Patents

Literature

78results about How to "Exit smoothly" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

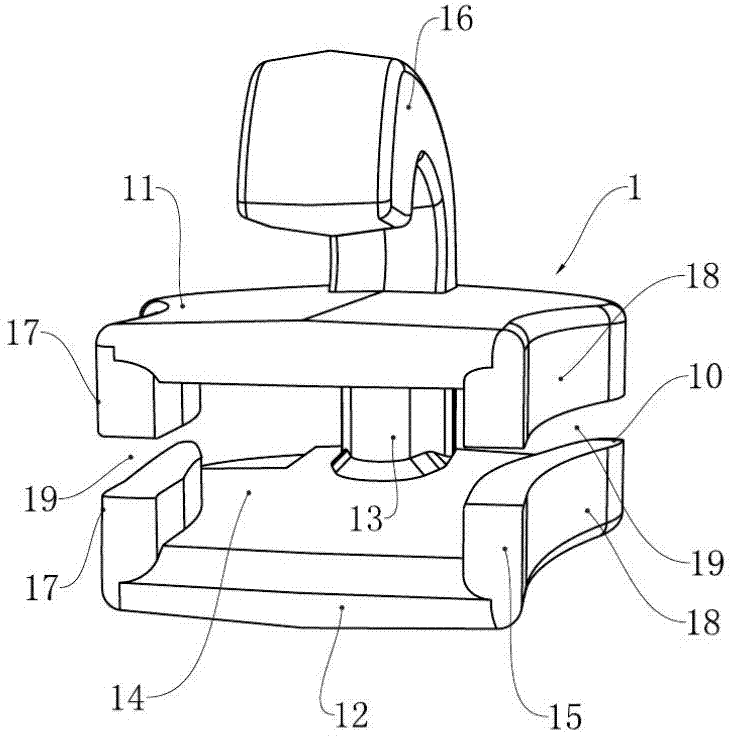

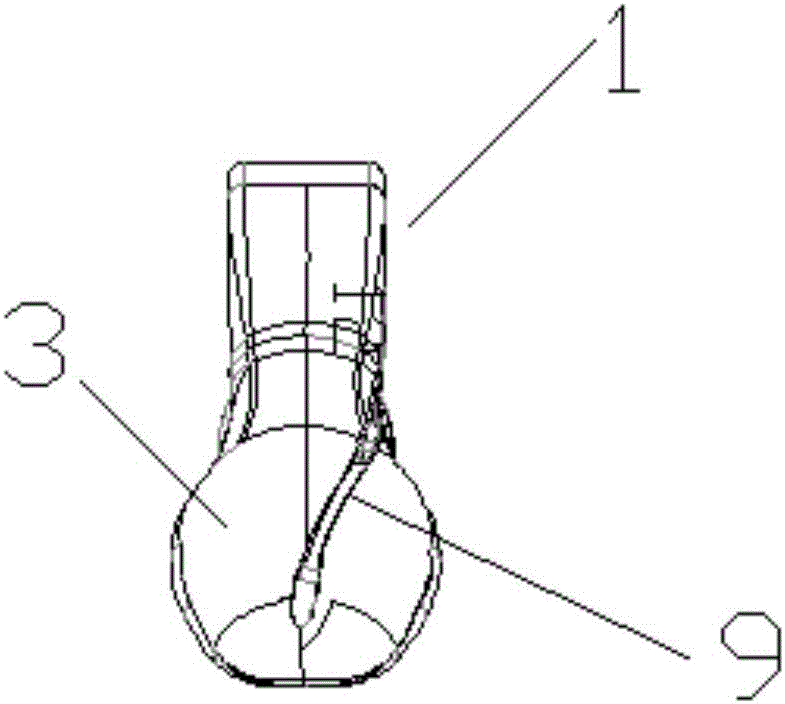

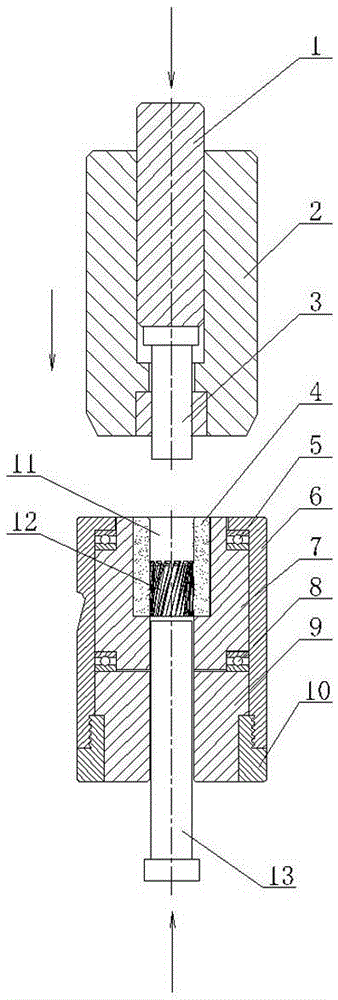

Parking mechanism of automobile transmission

The invention provides a parking mechanism of an automobile transmission. The parking mechanism of the automobile transmission comprises a shifting fork shaft, a shifting fork, a parking gear sleeve assembly, a gear hub, a parking toothed plate and a synchronizing ring; the shifting fork shaft is connected with a parking control mechanism; the shifting fork is composed of a shifting fork mounting sleeve and a clamping jaw; the shifting fork mounting sleeve sleeves the shifting fork shaft in a clearance fit manner; the clamping jaw is assembled with the parking gear sleeve assembly which sleeves the gear hub; the parking gear sleeve assembly is further matched with the parking toothed plate fixed on the bottom surface of a transmission housing; the parking toothed plate is located at the left side of the parking gear sleeve assembly; the gear hub is fixed on a drive shaft of the transmission; the synchronizing ring is mounted at the right side of the parking gear sleeve assembly and matched with drive gears of other gears of the transmission. The parking mechanism of the automobile transmission has the characteristics of simple structure and reliable performance; the manufacturing cost of parts is reduced, and the transmission housing is prevented from being damaged and normal operation of the automobile is guaranteed.

Owner:GREAT WALL MOTOR CO LTD

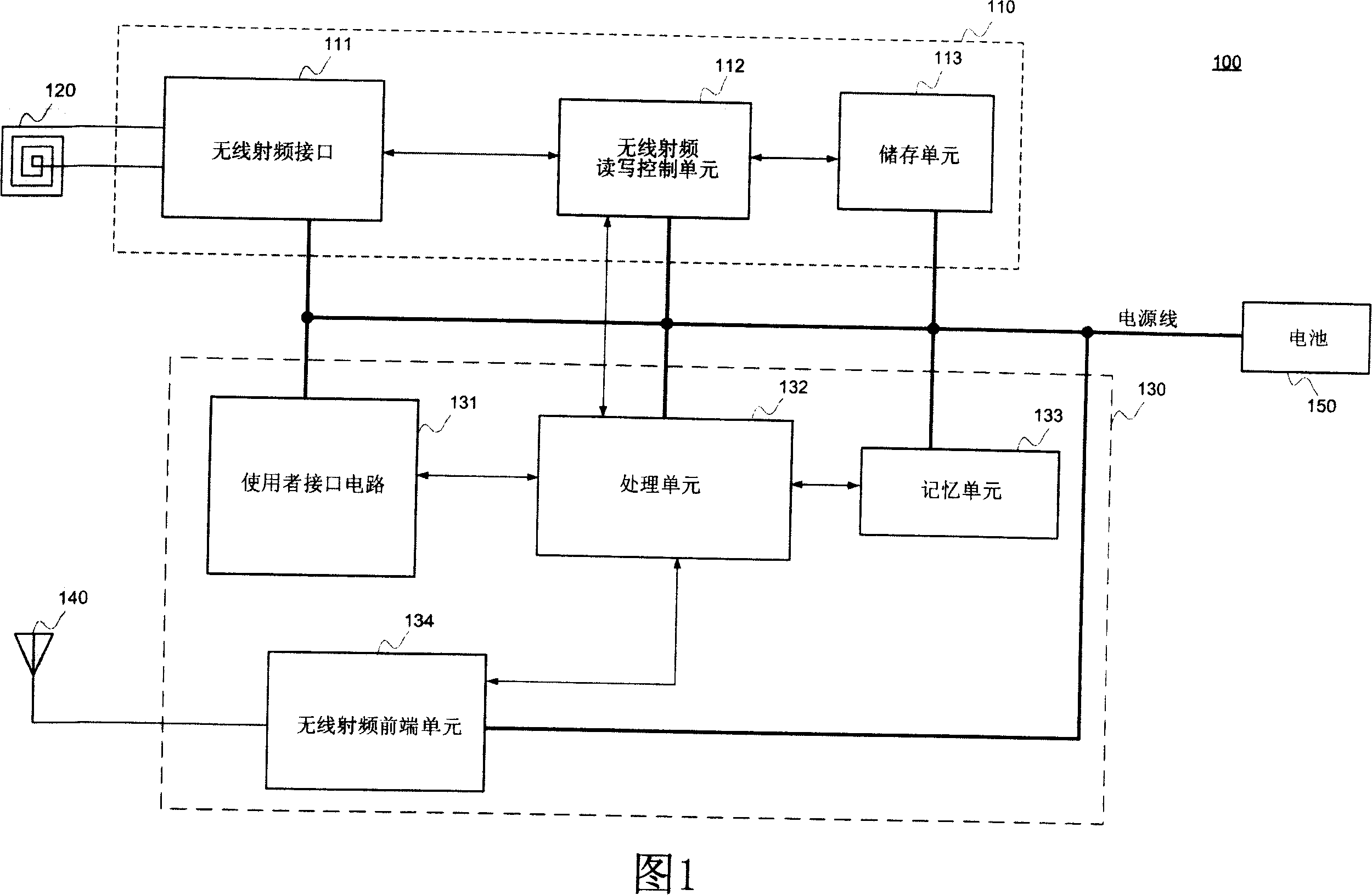

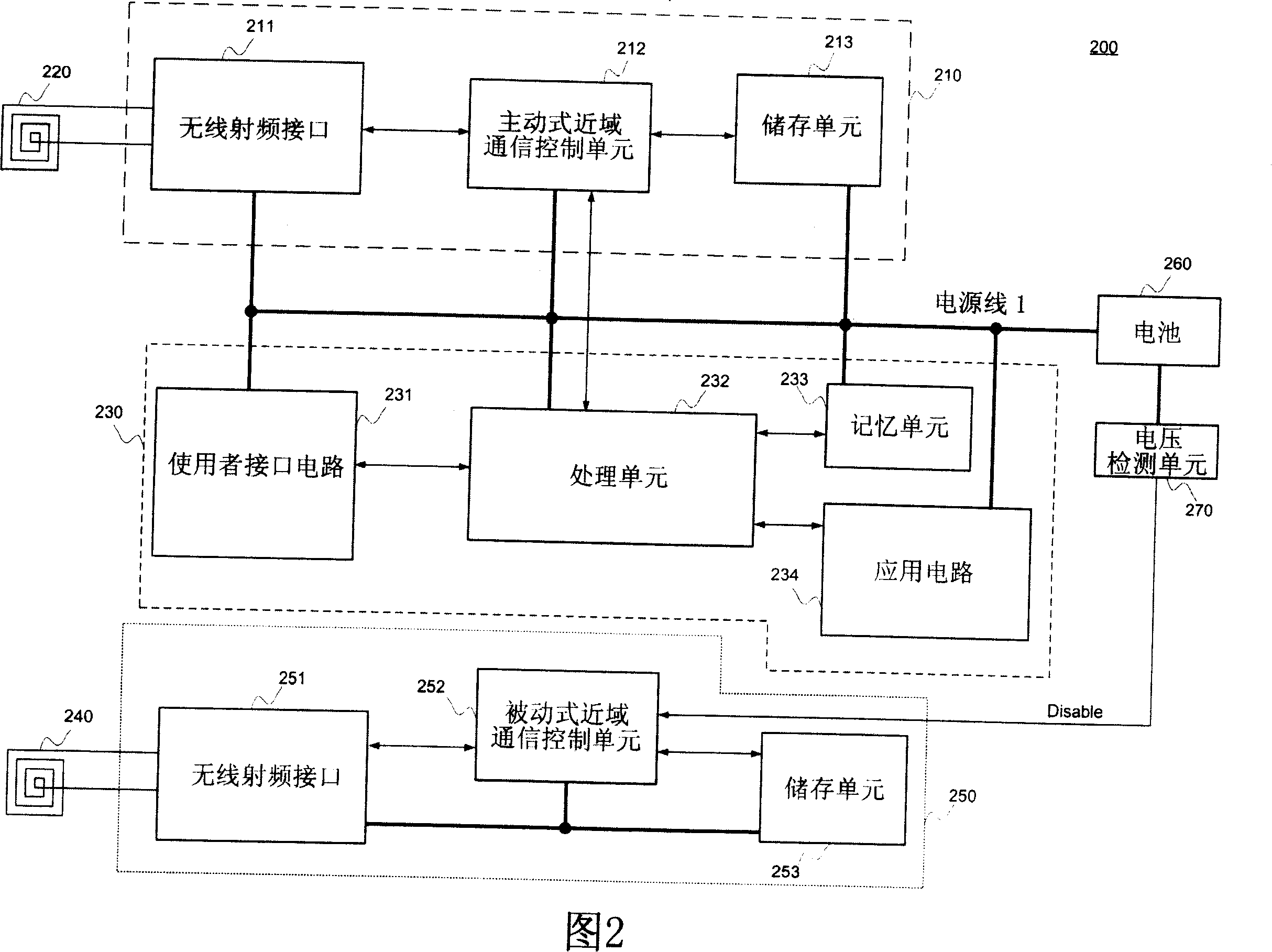

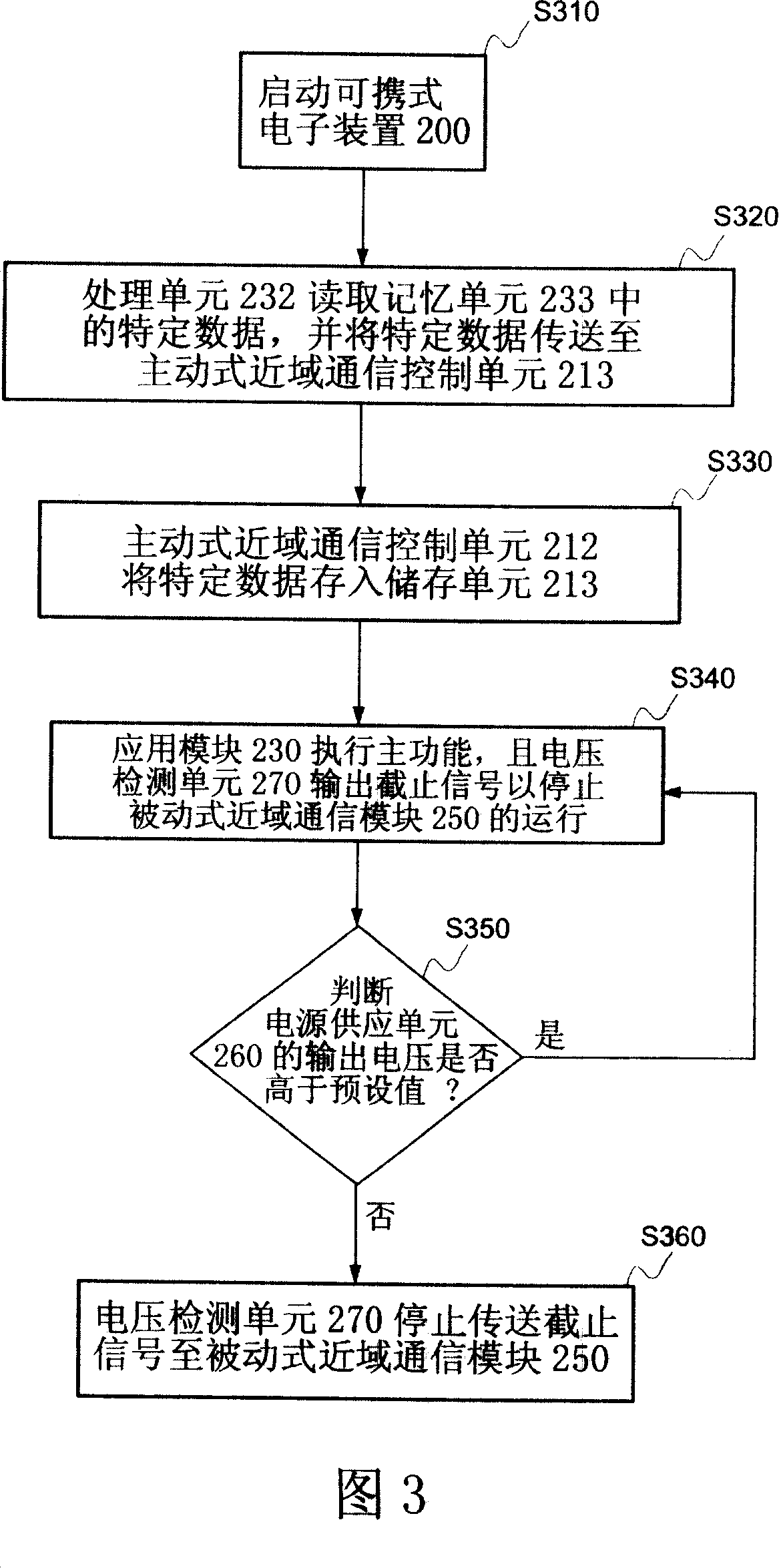

Portable electronic apparatus and operating method thereof

InactiveCN101110600AExit smoothlyNear-field in RFIDNear-field systems using receiversEngineeringApplication module

The invention discloses a portable electronic device and an operation method thereof. The portable electronic device includes an application module, an active near area communication module, a passive near area communication module and a power supply unit. The application module is used for executing a main function of the portable electronic device. The active near area communication module is coupled to the application module and used for communicating with the near area communication devices outside the portable electronic device. The passive near area communication module is used for communicating with the near area communication devices outside the portable electronic device. The power supply unit is coupled to the application module and the active near-area communication module, and is used for providing power required by the application module and the active near-area communication module.

Owner:MSTAR SEMICON INC

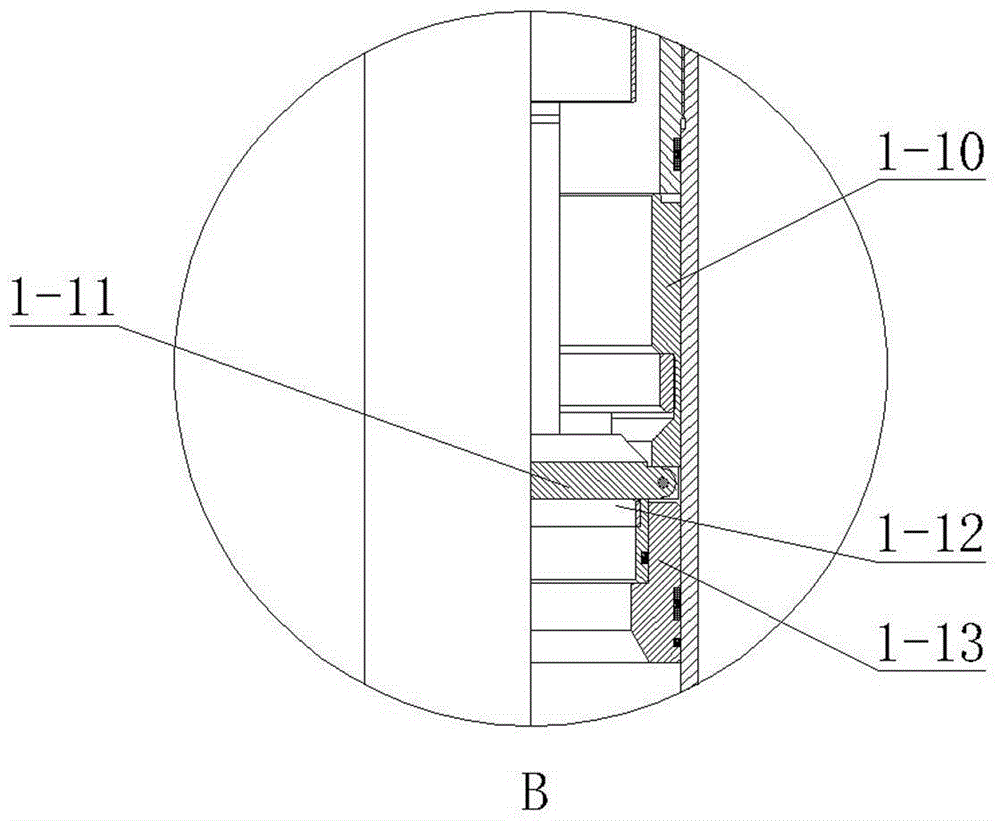

Repeatedly opened and closed anti-leakage valve with cylindrical panel valve sealing structure

ActiveCN104154248AEasy to useTo achieve the purpose of sealingWell/borehole valve arrangementsSealing/packingStructural engineeringMechanical engineering

Owner:DRIPRO

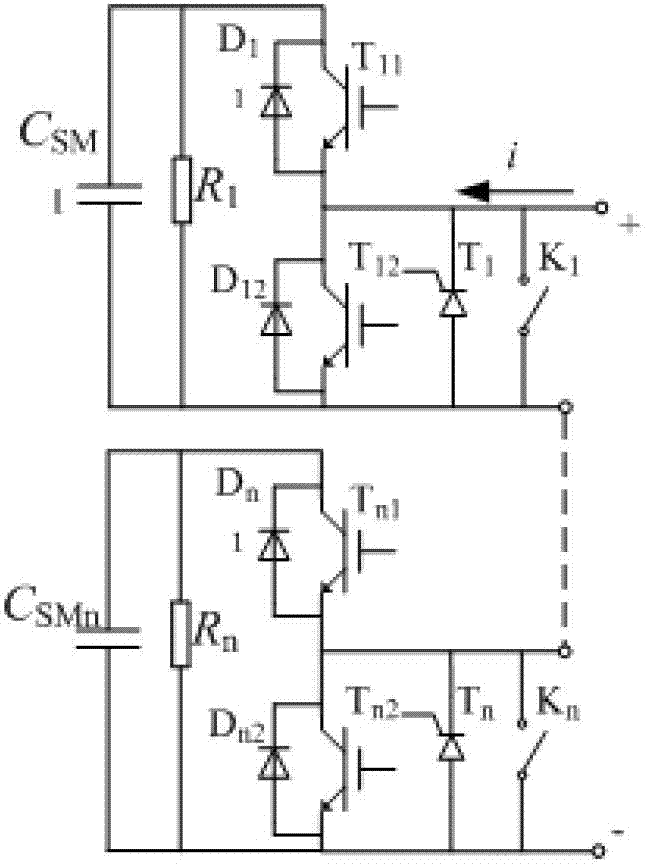

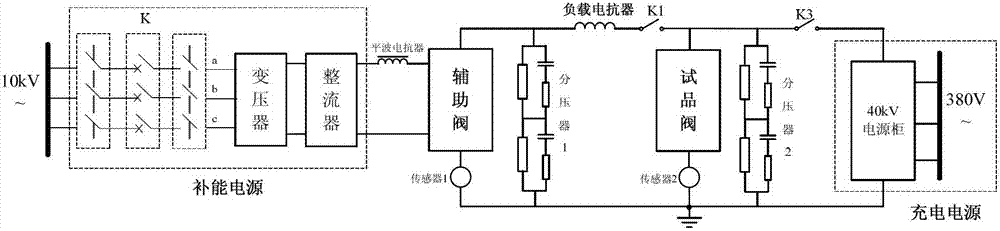

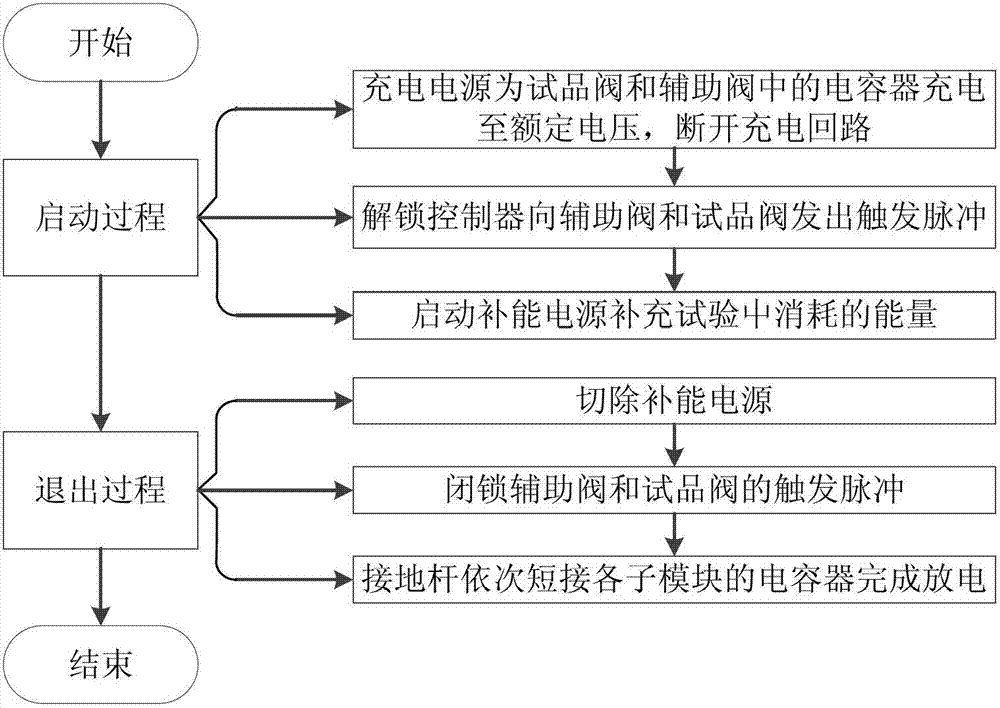

Start and quit method of modular multilevel converter (MMC) valve steady-state operation testing device

ActiveCN103163459AAchieve reasonable cooperationAvoid Overvoltage ProblemsAc-dc conversionPower supply testingComputer moduleEngineering

The invention relates to a start and quit method of a modular multilevel converter (MMC) valve steady-state operation testing device. The start and quit method of the MMC valve steady-state operation testing device comprises a start process and a quit process. The start process includes the following steps that (A) a discharging power source charge capacitors in an auxiliary valve and a specimen valve to nominal voltages, and charging return circuits are disconnected; (B) an unlocking controller sends triggering pulses to the auxiliary valve and the specimen valve; and (C) an energy supplementing power source is started to supplement energy which is consumed in a test. The quit process includes the following steps that (I) the supplementing power source is cut off; (II) the triggering pulses of the auxiliary valve and the specimen valve are closed; (III) a grounded rod is sequentially in short-circuit connection with the capacitors of each submoudle to accomplish discharge. The start and quit method of the MMC valve steady-state operation testing device can achieve reasonable coordination among each power source, the supplementing power source and the controller. The fact that the test can be safely and smoothly implemented is guaranteed. Smooth start and safe quit of the MMC valve steady-state operation testing device can be guaranteed.

