Bodywork component

A component and body technology, applied in the field of body components, can solve the problem that the volume cannot be changed in a short time, and achieve the effect of smooth mass production, high quality standards, and time reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

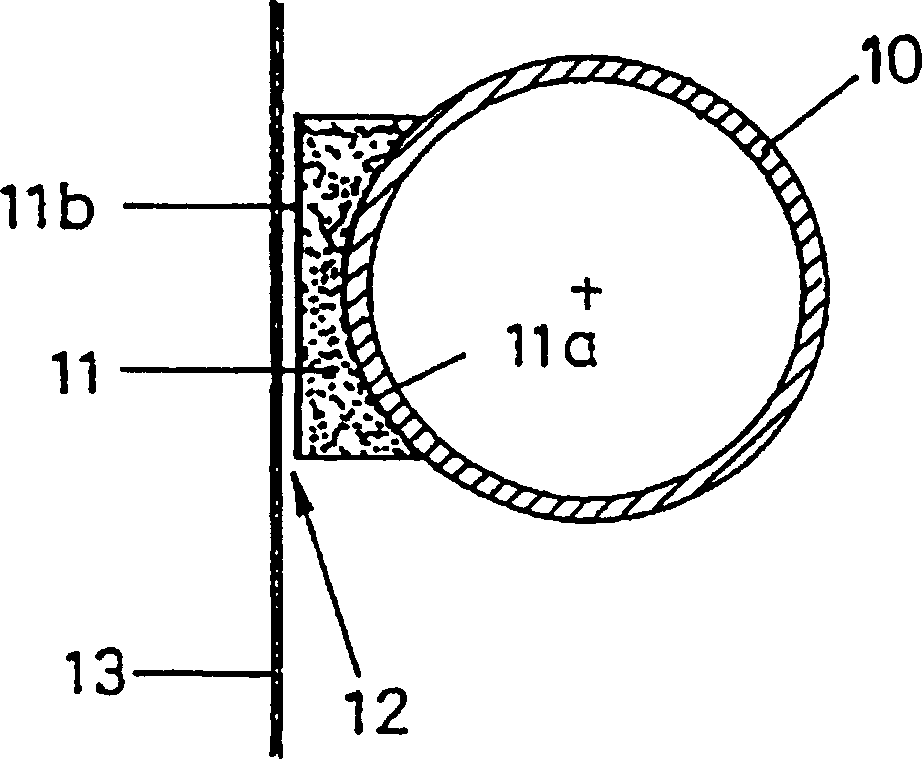

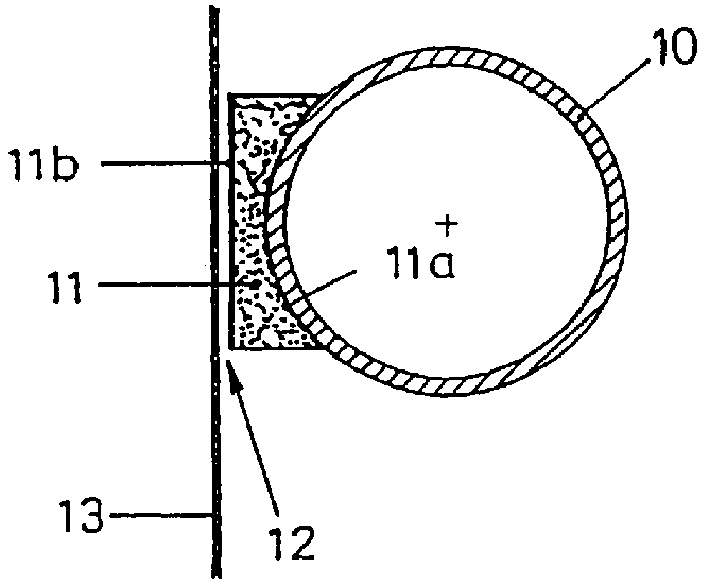

[0018] First refer to figure 1 . The body component according to the invention, which is shown in a very simplified schematic form in longitudinal section in the drawing, relates to a door of a motor vehicle. The automobile door comprises a door shell cladding plate 13 and a support beam 10, and the support beam 10 is a side anti-collision beam deviated in the transverse direction of the automobile door. Between the strut 10 and the door shell cladding is provided a material 11 which is initially installed in an expandable form and can expand in the space between the strut 10 and the door shell 13 when heated. The material 11 in this embodiment is a foam material which preferably has good sound-insulating properties. These expandable materials 11 expand when heated, preferably at a temperature above about 200° C., and form a connection between the door shell cladding 13 and the stay beam.

[0019] according to figure 2 Shown is an enlarged detail view that reproduces the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com