Patents

Literature

38results about How to "No increase in production costs" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

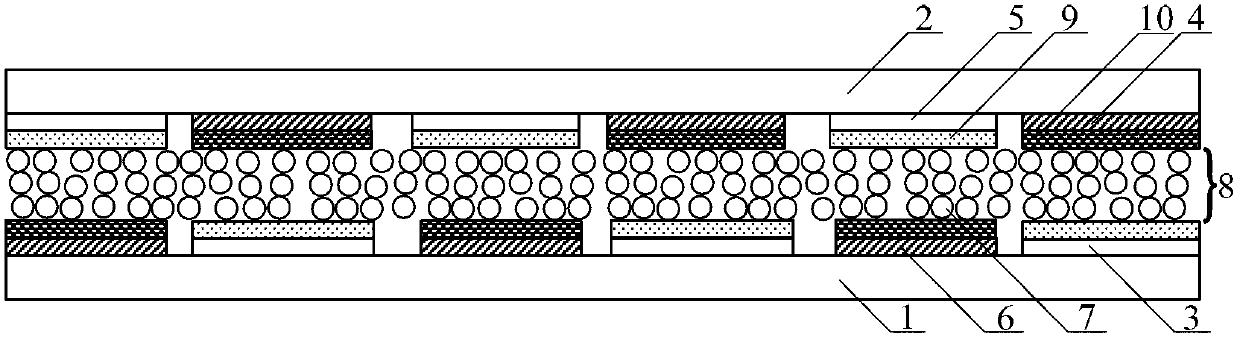

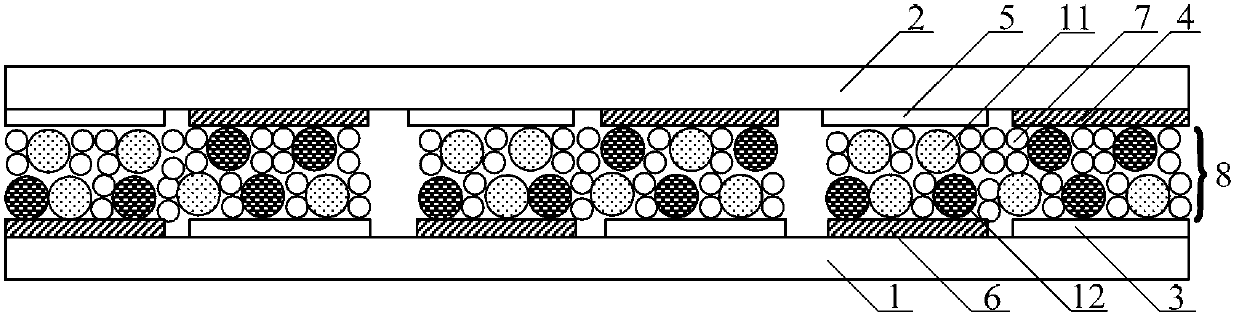

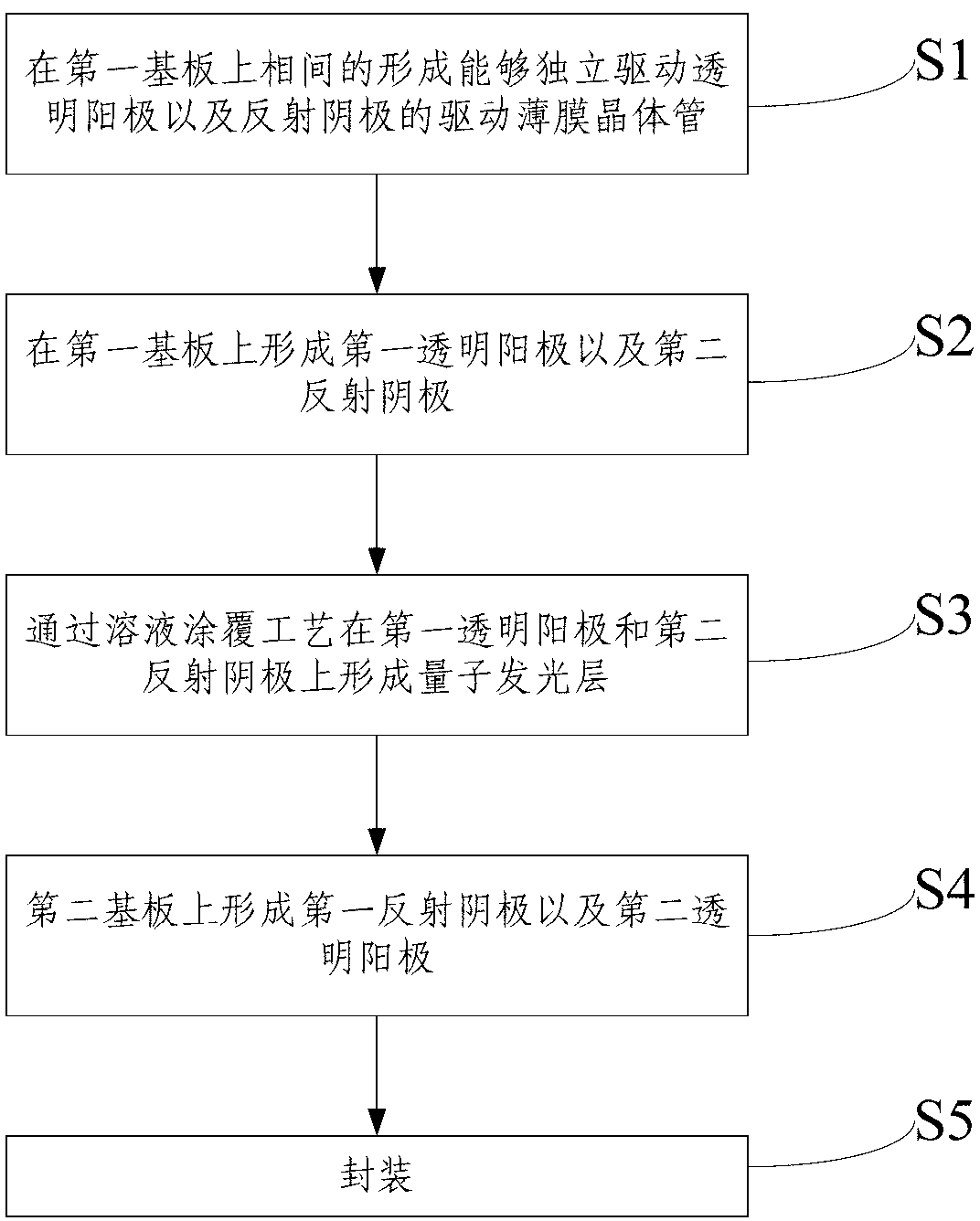

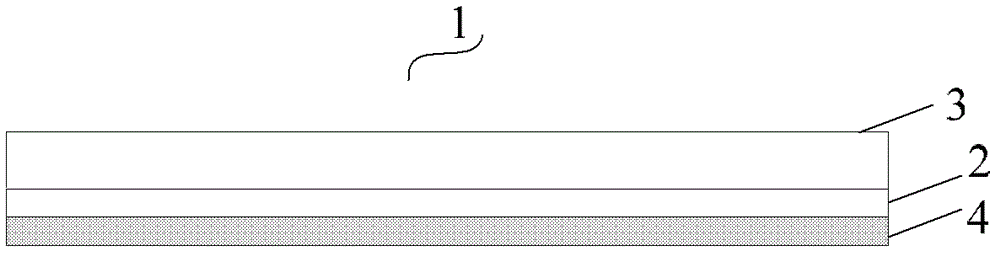

Double-face display device and preparation method thereof

ActiveCN103345884AImprove color gamutIncrease brightnessSolid-state devicesNanoopticsGamutDisplay device

The invention relates to the technical field of display, in particular to a double-face display device and preparation method of the double-face display device. According to the double-face display device, firstly, a quantum luminous layer containing quantum dot luminous materials is arranged between transparent electrodes and reflecting electrodes, and due to the fact that the quantum dot luminous materials are relatively narrow in full width at half maximum of emission peaks and high in luminous purity, the color gamut and the brightness of the double-face display device are improved, and the double-face display device has high display quality; secondly, through the fact that charge transfer particles are mixed in the quantum luminous layer, the structure of the double-face display device is simplified, steps of a preparation technology are reduced, and production cost is lowered; lastly, image display in two directions is achieved through one display panel, both the thickness and the weight are not increased compared with a traditional single-face display device, and therefore the double-face display device has the advantages of being more convenient to carry, light in weight, low in price and the like.

Owner:BOE TECH GRP CO LTD

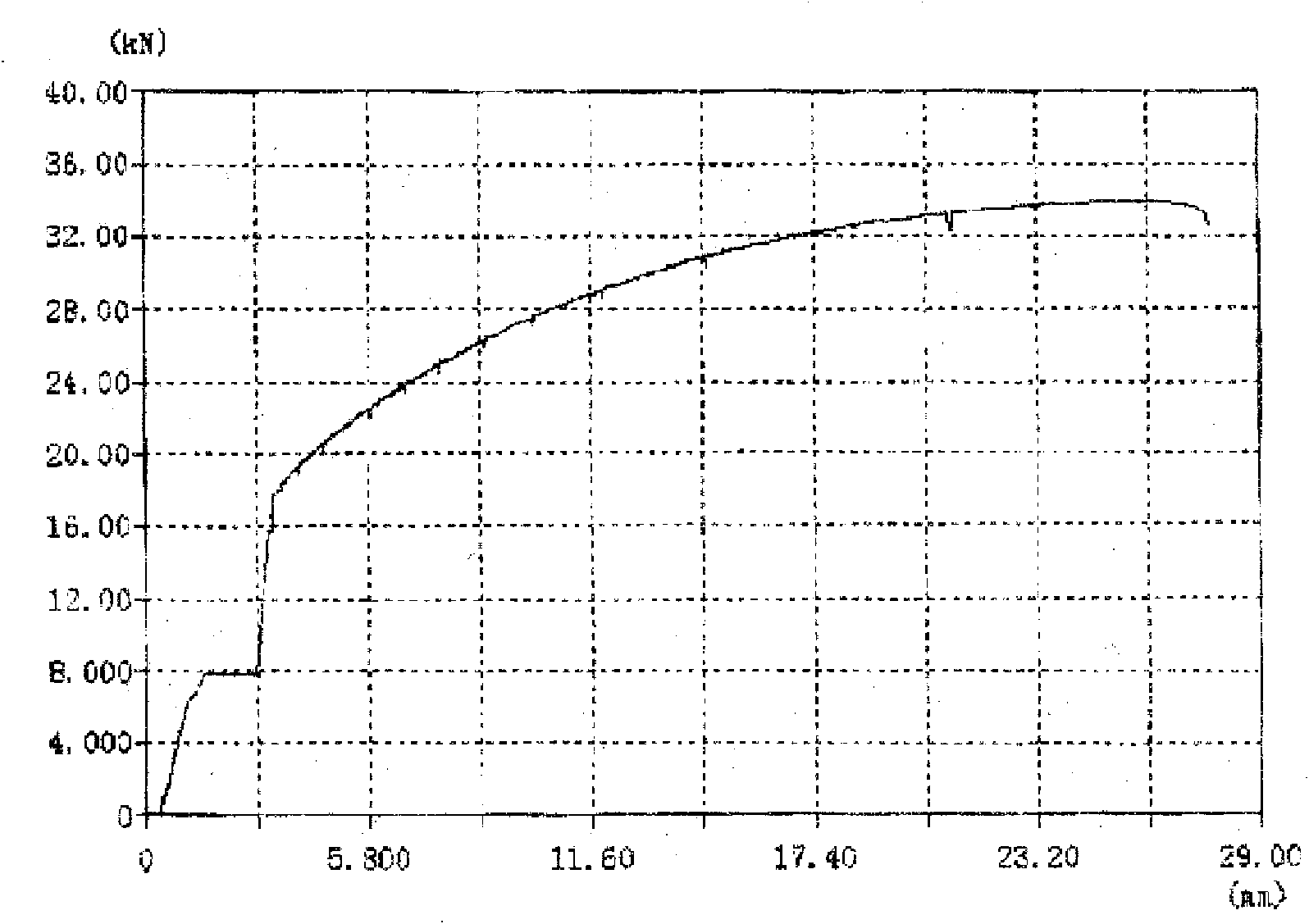

Lead-free copper alloy with limited Al and preparation method thereof

InactiveCN101638736ANo increase in production costsImprove toughnessChemical compositionTrace element

The invention discloses lead-free copper alloy with limited Al and a preparation method thereof. The lead-free copper alloy contains the following chemical components in percentage by weight: 60-65 percent of Cu, Sn being less than 0.0057 percent, Pb being less than 0.100-0.150 percent, 0.012 percent of Ni, 0.032 percent of Mn, 0.122-0.200 percent of Fe, 2-3 percent of Al, 0.018 percent of Si, 0.002 percent of P, S being less than 0.001 percent, 0.014 percent of Sb, 0.005 percent of As, 0.001 percent of Bi, Cr being less than 0.001, Cd being less than 0.0001 and the balance of Zn. The preparation method comprises the following steps: selecting industrial lead-free copper or a raw copper bar or copper scales with copper content being more than 62 percent as master alloy; preheating a masteralloy ingot to 1,100 DEG C until to be molten; adding required trace elements and slightly stirring and heating the trace elements and the molten alloy ingot to 1,200 DEG C; standing still an obtained mixture for half an hour and then dropping the temperature of the mixture to 1,000 DEG C; and carrying out pressure casting. Cutting, stretching and yield coefficients of an obtained pressure casting piece can all be effectively improved; and the pressure casting piece can meet the requirements of casting and machining.

Owner:卓美香

Zinc smelting technology for low-zinc high-iron roasting ore by wet method

InactiveCN104233373ASolving Quantitative SeparationsOptimizing Process ParametersPhotography auxillary processesProcess efficiency improvementZinc smeltingImpurity

The invention relates to a zinc smelting technology for a low-zinc high-iron roasting ore by a wet method. The technology comprises a leaching process, a purifying process and an electrolyzing process. The technology employs a smelting method that a wet method can solve the problem of lean impurity high-iron raw material, iron removal efficiency is high, and various production consumption and production cost are not increased. The quality of 58% qualified high-purity zinc is greater than or equal to 99.995%, and quality of 42% qualified high purity zinc is greater than or equal to 99.99%.

Owner:无锡市森信精密机械厂

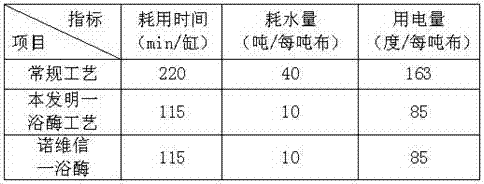

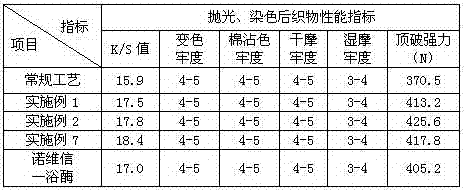

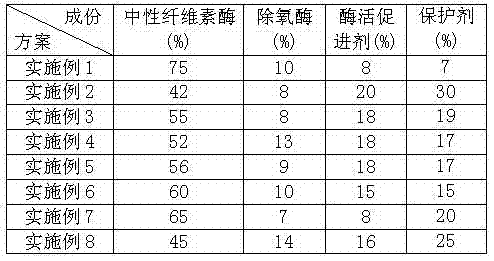

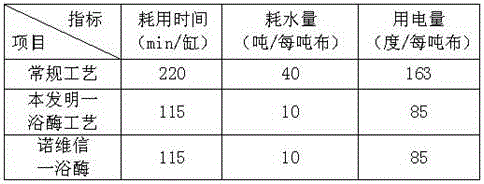

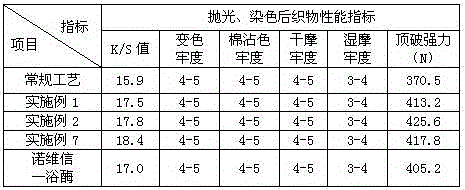

Enzyme additive for cotton knitted fabric and preparation method and application thereof

The invention discloses an enzyme additive for a cotton knitted fabric and a preparation method and an application thereof, and belongs to the technical field of pretreatment processes and formulas in the cotton knitted fabric dyeing and finishing industry. The enzyme additive for a cotton knitted fabric is characterized by comprising the following components by weight percentage: 40-75 of neutral cellulose, 6-15 of deoxyenzyme, 7-30 of protective agent and 8-20 of enzyme activity promoter. The enzyme additive for a cotton knitted fabric is applied to the deoxidizing, polishing dyeing one-bath process of cotton knitted fabrics; and with the method, enzyme activity is kept stable, the technological steps are shortened, the energy consumption is reduced, and the waste water discharge is reduced.

Owner:CHINA TEXTILE ACAD JIANGNAN BRANCH

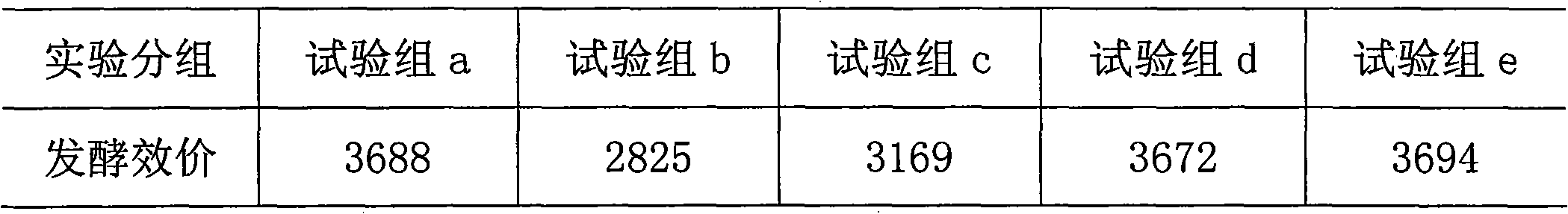

Recycling method of abamectin fermented waste water

ActiveCN101665817AImprove utilizationReduce pollutionMicroorganism based processesMultistage water/sewage treatmentWater sourceCulture fluid

The invention discloses a recycling method of abamectin fermented waste water, belonging to the technical field of the processing method of antibiotic fermented waste water. The method comprises the following steps: the fermented waste water generated in abamectin production is reused for fermenting to produce the abamectin after being processed by acid, alkali and saccharomycetes. In the recycling method of abamectin fermented waste water of the invention, the abamectin fermented waste water is processed by acid and alkali, and is processed by the saccharomycetes, and the obtained culture solution containing the saccharomycetes can be reused for fermenting to produce abamectin. Experiments prove that the fermented waste water can be used repeatedly after being processed by acid, alkali and saccharomycetes, and does not affect the fermentation valence. The application of the method can significantly improve utilization of water source, reduce environmental pollution, and does not add production cost compared with the routine waste water process method.

