AOI vision detection device with automatic overturning function

A visual inspection device and automatic flip technology, applied in the field of optical inspection, can solve the problems of inconvenient moving and changing positions, reducing inspection efficiency, inconvenient disassembly and assembly, etc., to achieve good application prospects, improve inspection efficiency, and facilitate the effect of picking, placing and fixing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the accompanying drawings.

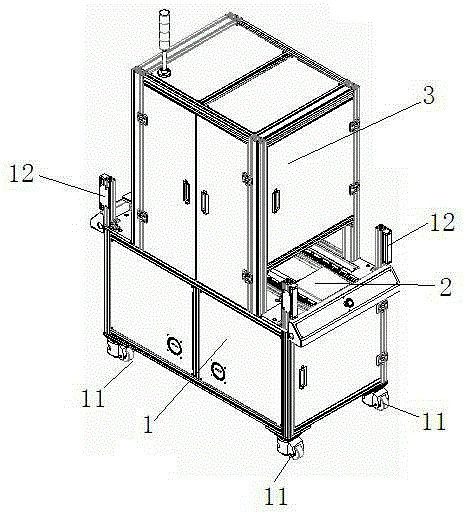

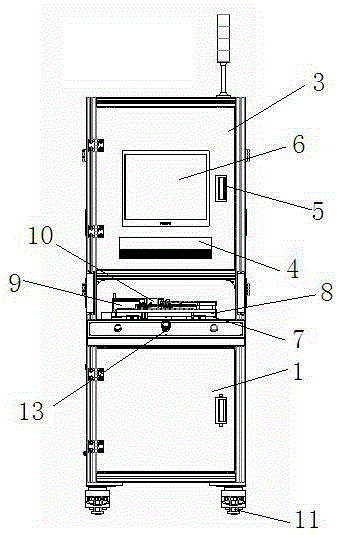

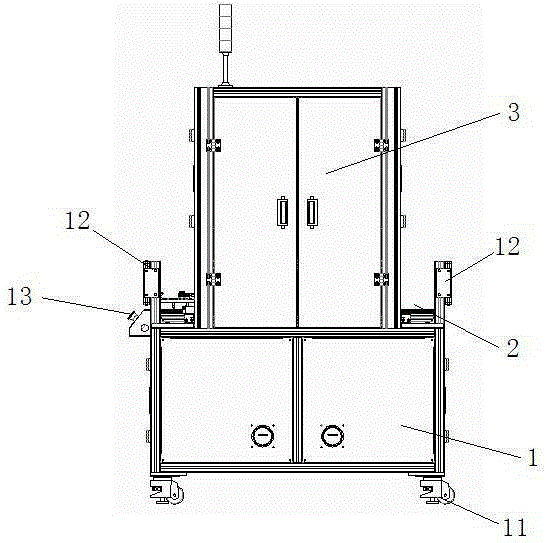

[0018] like figure 1 , figure 2 and image 3 As shown, the AOI visual detection device with automatic flip function of the present invention includes a carrying case 1, the upper surface of the carrying case 1 is provided with a conveyor belt 2, and the conveyor belt 2 is used to transmit the PCB board to be detected, so The top of the carrying case 1 is also provided with a detection case 3, the detection case 3 is bridged above the conveyor belt 2, and the detection case 3 is provided with an automatic camera 4, a processing terminal 5 and a display panel 6, and the automatic The shooting camera 4 is arranged directly above the conveyor belt 2, the output end of the automatic shooting camera 4 is connected with the processing terminal 5, the output end of the processing terminal 5 is connected with the display panel 6, and one of the entrances of the conveyor belt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com