Owner:CHINA EPRI ELECTRIC POWER ENG CO LTD +1

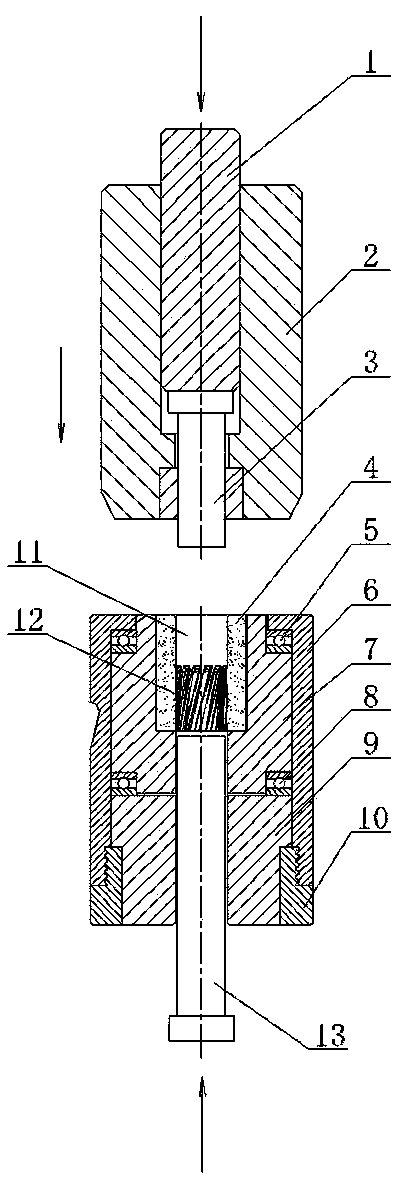

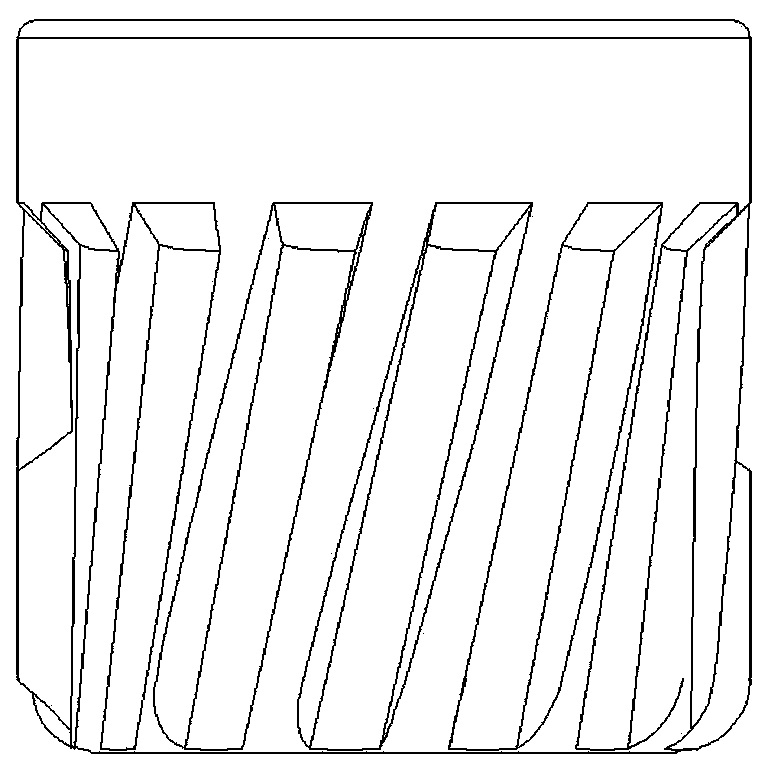

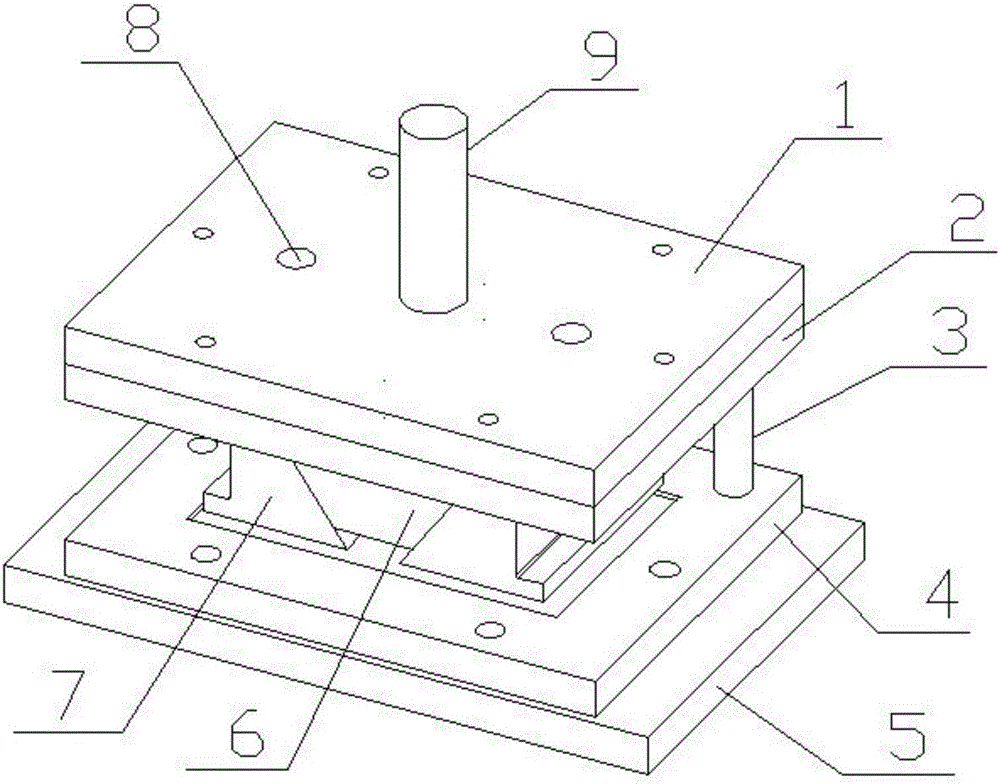

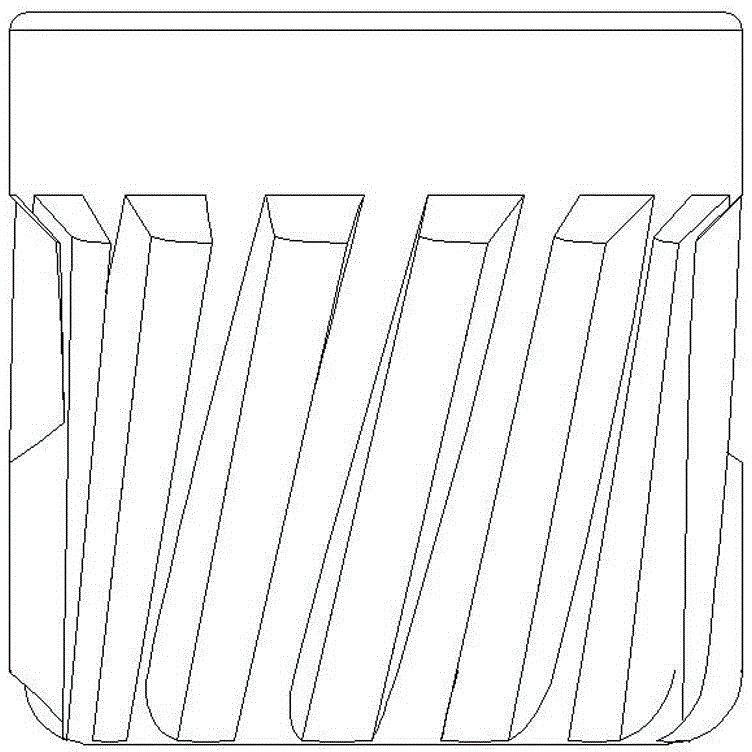

Helical gear heading mold

ActiveCN103447441AImprove processing efficiencyShorten the processing cycleForging/hammering/pressing machinesWheelsGear wheelAlloy

The invention discloses a helical gear heading mold. The helical gear heading mold consists of an upper die and a lower die, and is characterized in that the upper die comprises an upper die sleeve and a punch, wherein the punch is arranged in an inner hole of the upper die sleeve in a vertically moving manner; the lower die comprises a lower die sleeve and a rotary die body; the rotary die body is rotatably arranged in a cavity of the lower die sleeve through upper and lower planar bearings; an inner hole is formed in the middle of the rotary die body for fixing an alloy die core; the alloy die core is provided with a helical gear heading die cavity; the upper section of the die cavity is provided with a straight hole; the lower section of the die cavity is provided with a helical gear cavity which has the same shape as that of a headed helical gear; the bottom of the die cavity is communicated with a rear through ejector rod guide hole; a rear through ejector rod is movably arranged in the rear through ejector rod guide hole; during cold heading forming of the helical gear, the bottom surface of the upper die sleeve is tightly attached to the top surface of the alloy die core, and the head of the punch extends into the die cavity of the alloy die core. According to the helical gear heading mold, cold heading forming of helical gears on cold heading equipment can be realized, the helical gear machining efficiency is greatly improved, the helical gear machining period is shortened and the helical gear manufacturing cost is reduced.

Owner:宁波振华汽车零部件有限公司

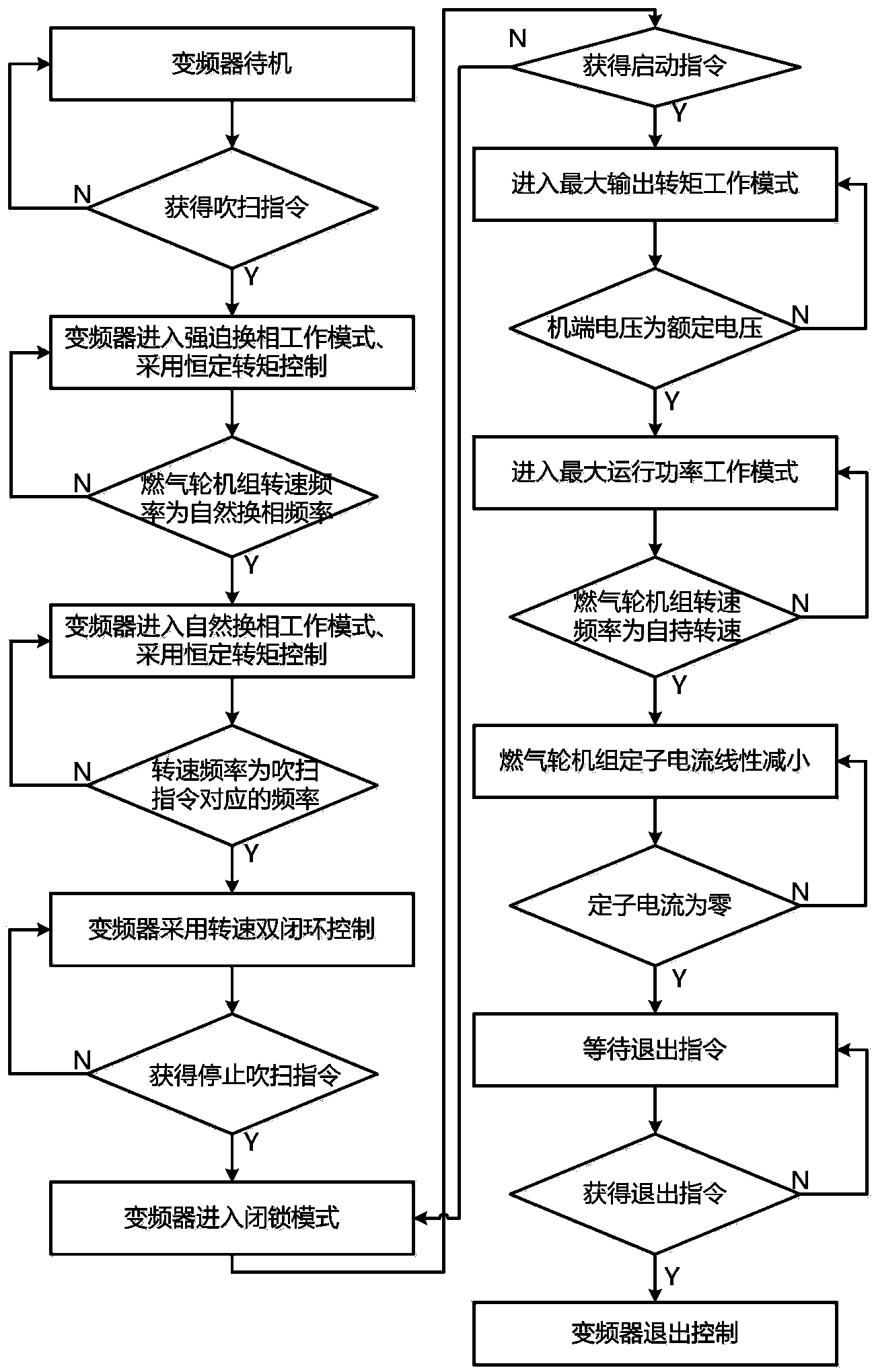

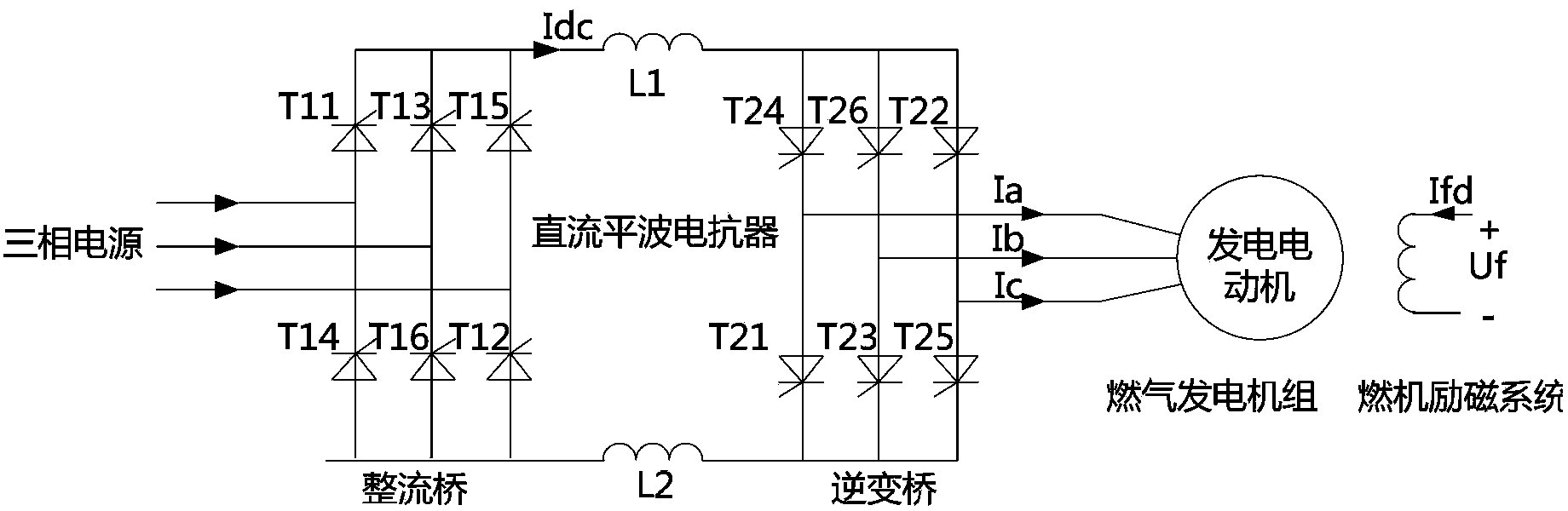

Variable frequency starting control method of heavy-type gas turbine unit

ActiveCN103457529AFast startupPrevent low frequency resonance from occurringElectric generator controlFrequency changerGas turbines

The invention provides a variable frequency starting control method of a heavy-type gas turbine unit. The method comprises the specific steps that A, after receiving a purging command, a frequency changer enters a forced commutation working mode; B, when the rotating speed frequency of the gas turbine unit is the natural commutation frequency, the frequency changer enters a natural commutation working mode; C, after receiving a purging stopping command, the frequency changer enters a locking mode; D, after receiving a starting command, the frequency changer enters a maximum output torque working mode; E, after the voltage of a generator terminal reaches the nominal voltage of the frequency changer, the frequency changer enters a maximum operation power working mode of the gas turbine unit; F, when the rotating speed of the gas turbine unit is the self-sustaining speed, the frequency changer enters a locking mode, and after receiving an exit command, the frequency changer enters the standby state. Compared with the prior art, the variable frequency starting control method of the heavy-type gas turbine unit provides the control strategy for different starting stages and the operation switching mode of the gas turbine unit, and the coordination control over the rotating speed of the gas turbine unit and the voltage of the generator terminal is achieved.

Owner:STATE GRID CORP OF CHINA +1

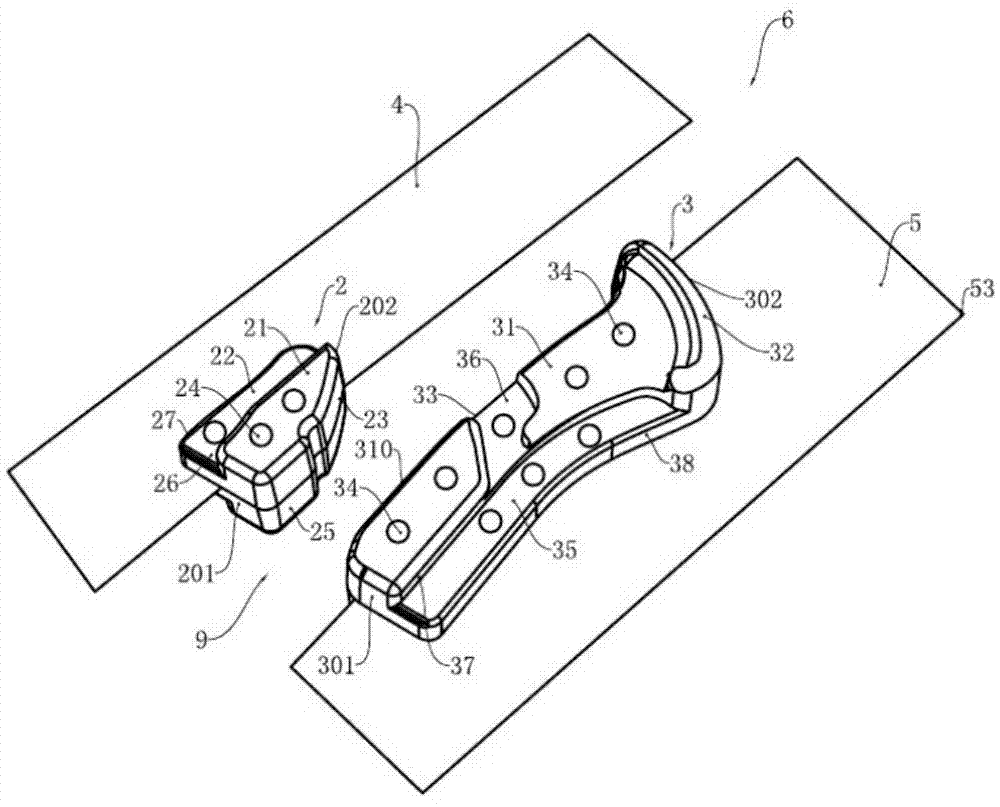

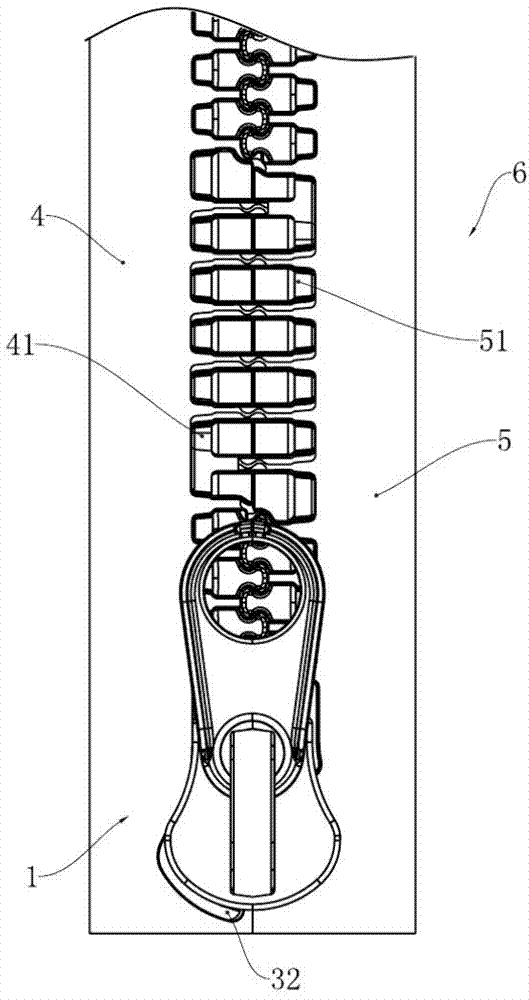

Quick-release zipper with upper stopping assembly, and clothes using zipper

The invention relates to a quick-release zipper, which comprises a left zipper tape, a right zipper tape, an upper stopping assembly and a zipper slider, wherein the upper stopping assembly comprises left and right upper stopping pieces which are arranged at the left and the right, and the right upper stopping piece comprises a right upper stopping main body inserted into the zipper slider; the axial extension length of the right upper stopping main body is not less than the length of the zipper slider, and a bulge capable of preventing the zipper slider from separating is arranged at the top of the right upper stopping main body; an outer convex arc part is arranged on the side in the right upper stopping main body, and the highest point of the outer convex arc part is positioned at the middle or middle lower area of the inner side of the right upper stopping main body; the outer side of the right upper stopping main body extends to the top end direction from the tail end in a smooth way, and the left upper stopping piece comprises a left upper stopping main body which can be accommodated by the zipper slider; and the axial extension length of the left upper stopping main body accommodated by the zipper slider is less than the length of the zipper slider. The invention also discloses clothes using the quick-release zipper. The lower stopping assembly is positioned at the upper part of the clothes, and the upper stopping assembly is positioned at the lower part of the clothes. With the characteristics and advantages, the invention can be applied to the upper stopping assembly of the quick-release zipper and the clothes.