Owner:内蒙古拜克生物有限公司

Arsenic-free glass bottle

The invention discloses an arsenic-free glass bottle, which solves the problems that the conventional food packing glass is not favorable for human health and environmental protection and cannot reach state specified standards due to higher arsenic and antimony dissolution amount. The arsenic-free glass bottle is prepared from raw materials comprising the following components in part by weight: 51 to 63 parts of quartz sand, 3 to 9 parts of lithium (or sodium or potassium) feldspar, 12 to 19 parts of calcite, 0 to 20 parts of dolomite, 1 to 3 parts of calcium sulfate, 0 to 2.2 parts of fluorite, 0 to 3 parts of sodium fluosilicate, 15 to 21 parts of soda ash, 0.1 to 0.5 part of sodium sulfate, 0.3 to 1 part of calcium sulfate and 0.1 to 0.5 part of cerium oxide. The components are mixed uniformly, melted, molded and annealed to form the arsenic-free glass bottle according to the conventional glass bottle manufacturing method. The arsenic of the arsenic-free glass bottle is far below the state specified dissolution permissible amount, so the arsenic-free glass bottle has no toxic or side effect on the human body and does not produce environmental pollution; and at the same melting temperature, the clarifying time is shortened to half time of using arsenic and antimony oxides, and the production capacity is improved by 10 percent.

