Cover plate and manufacturing method thereof, display panel and display device

A manufacturing method and cover plate technology, which is applied in semiconductor/solid-state device manufacturing, electrical components, diodes, etc., can solve the problems of complicated manufacturing process steps, large space occupied by the cover plate, and high production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

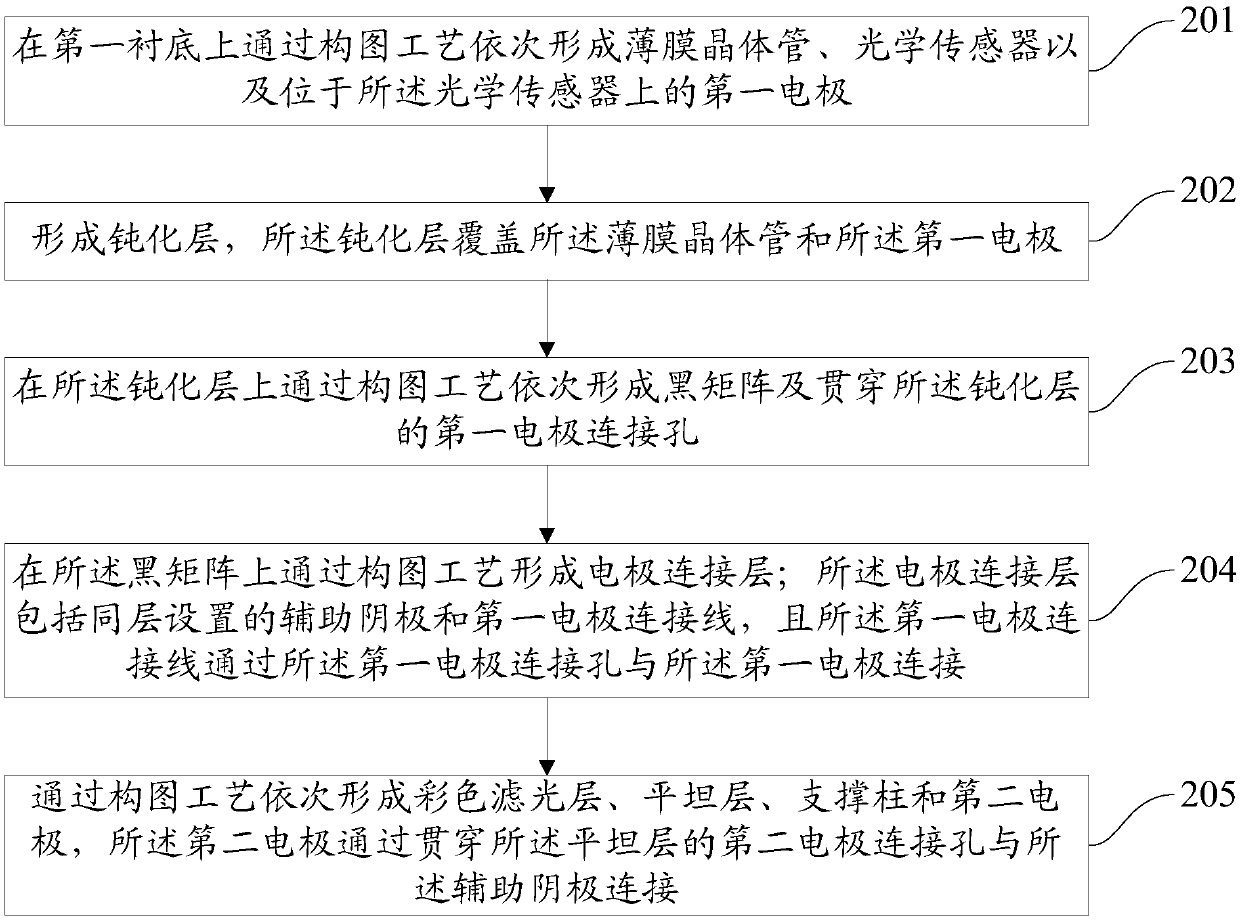

[0060] refer to figure 2 , which shows a flow chart of a method for manufacturing a cover plate according to an embodiment of the present invention, which may specifically include the following steps:

[0061] Step 201 , sequentially forming a thin film transistor, an optical sensor, and a first electrode on the optical sensor on a first substrate through a patterning process.

[0062] In the embodiment of the present invention, a thin film transistor is formed on the first substrate through a patterning process, an optical sensor is formed on the drain of the thin film transistor, and a first electrode is formed on the optical sensor.

[0063] Wherein, the drain of the thin film transistor is used as the lower electrode of the optical sensor at the same time, and the first electrode is the upper electrode of the optical sensor; the first electrode can be made of a transparent conductive material, such as ITO (Indium Tin Oxide, indium tin oxide) or IZO (Indium Zinc Oxide, in...

