PPR water pipe bending machining process

A technology of bending processing and water pipes, which is applied in the field of PPR water pipe bending processing technology, can solve the problems of excessive bending, tearing of PPR water pipes, unqualified bending of PPR water pipes, etc., and achieve the effect of accurate and reliable transmission and improved efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

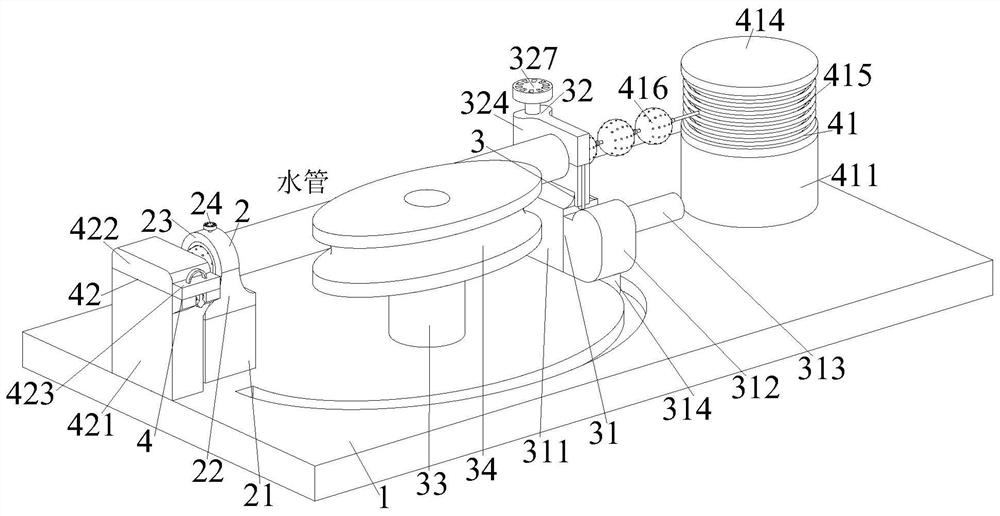

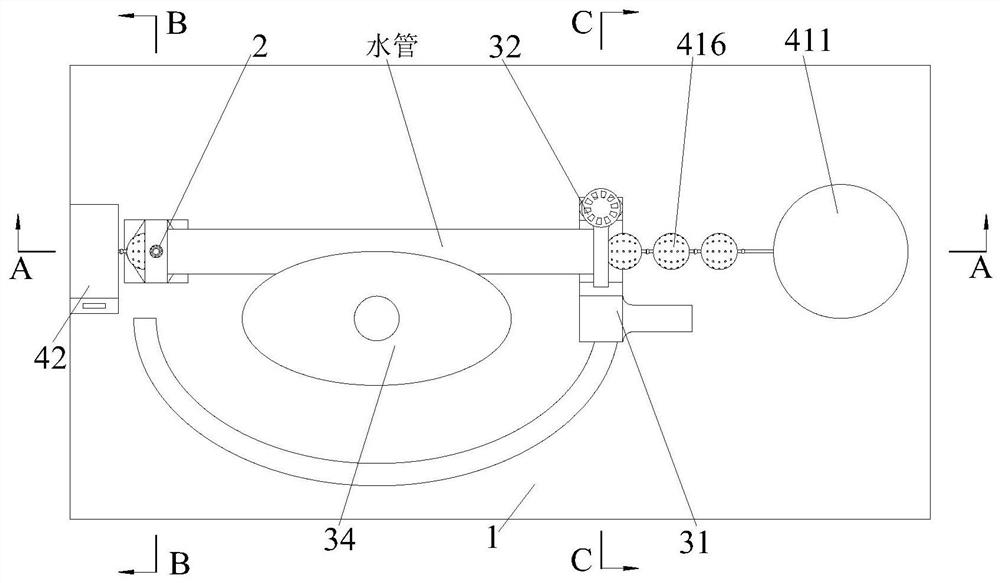

[0041] In order to make the technical means realized by the present invention, creative features, goals and effects easy to understand, the following combination Figure 1 to Figure 10 , to further elaborate the present invention.

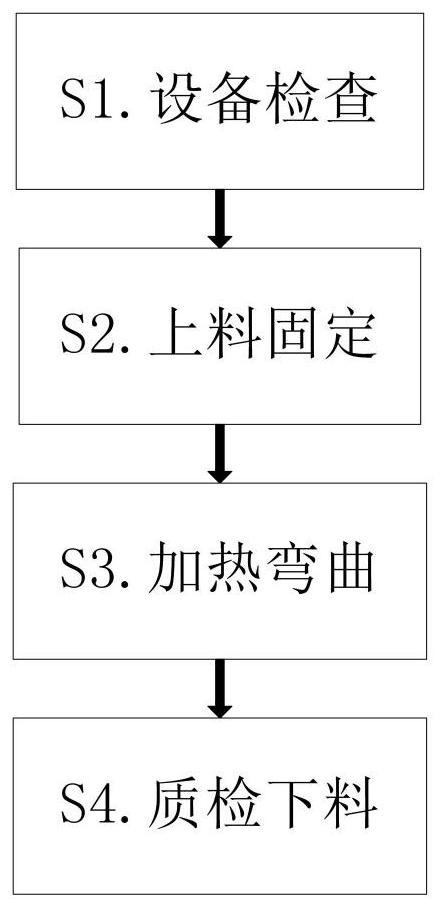

[0042] A PPR water pipe bending process, the specific bending process is as follows:

[0043] S1. Equipment inspection: Before using the PPR water pipe bending processing equipment to bend the PPR water pipe, check the PPR water pipe bending processing equipment;

[0044] S2. Loading and fixing: manually place the PPR water pipe to be bent on the workbench 1, and make the clamping device 2 and the support device 4 clamp and fix the PPR water pipe to be bent;

[0045] S3. Heating and bending: After the PPR water pipe is clamped and fixed, manually heat the clamped and fixed PPR water pipe to make it soft when heated. Water pipes are bent;

[0046] S4. Quality inspection blanking: After the PPR water pipe is bent, remove it manually and conduct qu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com