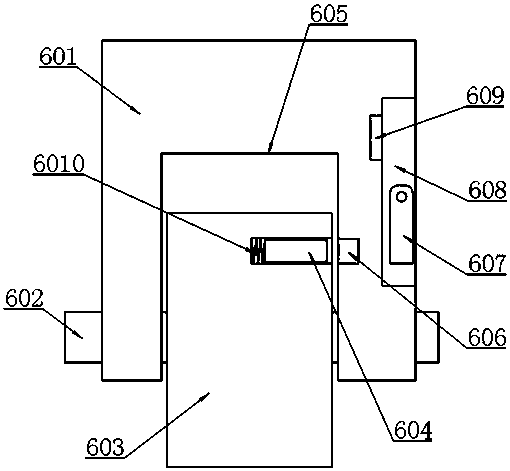

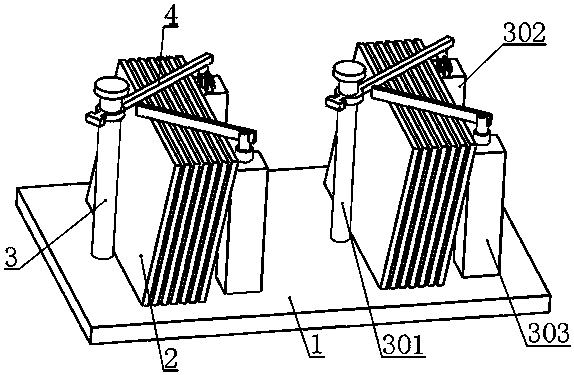

[0026] Example: as attached figure 1 , 2 , 3, 4, 5, 6 and attached Figure 7 As shown, a movable waste circuit board placement rack includes a frame bottom plate 1, and also includes a placement unit 3 arranged on the frame bottom plate 1 and used to limit and support the waste circuit board 2, and is arranged on the The fastening unit 4 on the fixed unit 3 and used to press down the waste circuit board 2, the lower surface of the frame bottom plate 1 is also provided with a movable unit 6 for carrying the waste circuit board 2, the The movable unit 6 includes an installation slot plate 601, a roller 603 arranged on the installation slot plate 601 through a rotating shaft 602, a magnet column 604 inserted in the side opening of the roller 603, and a magnet column 604 arranged on the side of the slot 605. Insert and lock the roller 603 through the magnet column 604 to fix the jack 606 after the rack is transported, and the outer surface of the mounting groove plate 601 is pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com