Owner:KEE (GUANGDONG) GARMENT ACCESSORIES LTD

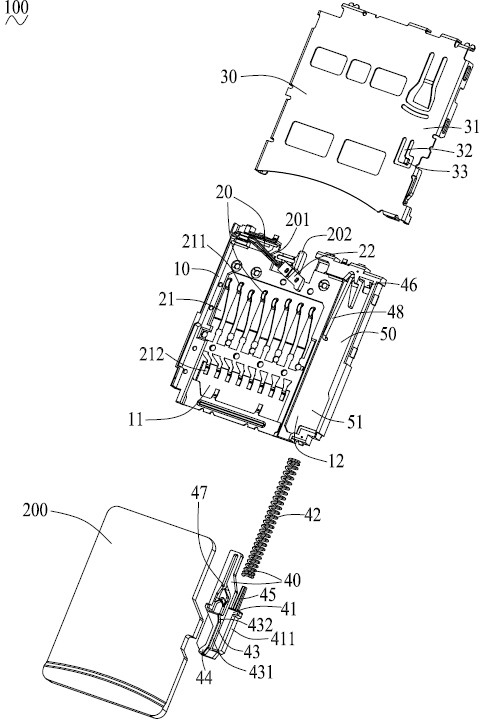

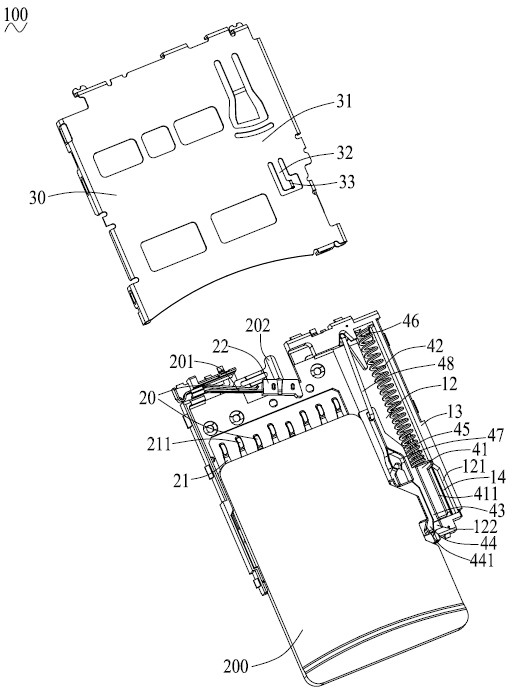

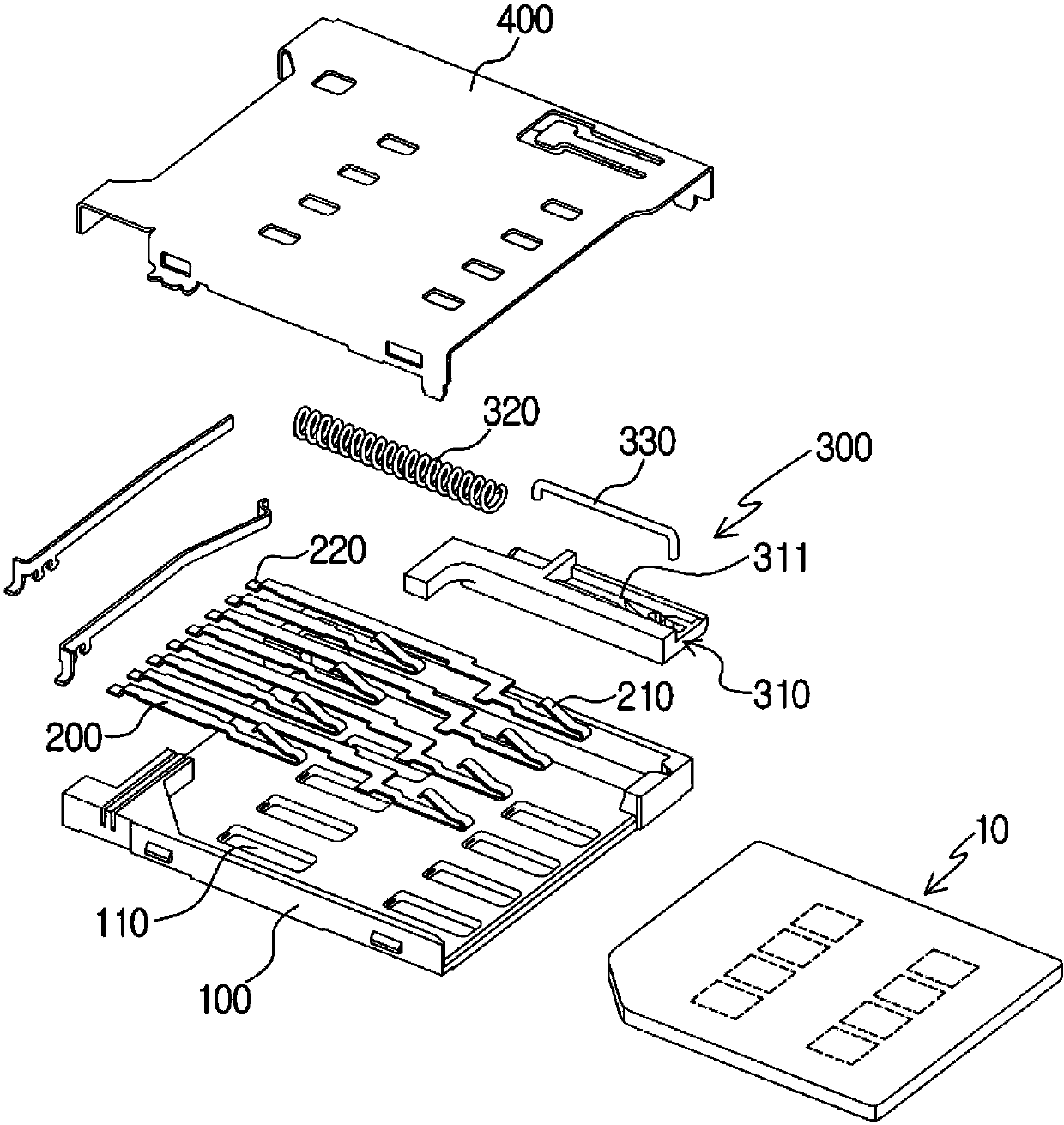

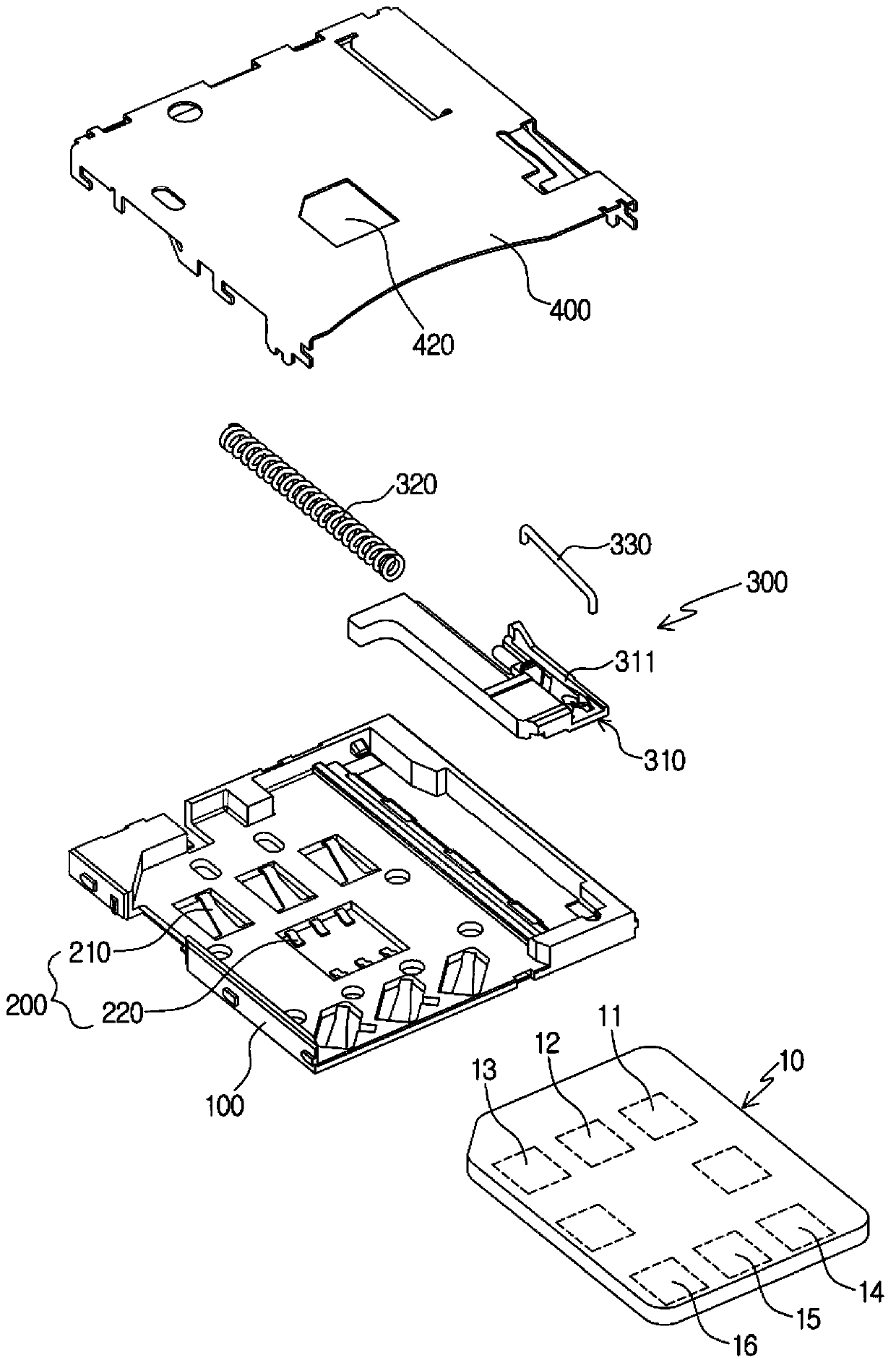

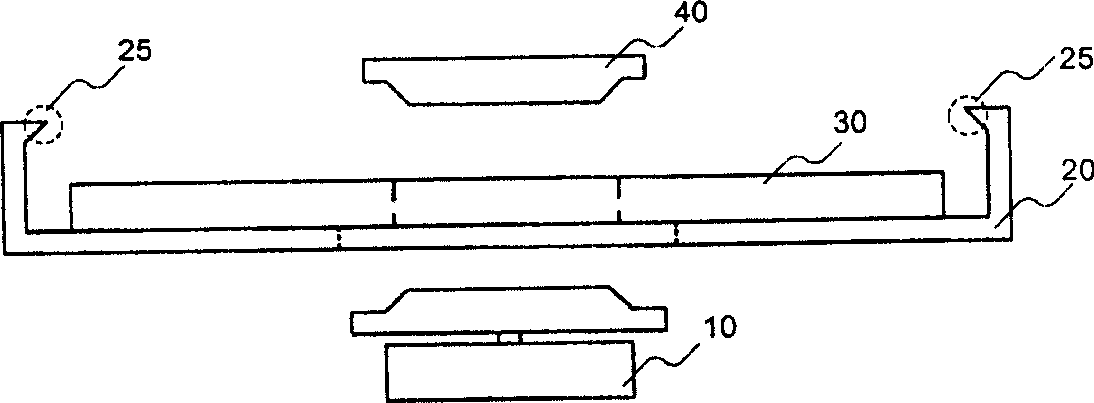

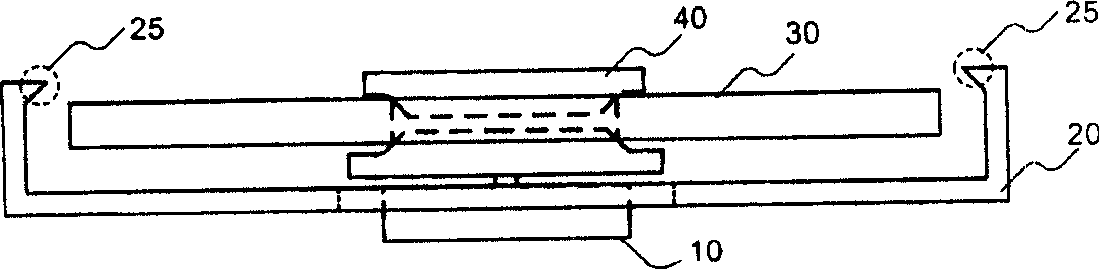

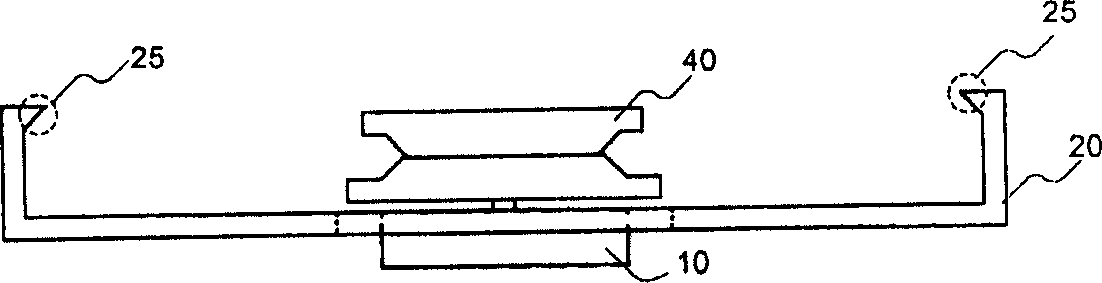

Card connector

ActiveCN102683985ALimit side to side shakingLimit shakingCoupling device detailsButt jointEngineering

The invention provides a card connector. The card connector comprises an insulating body, a plurality of conductive terminals fixed in the insulating body, a card withdrawing mechanism mounted on the insulating body and a shielding casing for shielding the insulating body, wherein the card withdrawing mechanism consists of a sliding block movably positioned on the insulating body, and an open slot in along the insertion direction of a butt joint electric card is formed on the sliding block; the shielding casing is provided with an upper wall for shielding the insulating body, and a cantilever extending in the insertion direction of the butt joint electric card and a bending piece extending downwards in the thickness direction of the upper wall from the rear end of the cantilever are arranged on the upper wall; and the bending piece extends downwards and enters into the open slot, and the bending piece is capable of preventing the insulating body from shaking side to side when the card connector is in an operation state, so as to prevent the butt joint electric card from withdrawing.

Owner:KUNSHAN JIAHUA ELECTRONICS

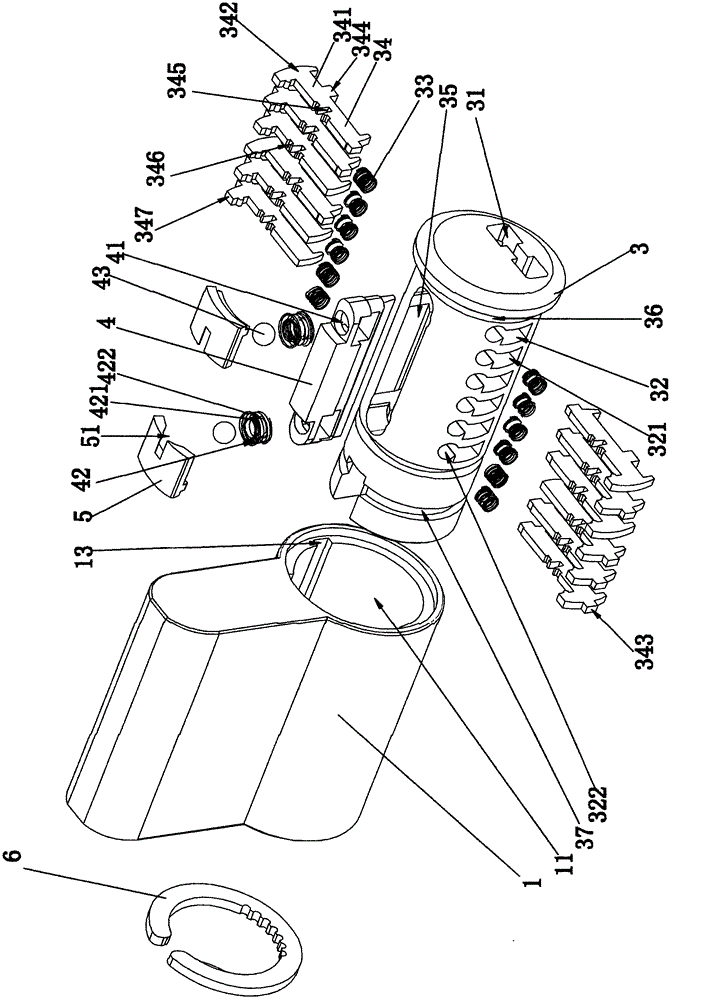

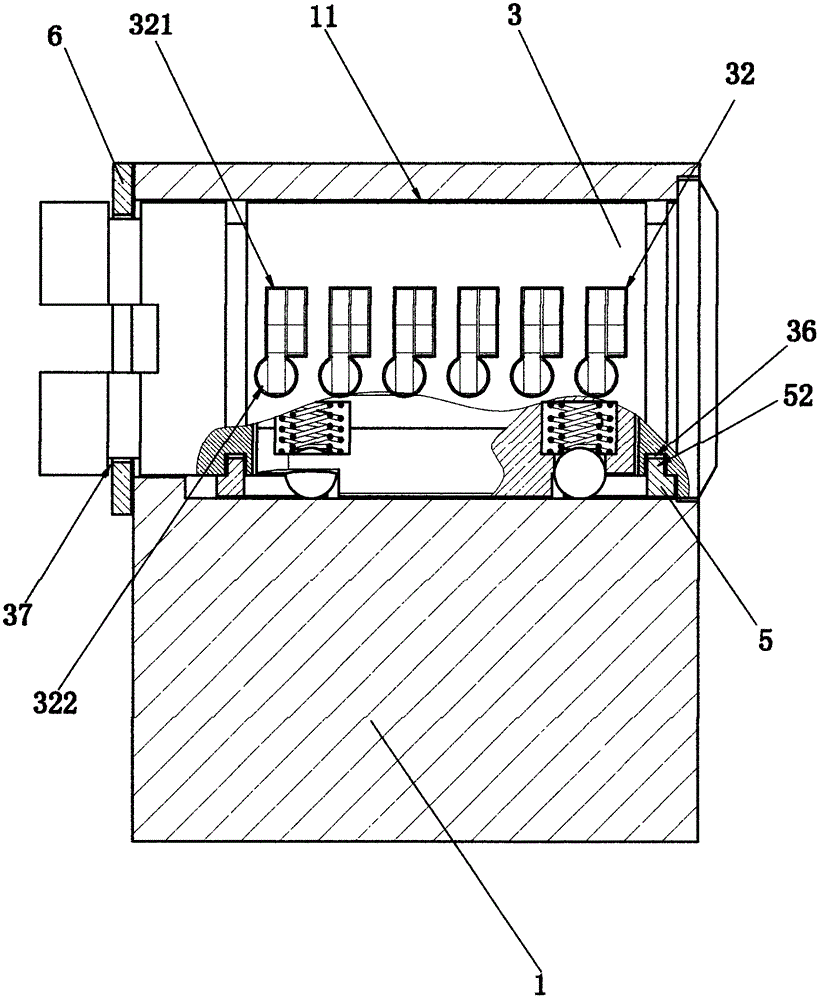

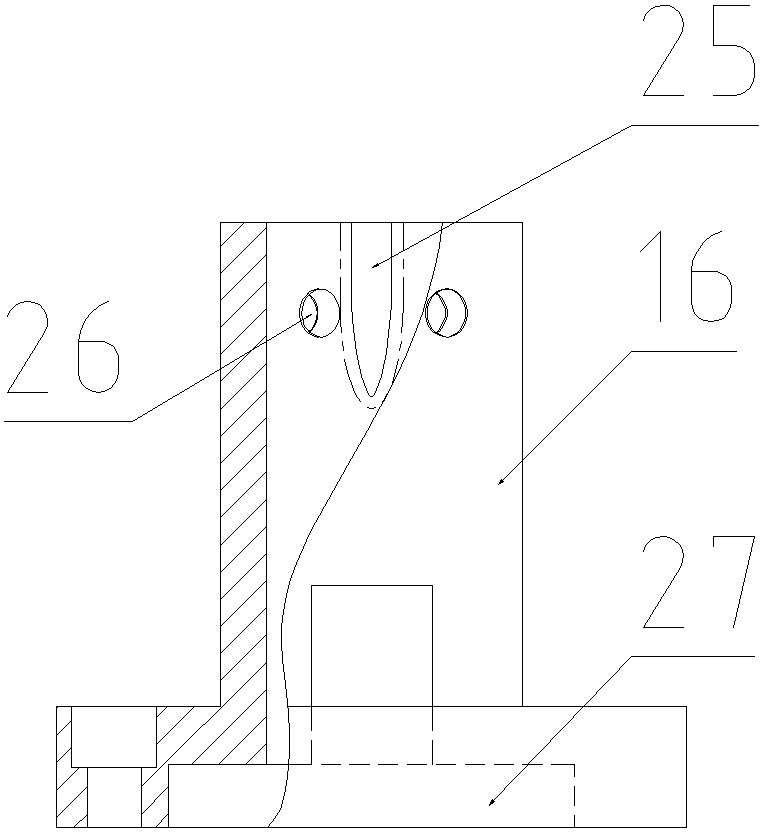

Passive-mode flexible-linkage plunger lock

The invention discloses a passive-mode flexible-linkage plunger lock. The lock comprises a lock case, a key and a lock cylinder, wherein a large lock case hole is formed in the lock case, a key hole is formed in the lock cylinder, slide fastener locking grooves and locking blade locking slots are formed in the large lock case hole, lock cylinder side holes are formed in the side wall of the lock cylinder, and blade springs and blades are arranged in the lock cylinder side holes; each blade comprises a blade body and blade end parts, locking bosses are arranged at the blade end parts, an unlocking slot and a false slot are formed in the blade body and matched with teeth of the key, and a blade spring boss is arranged in the position, close to the end part of the corresponding blade, of the blade body; the blade springs are propped against the blade spring bosses, the other ends of the blade springs are propped against the inner wall of the lock cylinder, a plunger groove is formed in the side wall of the lock cylinder, a locking plunger is arranged in the plunger groove, plunger inner holes are formed in the locking plunger, composite springs and steel balls are arranged in the plunger inner holes, the steel balls are covered with slide fasteners embedded in the slide fastener locking grooves, and a V-shaped groove is formed in each slide fastener. According to the passive-mode flexible-linkage plunger lock, technical opening difficulty is increased, the probability of illegal opening of the lock cylinder is effectively reduced, and safety and reliability are improved.

Owner:WENZHOU JUSHI SECURITY TECH CO LTD

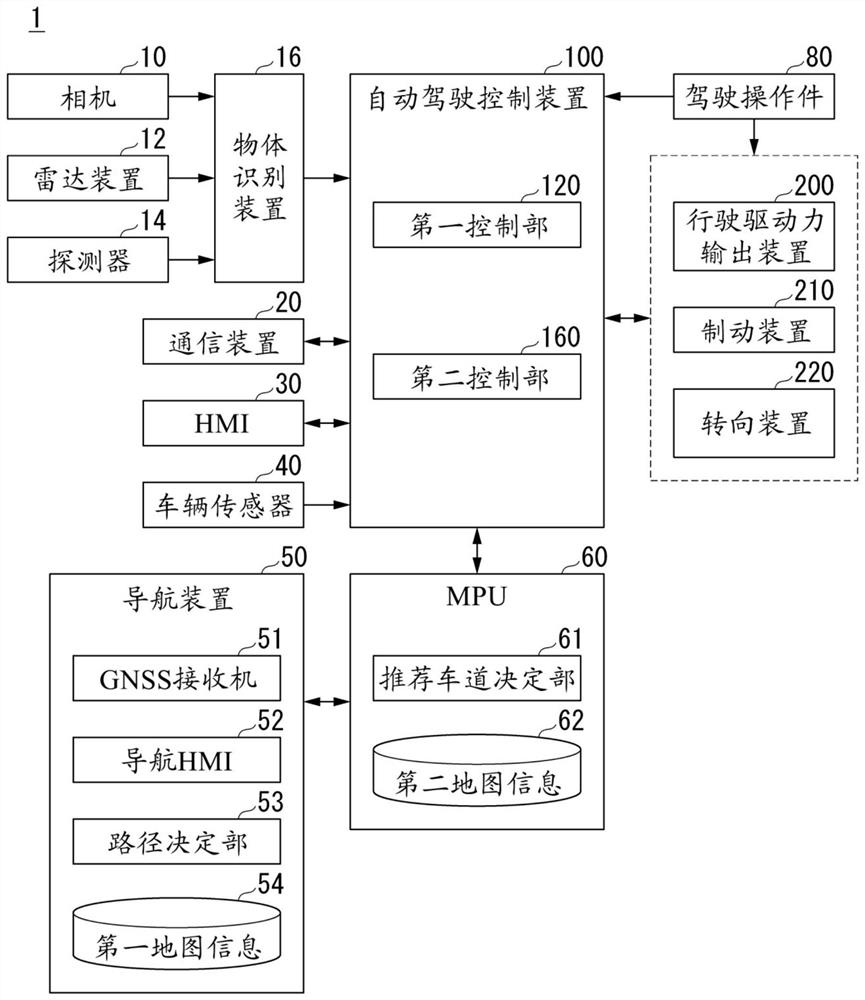

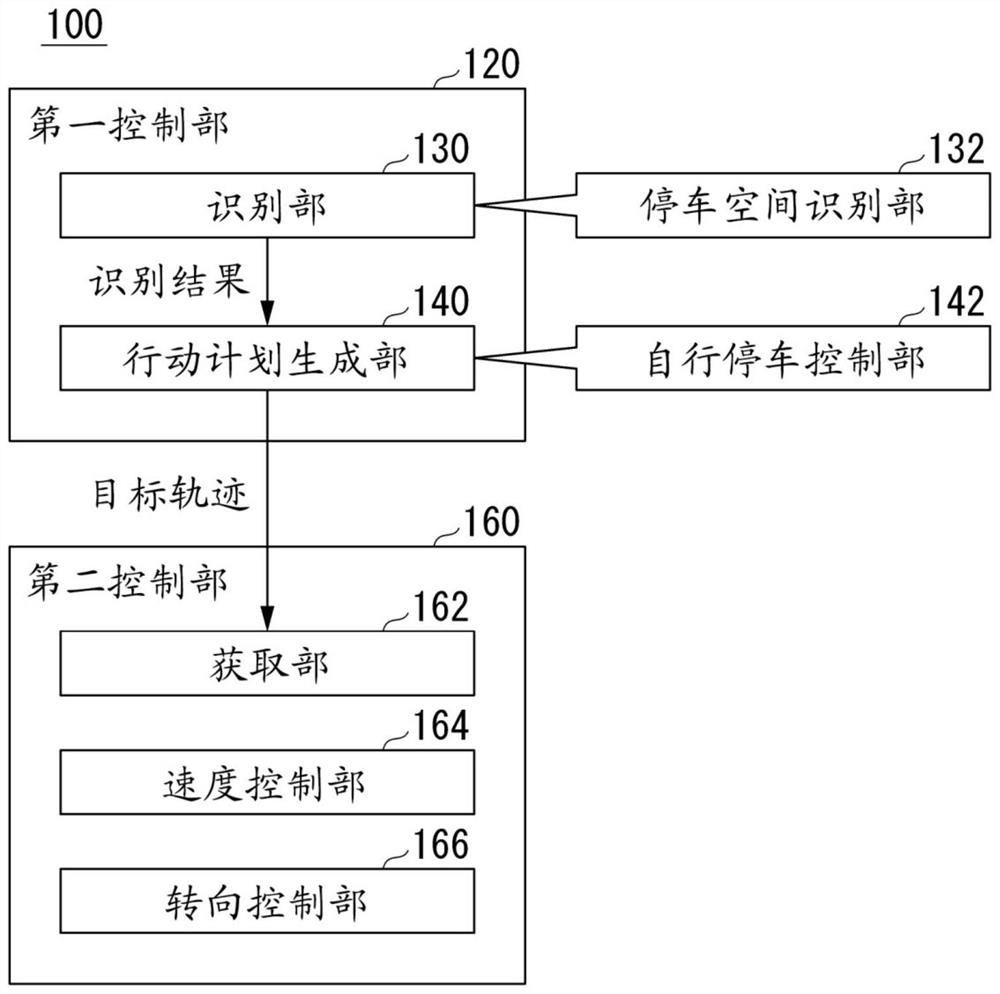

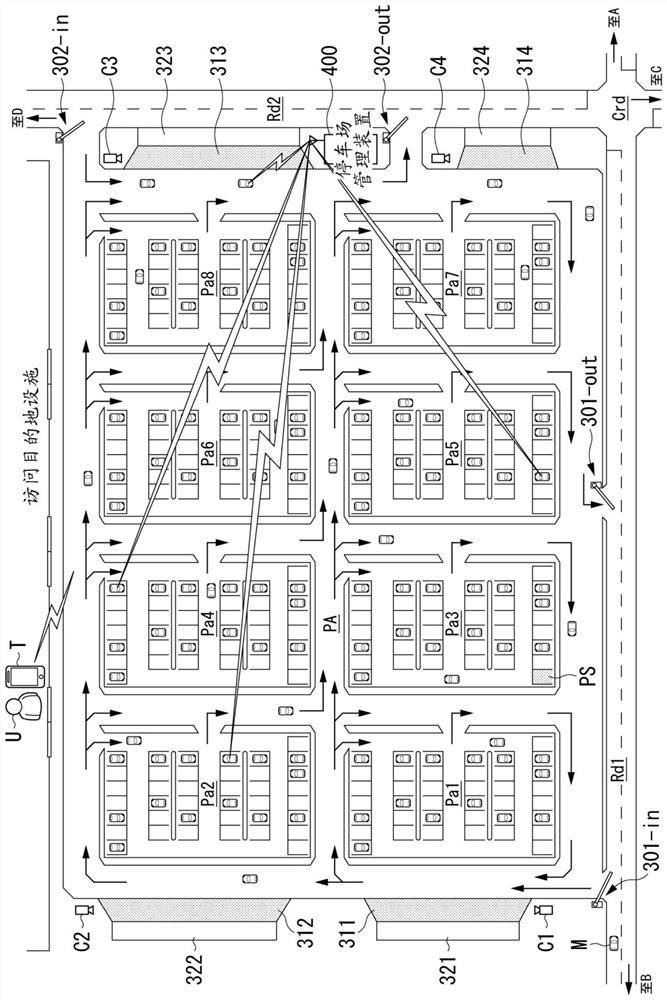

Parking lot management device, parking lot management method, and storage medium

ActiveCN111833645AExit smoothlyTicket-issuing apparatusReservationsParking spaceTransport engineering

The invention relates to a parking lot management device. The parking lot management device includes a platform selector configured to refer to information associated with a parking lot having a plurality of platforms and select one or more platforms from among the plurality of platforms in response to a leaving request for requesting movement of a vehicle parked in the parking lot from a parkingposition of the vehicle to the platform.