Owner:忻州鑫洋玻璃制品有限公司

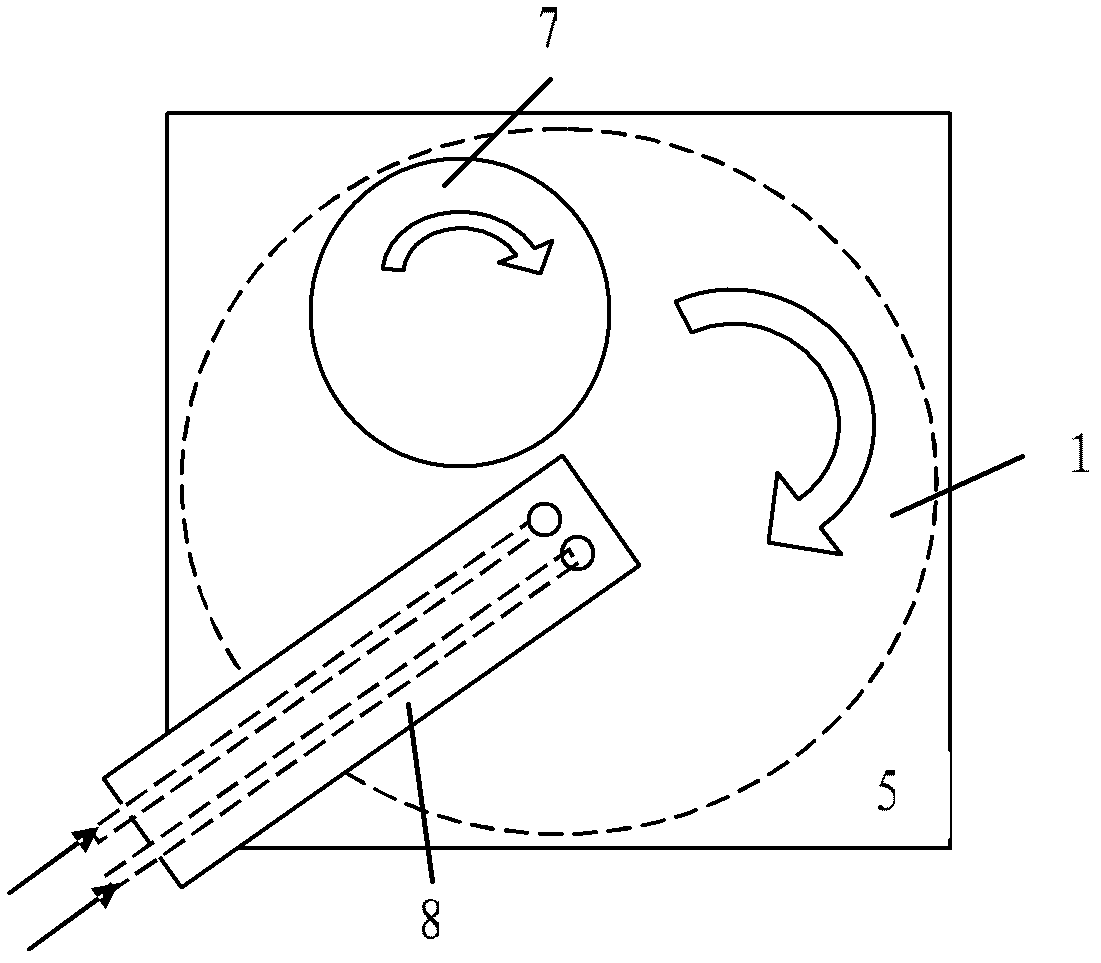

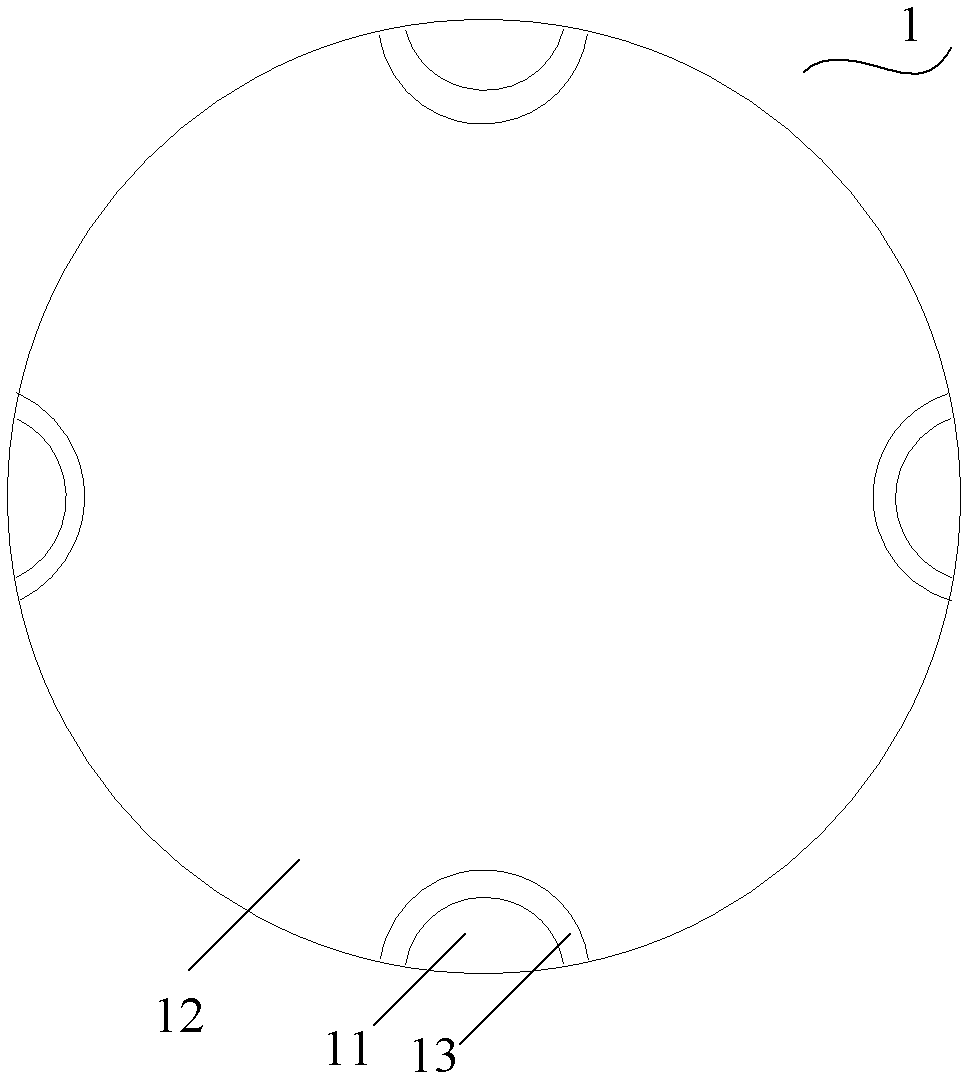

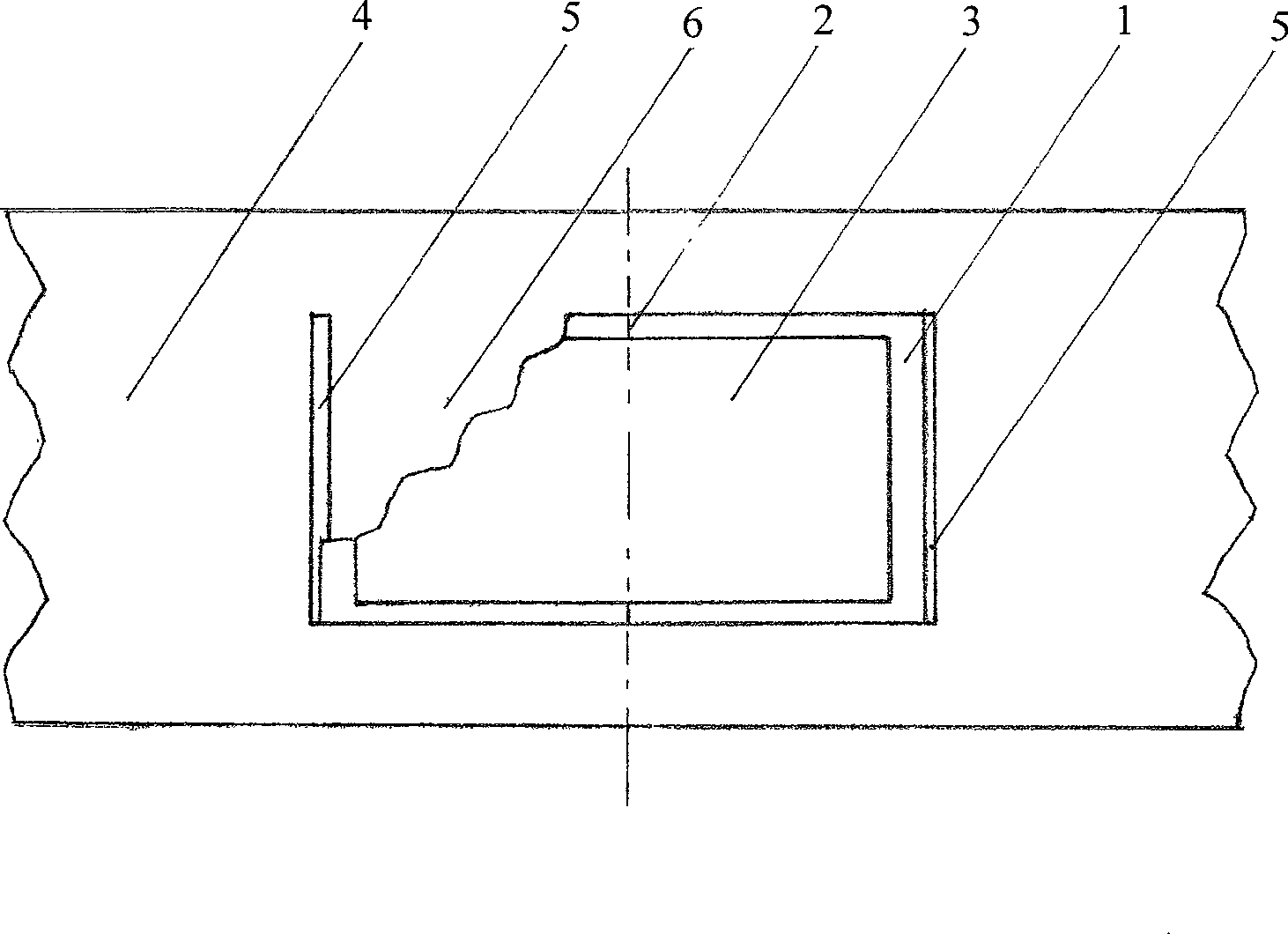

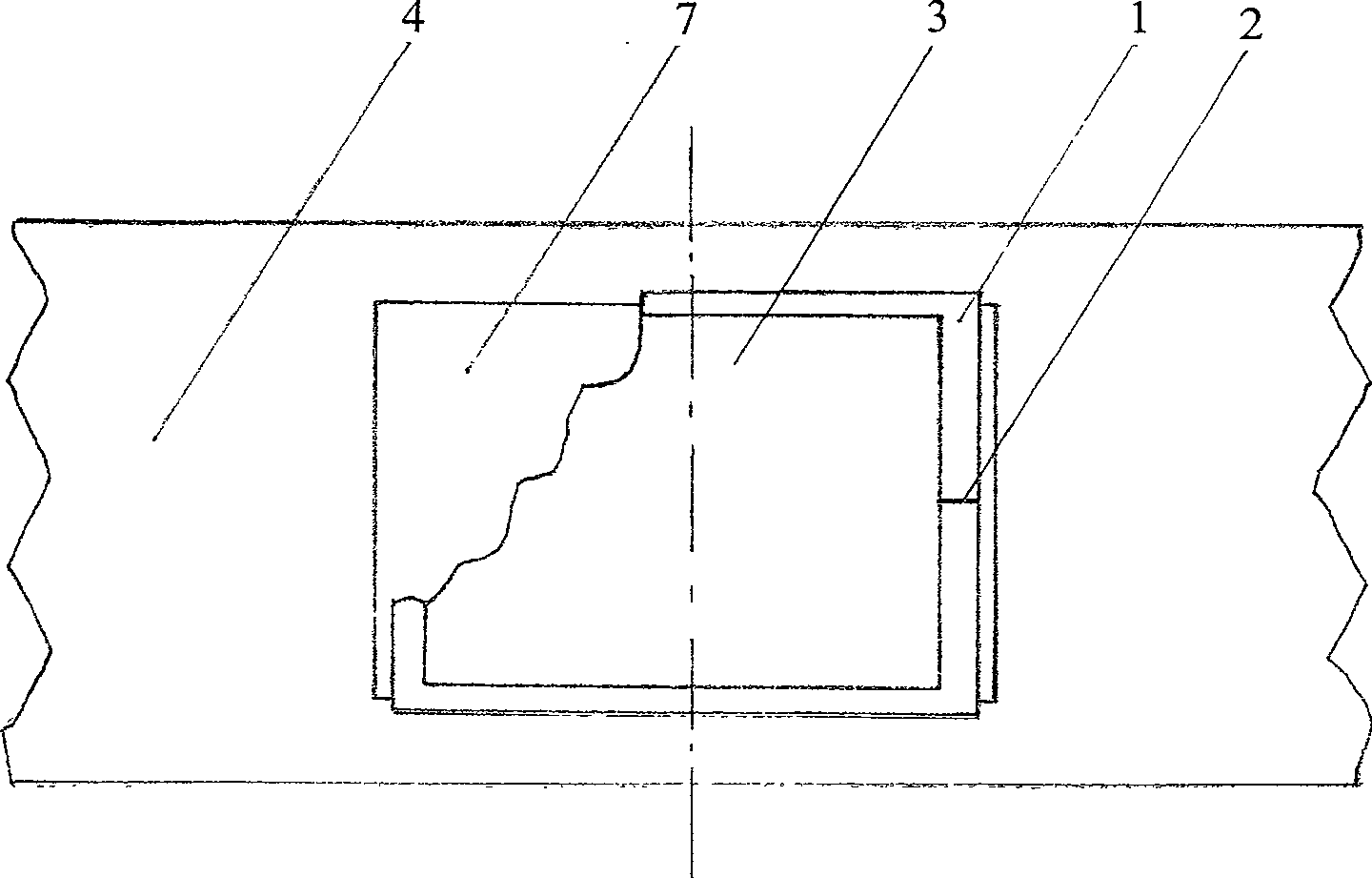

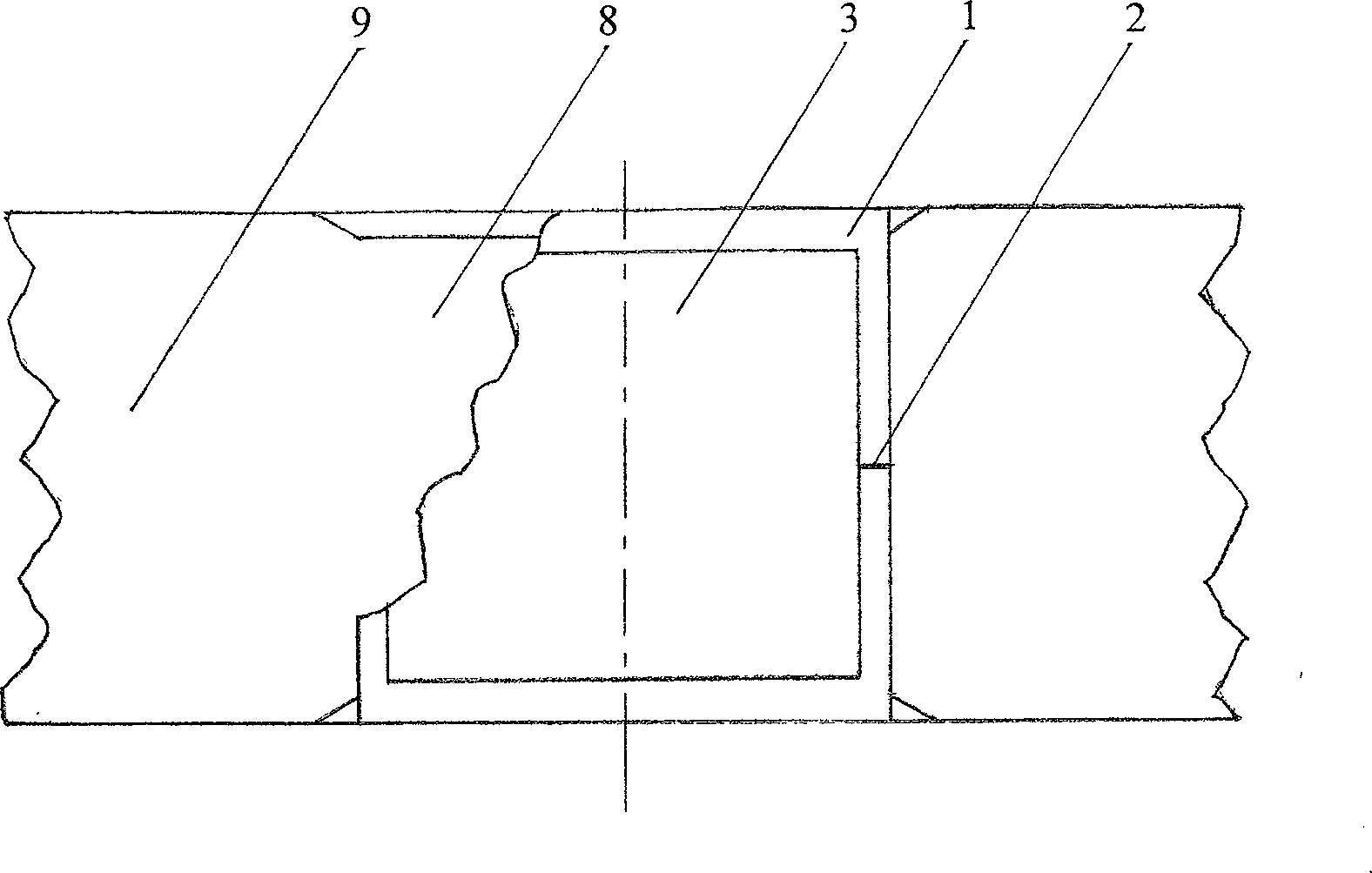

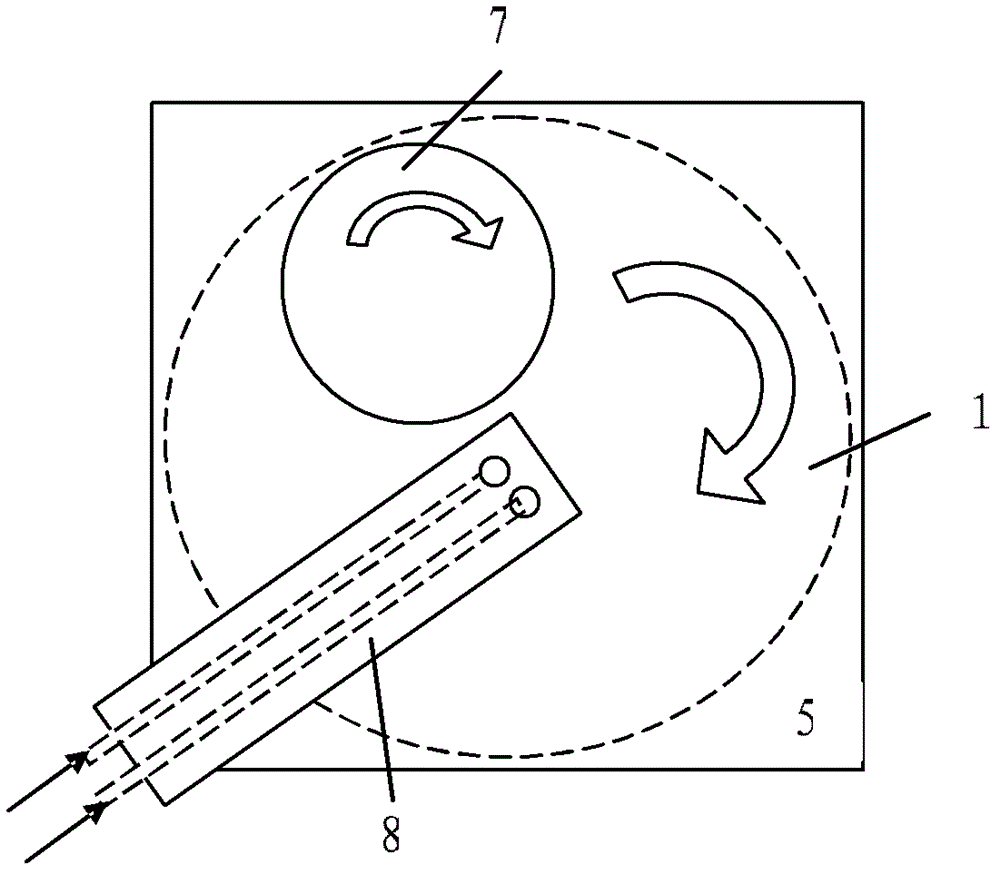

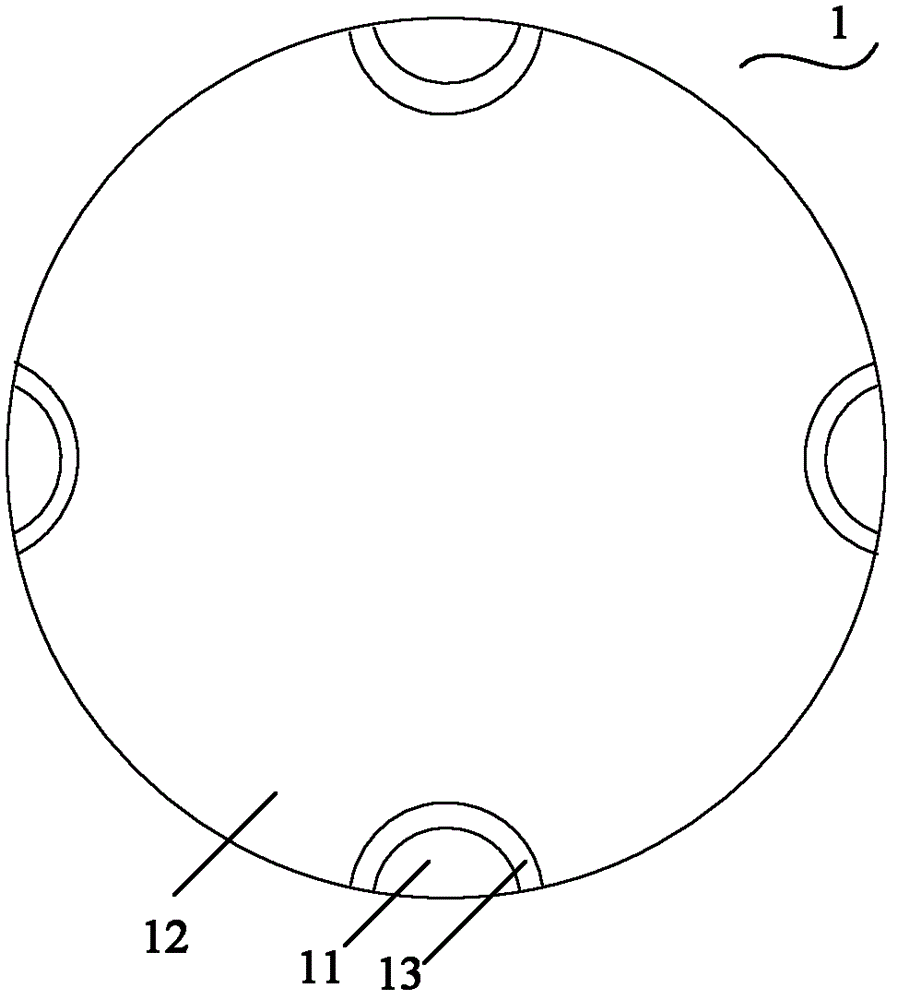

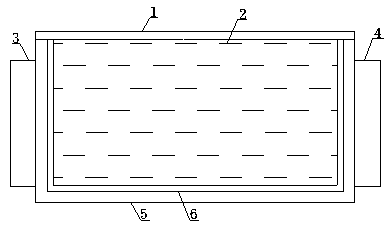

Grinding cushion, and grinding device and grinding method using grinding cushion

The invention discloses a grinding cushion, and a grinding device and a grinding method using the grinding cushion. The grinding cushion comprises first grinding areas and a second grinding area, wherein the first grinding areas are formed on the edge of the grinding cushion, and are used for grinding the edge of a wafer; the second grinding area can be used for at least accommodating an entire wafer surface, and is used for grinding the entire wafer; and grooves are formed between the first grinding areas and the second grinding area of the grinding cushion. The grinding device provided with the grinding cushion comprises a grinding table, a grinding head and a first conveying device, wherein the wafer is placed on the grinding cushion, and the edge of the wafer is contacted with the first grinding areas; the grinding table is kept static; the grinding head is rotated for grinding the edge of the wafer; and a liquid ejected by the first conveying device is only retained in the first grinding areas. Due to the adoption of the grinding cushion, the grinding device and the grinding method, the entire wafer surface can be ground, the edge of the wafer can be ground separately, the uniformity of the ground central area and the edge area of the wafer is improved, and the production yield of a semiconductor device is increased greatly.

Owner:SEMICON MFG INT (SHANGHAI) CORP

Arsenic-free glass bottle

The invention discloses an arsenic-free glass bottle, which solves the problems that the conventional food packing glass is not favorable for human health and environmental protection and cannot meet the national specified standards due to higher arsenic and antimony dissolution. The arsenic-free glass bottle is prepared from raw materials in part by weight: 100 parts of quartz sand, 6 to 18 parts of lithium (or sodium or potassium) feldspar, 24 to 38 parts of calcite, 0 to 40 parts of dolomite, 2 to 6 parts of sodium nitrate, 0 to 4.4 parts of fluorite, 0 to 6 parts of sodium fluosilicate, 30 to 40 parts of soda ash, 0.2 to 0.4 part of sodium sulfate, 0.6 to 1.0 part of calcium sulfate and 0.2 to 0.4 part of cerium oxide. The components are mixed uniformly, melted, shaped and annealed to form the arsenic-free glass bottle according to a conventional glass bottle manufacturing method. The arsenic content of the glass bottle is far lower than the national specified dissolution admitted amount, has no toxic or side effect on the human body, and does not produce environmental pollution; and at the same melting temperature, the settling time is shortened to half of time used by using arsenic and antimony oxides, and the production capacity is improved by about 10 percent.

