Method for preparing ultra-white ultra-fine aluminum hydroxide by cell mill water grinding method seed crystals

A technology of ultra-fine aluminum hydroxide and aluminum hydroxide, which is applied in the preparation of alkali metal aluminate/alumina/aluminum hydroxide, can solve the problems of low product quality and particle size, high production cost, and low product particle size. Achieve the effects of low production energy consumption, high production efficiency, high quality and particle size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, but not as a basis for limiting the present invention.

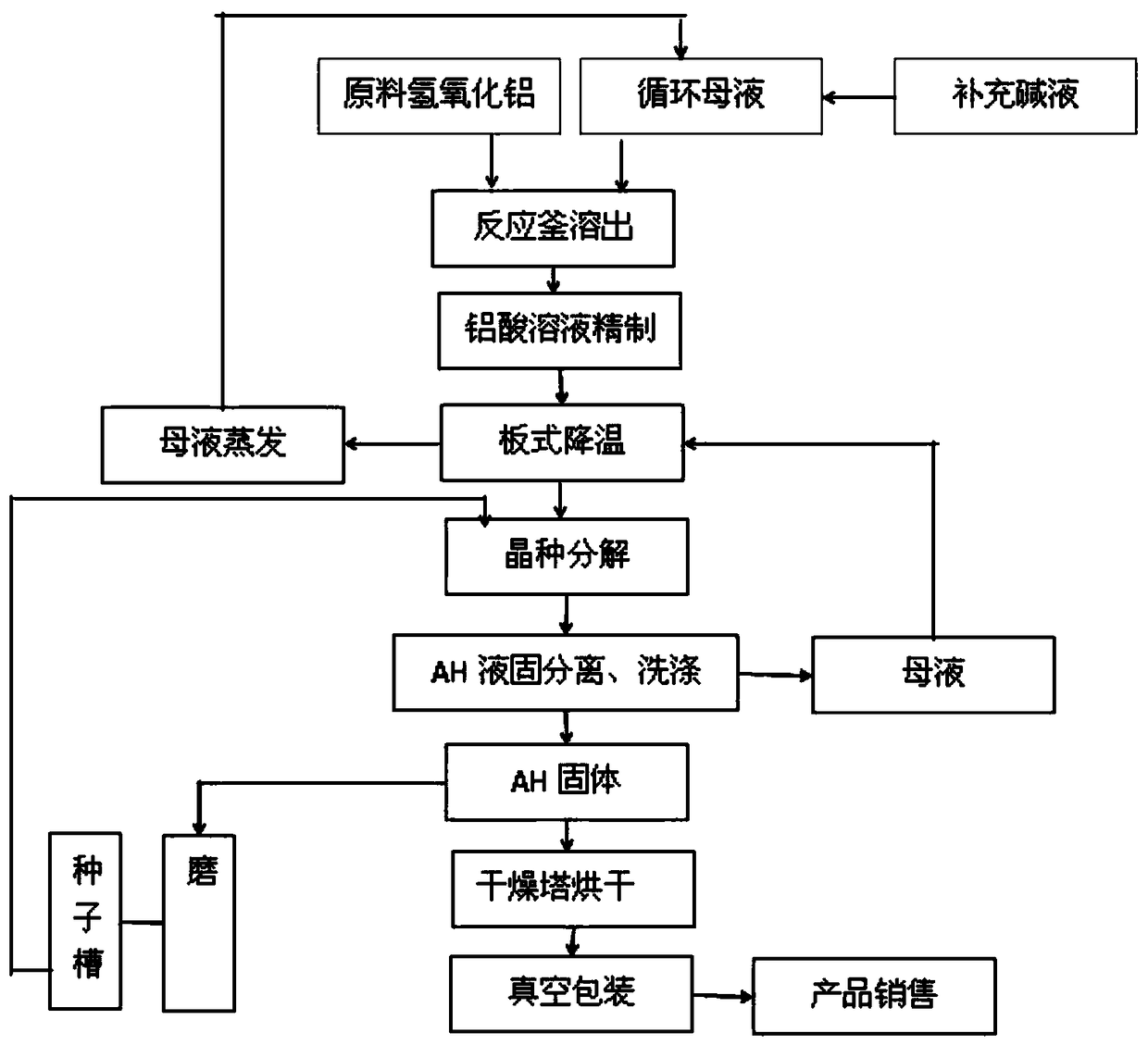

[0044] Example. The method for preparing ultra-white and ultra-fine aluminum hydroxide by cell mill water mill method seed crystal, such as figure 1 As shown, the preparation of micro-nano ultra-white ultra-fine aluminum hydroxide is realized by adding the seed crystal prepared by the cell mill water milling method to the aluminum-based micro-nano ultra-white ultra-fine aluminum hydroxide raw material sodium aluminate solution.

[0045] The raw material sodium aluminate solution is obtained by redissolving the raw material aluminum hydroxide and sodium hydroxide solution and then filtering and refining; the cell mill water milling method is a slurry mixed with aluminum hydroxide and water in a ratio of 1:1, according to Operated according to the operating procedure of the cell mill, after grinding...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com