Surface polishing device for high-refractive-index lens processing and using method of surface polishing device

A technology of lens processing and high refractive index, which is applied in the direction of grinding drive devices, metal processing equipment, grinding machines, etc., can solve the problems of fast clamping and processing, inability to guarantee work efficiency, troublesome manual focusing, etc., to achieve convenient access The effects of unloading, improving processing efficiency, and improving processing accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

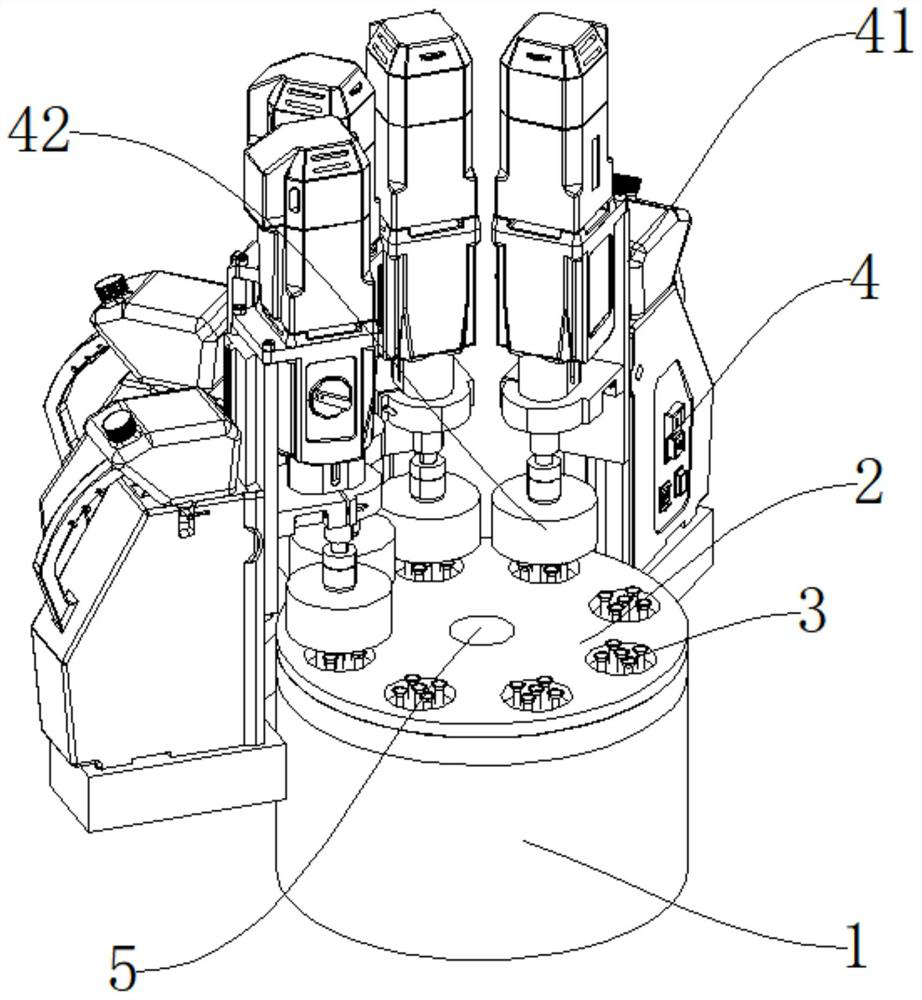

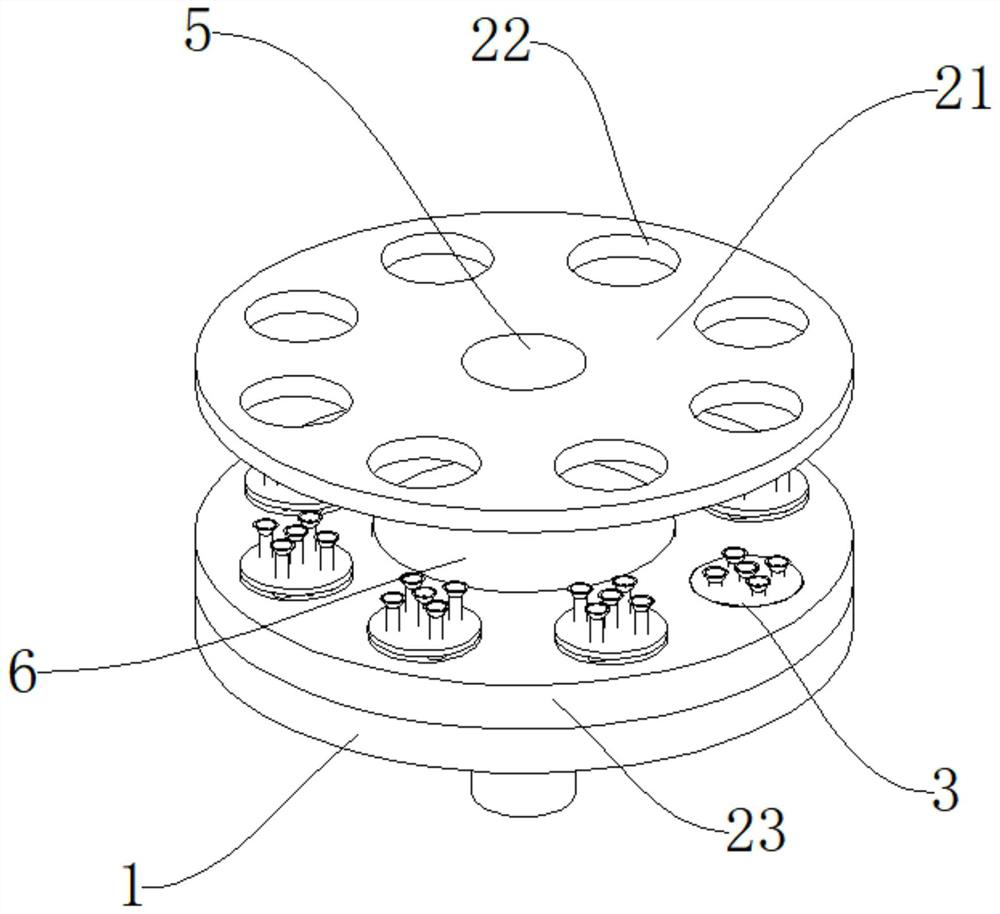

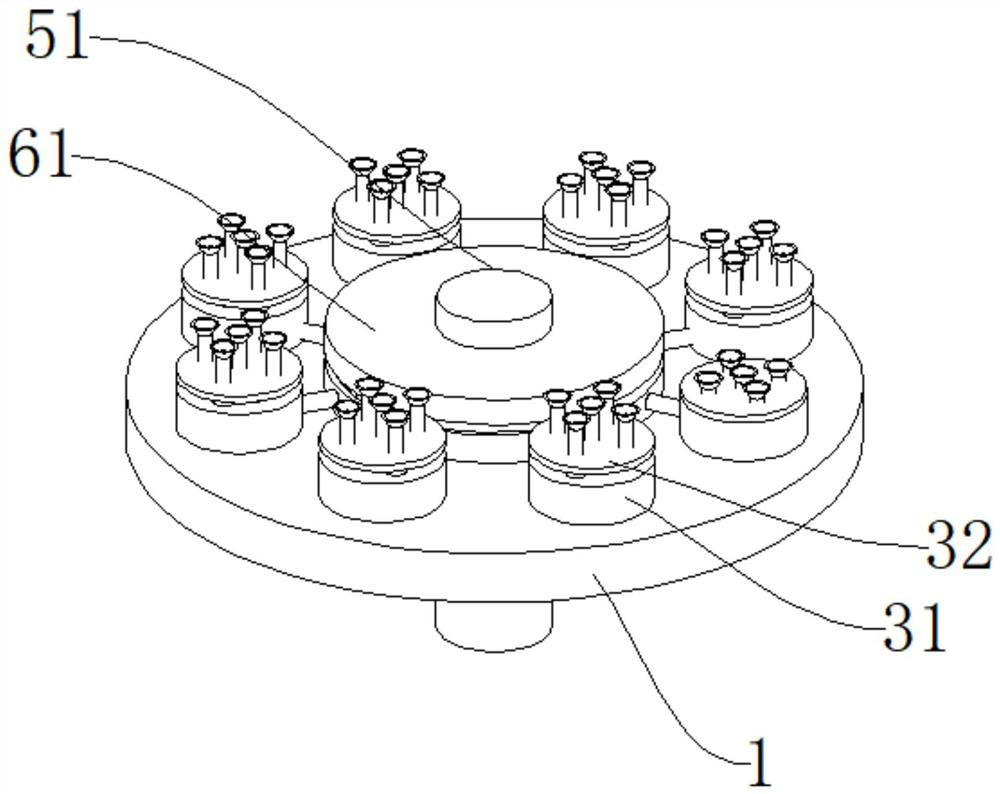

[0049] like Figure 1-Figure 8 As shown, the power mechanism 5 includes a main shaft 51, a sheave 52, a rotating wheel 53, and a linkage pin 54. One end of the main shaft 51 is connected to the limit plate 21 of the rotating mechanism 2, and the other end of the main shaft 51 is connected to the sheave 52. One end of the sheave 52 is provided with a The rotating wheel 53 is provided with a linkage pin 54, and the lower end of the rotating wheel 53 is connected to the first motor 55. When the first motor 55 is started, it drives the rotating wheel 53 to rotate, and when the rotating wheel 53 rotates, the linkage pin 54 is driven to make the rotating wheel 53 rotate. The linkage pin 54 drives the sheave 52 and the main shaft 51 to rotate intermittently, so that the limit disk 21 rotates intermittently; the rotating mechanism 2 includes the limit disk 21, the limit hole 22, and the rotating disk 23. The limit disk 21 is formed with eight There are limit holes 22, the lower end of...

Embodiment 2

[0051] The difference between this embodiment and Embodiment 1 is:

[0052] like Figure 9 , the power mechanism 5 includes a main shaft 51, a passive gear 511, an intermittent gear 512, and a second motor 513. One end of the main shaft 51 is connected to the limit plate 21 of the rotating mechanism 2, and the other end of the main shaft 51 is connected to the passive gear 511. The passive gear 511 and the intermittent gear 512 The lower end of the intermittent gear 512 is connected to the second motor 513. When the second motor 513 starts, it drives the intermittent gear 512 to rotate, and the intermittent gear 512 and the driven gear 511 are intermittently meshed, so that the driven gear 511 drives the main shaft 51 to rotate intermittently, so that the The limit plate 21 rotates intermittently.

[0053] The use method of the grinding surface device for high refractive index lens processing comprises the following steps:

[0054] a. When the lens needs to be processed, pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com