Owner:忻州鑫洋玻璃制品有限公司

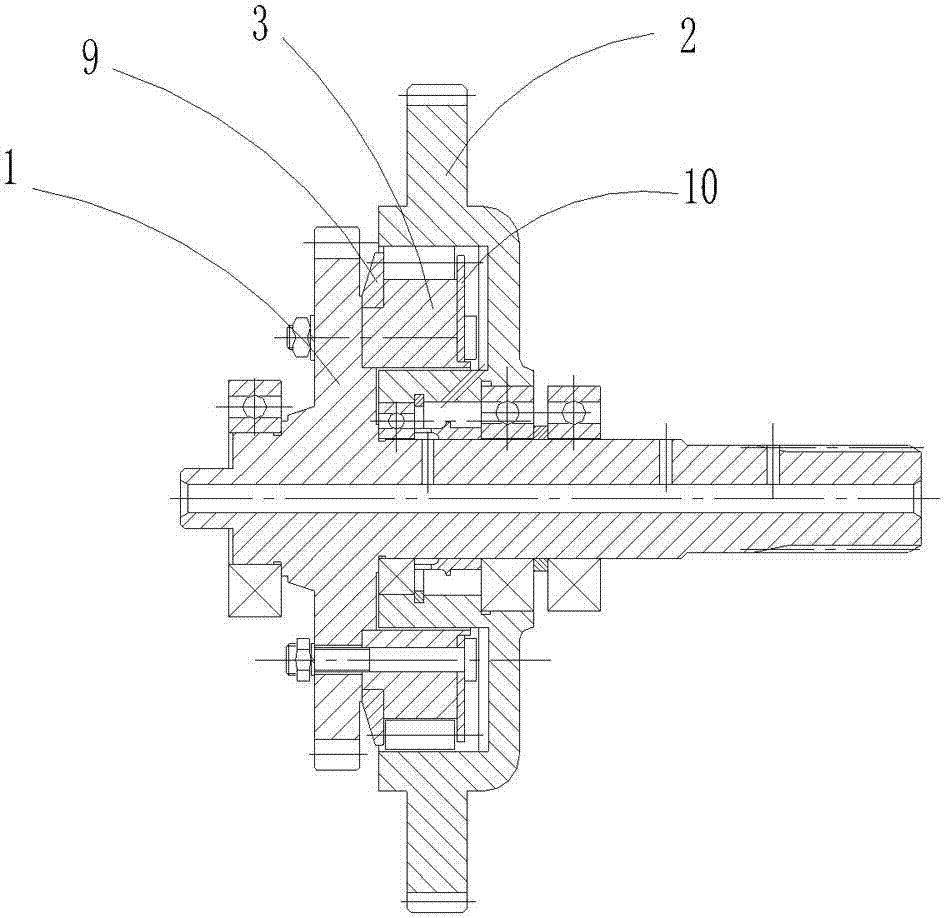

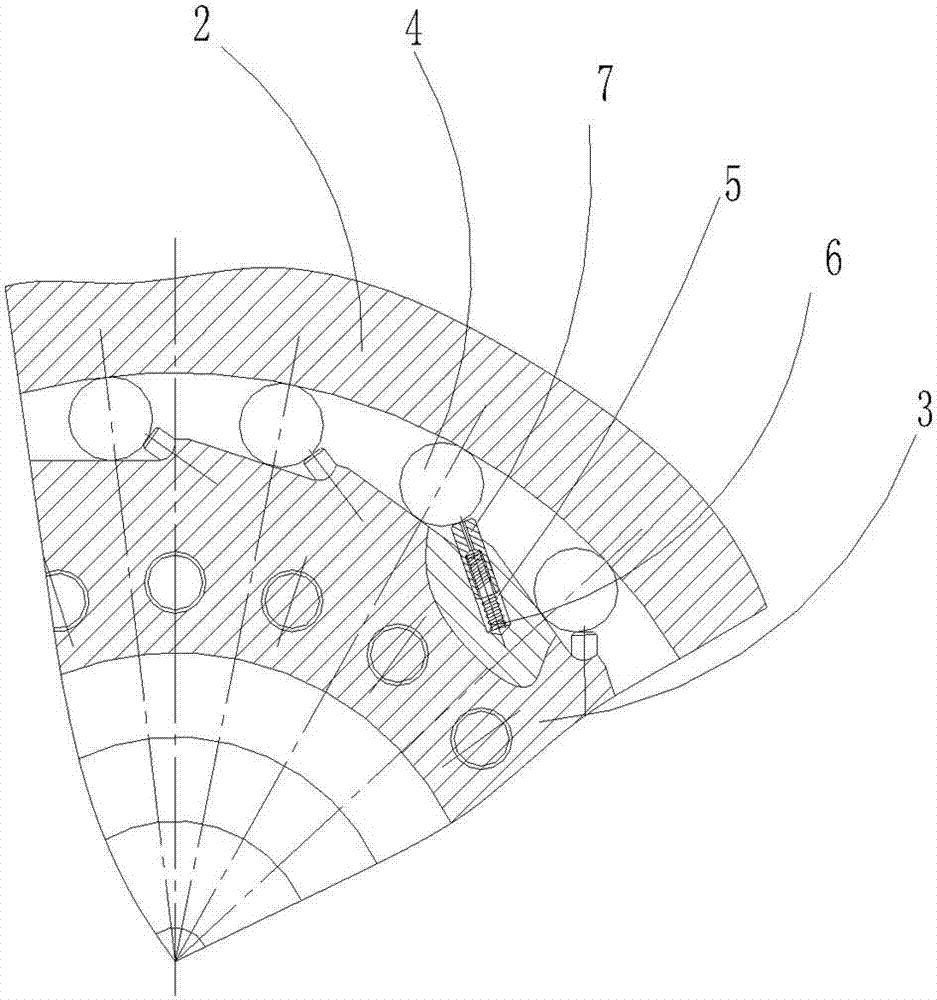

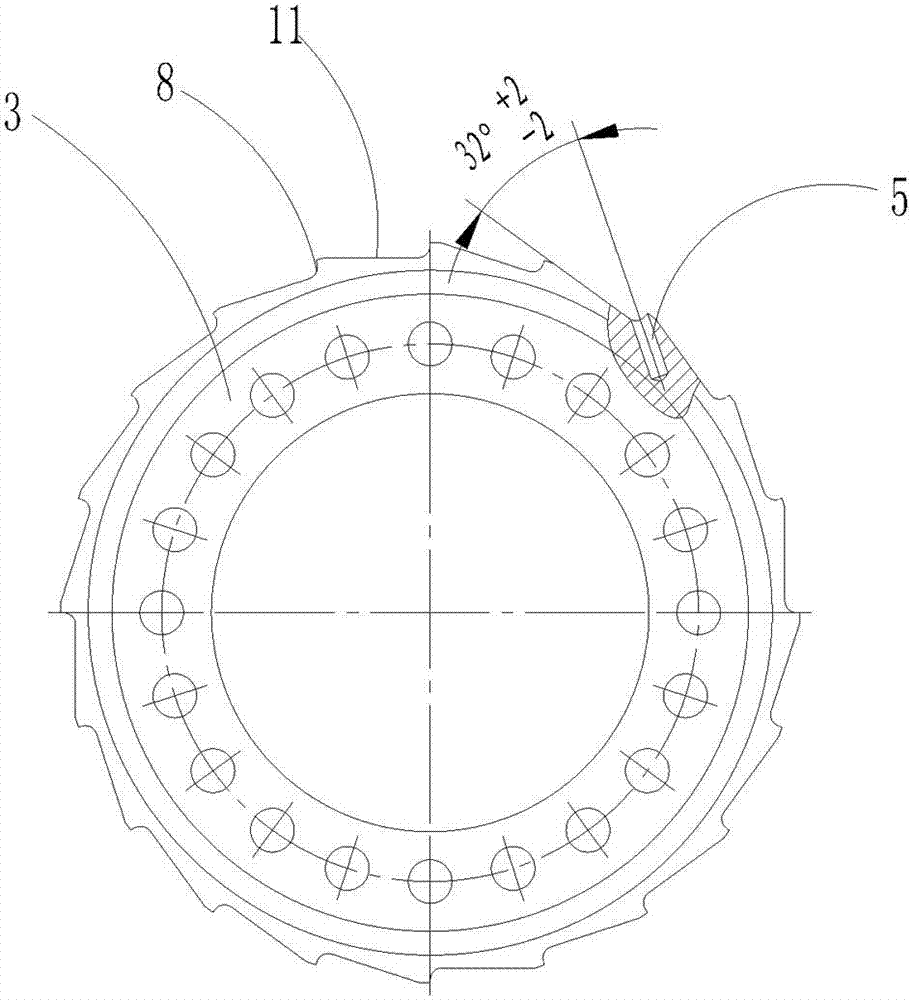

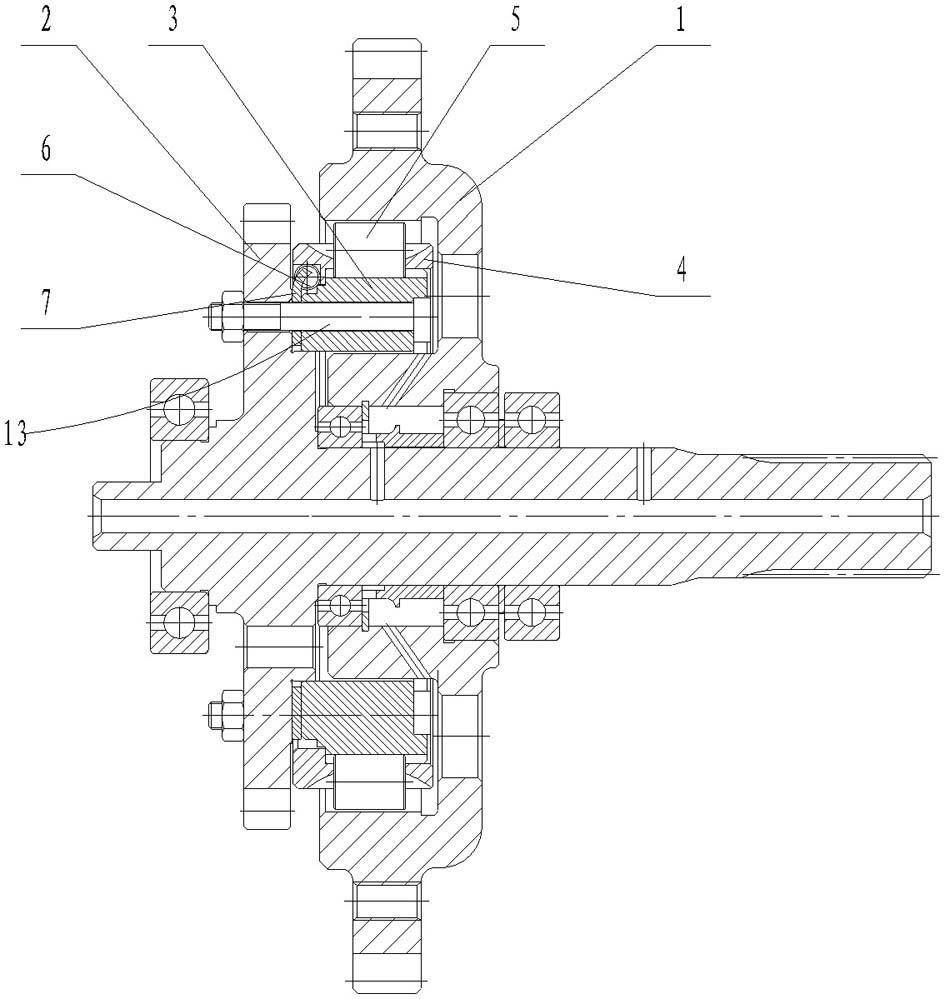

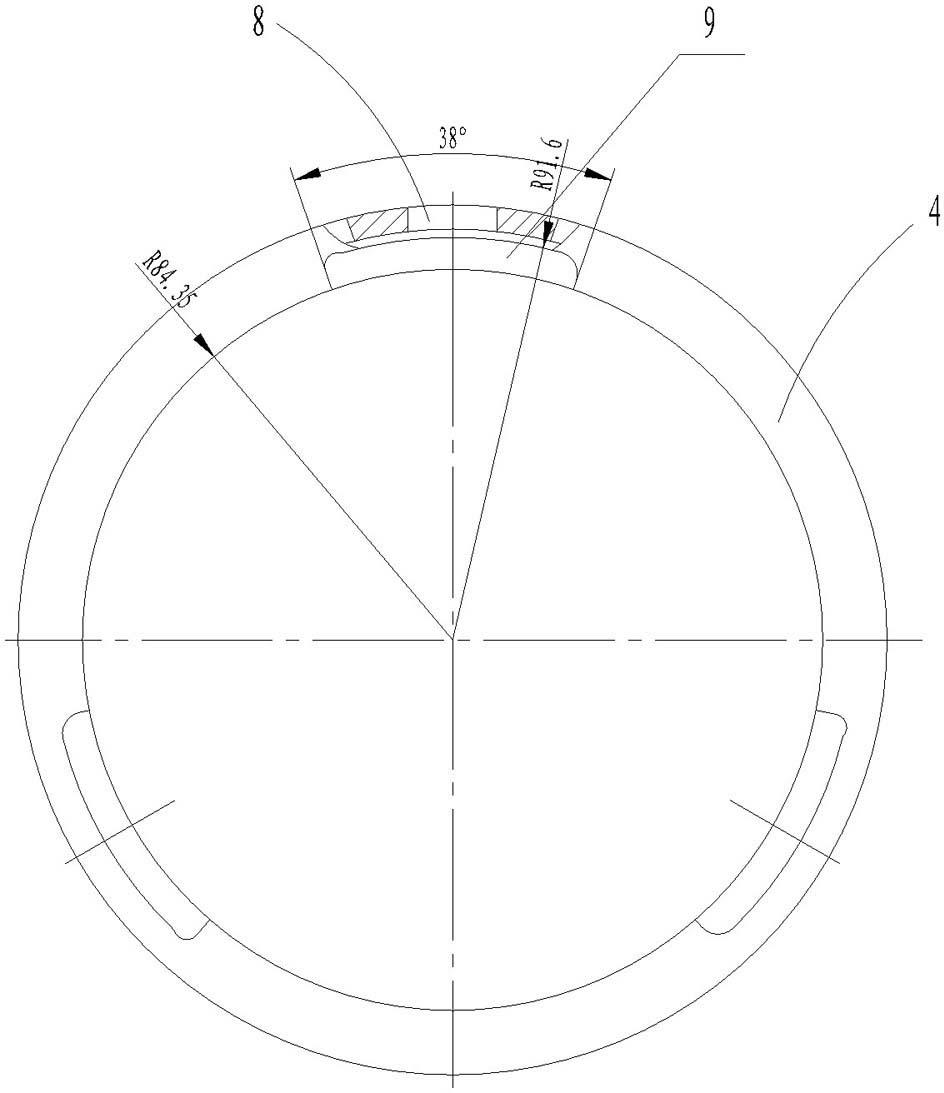

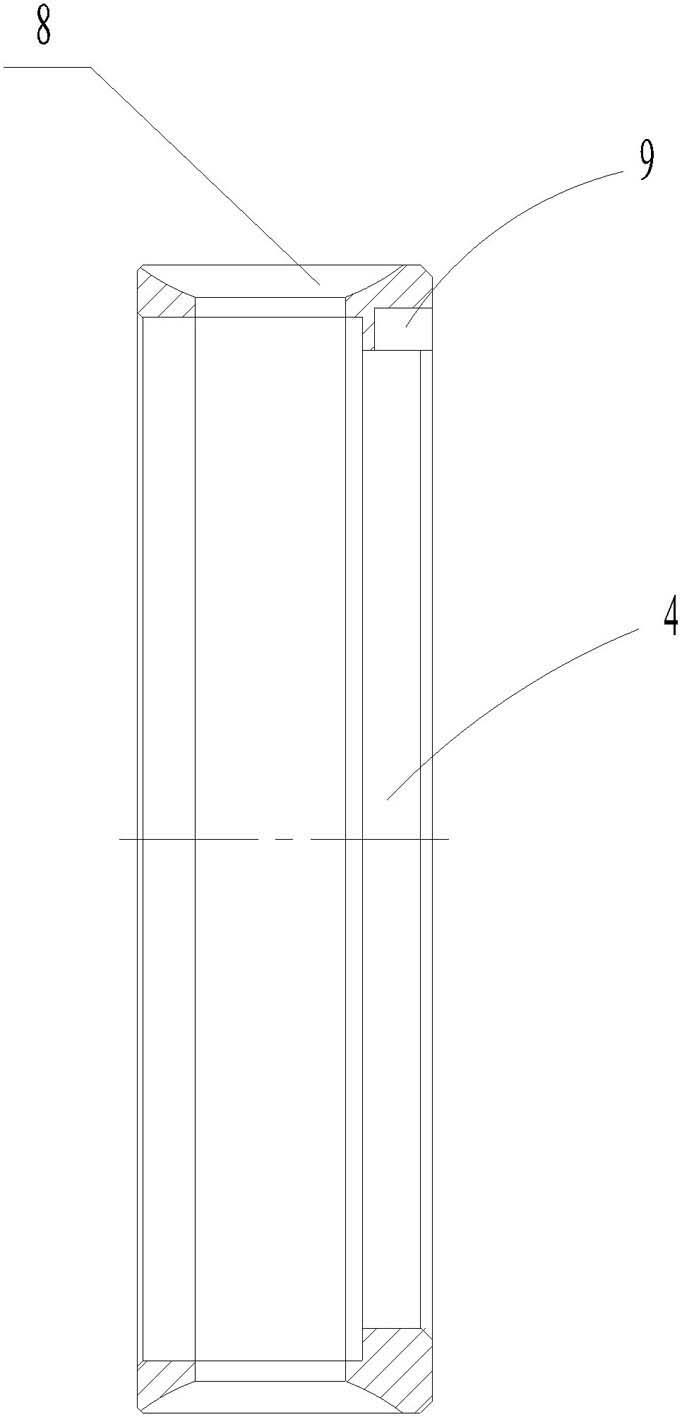

Spring resetting type overrunning clutch for energy-conservation type loader

The invention relates to the technical field of engineering machinery transmission, in particular to a spring resetting type overrunning clutch for an energy-conservation type loader with low rotating speed. An inclined angle between a spring resetting hole and an inner ring cam ranges from 30 degrees to 34 degrees; the diameter of the spring resetting hole ranges from 4.49mm to 4.538mm, and the depth of the spring resetting hole ranges from 15mm to 15.1mm; and the cross section of a roller path wall is circular arc-shaped. The spring resetting type overrunning clutch has a simple structure, a low reduction ratio, large transmission torque, good overloading performance and long service life, is stable in working and safe and reliable, and is beneficial to realizing energy conservation and emission reduction of the domestic loader and improving the performances of the whole loader.