Owner:HONDA MOTOR CO LTD

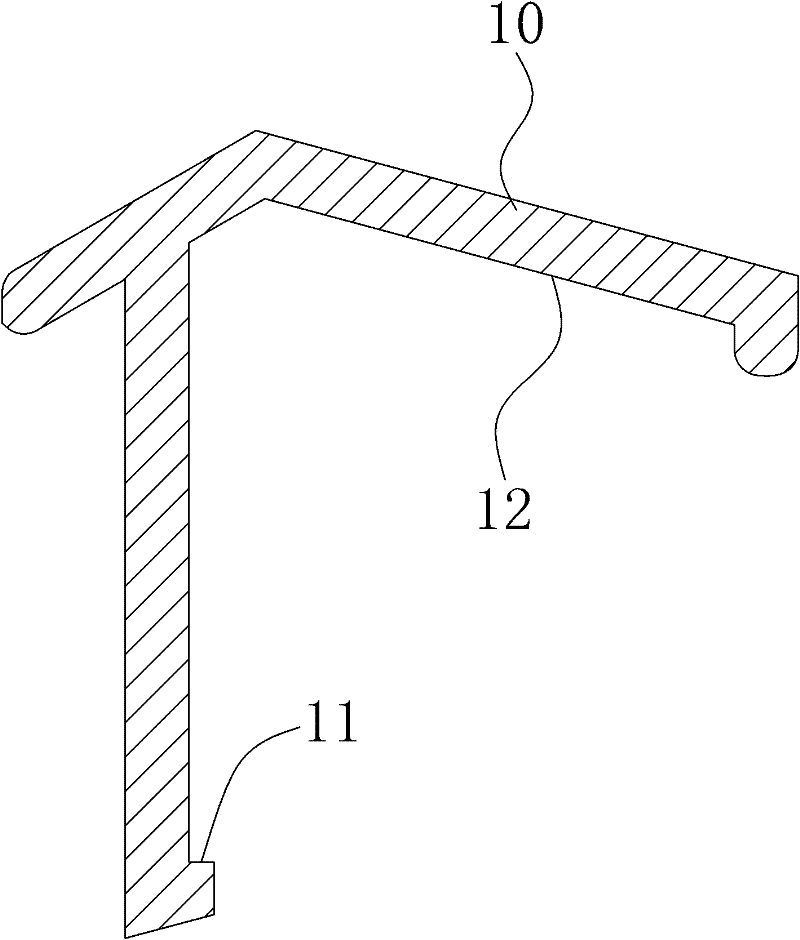

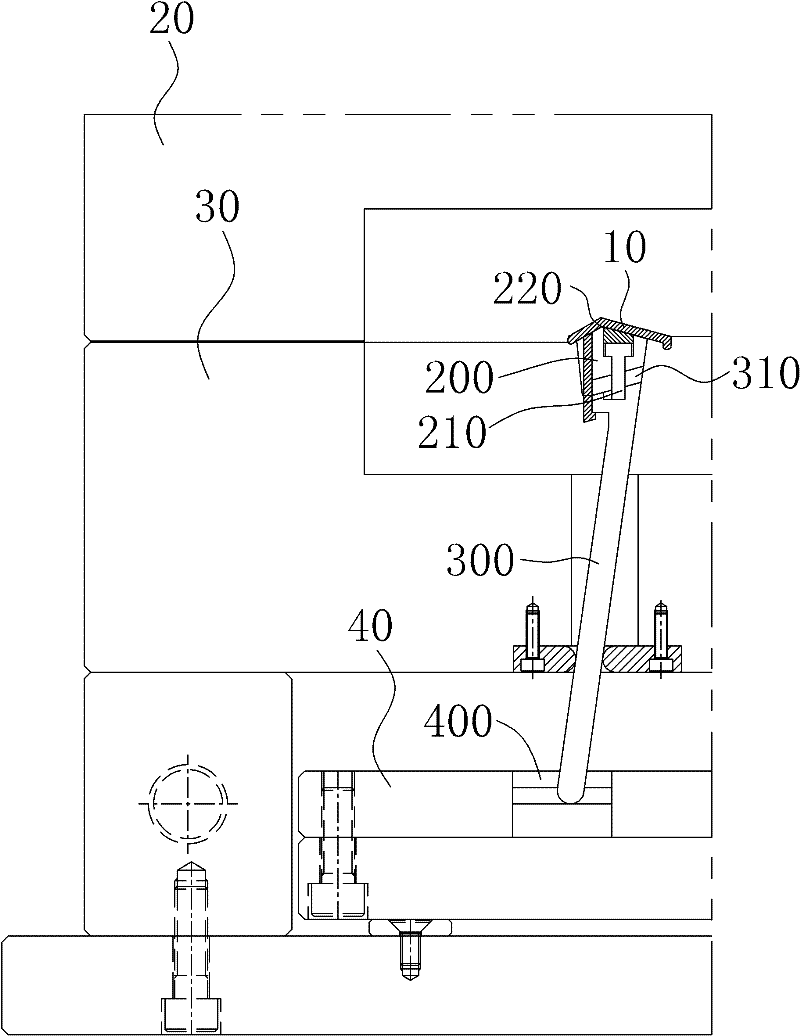

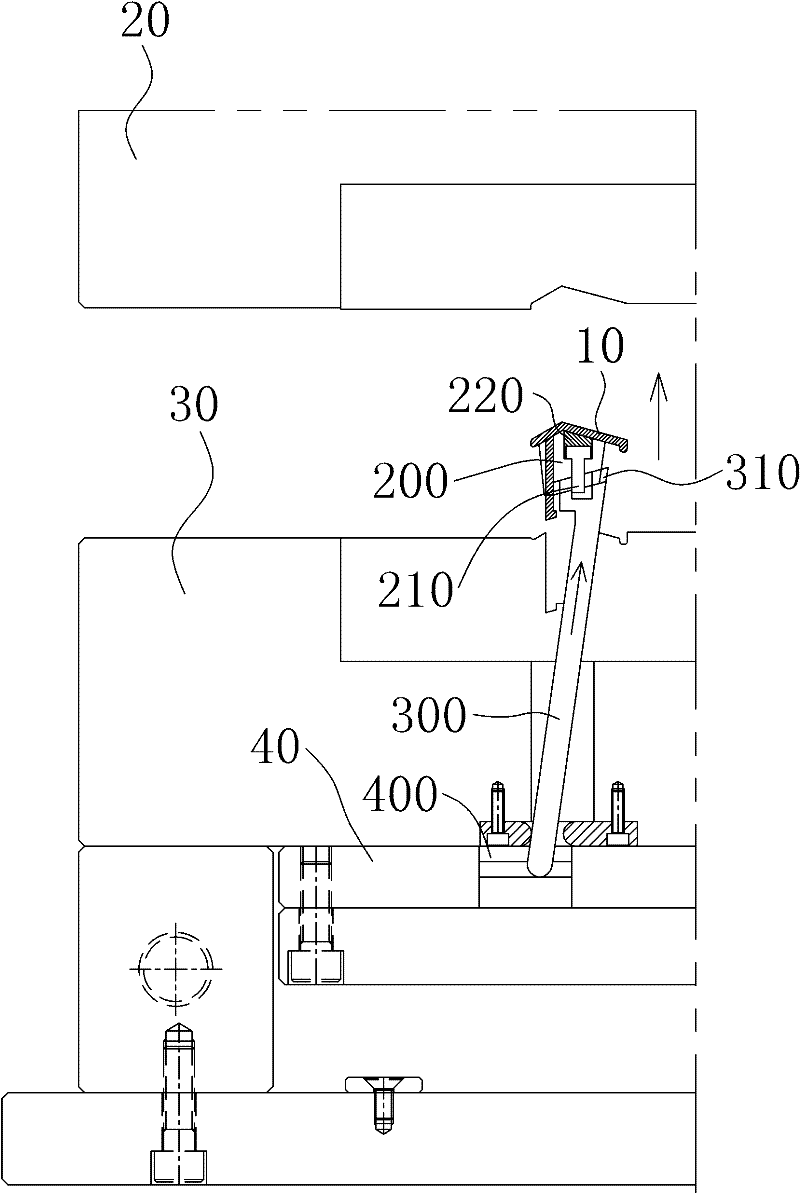

Bending die for producing electric box

Owner:LITEHARBOR LIGHTING TECHNOLOGY CO LTD

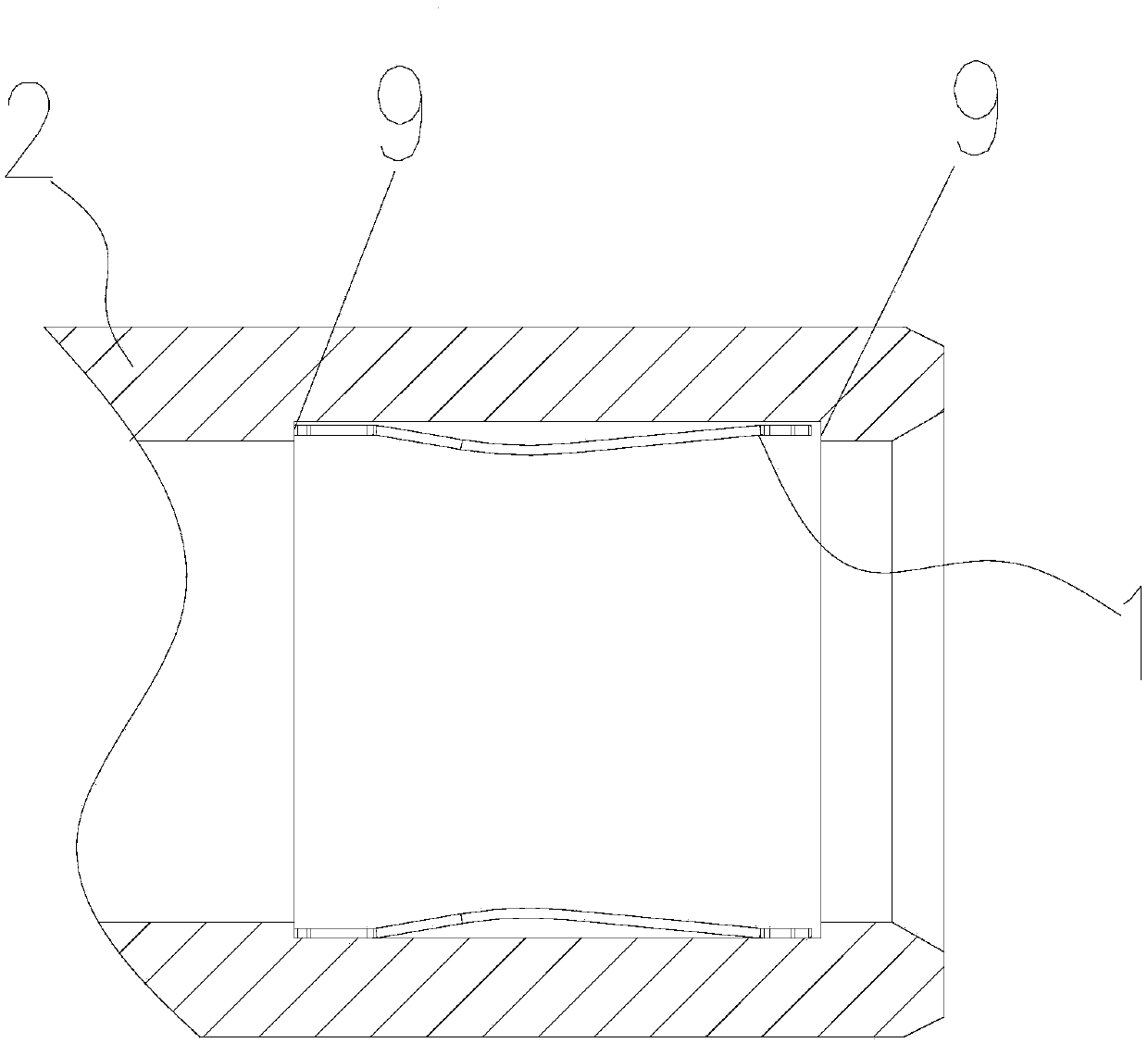

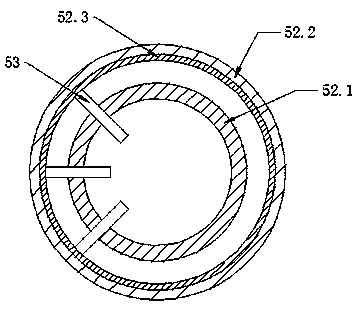

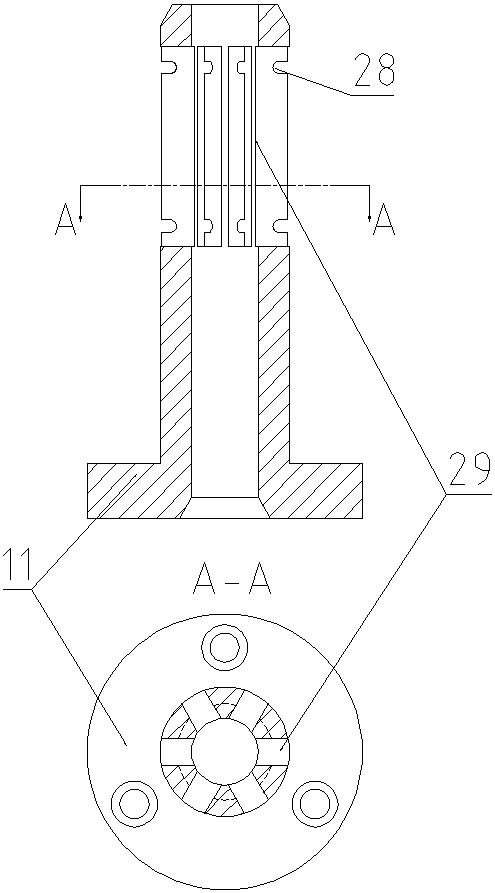

Crown spring mounting structure with good restriction and convenient disassembly

InactiveCN109638511AEasy charging connectionAvoid axial displacement and circumferential displacementSecuring/insulating coupling contact membersCoupling contact membersEngineeringAxial displacement

The invention belongs to the technical field of electric connectors and particularly relates to a crown spring mounting structure with good restriction and convenient disassembly. The crown spring mounting structure includes a crown spring and a sleeve. Elastic folding plates are uniformly distributed on the outer circumferential surfaces of the two ends of the crown spring. A plurality of throughholes are uniformly arranged on the cylinder surfaces of the two ends of the sleeve. The elastic folding plates are disposed in the through holes and have opposite folding directions. The free ends of the elastic folding plates are abutted against the walls of the through holes. The crown spring mounting structure has the beneficial effects that the axial displacement and the circumferential displacement of the crown spring in the sleeve can be avoided, the connection structure of the crown spring and the sleeve is firmly installed, which is convenient for charging connection; regardless of the diameter of the crown spring, the crown spring is convenient to disassemble and convenient to be taken out of the sleeve, thereby contributing to the maintenance of the crown spring; when the crownspring is maintained, the replacement of the connection structure of the sleeve and the crown spring can be avoided and the maintenance cost is saved.

