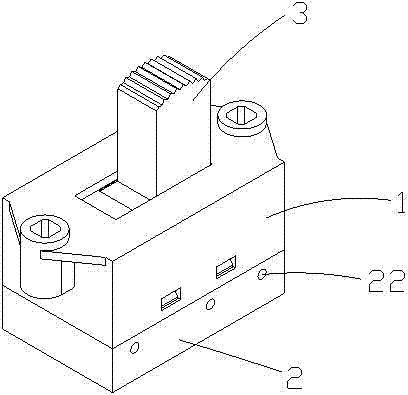

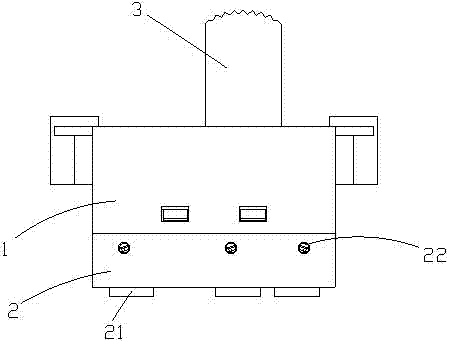

Motor power commutator

A technology of motor power supply and commutator, applied in the direction of electromechanical devices, electrical components, electric components, etc., can solve the problems of high labor cost and low efficiency, and achieve the effect of simplifying the wiring method of wires

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

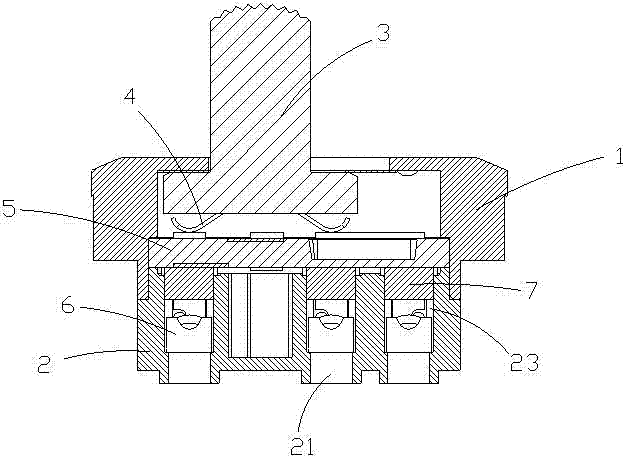

[0038] Embodiment 1: Wiring mode of remote control motor and motor power commutator

[0039] The negative end of the power supply is connected to the starting capacitor through the first connector, and the first connector is connected to any one of the second connecting pin 52 and the third connecting pin 53 through wires, and the motor The red wire is connected to the starting capacitor, the positive end of the power supply is connected to the gray wire of the motor through the second connector, and the second connector is connected to any of the fifth connecting pin 55 and the sixth connecting pin 56 through a wire. One connection pin, the orange wire of the motor is connected to the first connection pin 51 , and the yellow wire of the motor is connected to the fourth connection pin 54 .

Embodiment 2

[0040] Embodiment 2: Wiring mode of pull-speed motor and motor power commutator

[0041] The input terminal of the pull-speed switch is connected to the positive terminal of the power supply through wires, the output end of the pull-speed switch and the red wire of the motor are both connected to the start capacitor through wires, and the start capacitor is connected to the second connection pin 52 and the third connection lead through wires. Any one connection pin in the two pins 53, the negative end of the power supply and the gray wire of the motor are connected to the third connector through wires, and the third connector is connected to the fifth connection pin 55 and the sixth connection pin through wires. Any one of the two wiring pins of the pin 56, the orange wire of the motor is connected to the first wiring pin 51, and the yellow wire of the motor is connected to the fourth wiring pin 54.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com