Owner:HANGZHOU ZONGXING GEAR

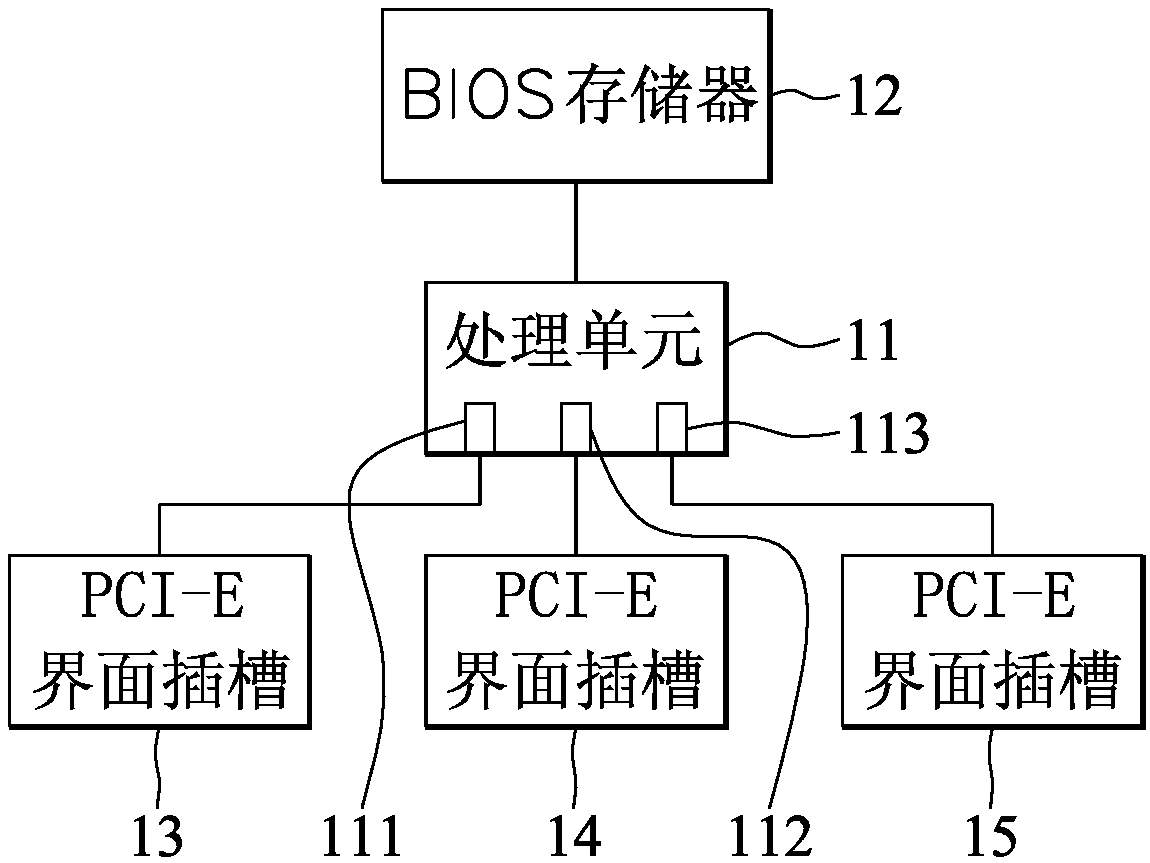

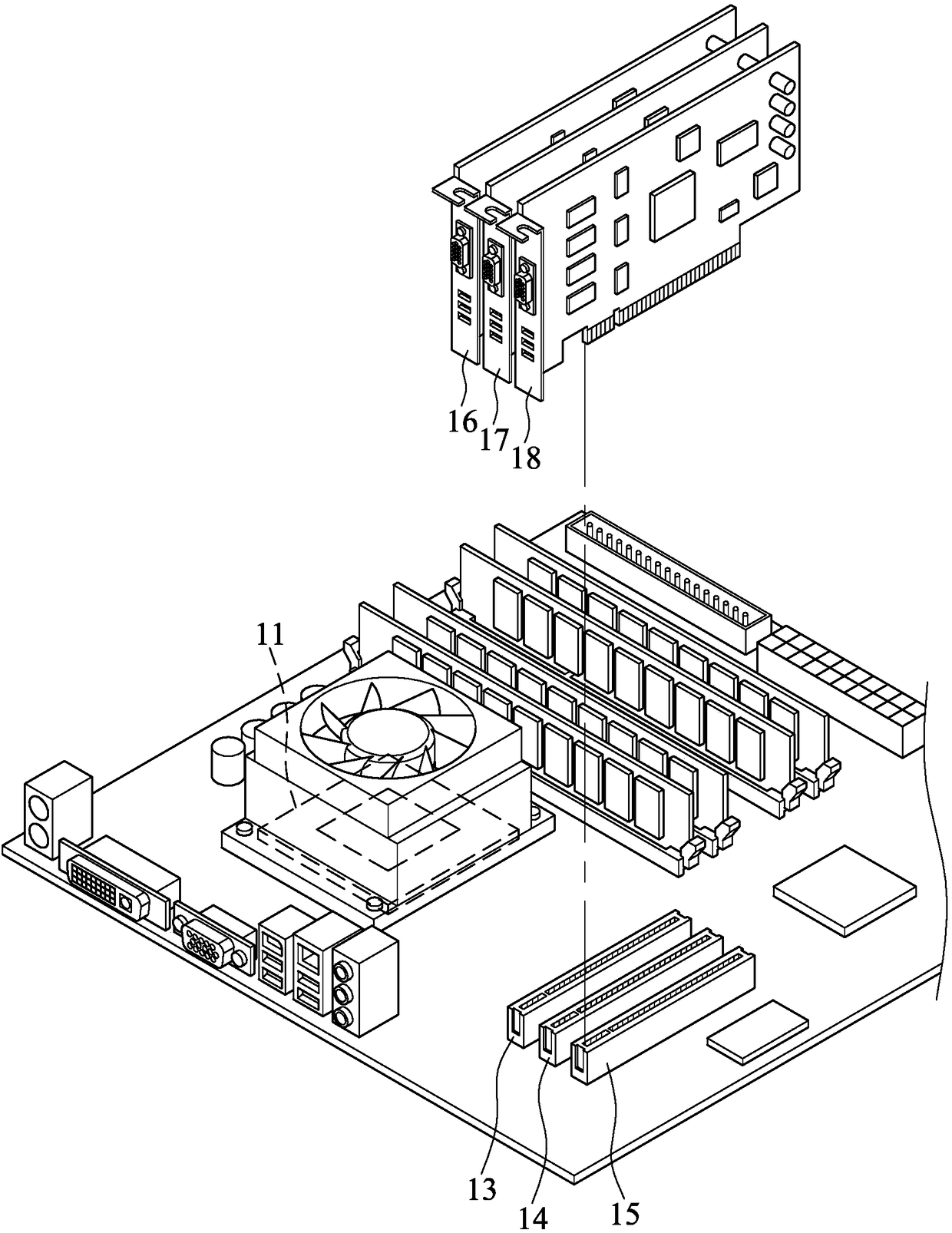

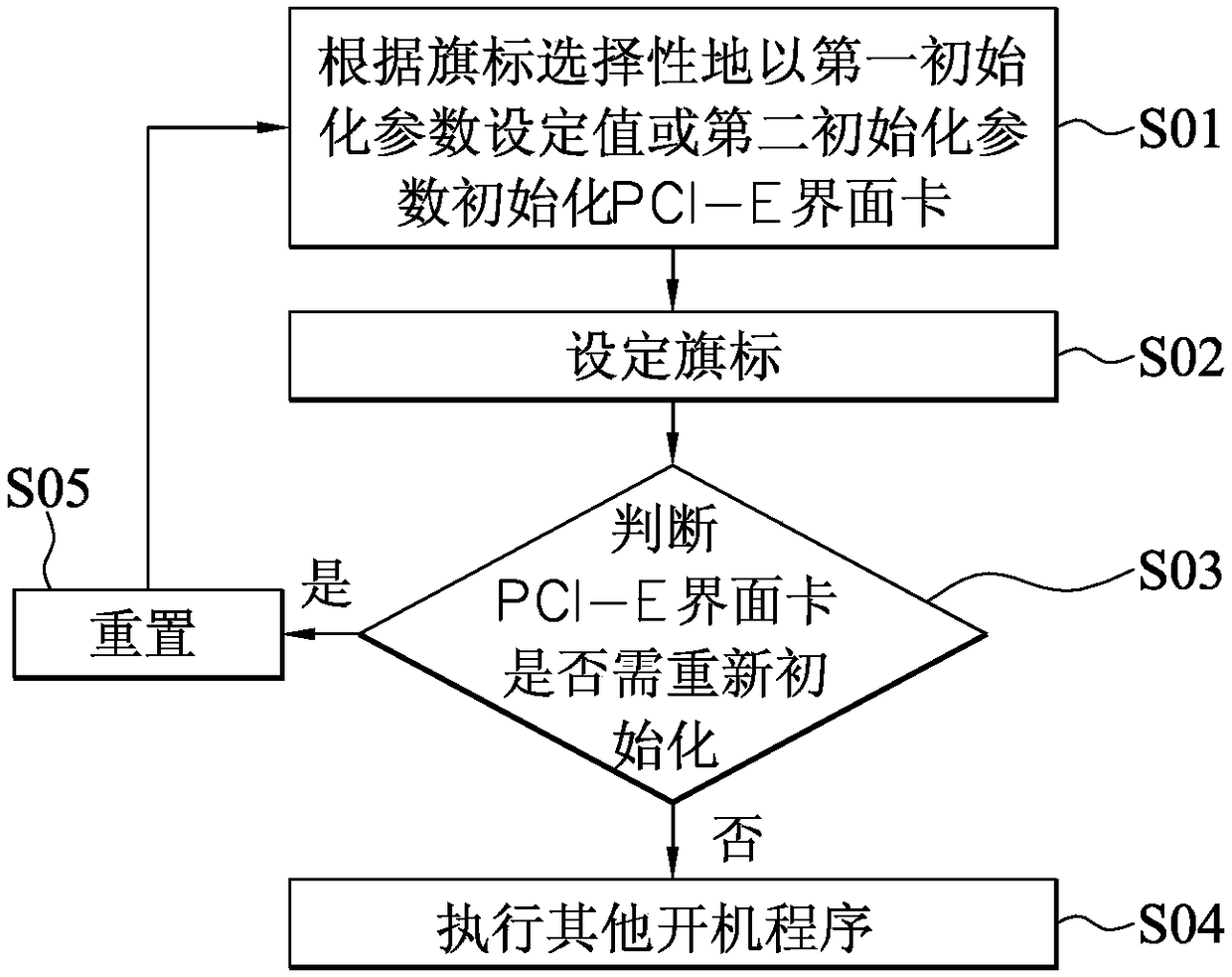

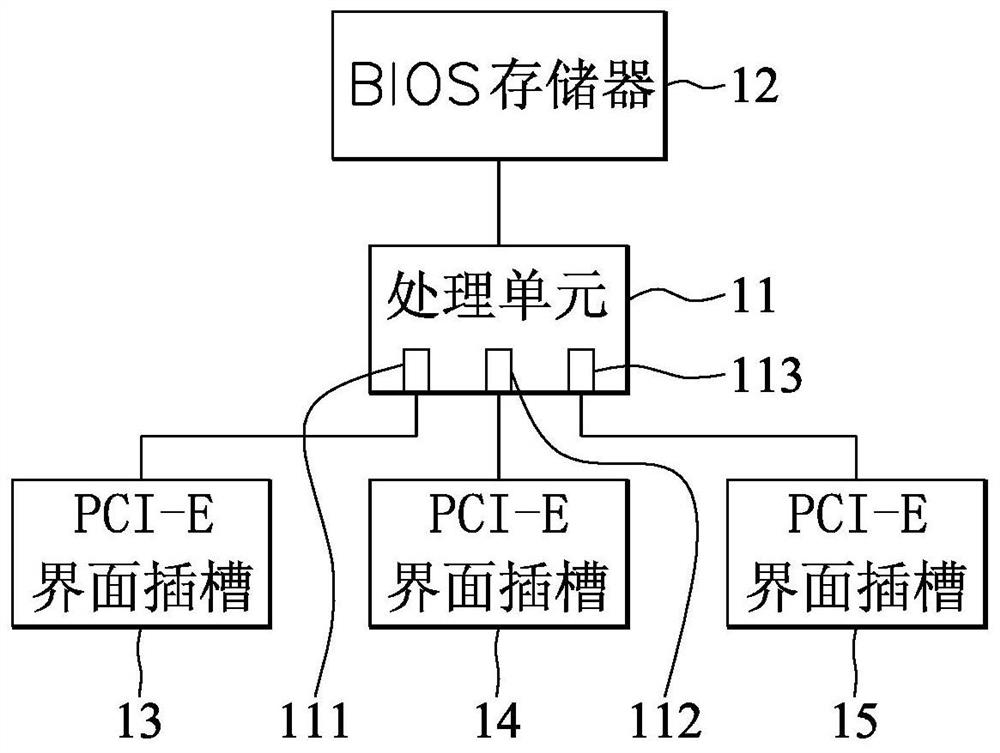

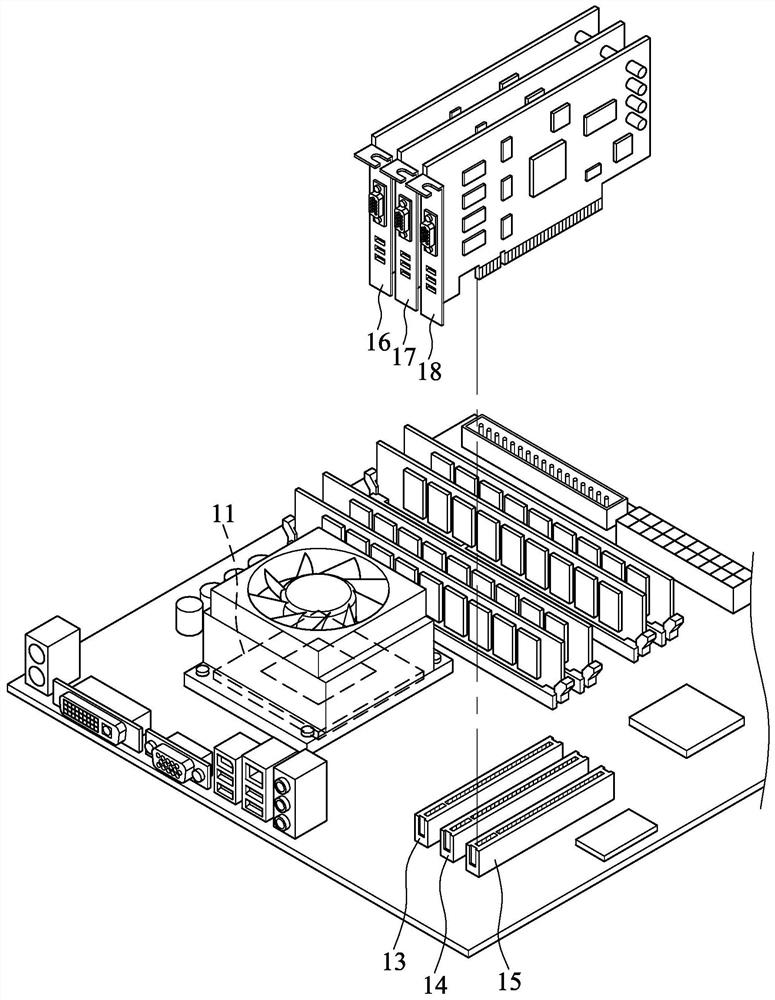

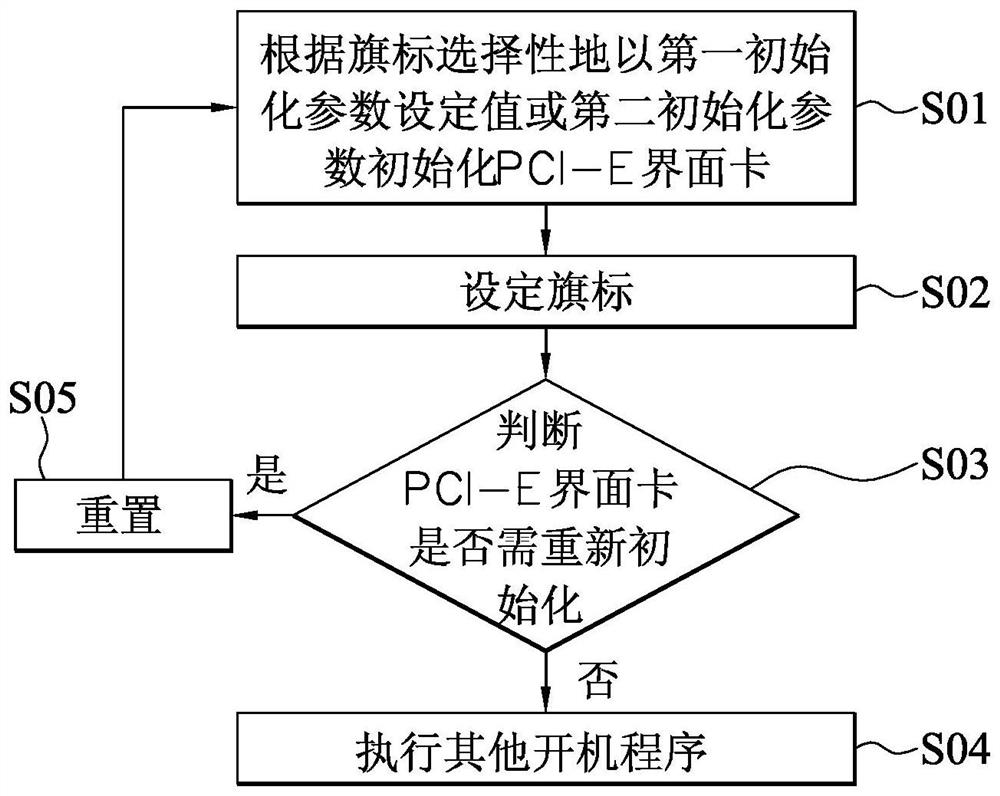

Initialization method for fast peripheral component interconnect express interface card

ActiveCN109002402ANo increase in production costsSmall attenuationElectric digital data processingRAID processing unitInput/output

The invention provides an initialization method for a fast peripheral component interconnect express interface card. The method includes the following steps: a processing unit uses a first initialization parameter contained by a basic input output system code to initialize a fast peripheral component interconnect express interface card inserted in a fast peripheral component interconnect express interface slot according to the first value preset by a flag by a startup program; the processing unit sets the flag to make the flag have the first value or a second value according to the initializedfast peripheral component interconnect express interface card by the startup program; the processing unit judges whether the initialized fast peripheral component interconnect express interface cardneeds to be reinitialized by the startup program; and when the fast peripheral component interconnect express interface card needs to be reinitialized, the processing unit uses a second initializationparameter contained by the basic input output system code to reinitialize the fast peripheral component interconnect express interface card according to the second value of the set flag.

Owner:MITAC COMP (SHUN DE) LTD +1

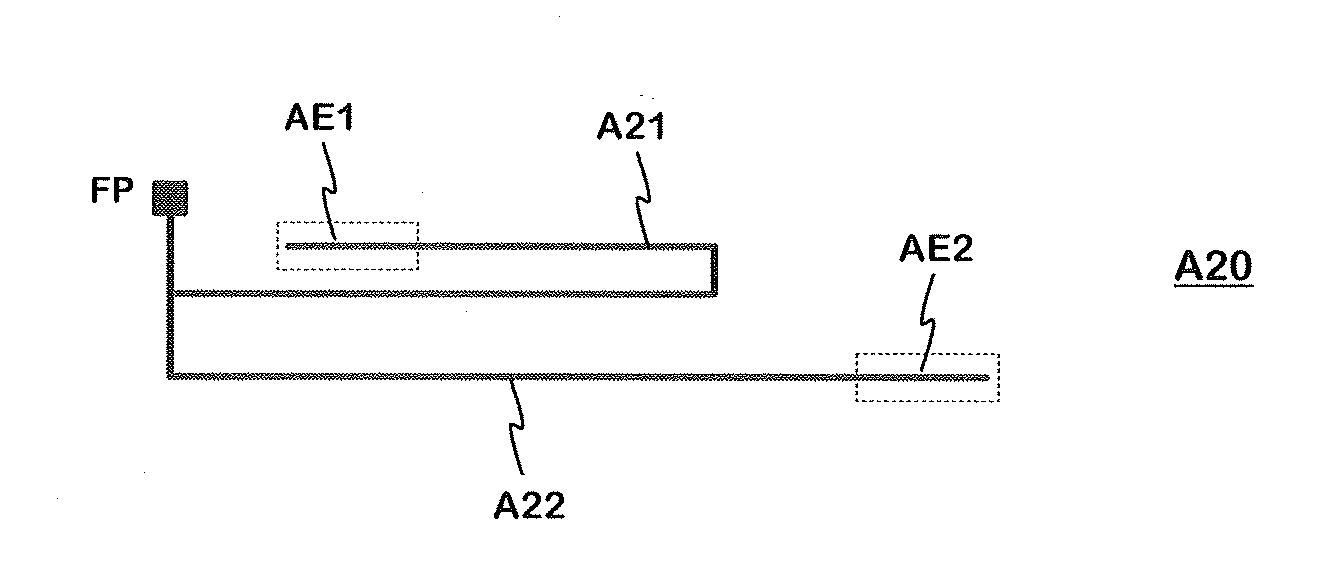

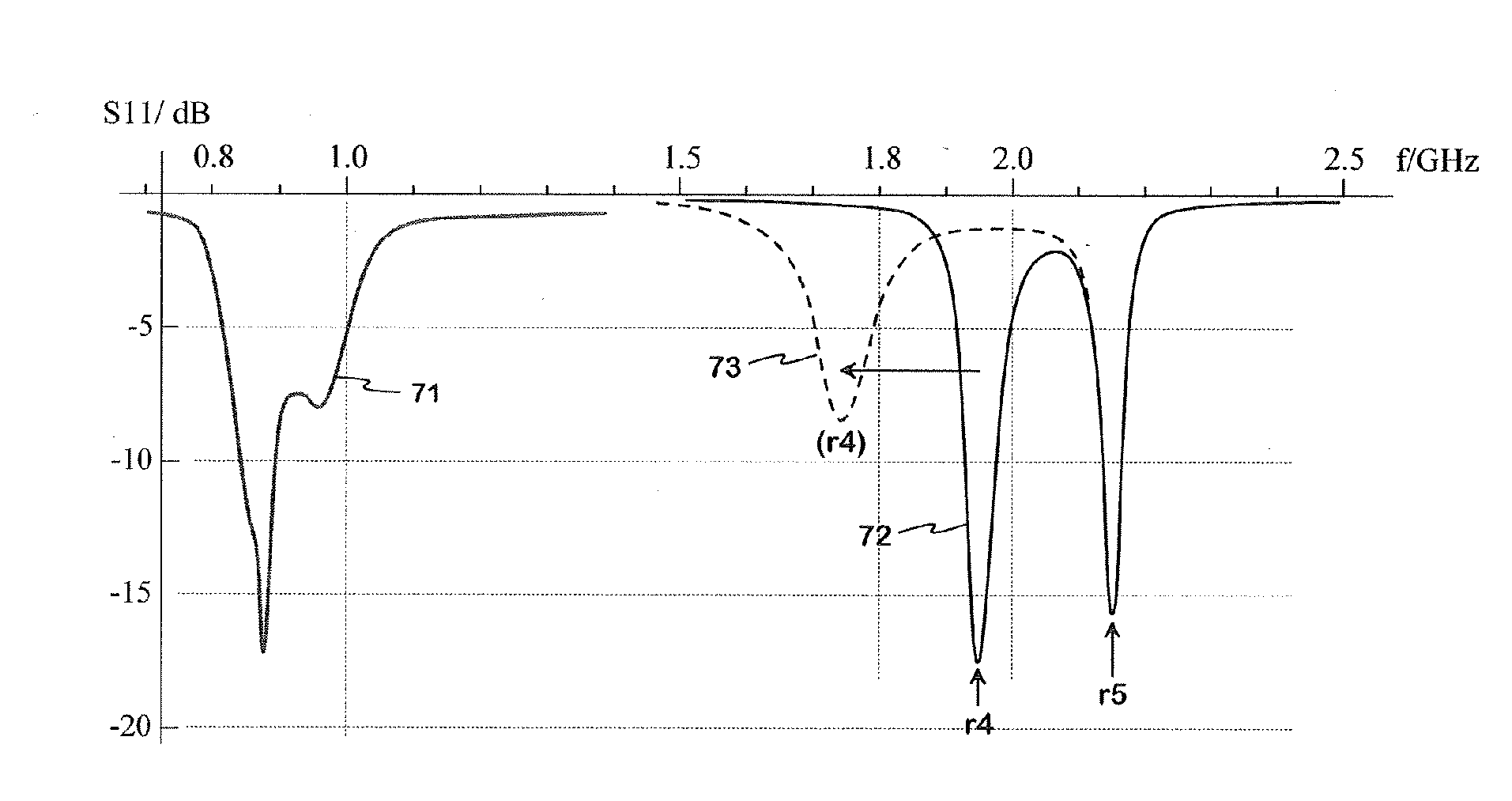

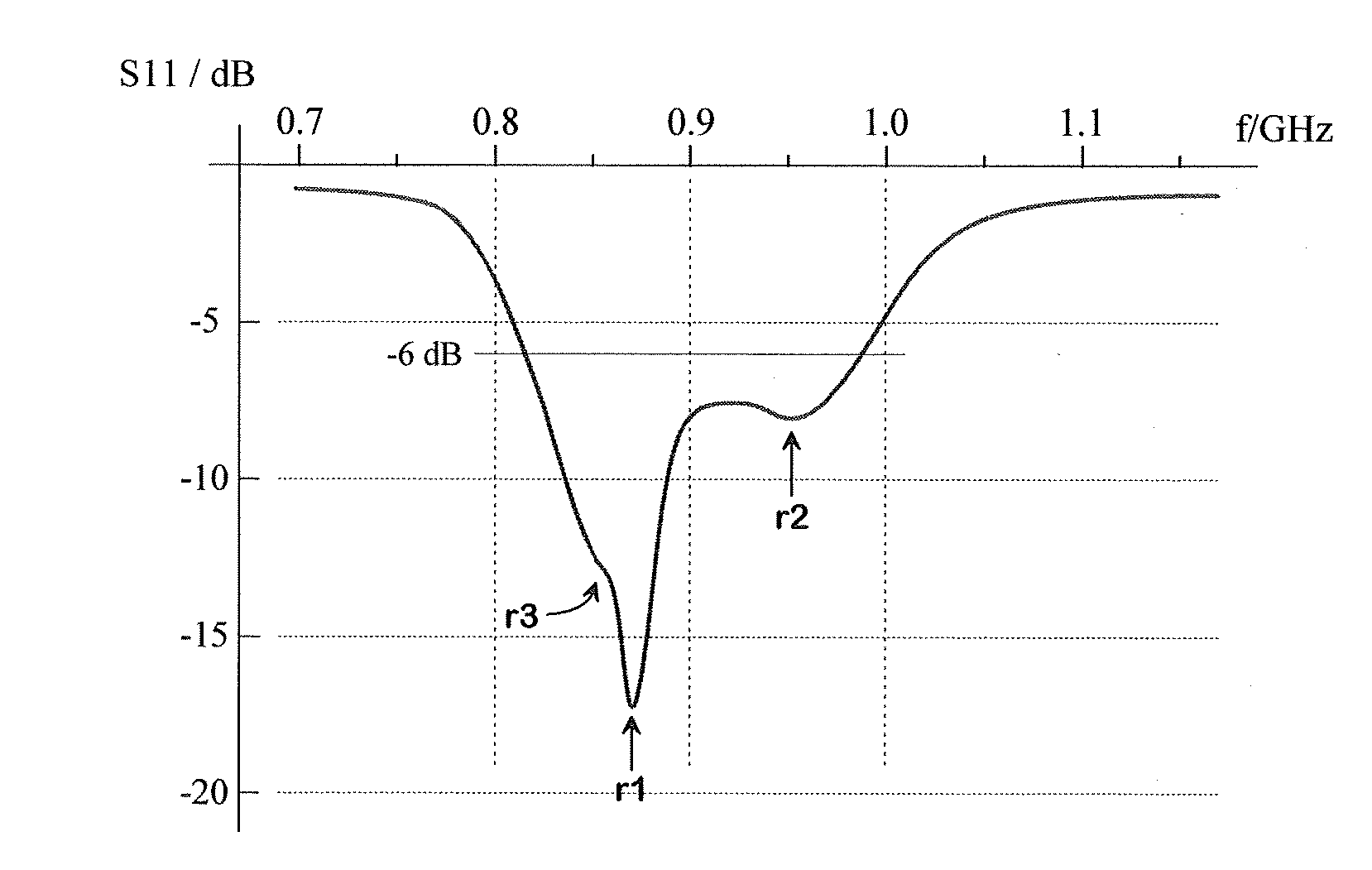

Multiresonance antenna

InactiveCN102318139ANo increase in production costsSimultaneous aerial operationsAntenna supports/mountingsElectricityResonance

An antenna especially intended for small-sized radio devices, which antenna has more than one resonance for shaping an operating band. The radiating element (320) of the antenna has, viewed from its feed point (FP), a first (321) and a second (322) arm with nearly equal electric lengths. The tail ends of the arms are located on different sides of the area confined by the outline of the radiator and point to opposite directions away from each other for exciting a double resonance in the antenna. The second arm has at least one extension towards the tail portion of the first arm. Also an operating band in the range of 900 MHz can be widened by means of the extra resonance without an extra element. The solution is simple and hardly causes rise in the production costs.