Owner:JIANGSU WANBANG DEHE NEW ENERGY TECH CO LTD

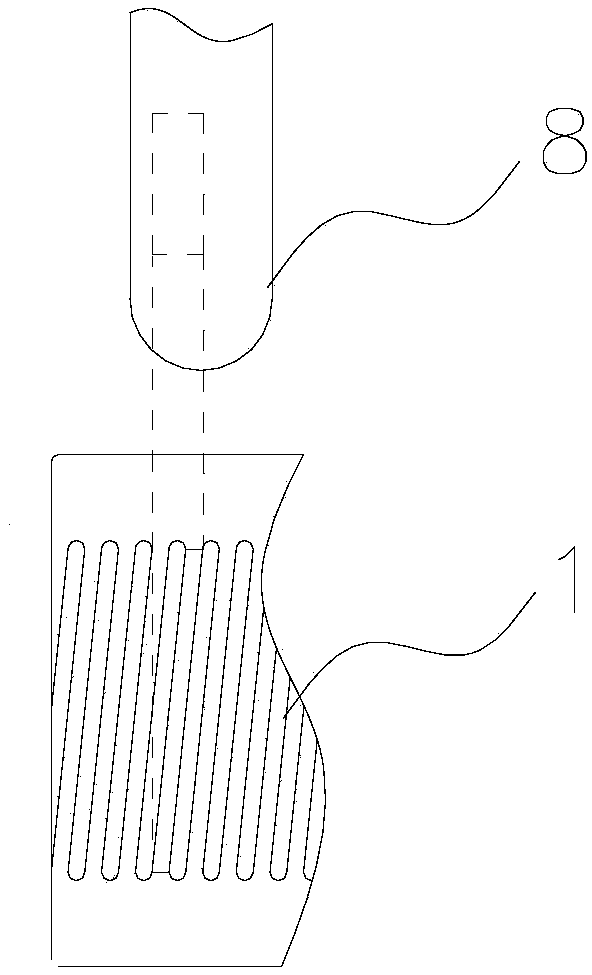

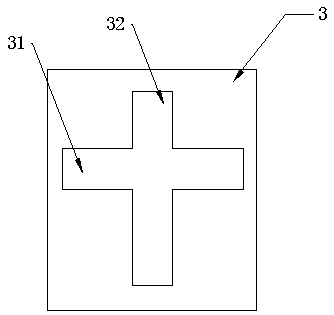

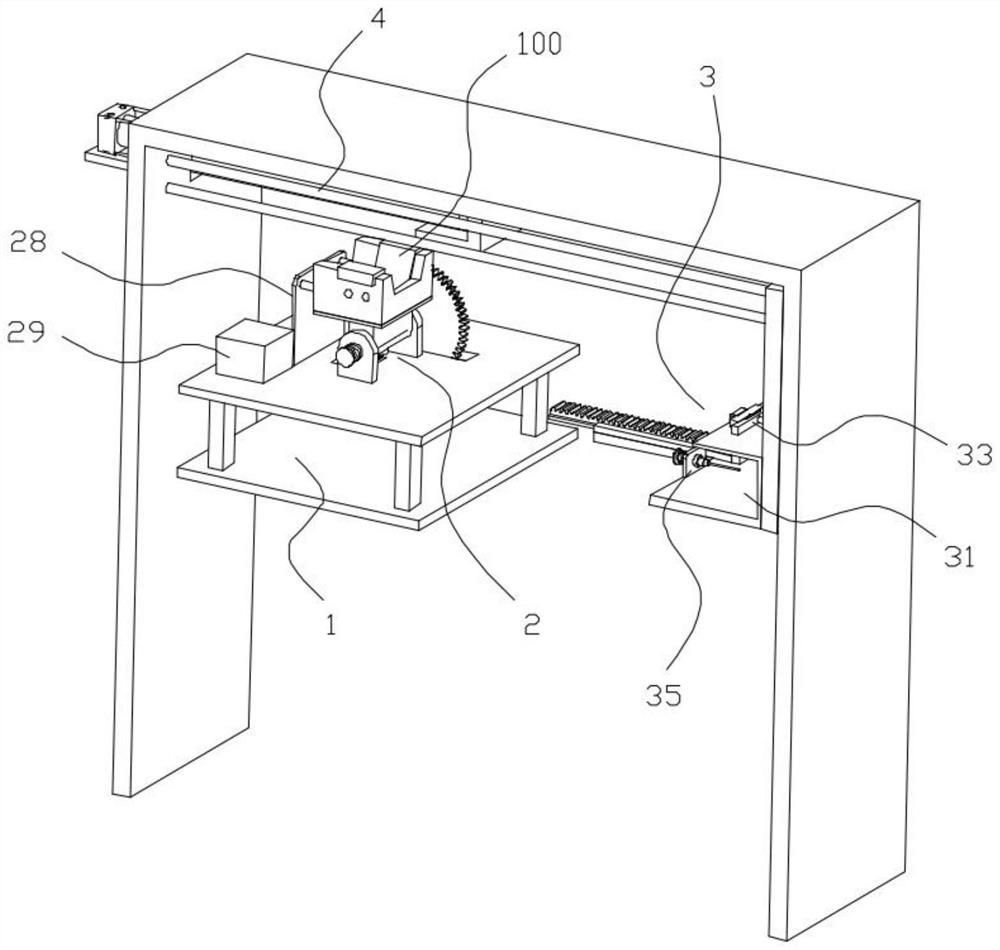

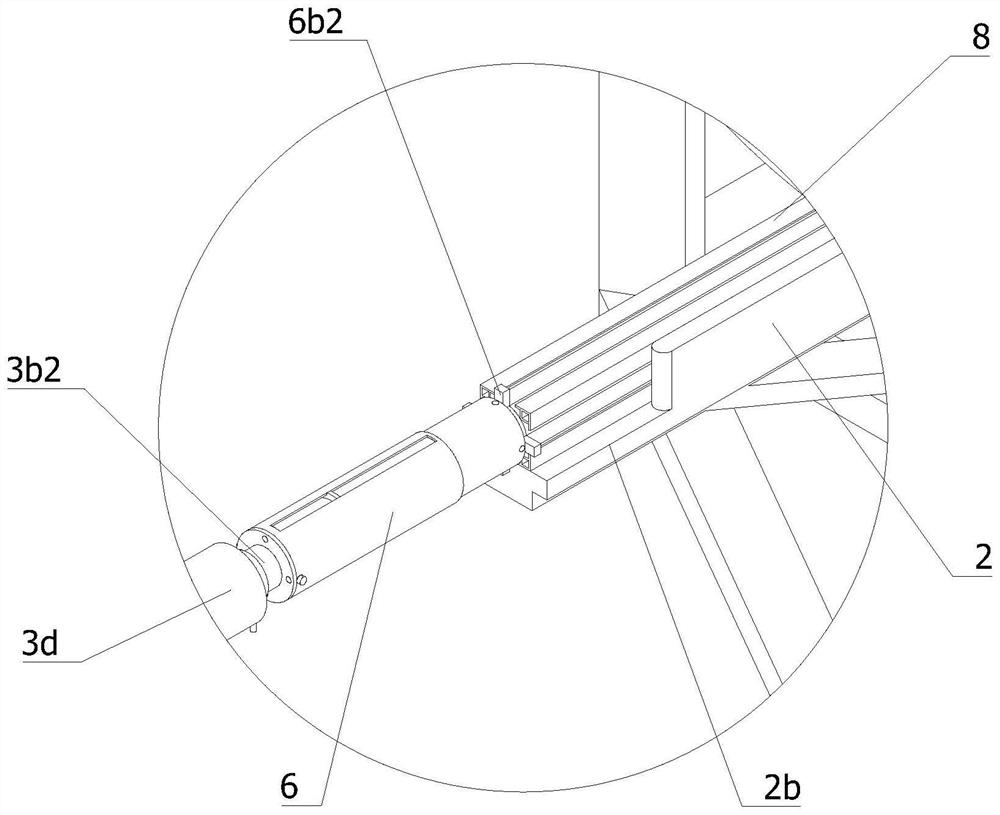

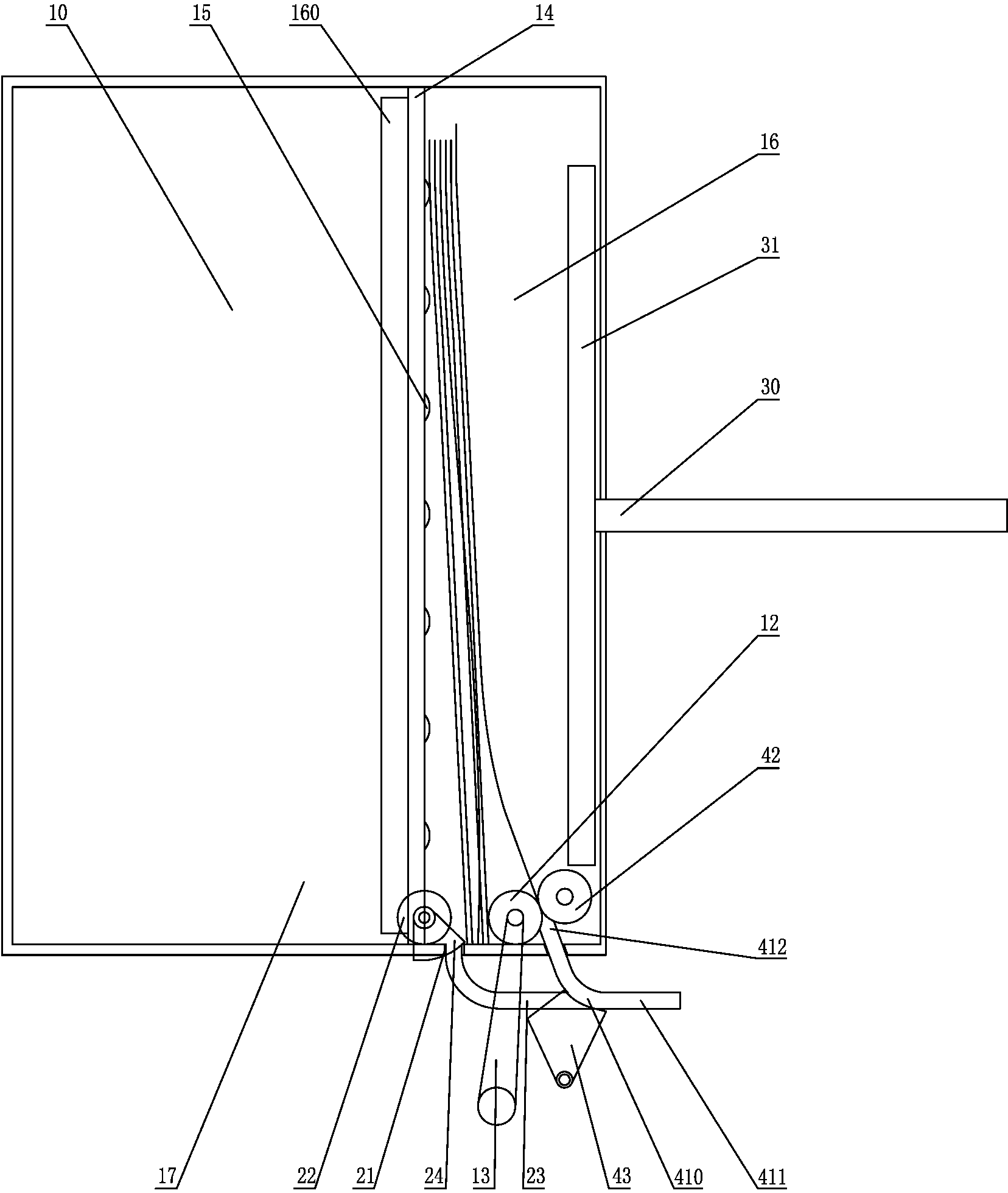

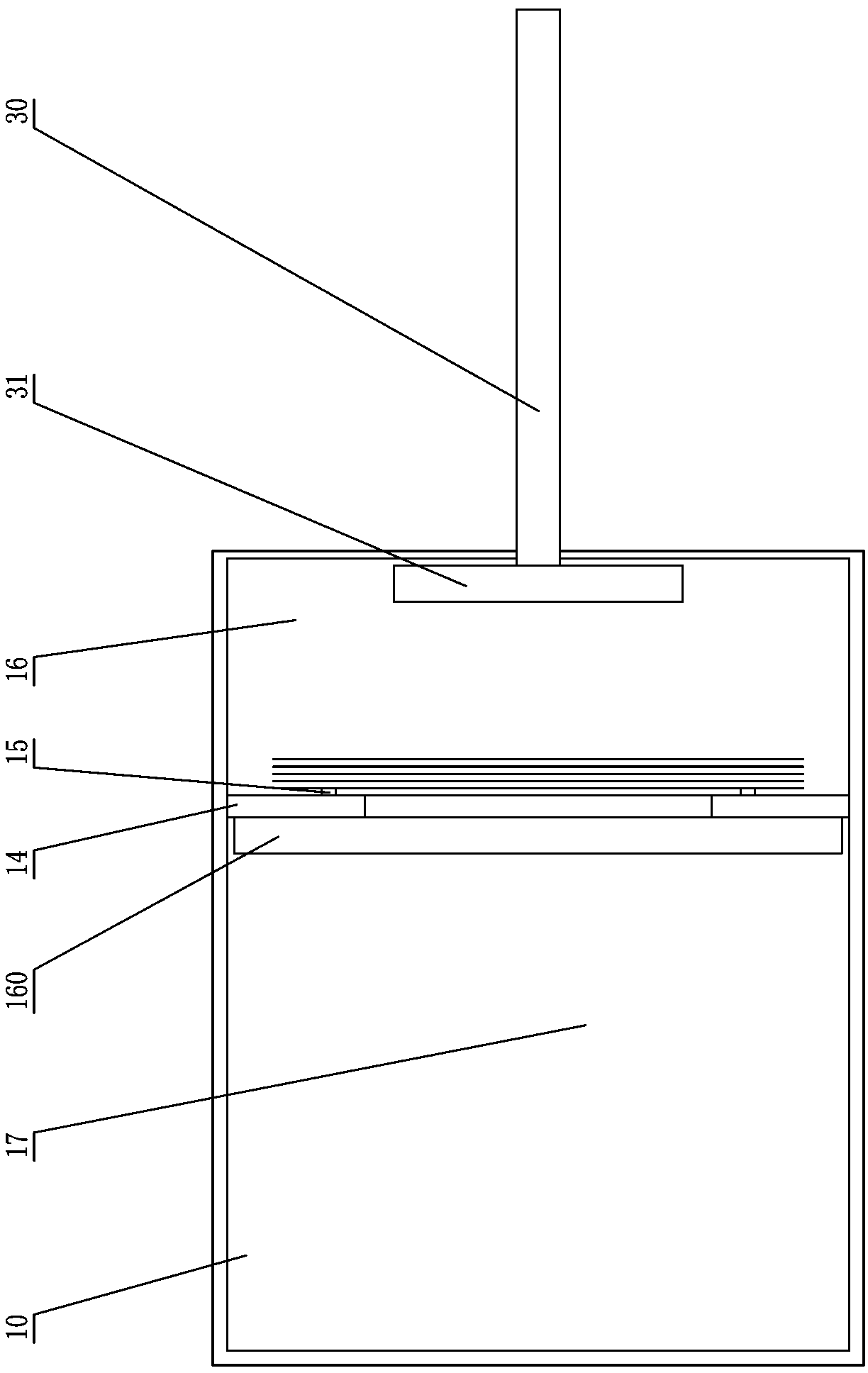

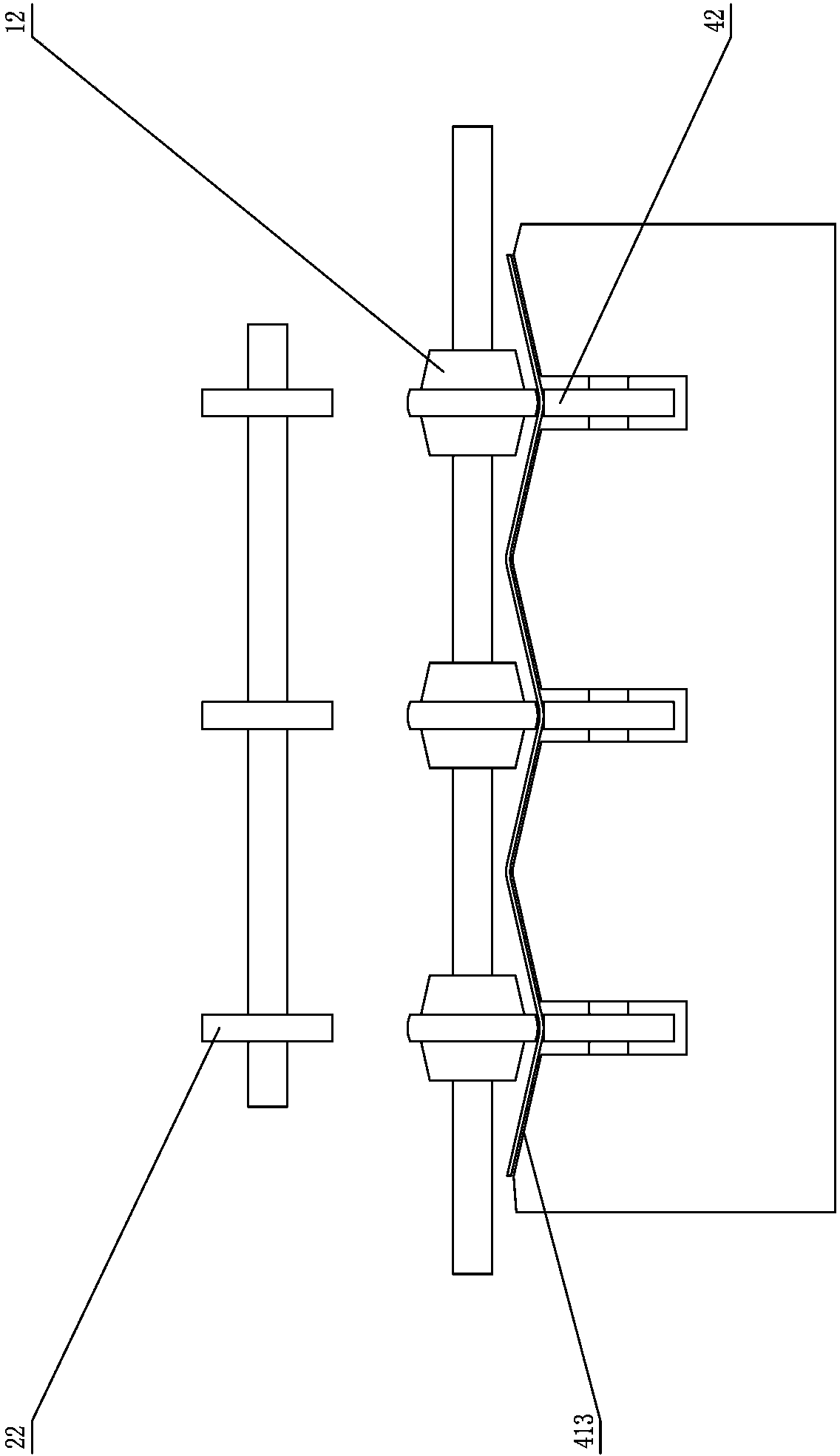

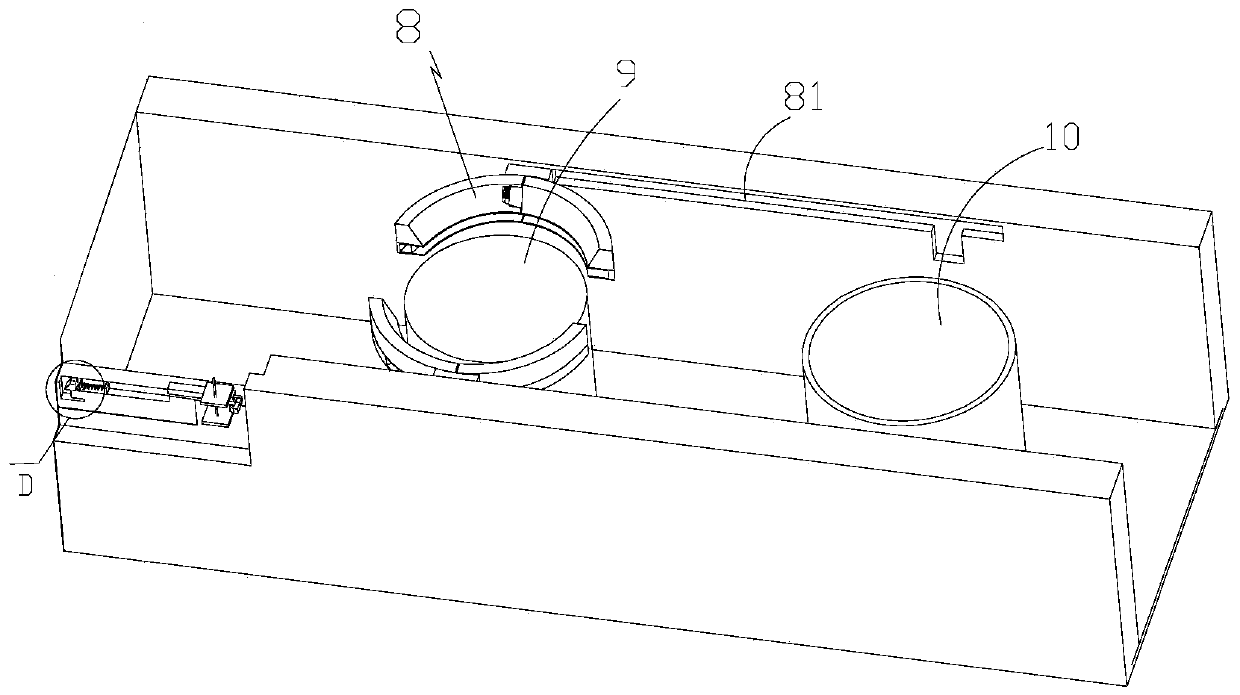

Inner and outer bag automatic thermal bonding device

InactiveCN112339348AAchieve alignmentEasy to operateBag making operationsPaper-makingEngineeringBilateral symmetry

The invention relates to an inner and outer bag automatic thermal bonding device. The device comprises a main frame body, an opening mechanism, a stretching mechanism and an edge folding thermal bonding mechanism, wherein the opening mechanism is arranged at the end of the main frame body, a movable frame body capable of sliding front and back is arranged in the main frame body, and the stretchingmechanism and the edge folding thermal bonding mechanism are installed on the movable frame body; the opening mechanism comprises a tray and a suction cup moving up and down, the stretching mechanismcomprises supporting plates A which are arranged in a bilateral symmetry mode and supporting plates B which are arranged in an up-down symmetry mode, the supporting plates A and the supporting platesB are connected with a front-back moving mechanism, the front-back moving mechanism is installed on the movable frame body, and a pressing plate is arranged on the main frame body on the outer sidesof the supporting plates A; and the edge folding thermal bonding mechanism comprises an edge folding pressing plate, a thermal bonding floating pressing plate and a thermal bonding welding head whichare arranged in the circumferential direction, the edge folding pressing plate is located on the inner side of the thermal bonding floating pressing plate, and the edge folding pressing plate, the thermal bonding floating pressing plate and the thermal bonding welding head move towards the center. The device is simple in operation, stable in operation, safe and reliable.

Owner:YANTAI VOCATIONAL COLLEGE

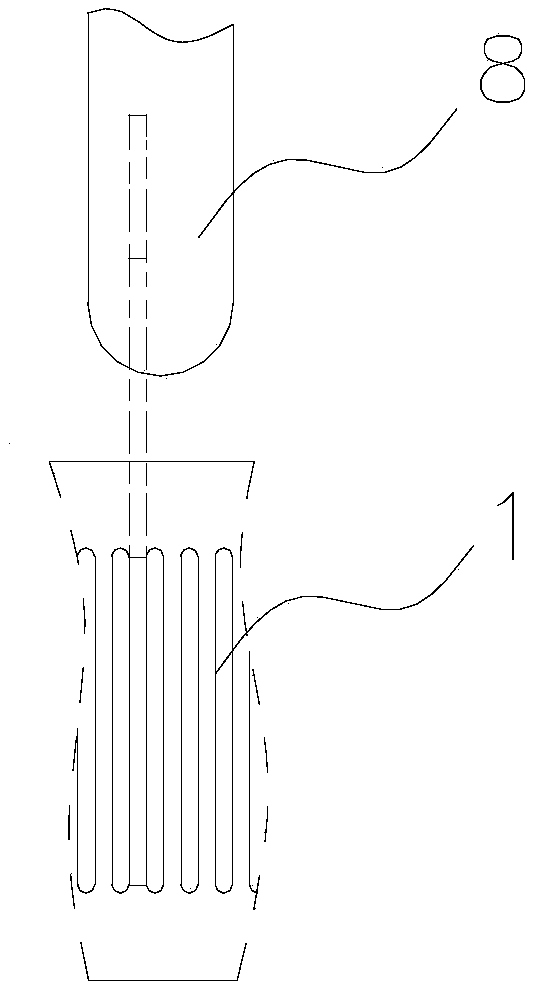

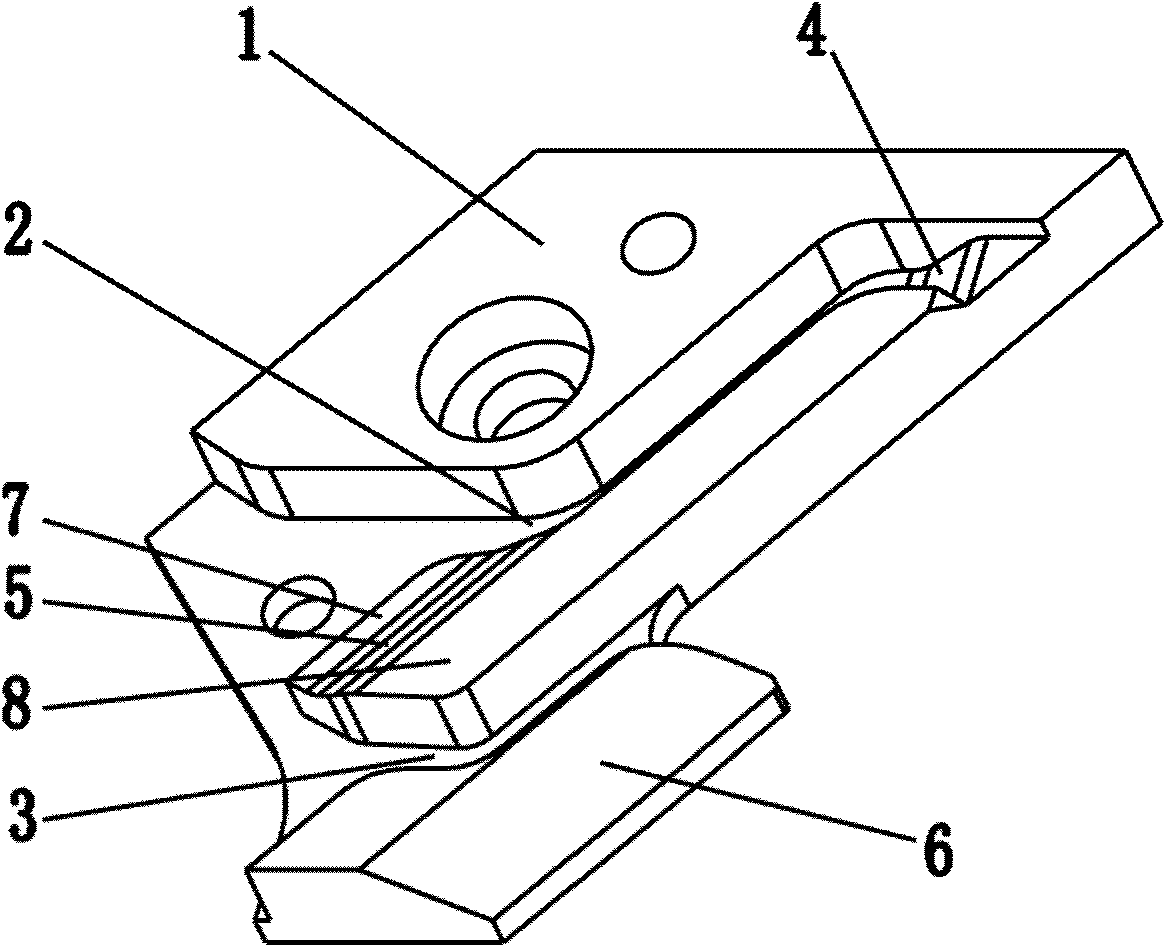

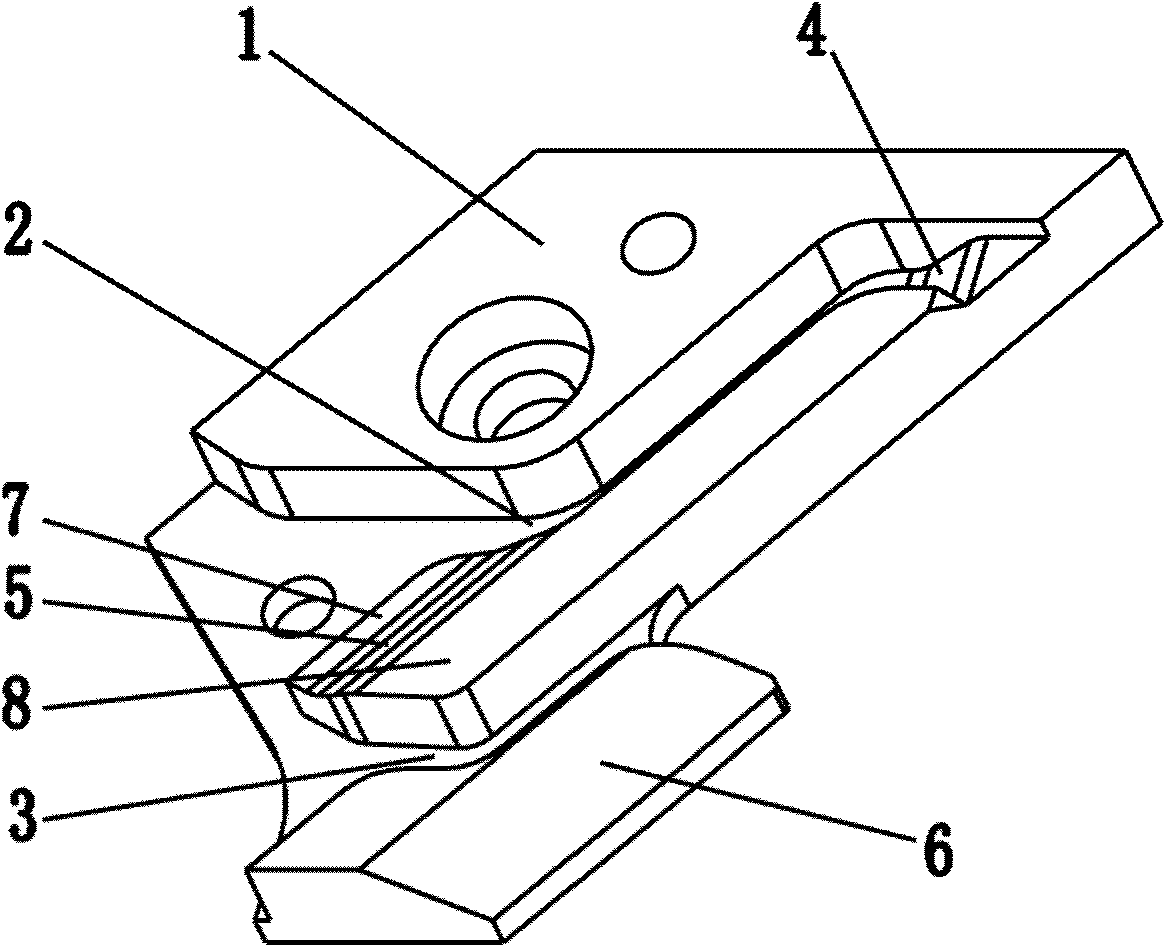

Stitch cam of computerized flat knitting machine

The invention discloses a stitch cam of a computerized flat knitting machine. A main body of the stitch cam is a trapezoidal plane. An additional block is also arranged at the bottom side of a first acute angle of a trapezoid and is connected with the main body into a whole; the stitch cam is provided with a first groove and a second groove, wherein the first groove extends from a first obtuse angle to a second acute angle of the trapezoid; the second groove extends from the middle of a first side edge to the part between the additional block and the main body; the first groove and the second groove are intersected at the first side edge ; a first inclined plate is formed at an included angle part between the first groove and the second groove; a second inclined plane is arranged at one end of the additional block away from the main body; and a third inclined plane is arranged at the bottom side of the first groove, so that the opening part of the first groove at the bottom edge is higher than other parts of the first groove. The invention provides a more diversified motion path for a crochet needle, also greatly reduces the weight of a machine head, lowers the production cost and is more convenient to mount; and during use, the phenomena of locking or inflexibility of the cam and the like can be avoided, a large amount of crochet needles can be prevented from being damaged and the use cost is lower.

Owner:NINGBO CIXING

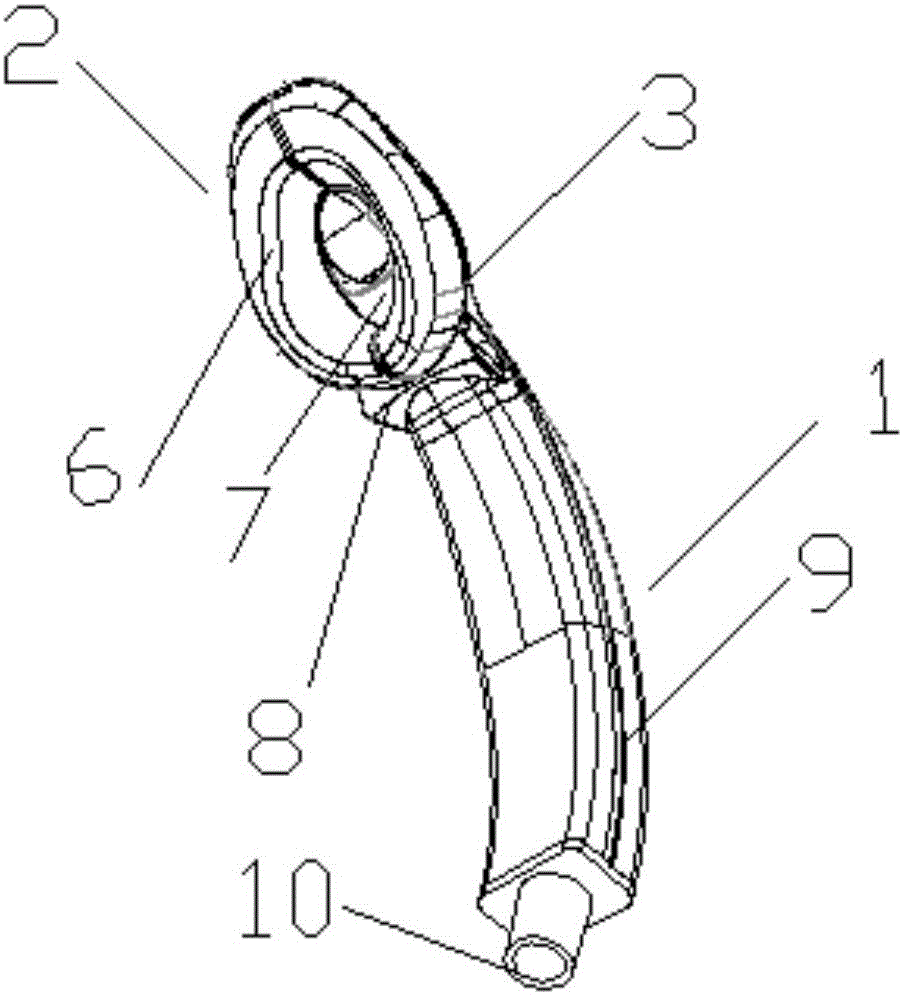

Two-section angle pin

The invention relates to a two-section angle pin that is applied to a mold. The two-section angle pin comprises: an angle pin seat, which is disposed in an upper ejector plate of the mold; a first section angle pin, one end of which is arranged on the angle pin seat and the other end of which is provided with a groove; a second section angle pin, which is mounted on the first section angle pin and provided with a stop pin, with one end of the stop pin located in the groove. For the two-section angle pin of the invention, when producing a product having an undercut at an inverse hook in the angle pin exit direction, the first section angle pin makes tilt movement to exit from the inverse hook of the product, and the second section angle pin makes vertical movement so as to make the two-section angle pin exit smoothly, thus finishing a demolding action.