Embodiment 2

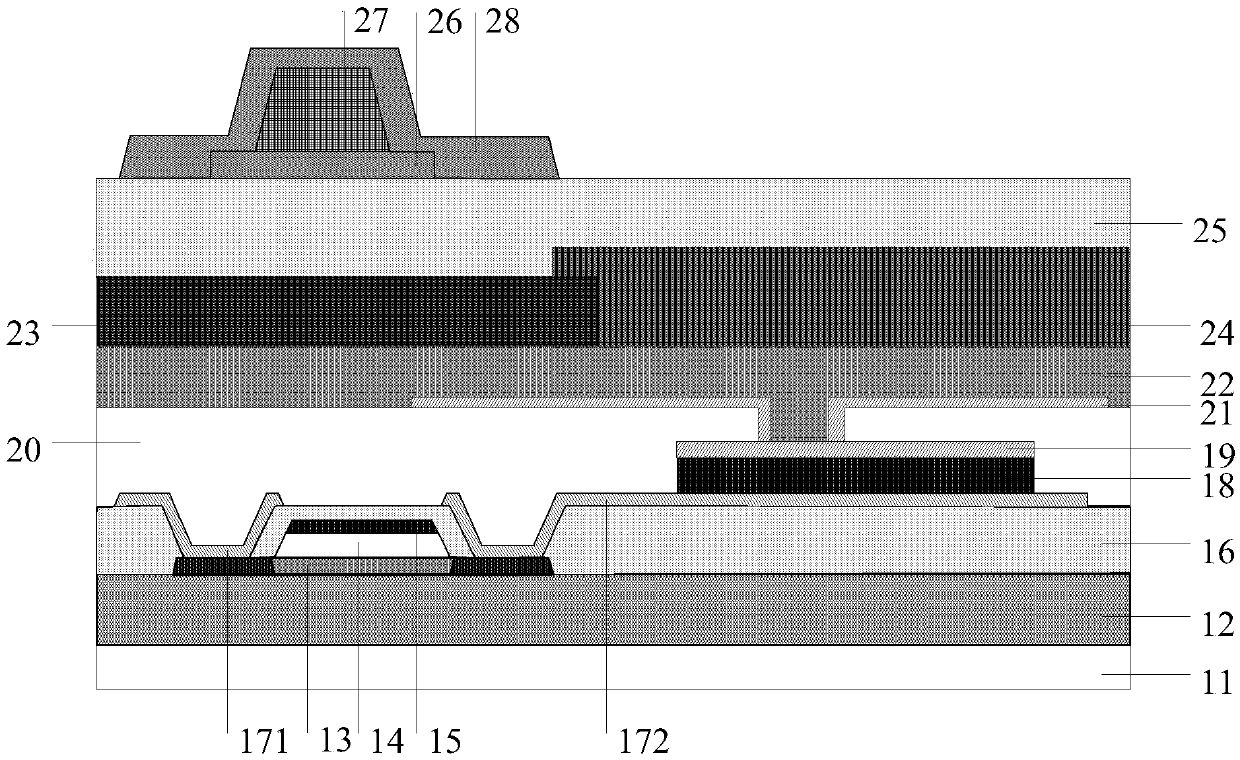

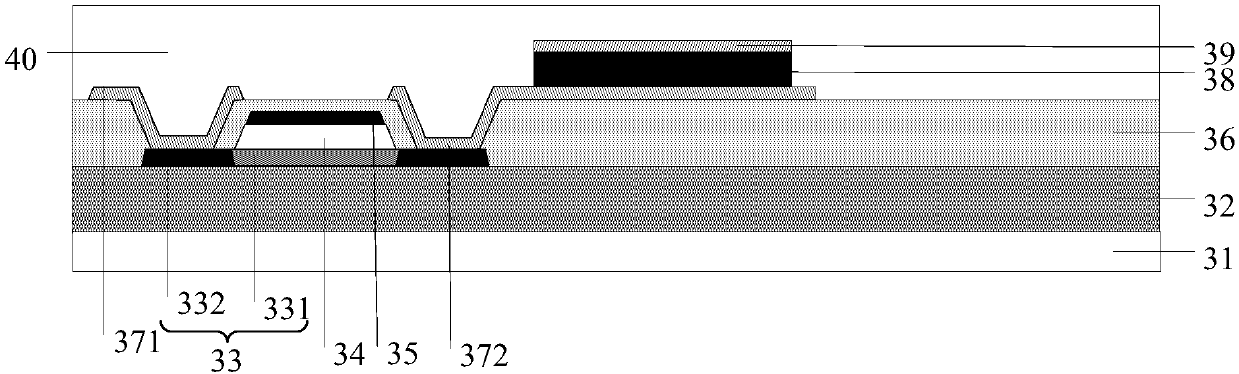

[0096] An embodiment of the present invention provides a cover plate, including a first substrate 31; a thin film transistor formed on the first substrate 31 in sequence, an optical sensor 38, and a first electrode 39 located on the optical sensor 38; a passivation layer 40 , the passivation layer 40 covers the thin film transistor and the first electrode 39; the black matrix 41 formed on the passivation layer 40; the electrode connection layer 42 formed on the black matrix 41, the electrode connection layer 42 includes an auxiliary cathode arranged on the same layer 421 and the first electrode connection line 422, and the first electrode connection line 422 is connected to the first electrode 39 through the first electrode connection hole M penetrating the passivation layer 40; the color filter layer 43, the flat layer 44, the support layer formed in sequence The pillar 45 and the second electrode 46 , the second electrode 46 is connected to the auxiliary cathode 421 through t...

Embodiment 3

[0103] An embodiment of the present invention provides a display panel, which includes the above-mentioned cover plate.

[0104] refer to Figure 10 , shows a schematic structural diagram of a display panel according to an embodiment of the present invention.

[0105] In the embodiment of the present invention, the display panel further includes a display substrate, the cover plate is fastened on the display substrate, and the display substrate includes: an anode 52, an organic light-emitting layer 53 and a cathode 54 stacked on the second substrate 51, and the cathode 54 In contact with the second electrode 46 .

[0106] Such as Figure 10 As shown, the contact position between the cathode 54 and the second electrode 46 is located at the position where the support column 45 is located.

[0107] Wherein, the material that cathode 54 adopts is a transparent conductive material, such as ITO or IZO etc.; The cathode 54 is contacted with the second electrode 43, and the second ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com