Owner:PULSE FINLAND

Arsenic-free glass bottle

The invention discloses an arsenic-free glass bottle. The objective of the invention is to overcome the problem that the dissolving-out amounts of arsenic and antimony in conventional glass for food package are high and cannot reach state-specified standard, which is unfavorable for human health and environmental protection. The arsenic-free glass bottle is prepared from the following raw materials by weight: 51 to 63 parts of quartz sand, 3 to 9 parts of lithium (or sodium and potassium) feldspar, 12 to 19 parts of calcite, 0 to 20 parts of dolomite, 1 to 3 parts of sodium nitrate, 0 to 2.2 parts of fluorite, 0 to 3 parts of sodium fluosilicate, 15 to 21 parts of sodium carbonate, 0.1 to 0.5 part of sodium sulfate, 0.3 to 1 part of calcium sulfate and 0.1 to 0.5 part of cerium oxide. Theabove raw materials are uniformly mixed; and then uniform mixing, melting, shaping and annealing are successively carried out according to conventional manufacturing methods for glass bottles so as toprepare the arsenic-free glass bottle. The arsenic content of the arsenic-free glass bottle is far lower than an allowable dissolving-out amount prescribed in national standard, so the arsenic-free glass bottle is free of toxic and side effect to human beings and does not produce environmental pollution. Under same melting temperature, the clarification time of the arsenic-free glass bottle is 1 / 2 the clarification time of glass using arsenic antimony oxide, and production capability is improved by 10% or so.

Owner:梁泽超

Arsenic-free glass bottle

The invention discloses an arsenic-free glass bottle, which aims to solve the problem that the existing glass bottle (for food packaging) with high arsenic and antimony releases is bad for human health and environmental protection and can not meet the state-specified standards. The arsenic-free glass bottle is prepared from the following compositions in part by weight: 100 parts of quartz sands, 6 to 18 parts of lithium (or sodium, potassium) feldspars, 24 to 38 parts of calcites, 0 to 40 parts of dolomites, 2 to 6 parts of sodium nitrates, 0 to 4.4 parts of fluorites, 0 to 6 parts of sodium fluosilicates, 30 to 40 parts of calcined sodas, 0.7 to 0.9 parts of sodium sulfates, 1.5 to 1.9 parts of calcium sulfates, and 0.7 to 0.9 parts of cerium oxides through the steps of evenly mixing the compositions, and then carrying out even blending, founding, forming and annealing on the obtained mixture according to the existing glass manufacturing method so as to obtain the arsenic-free glass bottle. In the arsenic-free glass bottle of the invention, the arsenic content is far below the state-specified allowable release, therefore, the arsenic-free glass bottle has non-toxic side effects on the human body and does not lead to environmental pollution; and at a same melting temperature, the clarification time is reduced to half of that by using arsenic and antimony oxides, therefore, the production capacity is about 10 percent.

Owner:忻州鑫洋玻璃制品有限公司

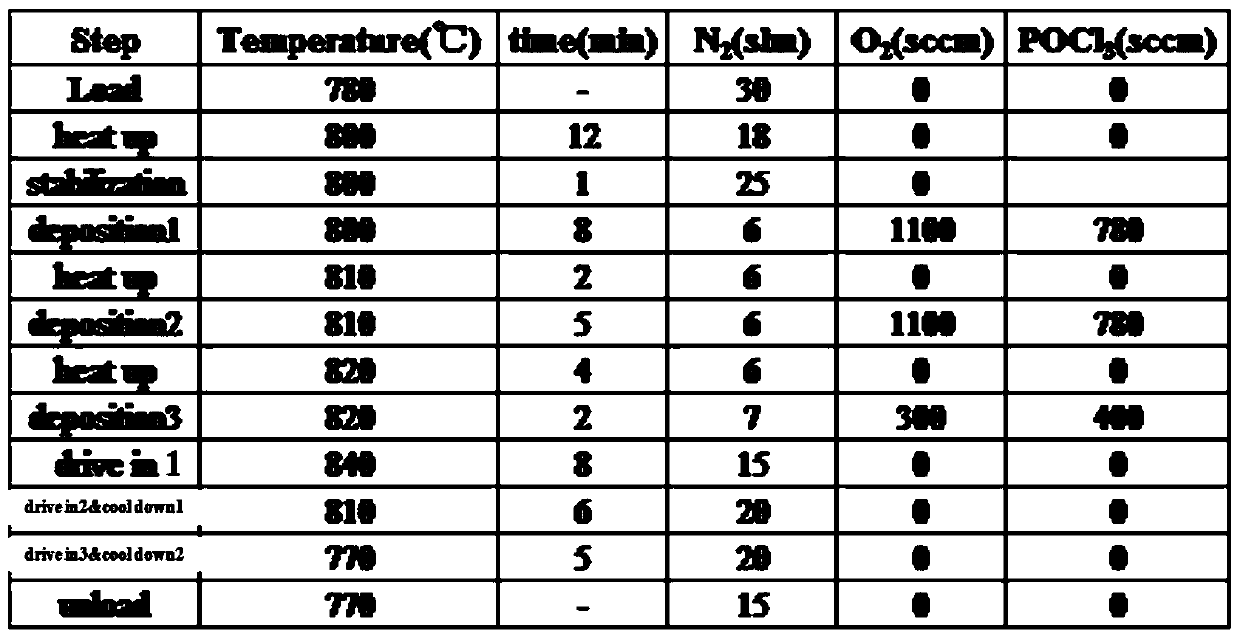

Diffusion method of monocrystalline silicon base inverted pyramid-like suede structure

ActiveCN110112260AFully deposited evenlySpread evenlyFinal product manufactureSemiconductor/solid-state device manufacturingDiffusion methodsReduction procedure

The invention provides a diffusion method of a monocrystalline silicon base inverted pyramid-like suede structure. The method comprises the steps of: employing a P-type monocrystalline silicon wafer as a monocrystalline silicon substrate, performing the anisotropic etching on the front surface of the monocrystalline silicon substrate to obtain a uniformly distributed inverted pyramid-like structure; and putting the silicon wafer having the inverted pyramid-like structure into a diffusion furnace for step-by-step diffusion, wherein the step-by-step diffusion comprises deposition of a phosphorussource under the condition of sequentially increasing the temperature and the temperature reduction procedure with at least two gradients. The design of three-step ordered deposition is beneficial tothe full and uniform deposition of the phosphorus source on the surface of the silicon wafer; the temperature reduction is divided into two steps of buffer type temperature reduction, so that a deadlayer formed by accumulation of excessive phosphorus sources on the surface of the silicon wafer is reduced, the diffusion sheet resistance obtained by the method is ideal sheet resistance and the uniformity is good.

Owner:SUZHOU TALESUN SOLAR TECH CO LTD

Roller retainer type overrun clutch for energy-saving and environmental-friendly loader

InactiveCN102518709AEmission reductionReduce fuel consumptionFreewheel clutchesReduction ratioEngineering

The invention relates to the technical field of engineering machinery transmission, in particular to a spring reset type overrun clutch applied to an energy-saving loader with low rotating speed. An included angle between a spring reset hole and an inner ring cam is 30 degrees-34 degrees, the diameter of the spring reset hole is 4.49mm-4.538mm, the depth of the spring reset hole is 15mm-15.1mm, and a cross section of a raceway wall is in a circular arc shape. The overrun clutch has a simple structure, low reduction ratio, large transmission torque, favorable overload performance, stability in operation, safety and reliability and long service life, and is beneficial for realization of energy conservation and emission reduction as well as improvement of whole machine performances of a domestic loader.

Owner:HANGZHOU ZONGXING GEAR

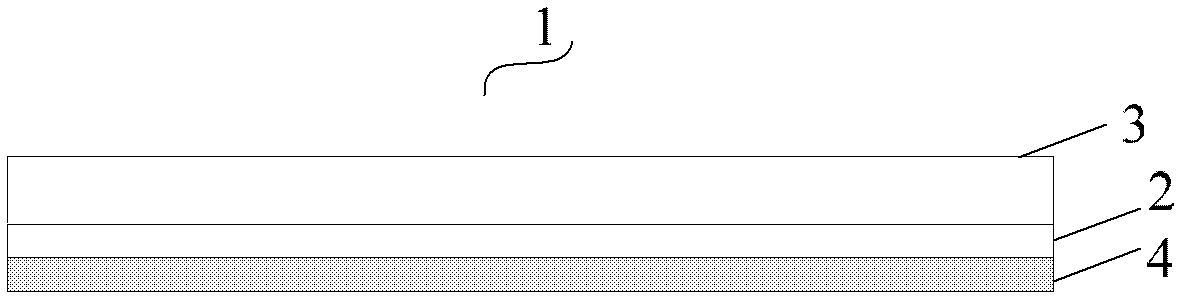

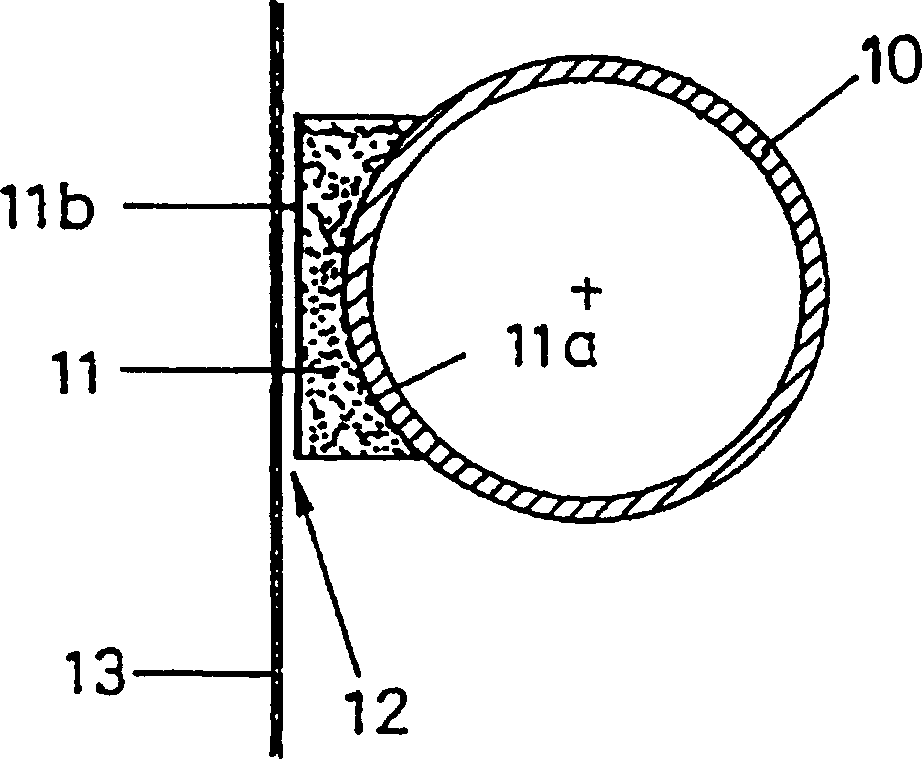

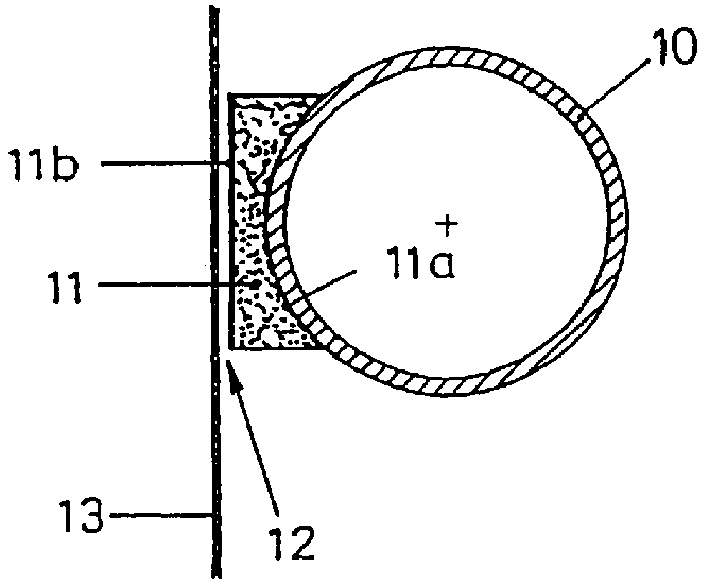

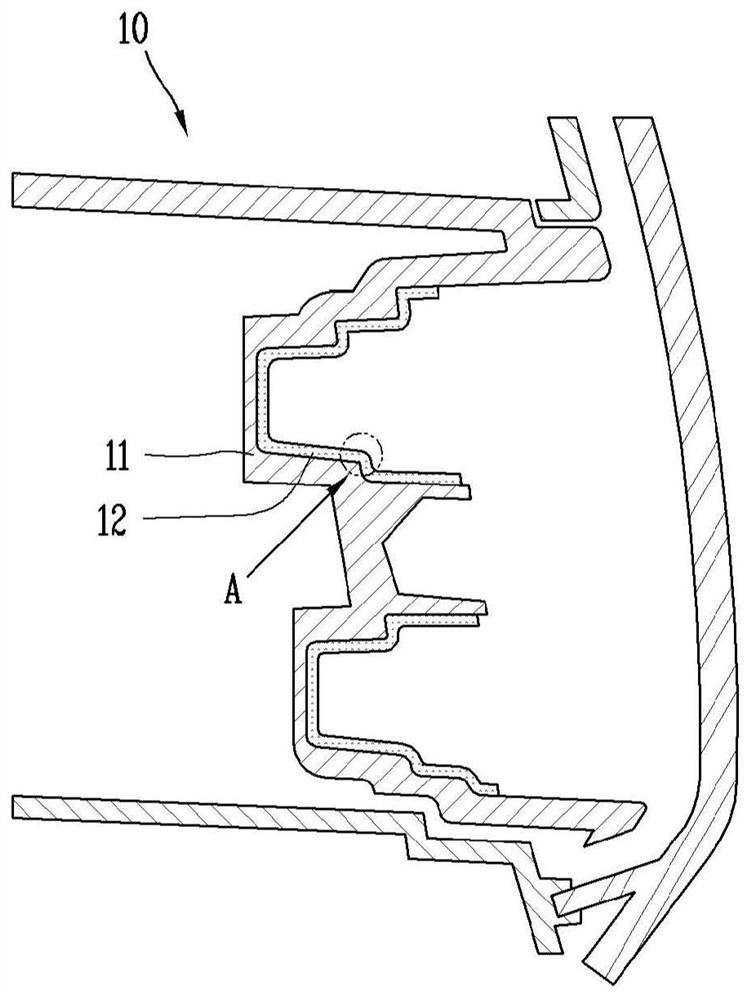

Bodywork component

Bodywork component comprising at least one outer sheet metal, at least one reinforcement support and one foamed material disposed in-between the outer sheet metal and the reinforcement support, wherein the foamed material is a blown material (11) that is initially placed in blowable form and then blown by feeding heat into the space (12) between the reinforcement support (10) and the outer sheet metal (13). The bodywork component can be produced by initially placing an expandable material (11) in the form of a foamed material and expanding said expandable material (11) by feeding heat into the space (12) in-between the reinforcement support (10) and the outer sheet metal (13), thereby producing a connection between the reinforcement support (10) and the outer sheet metal (13).

Owner:VOLKSWAGEN AG

Initialization Method of Fast Peripheral Component Interconnect Interface Card

ActiveCN109002402BNo increase in production costsSmall attenuationElectric digital data processingProcessing elementBIOS

The present invention provides an initialization method of a fast peripheral component interconnection interface card. The method includes: a processing unit initializes a first initialization parameter included in a basic input output system code according to a preset first value of a flag in a boot program. The fast peripheral component interconnection interface card inserted into the fast peripheral component interconnection interface slot, the processing unit sets the aforementioned flag according to the initialized fast peripheral component interconnection interface card in the boot program, so that the flag has the first value or The second value, the processing unit judges whether the express peripheral component interconnection interface card needs to be re-initialized after the initialization in the boot procedure, and when the express peripheral component interconnection interface card needs to be re-initialized, the processing unit according to the set flag. The binary BIOS code includes a second initialization parameter to reinitialize the Express Peripheral Component Interconnect Interface card.