Owner:SUZHOU MITAC PRECISION TECH

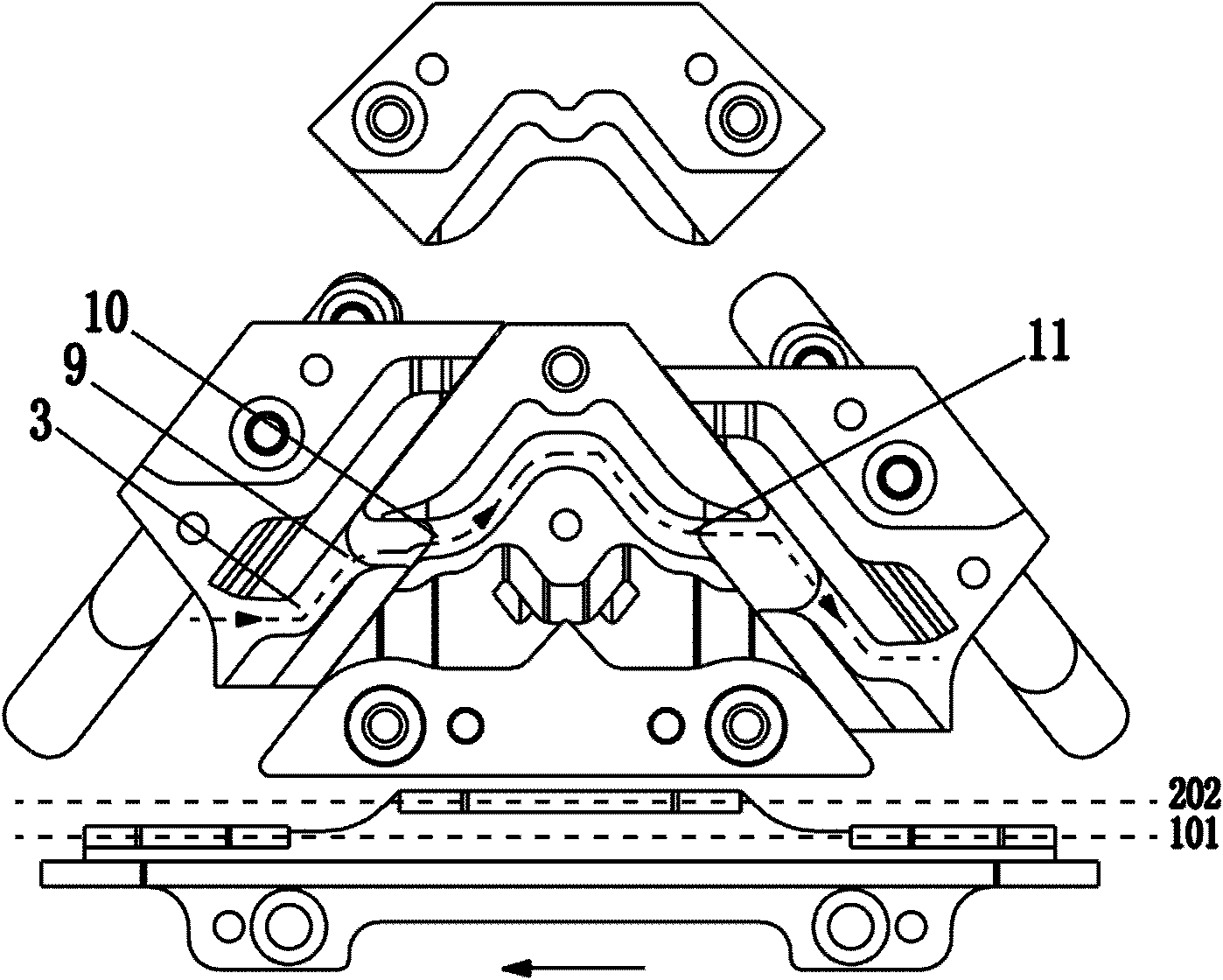

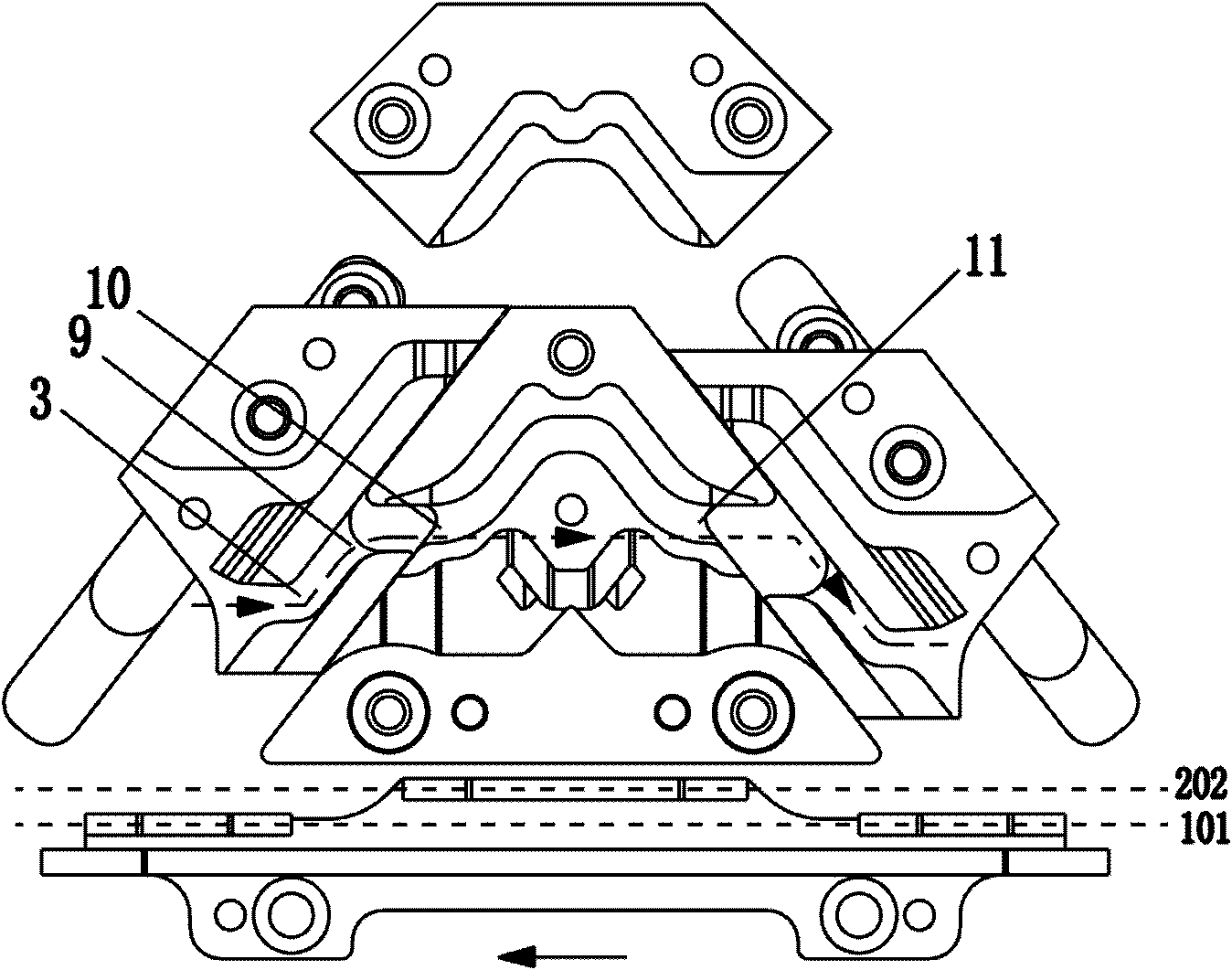

Floating grinding device and method of steel jacket for side rolling resistant torsion bar device

ActiveCN108723904AEasy to operateFix outer diameter dimension wavy floatingRevolution surface grinding machinesGrinding drivesSteel jacketWave shape

The invention provides a floating grinding device and method of a steel jack for a side rolling resistant torsion bar device. The floating grinding device comprises a support for supporting a torsionbar shaft to horizontally arrange, and a floating grinding assembly for grinding the steel jack on the torsion bar shaft. The floating grinding device is characterized in that the floating grinding assembly comprises a motor base, a driving motor which is mounted on the motor seat and can horizontally move on the motor seat, and a circumferential grinding cutter which is coaxially mounted on a rotating shaft of the driving motor, wherein a central axis of the circumferential grinding cutter is as high as a central axis of the torsion bar shaft; the driving motor moves to drive the circumferential grinding cutter to sleeve the sleeve jack to be coaxially aligned with the torsion bar shaft; and the circumferential grinding cutter is in radial elastic contact with the outer circumferential surface of the steel jack. According to the floating grinding device, the wave-shaped fluctuation of the outside diameter of the steel jacket can be effectively recovered, and the deviated steel jacketcan be aligned on the basis that a torsion bar of the side rolling resistant torsion bar device is not damaged; in addition, the grinding efficiency is high; the processing reliability is high; and the operation is simple and convenient.

Owner:ZHUZHOU TIMES NEW MATERIALS TECH

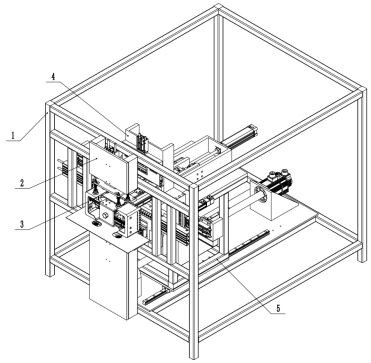

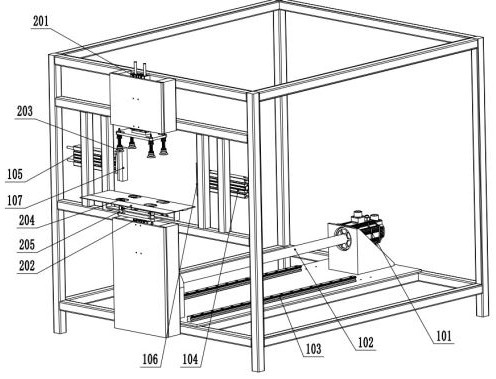

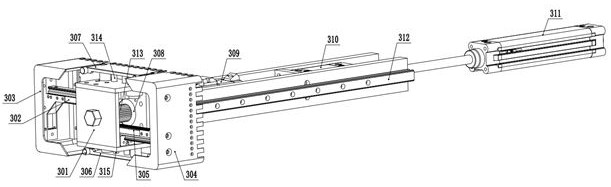

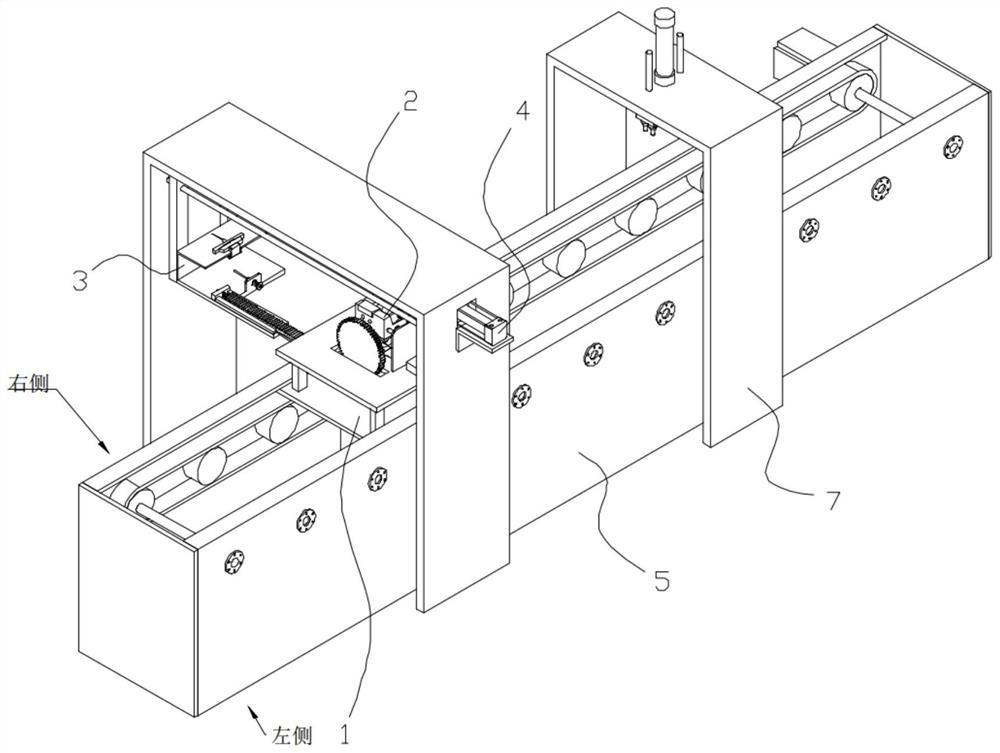

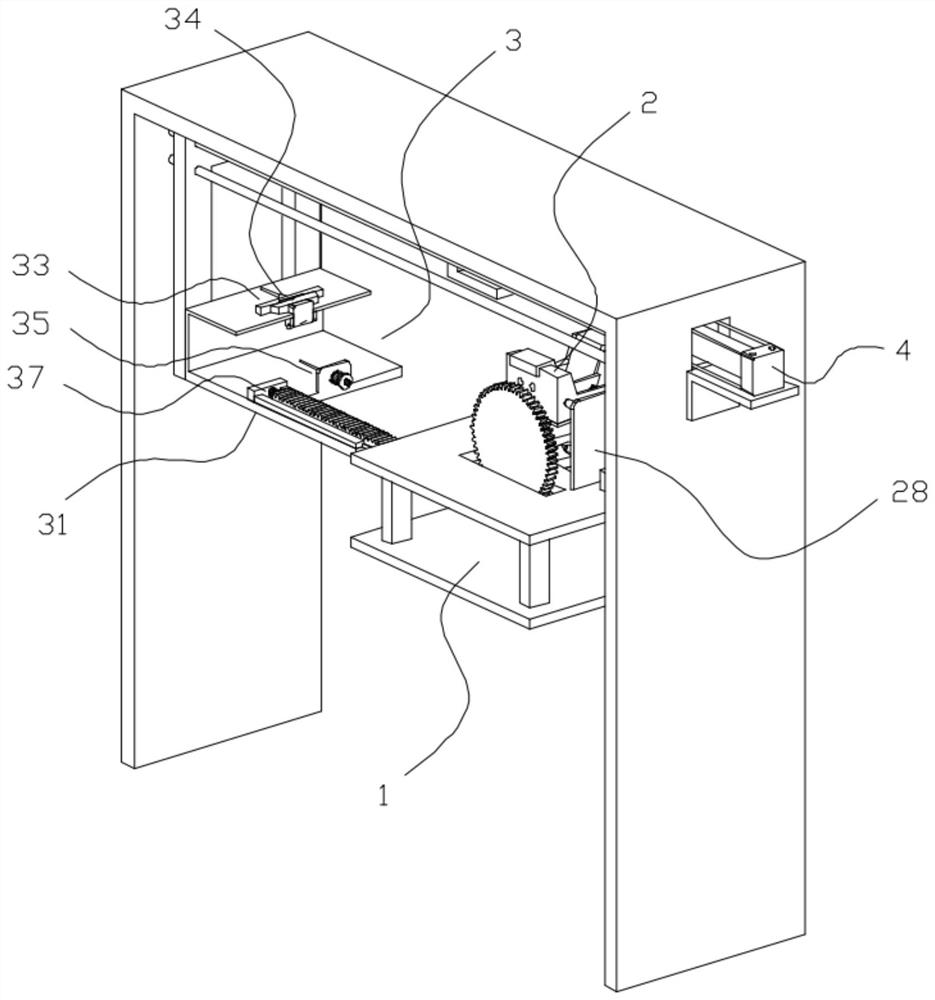

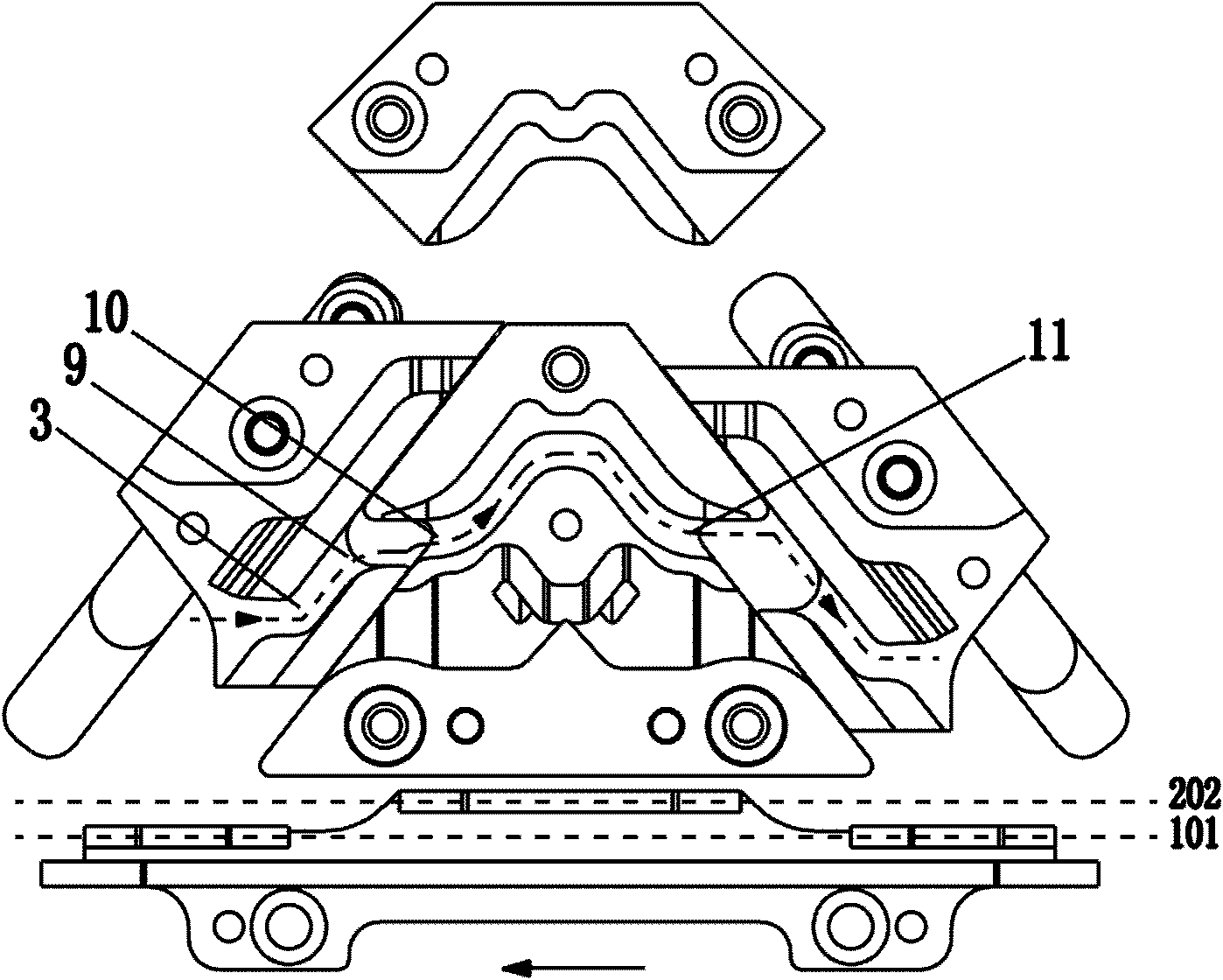

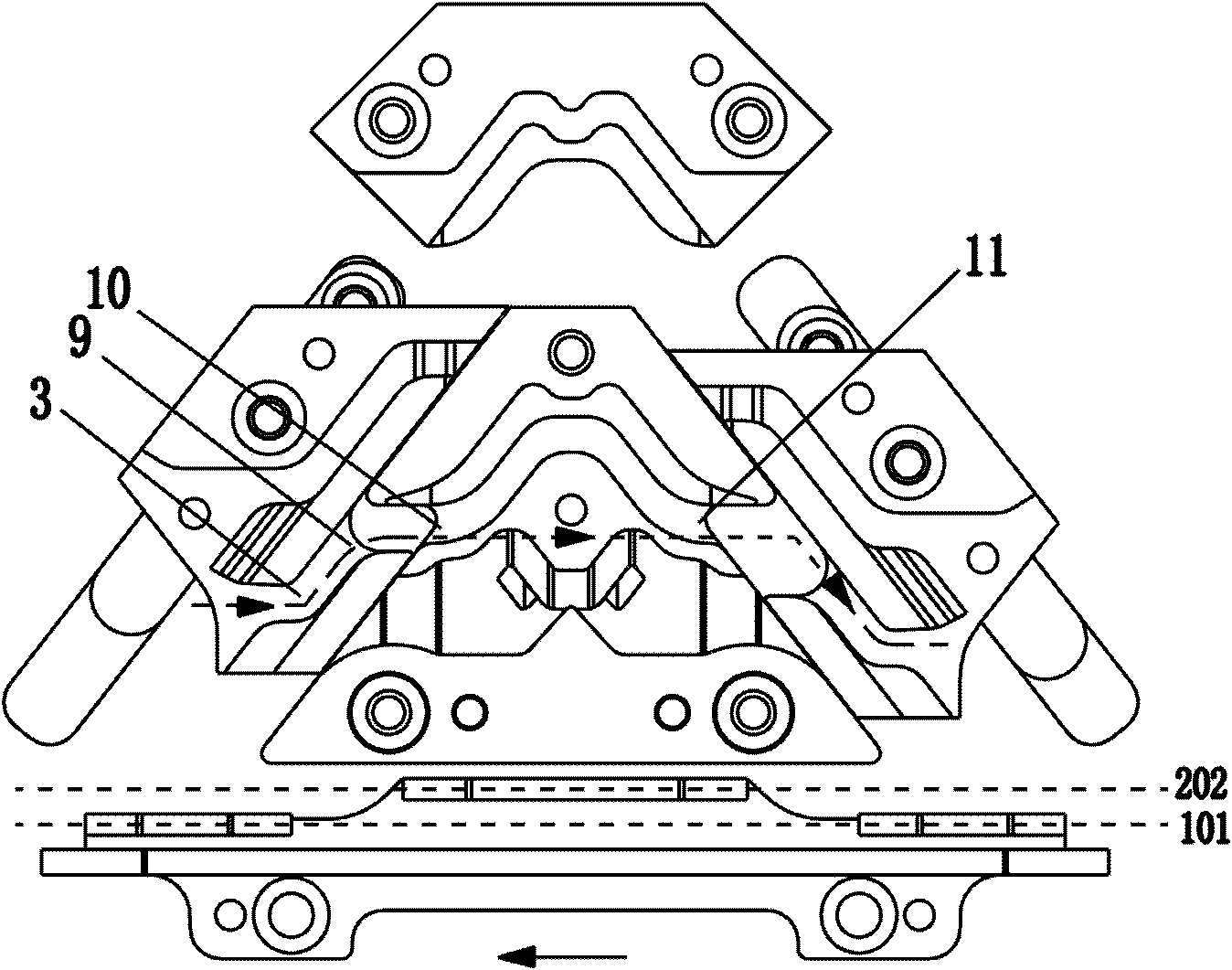

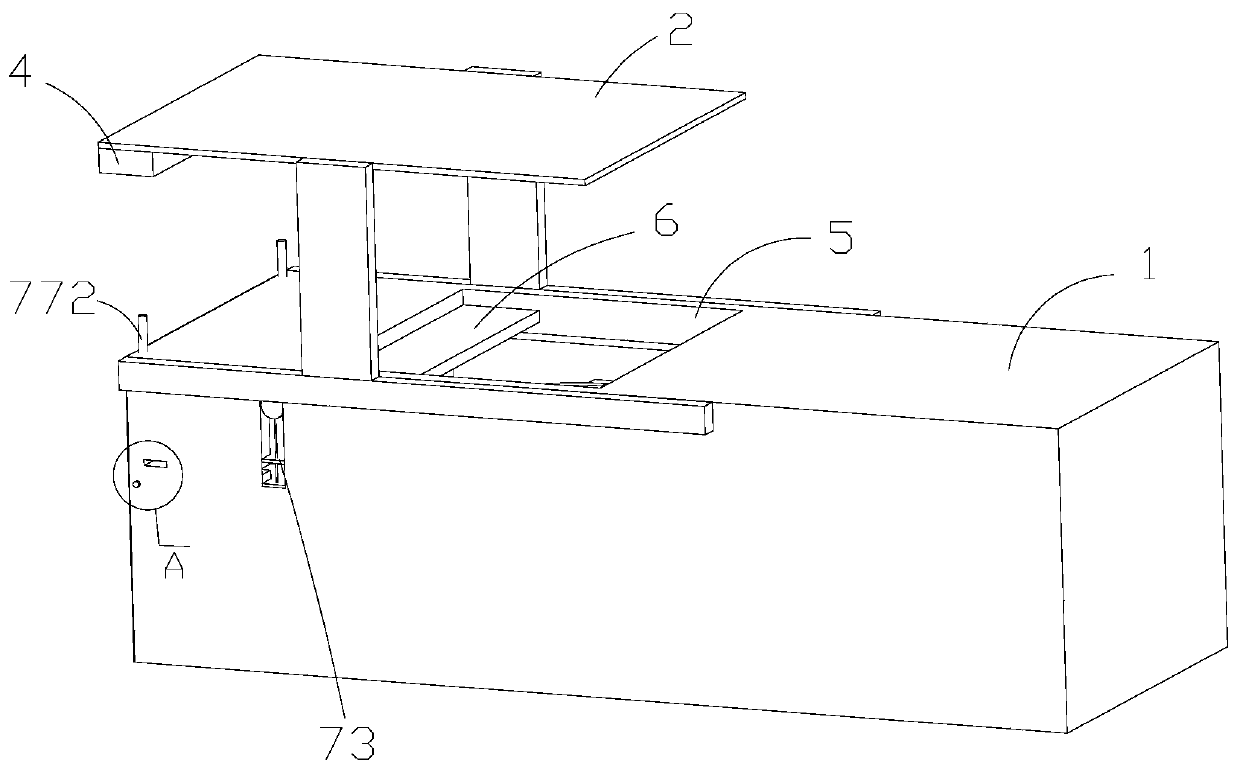

Intelligent operation and maintenance machining production line for building steel members

ActiveCN111843501AQuick assemblyImprove assembly efficiencyOther manufacturing equipments/toolsBuilding productProduction line

The invention discloses an intelligent operation and maintenance machining production line for building steel members, and relates to the technical field of building product machining. The intelligentoperation and maintenance machining production line comprises a carrier, a press-fitting welding mechanism, a drilling mechanism and a conveying platform; the carrier is used for bearing a fixing tool and transferring a connecting piece to stations by means of the conveying platform, the fixing tool used for clamping the connecting piece is arranged on the carrier, and the connecting piece can berotated to a horizontal state during assembly; the press-fitting welding mechanism is located on one side of the conveying platform, horizontal movement of the press-fitting welding mechanism is achieved through a horizontal movement mechanism, and the press-fitting welding mechanism is matched with the fixing tool to achieve welding and fixing of a reinforcing rib and the connecting piece; the drilling mechanism is located at the next station of the press-fitting welding mechanism and used for achieving drilling treatment of the upper portion of the connecting piece; and the conveying platform is used for conveying the carrier to the stations. According to the intelligent operation and maintenance machining production line for the building steel members, an assembly line type productionmode is adopted, so that rapid assembling operation of the roof steel members is achieved, and compared with traditional manual operation, the assembling efficiency and the assembling precision are remarkably improved, and the labor cost is saved.