Owner:MITAC COMP (SHUN DE) LTD +1

Method for sewing trade-mark on clothes able to be turned for being hidden

A method for sewing the trademark on the clothes, which can be turned over for hiding it, features that parellel two insertion slots are made at the position where the trademark is arranged, a thin belt is passed through them and its both ends are jointed to become a ring, and a trademark is attached to the belt ring.

Owner:季伟林

Polishing pad, polishing device and polishing method using same

The invention discloses a grinding cushion, and a grinding device and a grinding method using the grinding cushion. The grinding cushion comprises first grinding areas and a second grinding area, wherein the first grinding areas are formed on the edge of the grinding cushion, and are used for grinding the edge of a wafer; the second grinding area can be used for at least accommodating an entire wafer surface, and is used for grinding the entire wafer; and grooves are formed between the first grinding areas and the second grinding area of the grinding cushion. The grinding device provided with the grinding cushion comprises a grinding table, a grinding head and a first conveying device, wherein the wafer is placed on the grinding cushion, and the edge of the wafer is contacted with the first grinding areas; the grinding table is kept static; the grinding head is rotated for grinding the edge of the wafer; and a liquid ejected by the first conveying device is only retained in the first grinding areas. Due to the adoption of the grinding cushion, the grinding device and the grinding method, the entire wafer surface can be ground, the edge of the wafer can be ground separately, the uniformity of the ground central area and the edge area of the wafer is improved, and the production yield of a semiconductor device is increased greatly.

Owner:SEMICON MFG INT (SHANGHAI) CORP

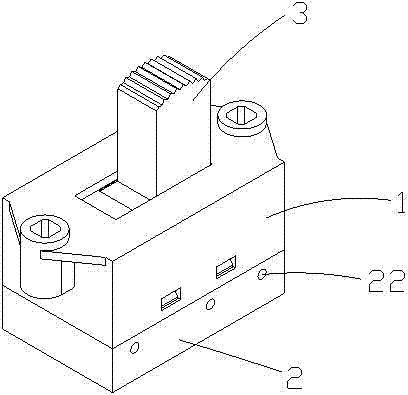

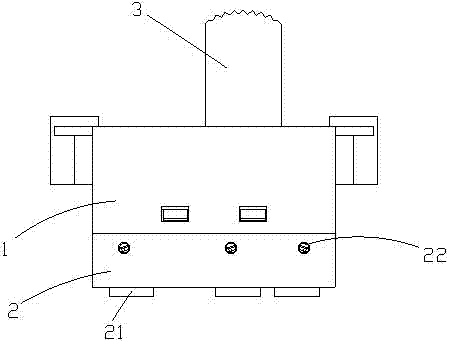

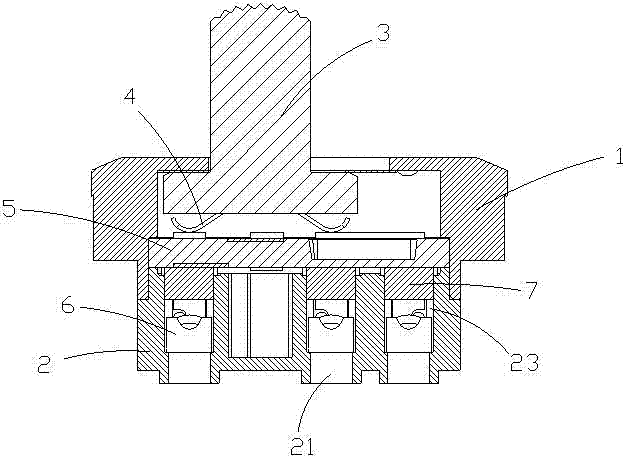

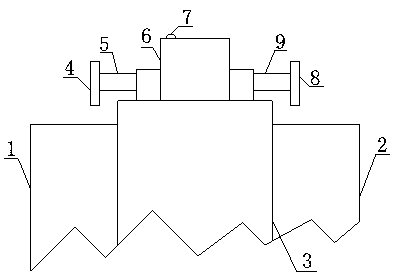

Motor power commutator

PendingCN107332399ASimplify wiring methodsAchieve phase inversionSupports/enclosures/casingsCommutatorPower flow

The invention discloses a motor power commutator which comprises an upper cover, a pedestal, a poking handle, reeds and a deflector. A first wiring pin and a second contact are connected through a first conducting sheet, and a fourth wiring pin and a first contact are connected through a second conducting sheet. The pedestal is provided with wiring holes corresponding to each wiring pin of the deflector, the deflector is placed on the pedestal, and each wiring pin of the deflector is positioned in corresponding wiring hole. Two reeds are correspondingly arranged on the lower portion of the poking handle, the reeds on the lower portion of the poking handle are contacted with the wiring pins on the upper portion of the deflector. The poking handle and the deflector are installed on the pedestal in a tightly pressing manner through the upper cover, and the upper end of the poking handle penetrates through and projects out of the top of the upper cover. The motor power commutator satisfies the requirements of motor conjunction boxes of different specifications. The deflector employs a bi-layer structure. The current direction is changed by poking any of the two ends of the poking handle to realize clockwise and counter-clockwise rotation of a switch. The motor power commutator has rapid wire plugging and pushing function.

Owner:温州市圣帕电子科技有限公司 +1

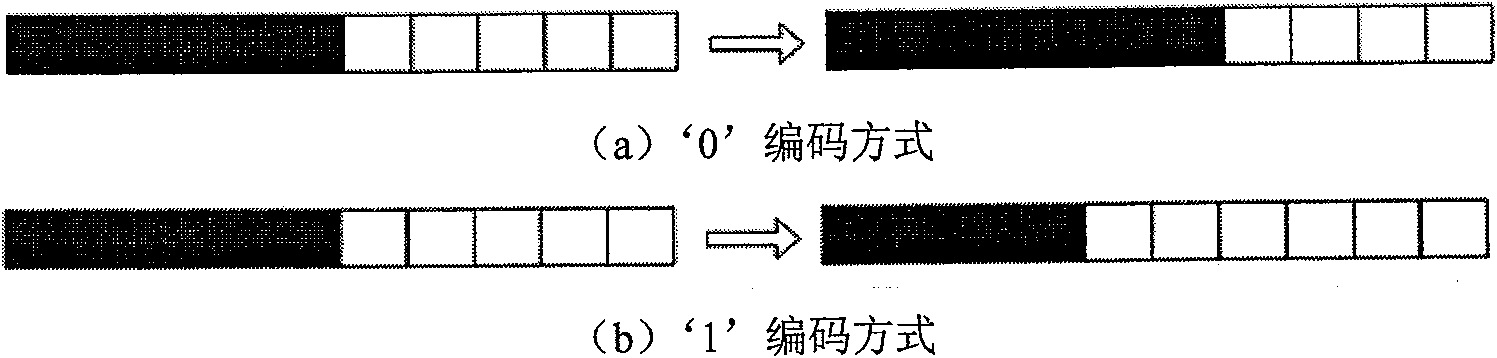

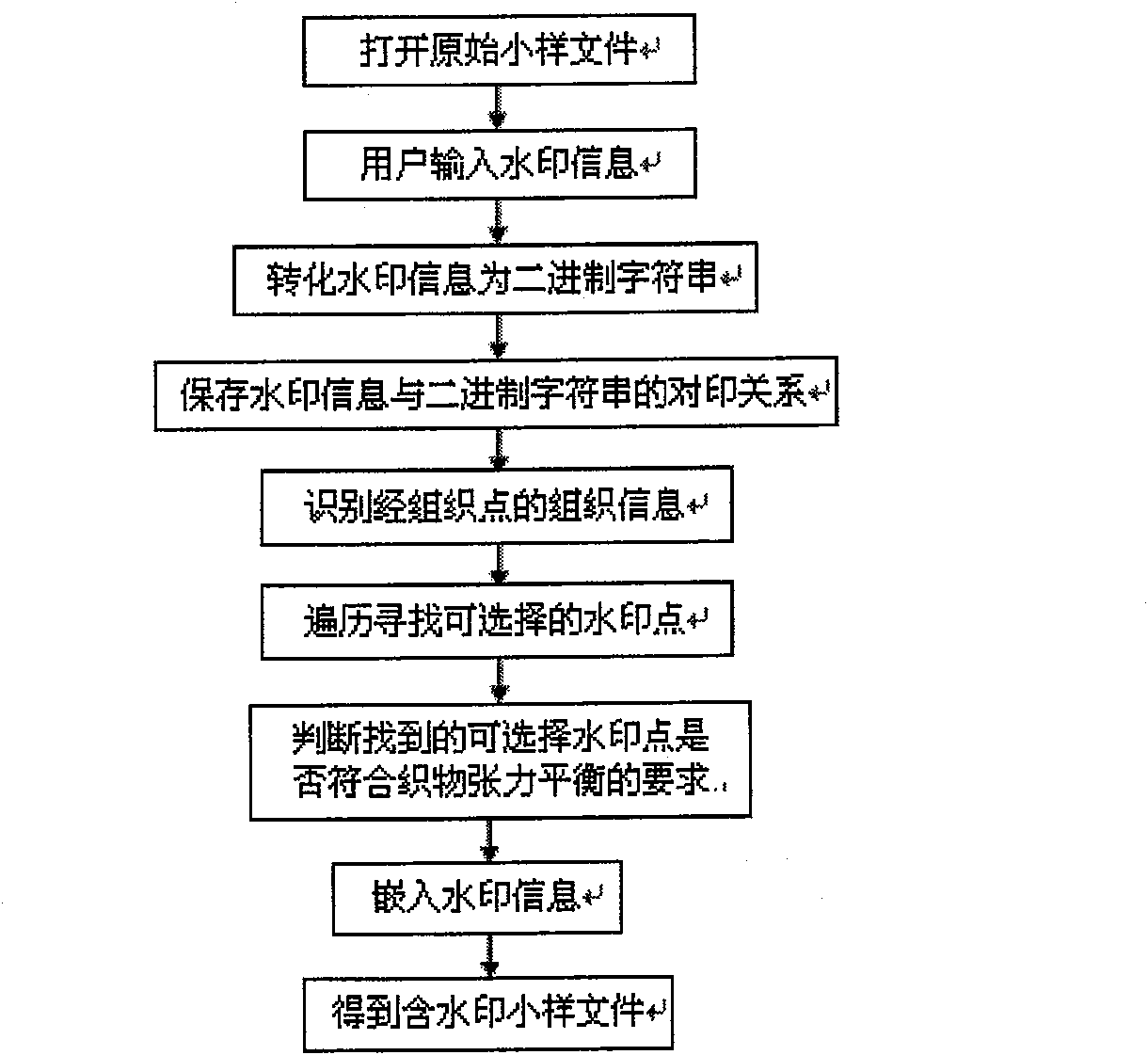

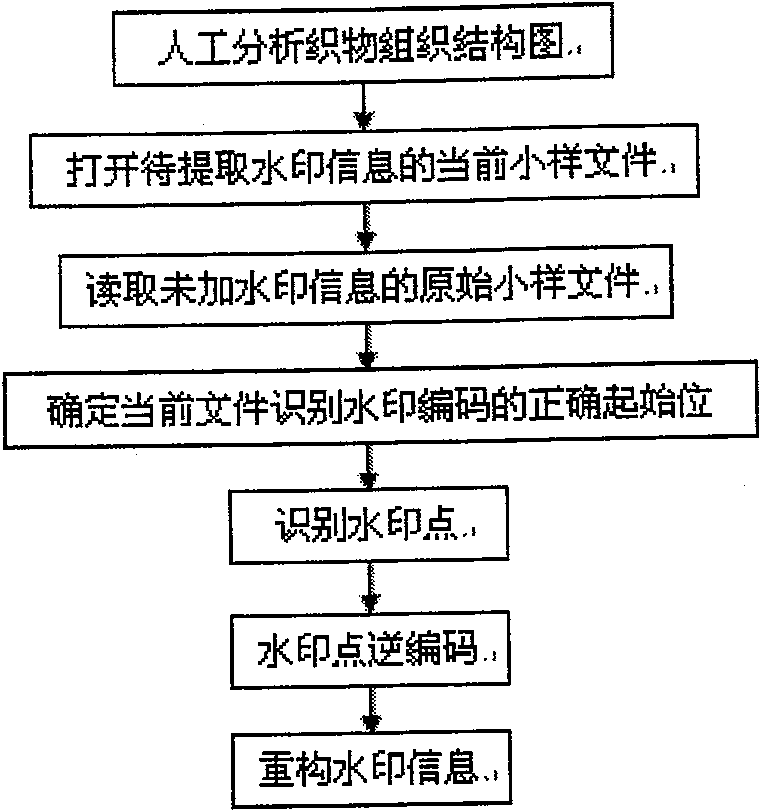

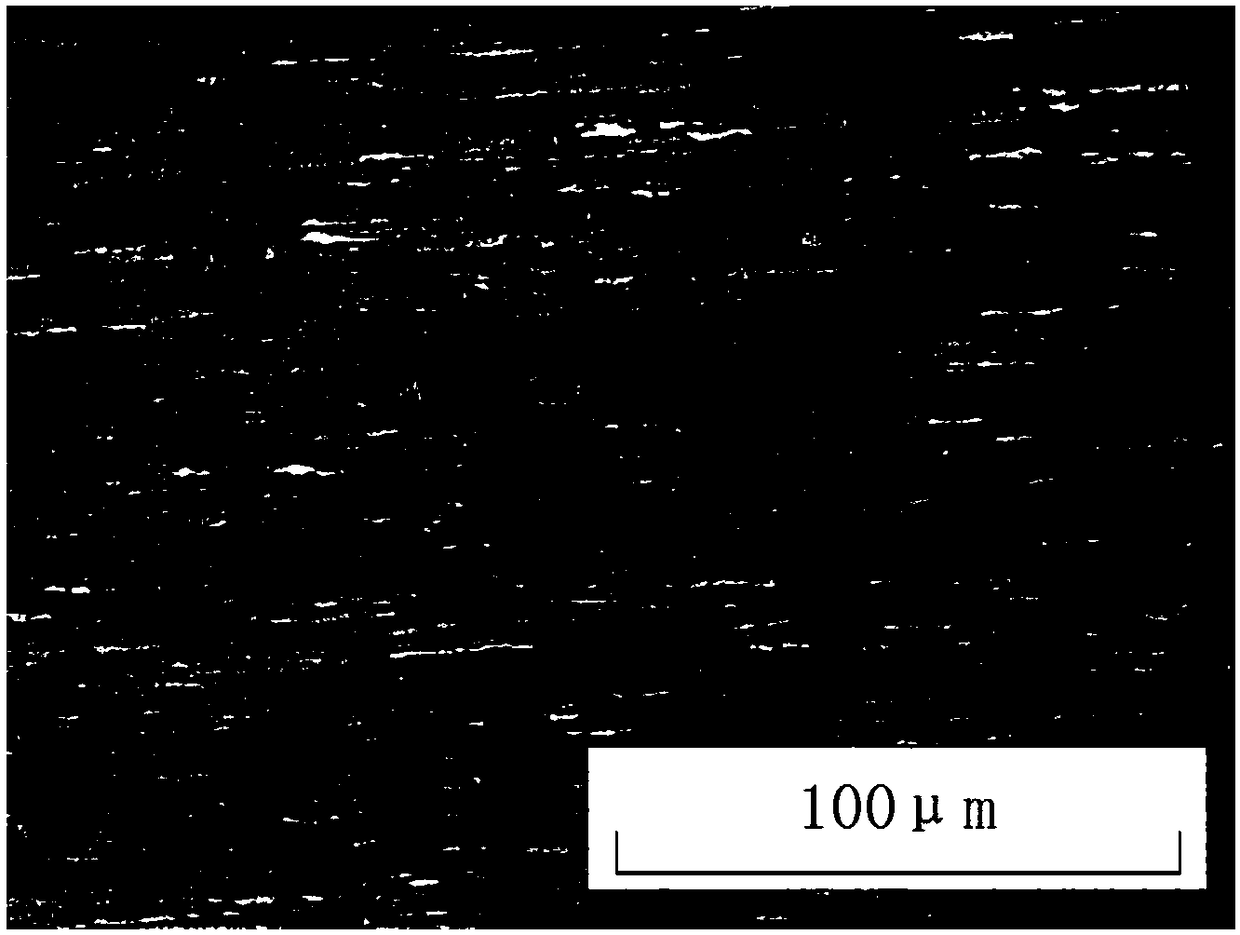

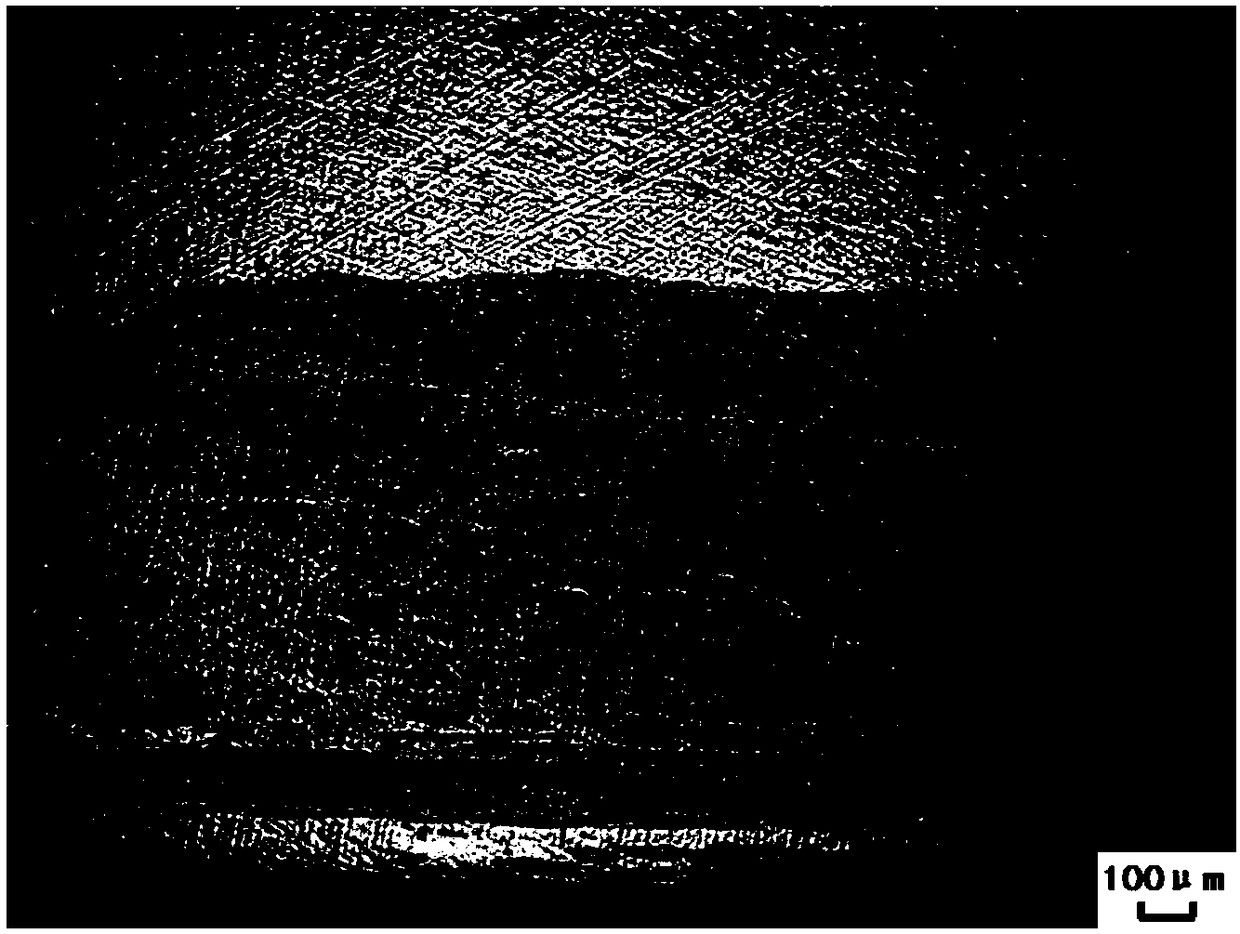

Multiple tissue fabric water mark technology anti-counterfeit method

InactiveCN100555321CIncrease the difficultyProtect private label graphicsMarking textilesInspecting textilesField testsComputer science