Owner:CHONGQING CITY VOCATIONAL COLLEGE

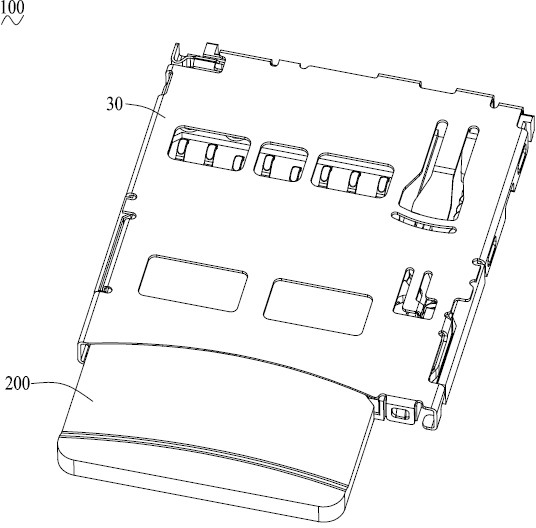

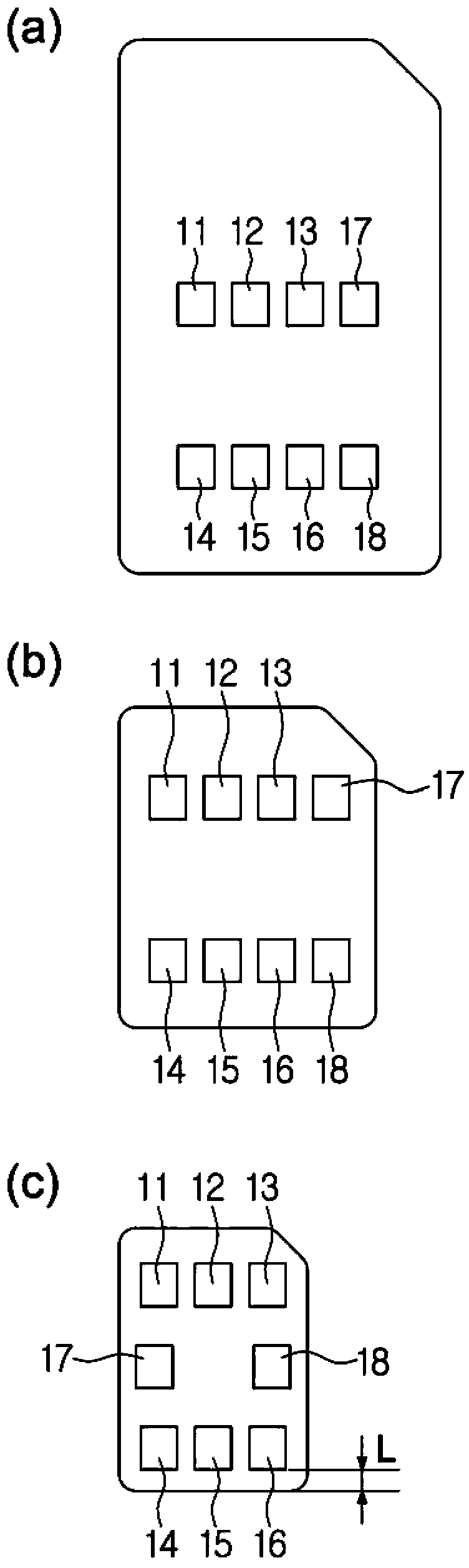

Socket for NANO sim card

ActiveCN103872499AEx situ identification of layout structureIdentify layout structureConveying record carriersCoupling contact membersEngineeringPrinted circuit board

Provided is a nano SIM card socket including first to third connection units arranged in a line, and fourth to sixth connection units arranged to be parallel to the first to third connection units. The nano SIM card socket comprises first to sixth terminals, each terminal including contact units respectively contacting the connection units of the nano SIM card and a soldering unit to be soldered to a printed circuit board; a housing including through-holes for the first to sixth contact units disposed positions respectively corresponding to positions of the connection units of the nano SIM card when the nano SIM card is inserted; and a cover coupled to the housing to form an insertion space in which the nano SIM card is inserted.

Owner:UJU ELECTRONICS

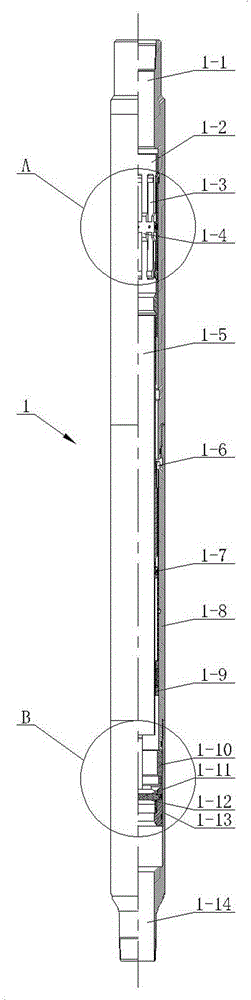

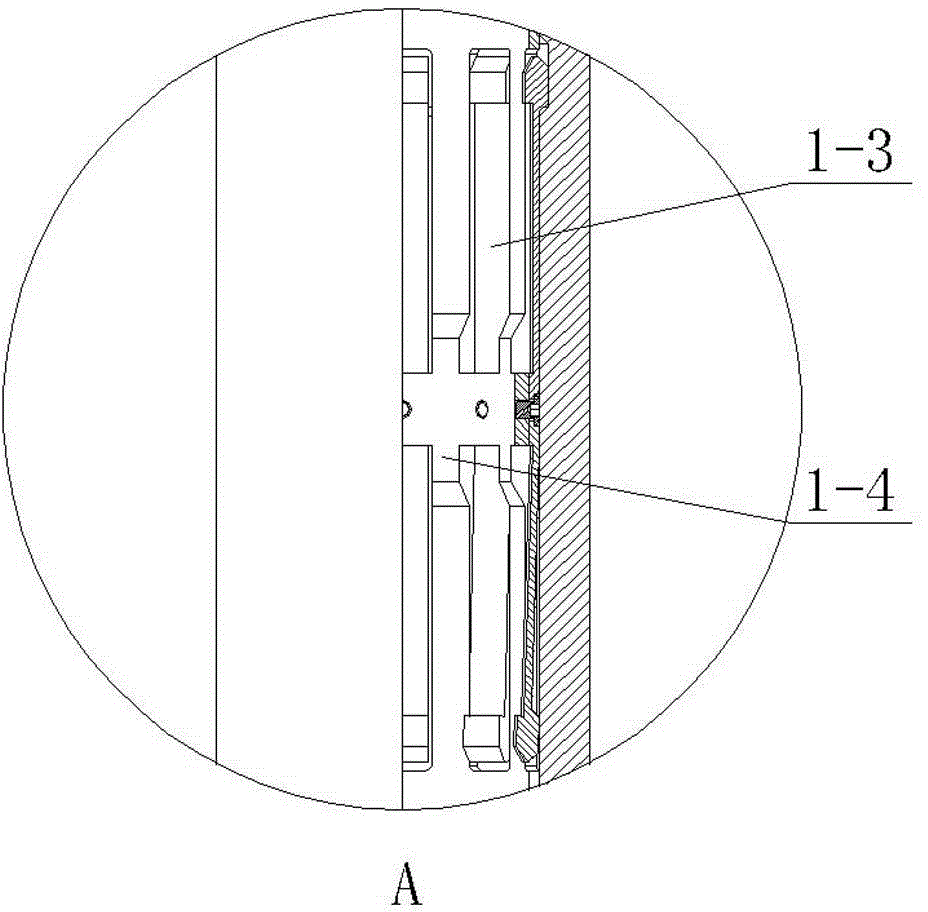

Threaded sleeve

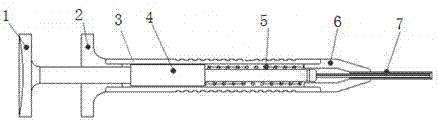

The invention discloses a threaded sleeve, comprising a shell and an inner cavity located in the shell and playing a role of a surgical equipment passage in a minimally invasive surgery. The shell comprises a large-diameter section and a small-diameter section; at least one threaded track is arranged on the outer surface of the small-diameter section; the thread of the threaded track comprises a forward surface and a backward surface; the forward surface and the outer surface of the shell are arranged to form an acute angle; and the backward surface and the outer surface of the shell are arranged to form a right angle or an obtuse angle. The invention has the beneficial effects that: the threaded track with the forward surface as an acute-angle slope and with the backward surface as a right-angle or obtuse-angle plane is adopted to ensure that the sleeve can realize the forward and backward manners, therefore, the sleeve cannot fall off during the surgery and the sleeve can smoothly exit from the tissue after the surgery; and the double-thread or multi-thread track is adopted to ensure that the sleeve can be more quickly screwed in and out after the surgery but is not easy to be pulled away because of the abdominal pressure.

Owner:TOUCHSTONE INTERNATIONAL MEDICAL SCIENCE CO LTD

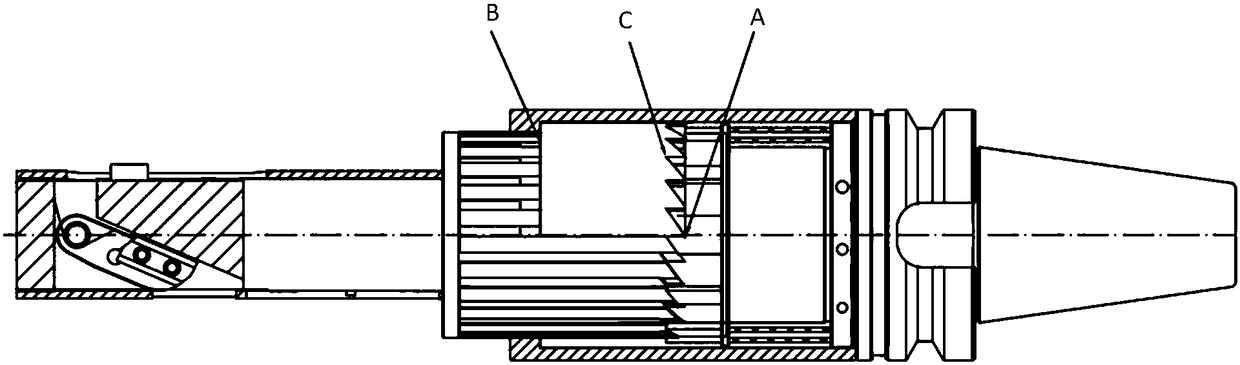

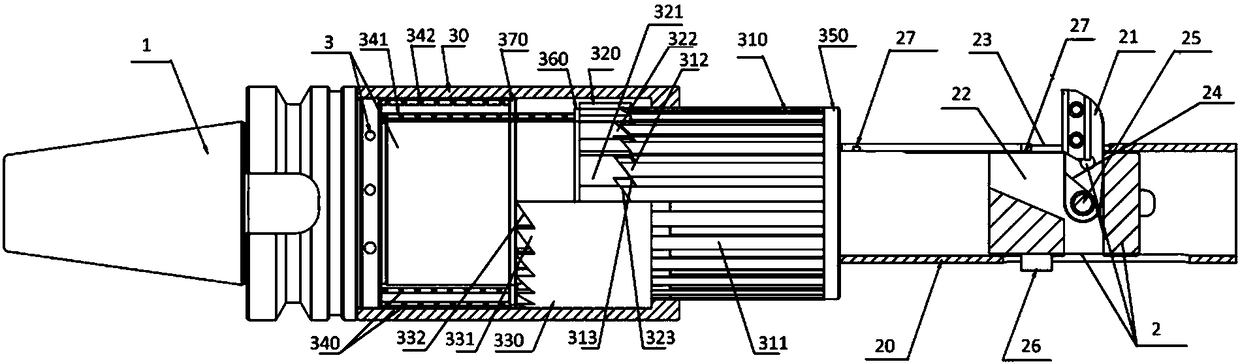

Reverse scraper tool for reverse stepped hole machining

The invention discloses a reverse scraping tool for machining a reverse step hole. The reverse scraping tool comprises a tool body, a reverse scraping tool bit assembly and a transposition assembly. The reverse scraping tool bit assembly comprises a tool apron and a sliding sleeve matched with the outer side wall of the tool apron, the tool apron is provided with a groove capable of containing a reverse scraping tool bit, the reverse scraping tool bit is arranged in the groove in the manner that the reverse scraping tool bit can overturn in the preset direction and stretch out of the groove, and the sliding sleeve is provided with an opening for the reverse scraping tool bit to stretch out in the sliding process of the sliding sleeve. The transposition assembly is arranged between the tool body and the reverse scraping tool bit assembly so as to drive the sliding sleeve to slide along the preset track to achieve state switchover for the tool bit to stretch out of the groove, and accordingly, the tool bit assembly can smoothly penetrate a to-be-machined hole in the machining process. According to the reverse scraping tool for machining the reverse step hole, the machining auxiliary time can be effectively shortened, and the production efficiency is improved; and operation risks are reduced, and the effects that the implementation effect is good, the safety coefficient is high, operation difficulty is low, and the production efficiency is effectively improved are achieved.

Owner:MIANYANG MIANGONG TOOLS

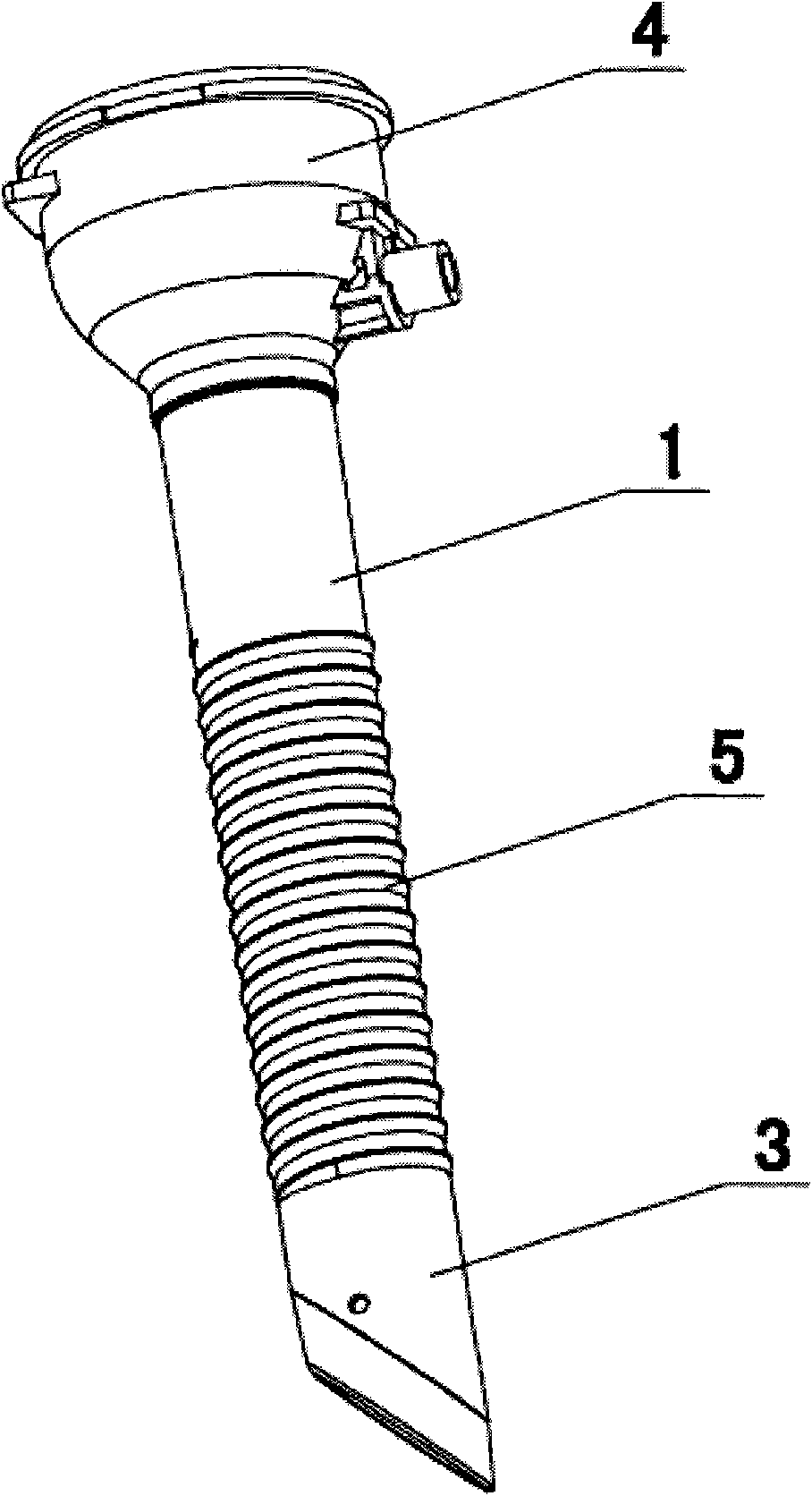

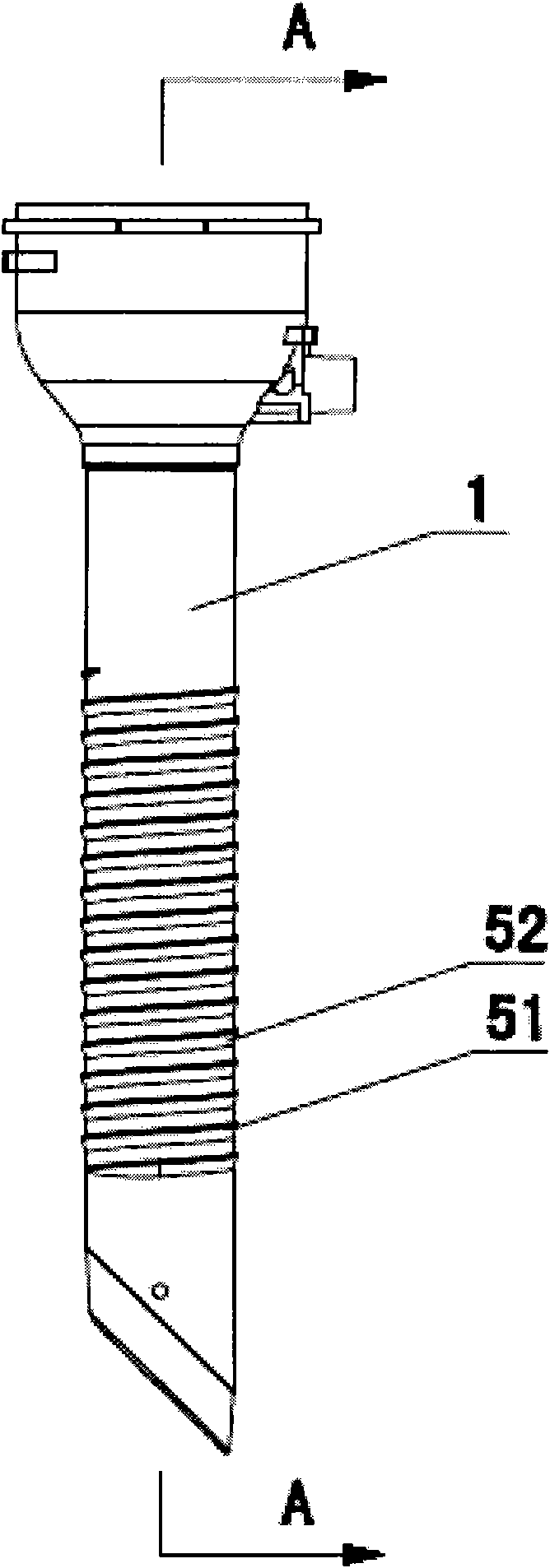

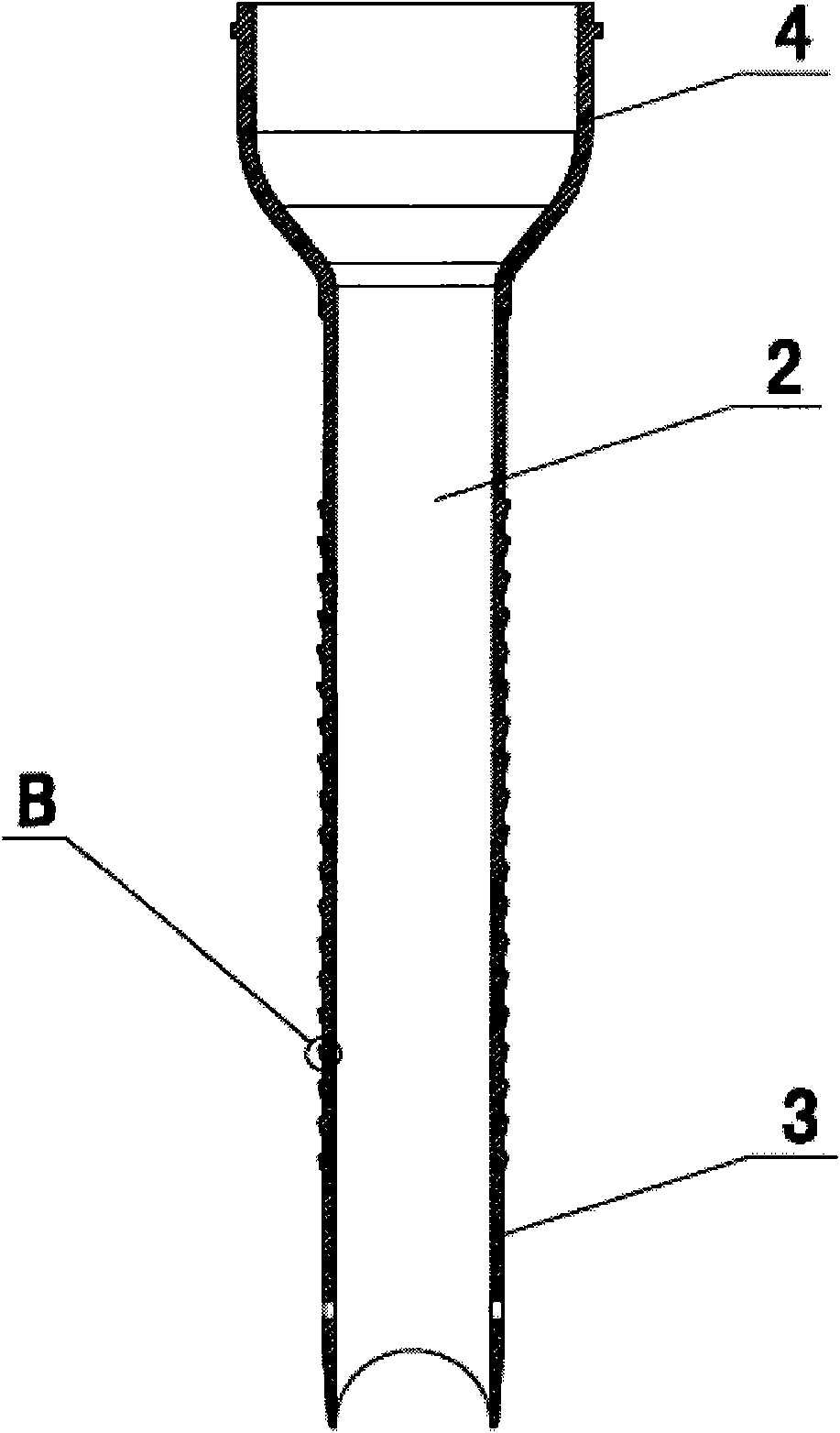

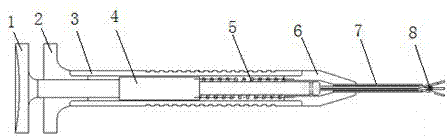

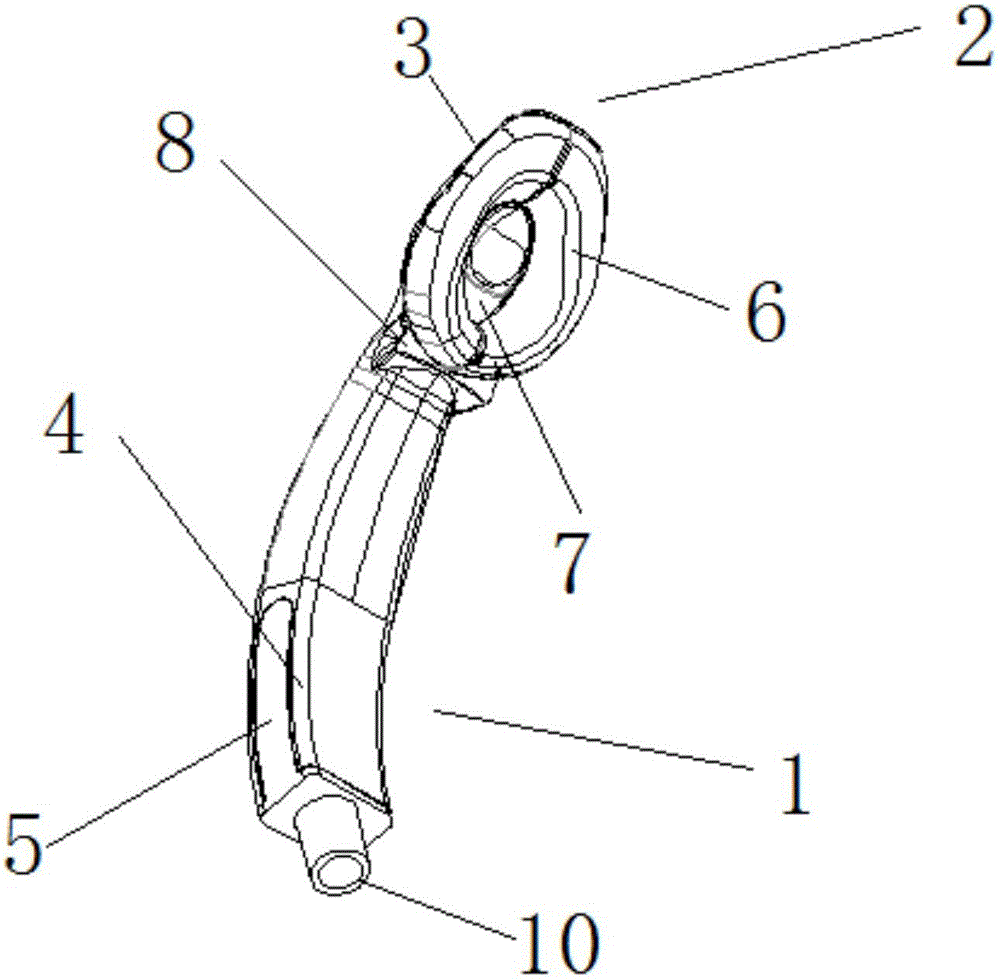

Lenticular nucleus supporter for cataract surgery

InactiveCN102784030BExit smoothlyReasonable structural designEye surgeryPosterior lens capsuleUltrasonic emulsification

The invention provides a lenticular nucleus supporter for a cataract surgery. The supporter is formed by an infusion handle, an infusion tube tail cover, an infusion tube, an infusion rod, a spring, an infusion tube cover, an infusion needle head and an infusion three-jaw. The infusion tube is hollowed, one end of the infusion tube is embedded into the infusion tube tail cover, the other end of the infusion tube is embedded into the rear end of the infusion tube cover, the front end of the infusion tube cover is in a cone shape, one end of the infusion needle head is embedded into the front end of the infusion tube cover, the infusion three-jaw is three thin steel wires, the tail end of each steel wire is fixed with the front end of the infusion rod, the spring is sleeved outside a front section of the infusion rod, a middle section of the infusion rod is adapted to the infusion tube in diameter, and the infusion handle is fixedly connected with the tail end of the infusion rod. According to the lenticular nucleus supporter, the infusion three-jaw is utilized to form a fan-shaped strut in an eye when the laceration of a posterior lens capsule occuring in an ultrasonic emulsification operation so as to support a downfallen nucleus, so that the operation is enabled to be carried out smoothly. The infusion needle head can also be used as an auxiliary hook, and the functions of chopping and rotating the nucleus can be played. The supporter has reasonable design, is simple and convenient to manufacture, adopts metal materials, can be disinfected at high temperature and high pressure, can be used repeatedly, and is low in cost.