Owner:ZHEJIANG UNIV

A high-temperature creep-resistant molybdenum plate doped with K and Si elements and its preparation method

ActiveCN106399787BReduce the type of dopingImprove high temperature creep resistanceReduction treatmentSilicon

The invention relates to a high-temperature creep-resistant Mo (Molybdenum) plate doped with K (Potassium) and Si (Silicon) elements and a preparation method thereof. The preparation method comprises the following steps of 1, respectively weighing a required K source and a required Si source according to the contents of K and Si in the Mo plate, and performing preparation to obtain a mixed solution; 2, uniformly mixing the mixed solution obtained in the step 1 with a Mo source, and performing drying to obtain a doped Mo source; 3, performing reduction treatment on a mixture obtained in the step 2 to obtain doped Mo powder; 4, performing compression, sintering and rolling treatment on the doped Mo powder obtained in the step 3 to obtain a doped Mo plate; and 5, performing annealing treatment on the doped Mo plate obtained in the step 4 to obtain a Mo-K-Si high-temperature creep-resistant Mo plate with the thickness being 0.5 to 4mm. The high-temperature creep-resistant Mo plate provided by the invention has the advantages that the material has very high high-temperature creep-resistant performance; the creep-resistant performance at a temperature below 1900 DEG C is much better than that of pure Mo; and the Mo plate can be used as a high-temperature sintering setter plate or a structural component in a high-temperature furnace.

Owner:安泰天龙钨钼科技有限公司 +1

Locking device of robot

The invention discloses a locking device of a robot. The locking device comprises a shell, a gear disc, grooves, a buckle I, a buckle II, a clamp head and a control system. The gear disc is fixed to the shell through the buckle I. The two grooves are formed on the surface of the gear disc. The clamp head is fixedly mounted on the shell through the buckle II. Through an electric wire, one way of the control system is connected with the buckle I, and the other way of the control system is connected with the buckle II. The control system is composed of a switch, a single-chip microcomputer, a power source and a divider, the switch is connected with the single-chip microcomputer, the single-chip microcomputer is connected with the power source, and the power source is connected with the divider. The situation that a rotary knob cannot be twisted in place at a time during manual adjustment cannot happen, the work time cannot be wasted, the rotary knob cannot be damaged, a machine can be shut down fast, and production expenditures cannot be increased.

Owner:徐州木牛流马机器人科技有限公司

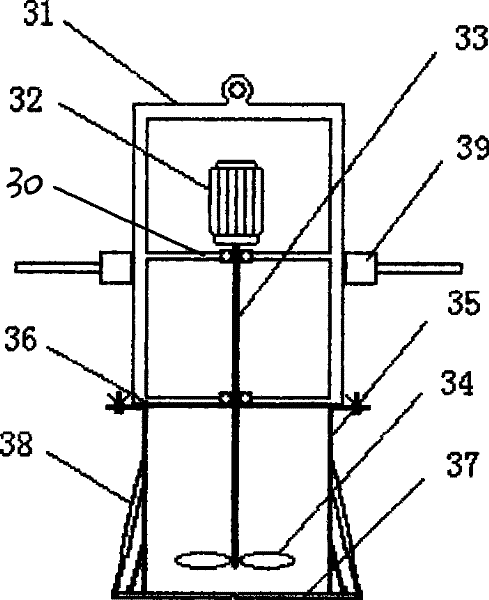

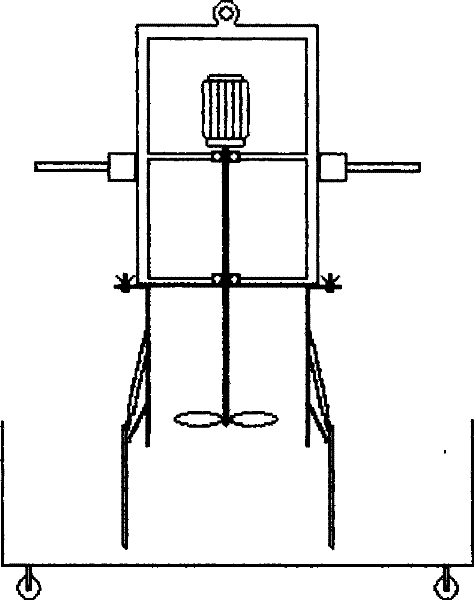

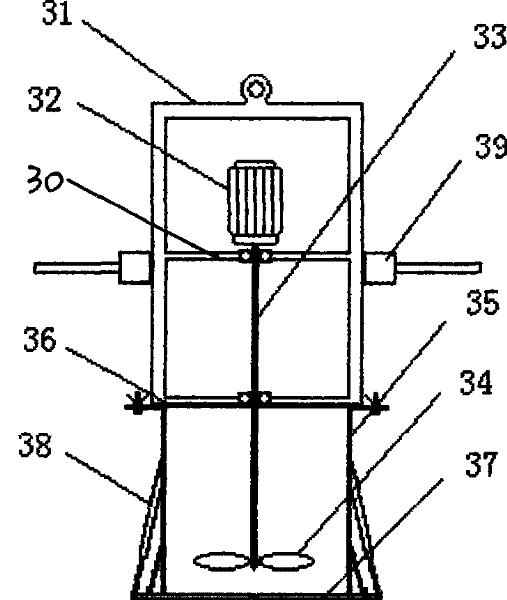

Polyurethane foaming agitating device

Owner:YANTAI ZHENGHAI HIGH TECH

Case shading device

InactiveCN109548331AExtended service lifeEliminate injury to the arm of the staffCasings/cabinets/drawers detailsEngineeringMechanical engineering

Owner:徐州市奥仕捷电子机箱有限公司

Protective device for transformer coil

InactiveCN109350898AAvoid spreadingNo increase in production costsTransformers/inductances coils/windings/connectionsFire rescueTransformerControl store

The invention discloses a protective device for a transformer coil. The protective device comprises a coil I, a coil II, a bracket, a spray head I, an adapting tube I, a storage controller, an inductor, a spray head II and a connecting tube II, wherein the coil I and the coil II are fixedly mounted at the two sides of the bracket; the two ends of the storage controller are fixedly equipped with the adapting tube I and the connecting tube II; the tail end of the adapting tube I is fixedly equipped with the spray head I; the tail end of the connecting tube II is fixedly equipped with the spray head II; and the inductor is mounted on the surface of the storage controller. The protective device can control fire behaviour at first time, does not increase production expense, does not cause greater fire behaviour, avoids occurrence of a safety accident, can reduce loss to the greatest extent of effectively preventing fire spread, and can reduce the loss to be lowest.

Owner:江苏盛久变压器有限公司

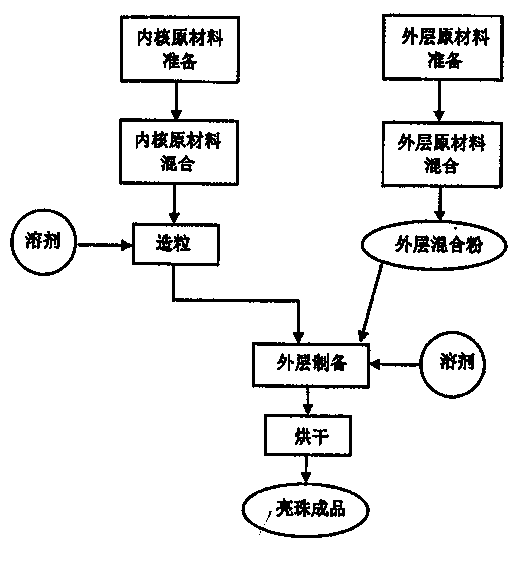

Method for preparing smokeless fireworks bright beads

InactiveCN109160866AIncreased effective ignition rateNo increase in production costsExplosive working-up apparatusAdhesivePolyvinyl chloride

The invention discloses a method for preparing smokeless fireworks bright beads. The smokeless fireworks bright beads are characterized by comprising four kinds of red, green, purple and yellow, eachof the smokeless fireworks bright beads comprises a kernel and an outer layer, and the smokeless fireworks bright beads are in the shape of beads, wherein the kernel comprises the following componentsin percentage by mass: red: 55% of KMnO4, 24% of SrCO3, 17% of epoxy slices and 4% of dextrin; green: 50% of Ba(NO3)2, 10% of magnesium powder, 10% of aluminum powder, 7% of resins, 7% of rare earth,15% of KCIO4 and 1% of epoxy slices; purple: 20% of CuO, 40% of KCIO4, 10% of polyvinyl chloride, 10% of phenolic resins, 8% of magnesium powder and 8% of aluminum powder; yellow: materials containing sodium salt; the outer layer is a flame slow combustion delaying layer, and is designed according to zero oxygen balance, the consumption is 15-45% of the weight of the bright beads, and the outer layer comprises the components in percentage by mass of 0-86.2% of potassium nitrate, 0-84.2% of ammonium dichromate, and 13.8-15.8% of an adhesive. The smokeless fireworks bright beads have the advantages of being high in effective binding force, simple in technology, free from new equipment, little in smog, good in ornamental effect, high in promotion and application value, and the like.

Owner:浏阳市达丰出口花炮厂

Hanging hook applicable to glass bottle

Owner:徐州嘉恒玻璃制品有限公司

Enzyme additive for cotton knitted fabric and preparation method and application thereof

InactiveCN102888755BDoes not affect the hair removal effectShort processBiochemical fibre treatmentCelluloseWater discharge

The invention discloses an enzyme additive for a cotton knitted fabric and a preparation method and an application thereof, and belongs to the technical field of pretreatment processes and formulas in the cotton knitted fabric dyeing and finishing industry. The enzyme additive for a cotton knitted fabric is characterized by comprising the following components by weight percentage: 40-75 of neutral cellulose, 6-15 of deoxyenzyme, 7-30 of protective agent and 8-20 of enzyme activity promoter. The enzyme additive for a cotton knitted fabric is applied to the deoxidizing, polishing dyeing one-bath process of cotton knitted fabrics; and with the method, enzyme activity is kept stable, the technological steps are shortened, the energy consumption is reduced, and the waste water discharge is reduced.

Owner:CHINA TEXTILE ACAD JIANGNAN BRANCH

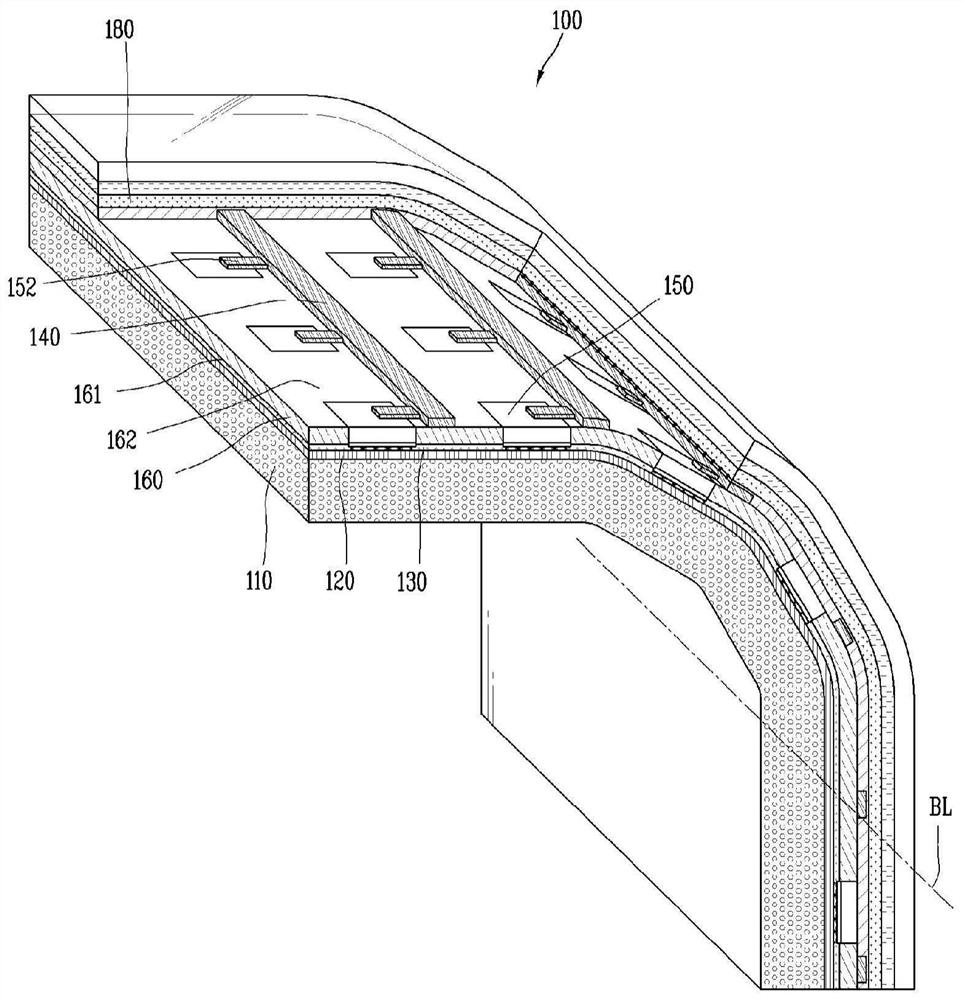

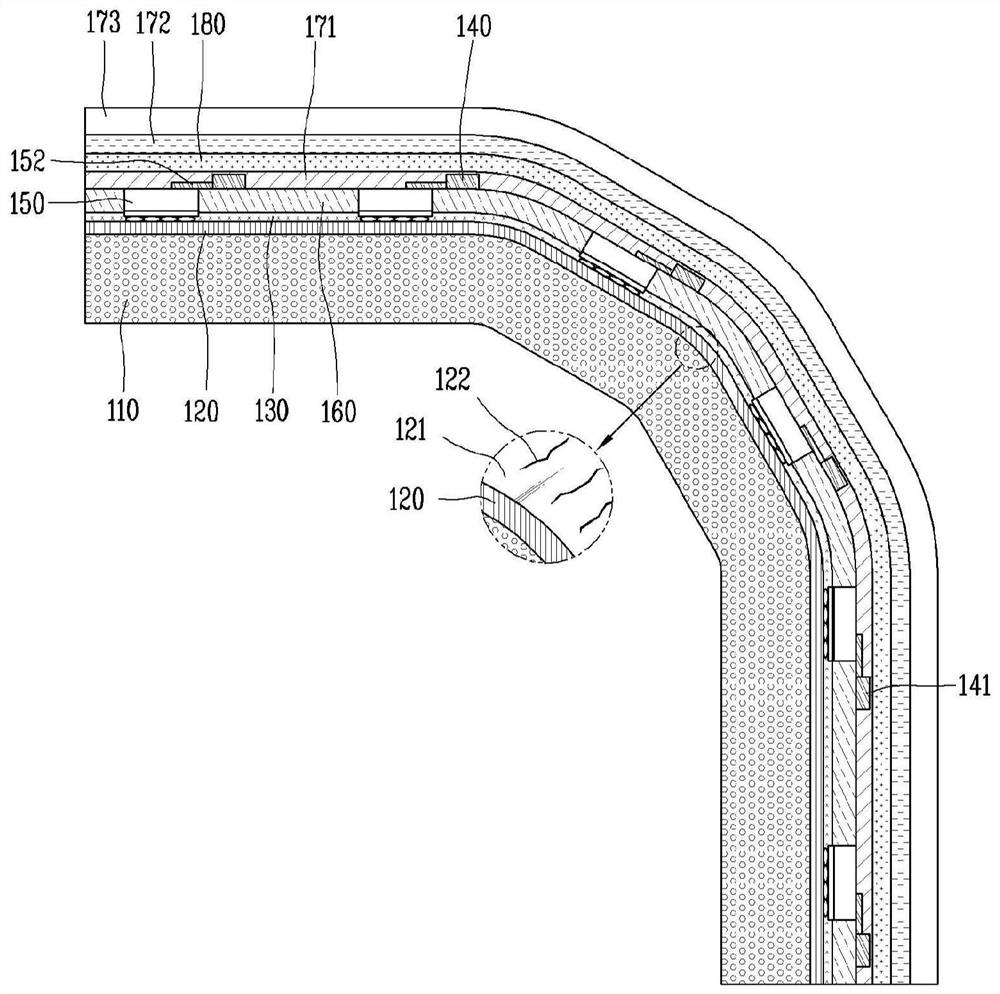

Lamp using semiconductor light-emitting device and manufacturing method thereof

ActiveCN112106210AImprove light extraction rateNo increase in production costsVehicle headlampsSolid-state devicesEngineeringSemiconductor

The present invention relates to a lamp and, more particularly, to a lamp using a semiconductor light-emitting device, and a method of manufacturing same. The present invention provides the lamp comprising: a substrate; a plurality of semiconductor light-emitting devices disposed on the substrate; a flat layer formed between the semiconductor light-emitting devices; and a spacer disposed between the substrate and the flat layer, in which an air gap is formed between each of the semiconductor light-emitting devices and the spacer.

Owner:LG ELECTRONICS INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com