Owner:HANGZHOU FIRST PEOPLES HOSPITAL

Stitch cam of computerized flat knitting machine

The invention discloses a stitch cam of a computerized flat knitting machine. A main body of the stitch cam is a trapezoidal plane. An additional block is also arranged at the bottom side of a first acute angle of a trapezoid and is connected with the main body into a whole; the stitch cam is provided with a first groove and a second groove, wherein the first groove extends from a first obtuse angle to a second acute angle of the trapezoid; the second groove extends from the middle of a first side edge to the part between the additional block and the main body; the first groove and the secondgroove are intersected at the first side edge ; a first inclined plate is formed at an included angle part between the first groove and the second groove; a second inclined plane is arranged at one end of the additional block away from the main body; and a third inclined plane is arranged at the bottom side of the first groove, so that the opening part of the first groove at the bottom edge is higher than other parts of the first groove. The invention provides a more diversified motion path for a crochet needle, also greatly reduces the weight of a machine head, lowers the production cost andis more convenient to mount; and during use, the phenomena of locking or inflexibility of the cam and the like can be avoided, a large amount of crochet needles can be prevented from being damaged and the use cost is lower.

Owner:NINGBO CIXING

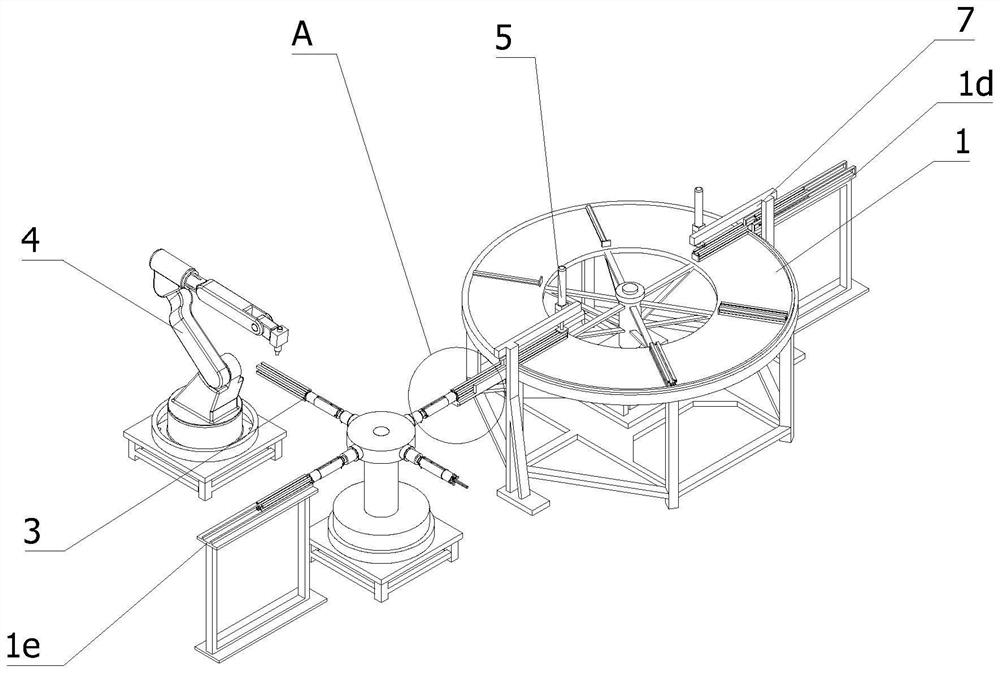

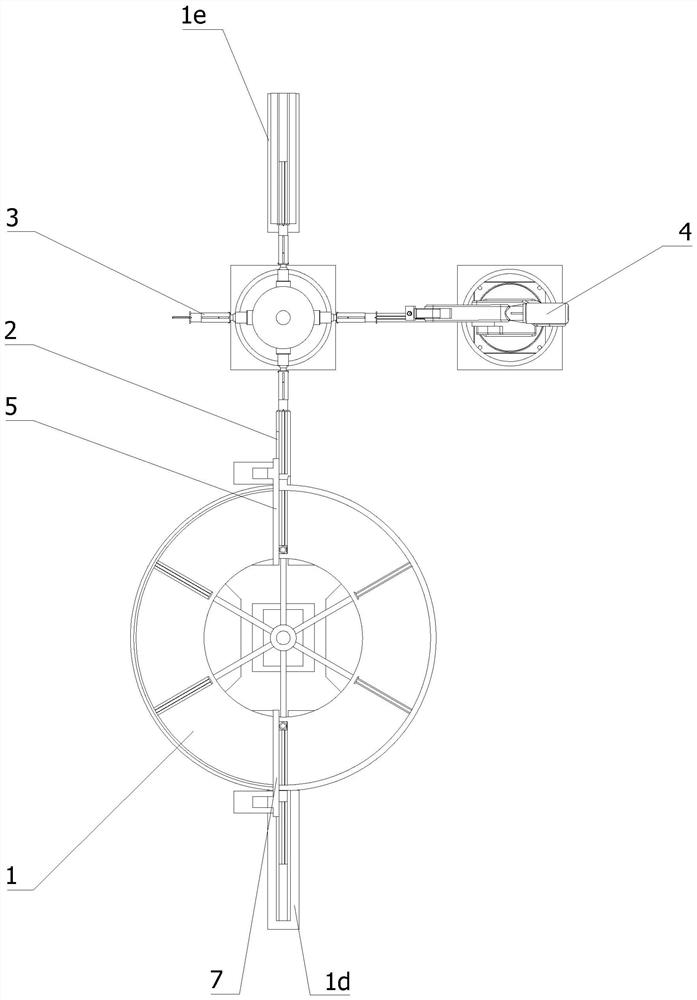

Aluminum profile spraying production line

PendingCN114558722AAchieve sprayingQuality improvementSpraying apparatusCircular discManufacturing line

The invention relates to the field of aluminum profile spraying, in particular to an aluminum profile spraying production line which comprises a rotating disc type conveying table, a pre-clamping track, a spraying robot and an auxiliary spraying device. The auxiliary spraying device comprises a disc and flexible clamping mechanisms, the flexible clamping mechanisms are arranged on the periphery of the disc and can be inserted into a through opening formed in the aluminum profile so as to fix the aluminum profile, and each flexible clamping mechanism can rotate on the disc. A rotary driver used for driving the flexible clamping mechanisms to rotate is further arranged on the disc and located at the position of each flexible clamping mechanism, each rotary driver is fixed to the disc through a machine shell, and the disc can be further rotationally arranged on a rotary table. According to the aluminum profile spraying device, the flexible clamping mechanism is inserted into an aluminum profile through opening to fix the aluminum profile, so that the surface of the clamped aluminum profile can still be completely sprayed, and the spraying quality of the aluminum profile is improved.

Owner:孟庆松

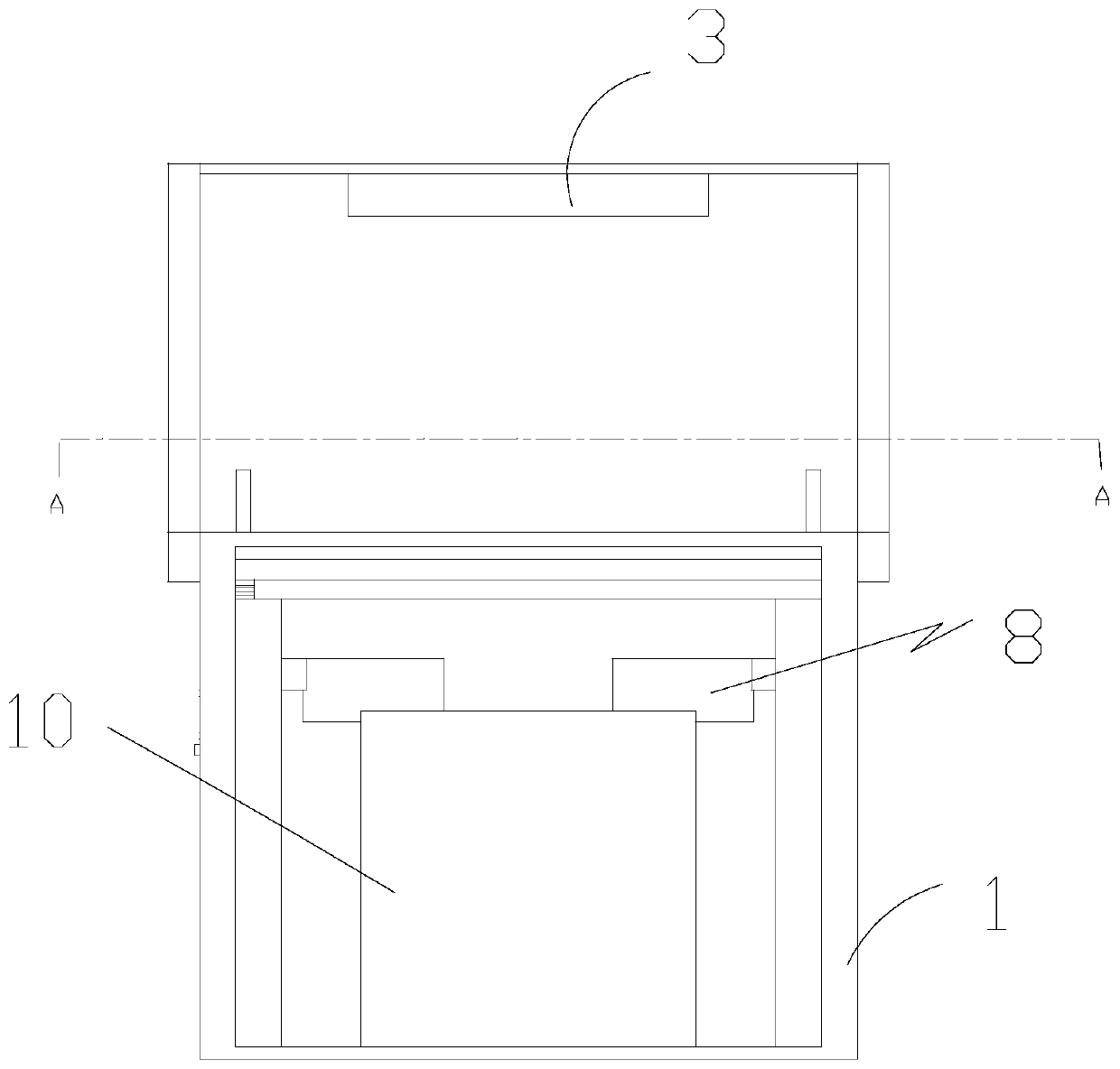

Bill storage device

InactiveCN103985187AExit smoothlyConvenient uprightCoin/currency accepting devicesEngineeringMechanical engineering

Disclosed is a bill storage device which includes a storage box and a bill entrance mechanism and a bill exit mechanism, which are arranged on the storage box. The bill exit mechanism is arranged at one side of the bill entrance mechanism. The bill exit mechanism includes a bill exit port arranged on the storage box and a bill withdrawing wheel arranged in the storage box and on an edge of the bill exit port. The storage box includes a temporary storage area and a storage area. Both of the bill exit mechanism and the bill entrance mechanism are arranged in the temporary storage area. An intermediate wheel, a rotating shaft of which is capable of moving, is also arranged in the temporary storage area. The intermediate wheel cooperates with the bill withdrawing wheel when bills exit. When the bills exit, the intermediate wheel moves towards the bill withdrawing wheel and because the rotating shaft of the intermediate wheel is capable of moving, when the bills exit, a gap between the intermediate wheel and the bill withdrawing wheel can be adjusted according to the thickness of bills which are withdrawn so that it is ensured that the withdrawn bills can successfully exit.

Owner:SHENZHEN BROADZONE INTELLIGENCE TECH CO LTD

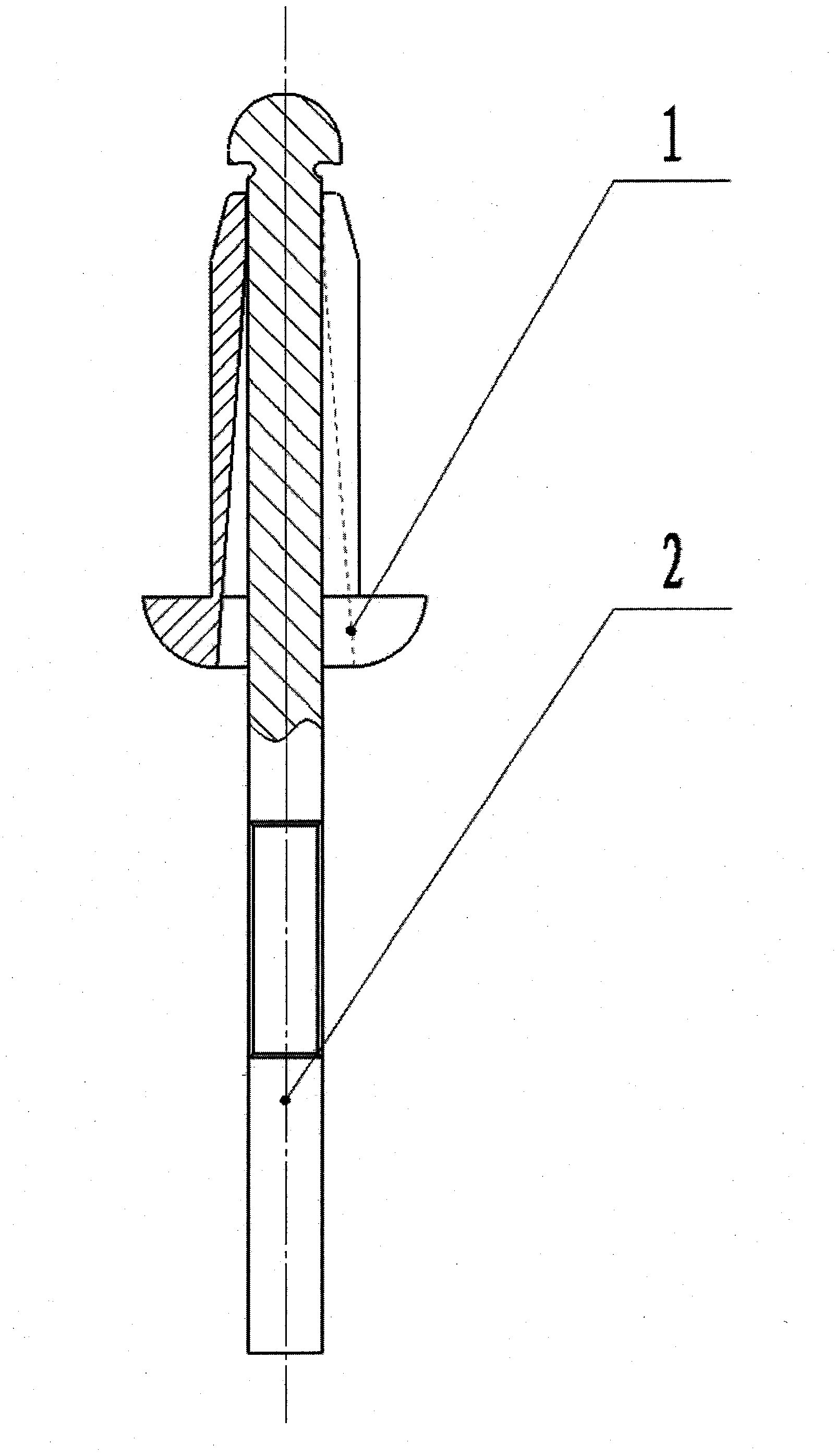

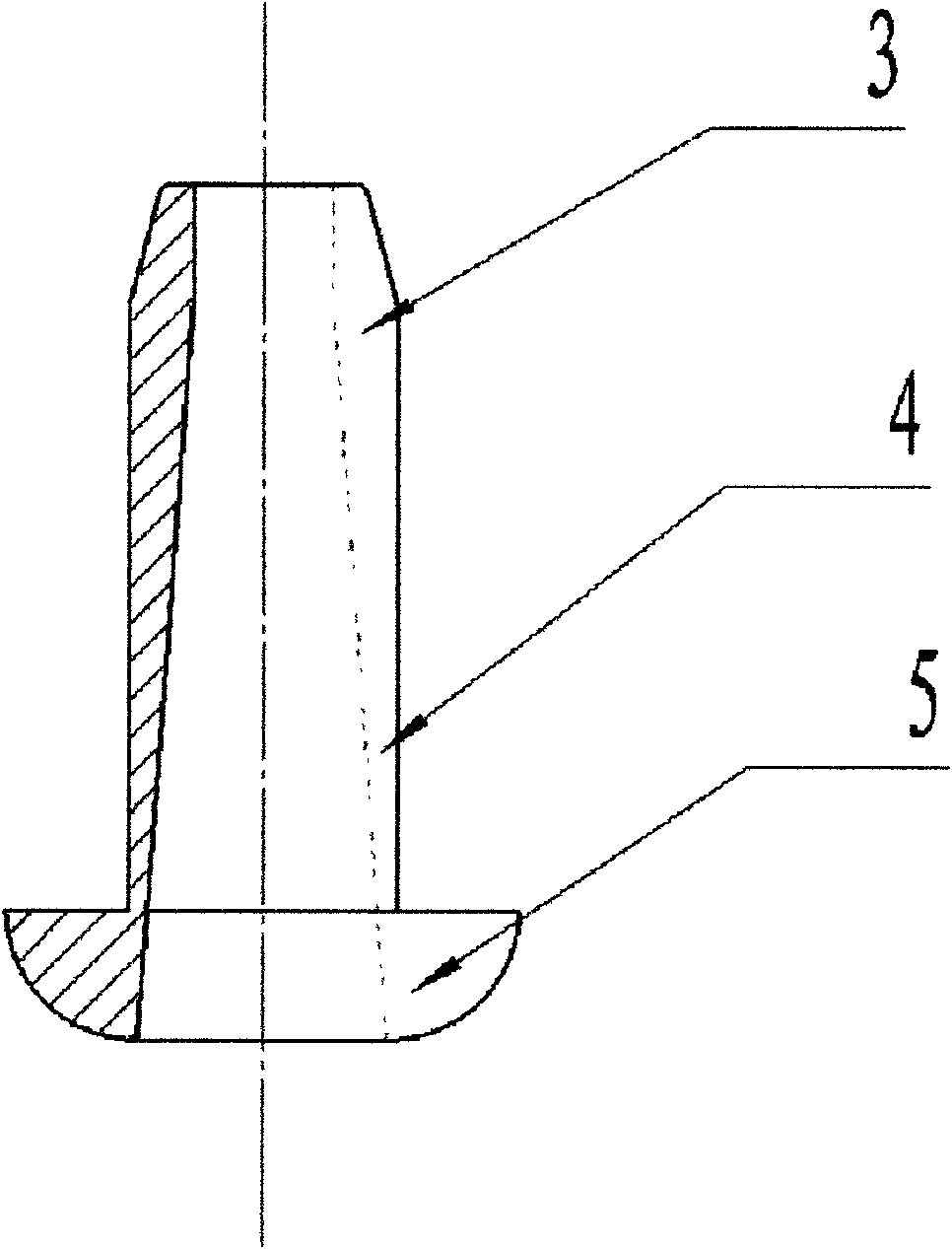

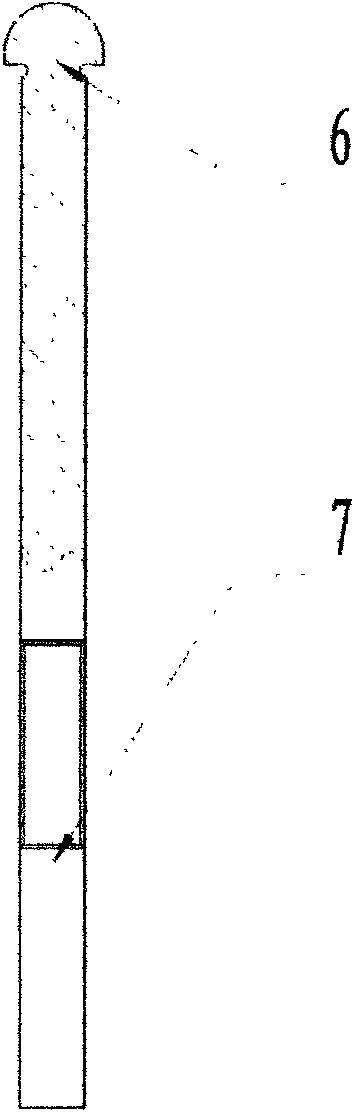

Circulation type rivet with rivet core

The invention relates to a circulation type rivet with a rivet core, which comprises a rivet body and a rivet core. The materials of the rivet core are harder than those of the rivet body. A cavity is arranged at the middle part of the rivet body; the rivet core comprises a rivet core head part and a pull rod; the rivet core head part is positioned at the upper end of the pull rod; the upper part of the pull rod is sleeved in the cavity; the cavity comprises an upper cylinder surface and a lower cone surface; the maximum internal diameter of a lower cone is slightly smaller than the diameter of the outer cylinder surface of the rivet body; a chamber angle is formed at the head part of the outer cylinder surface of the rivet body; the diameter at the least position of the chamber angle is basically consistent with that at the largest position of the head part of the rivet core; the diameter at the largest position of the head part of the rivet core is slightly smaller than that of a circular ring at the middle section of the lower cone surface of the cavity; the top end of the head part of the rivet core is a hemispherical surface; the bottom surface of the hemispherical surface is a concave surface; the concave surface is connected with the top end of the pull rod of the rivet core; and threads are arranged on the cylinder surface of the middle lower end of the pull rod. The circulation type rivet with the rivet core improves the resource utilization rate and reduces the use cost.

Owner:许进

Separate edge cup type air duct capable of sealing tissue around throat

The invention provides a medical cannula type non-inflatable throat cup air duct which allows a tracheal catheter to be conveniently inserted and which automatically withdraws after the catheter is inserted. A cup fits an anatomical structure around a throat in shape, and is closely attached to surrounding tissues through a sealing ring. Through a separate edge buckle design at one side of a main air duct, the tracheal catheter can be inserted conveniently, and the cup type air duct can withdraw conveniently after the tracheal catheter is inserted. An epiglottis holder, corresponding to the position of epiglottis, is arranged inside the throat cup. The main air duct is provided with a tongue root stand corresponding to the position of a tongue root. The outer sidewall of the main air duct is provided with a C stomach tube slot. When a stomach tube is used, the stomach tube can be separated from the main air duct according to needs. According to the invention, the cup type air duct better fits the anatomical structure around the throat. The cup structure is made from flexible manmade rubber, and the sealing ring is additionally adopted. In this way, the air duct exhibits better air tightness, and will not oppress or damage soft tissues around the throat.

Owner:TIANJIN MEDAN MEDICAL CORP

Safe and reliable glass hot fix stone grinding equipment

ActiveCN111571426AImprove automationQuick closeLapping machinesWork carriersGrinding millManufacturing engineering

The invention discloses safe and reliable glass hot fix stone grinding equipment. A shell, a lifting plate, an adsorption disc, an abutting block, a feeding port, a movable door, a drive device, a clamping device, a grinding machine and a cleaning barrel are included. The drive device comprises a first spring, a first rack, a sliding groove, a clockwork spring, a gear, a limiting block and a pneumatic mechanism. The clockwork spring is fixedly arranged on the sliding groove and penetrates through two guiding blocks to be fixed to the guiding blocks. The movable door is rapidly opened during feeding through the pneumatic mechanism, and slow moving is conducted during lifting plate reset; furthermore, through the clamping device, glass hot fix stones are automatically fixed in the grinding process, and the glass hot fix stones on the clamping device are automatically placed into the cleaning barrel to be cleaned; on one hand, the equipment grinding efficiency is improved, on the other hand, the equipment feeding safety is improved due to the special moving manner of the movable door, grinding is further conducted in the seal environment, and grinding safety is improved.

Owner:浦江欣奕莱钻业有限公司

Optical disk drive tray withdraw control method

Owner:LITE ON TECH CORP

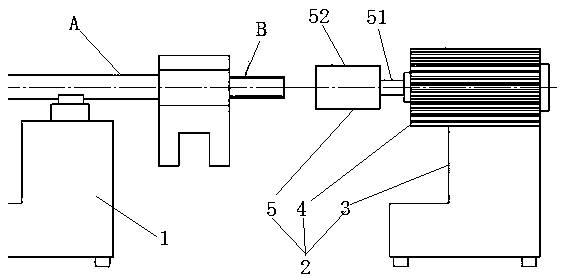

Helical gear heading mold

ActiveCN103447441BImprove processing efficiencyShorten the processing cycleForging/hammering/pressing machinesWheelsAlloyEngineering

The invention discloses a helical gear heading mold. The helical gear heading mold consists of an upper die and a lower die, and is characterized in that the upper die comprises an upper die sleeve and a punch, wherein the punch is arranged in an inner hole of the upper die sleeve in a vertically moving manner; the lower die comprises a lower die sleeve and a rotary die body; the rotary die body is rotatably arranged in a cavity of the lower die sleeve through upper and lower planar bearings; an inner hole is formed in the middle of the rotary die body for fixing an alloy die core; the alloy die core is provided with a helical gear heading die cavity; the upper section of the die cavity is provided with a straight hole; the lower section of the die cavity is provided with a helical gear cavity which has the same shape as that of a headed helical gear; the bottom of the die cavity is communicated with a rear through ejector rod guide hole; a rear through ejector rod is movably arranged in the rear through ejector rod guide hole; during cold heading forming of the helical gear, the bottom surface of the upper die sleeve is tightly attached to the top surface of the alloy die core, and the head of the punch extends into the die cavity of the alloy die core. According to the helical gear heading mold, cold heading forming of helical gears on cold heading equipment can be realized, the helical gear machining efficiency is greatly improved, the helical gear machining period is shortened and the helical gear manufacturing cost is reduced.

Owner:宁波振华汽车零部件有限公司

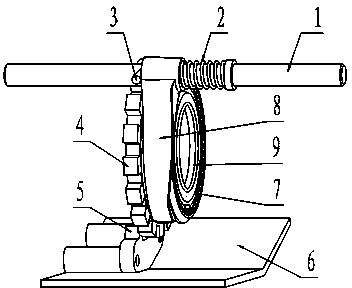

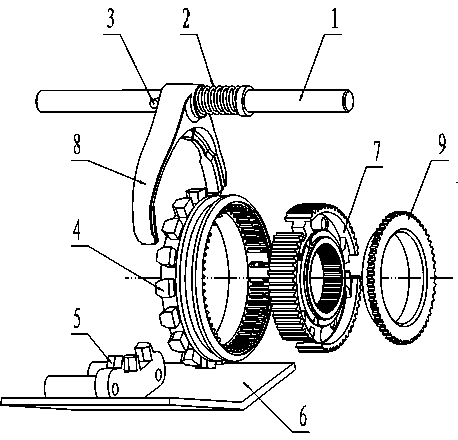

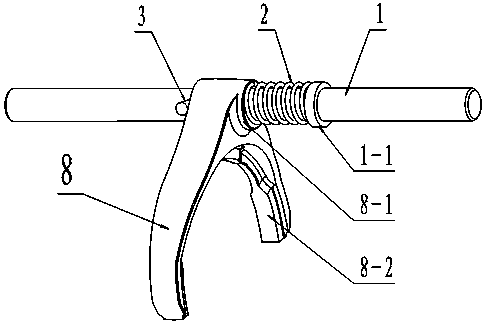

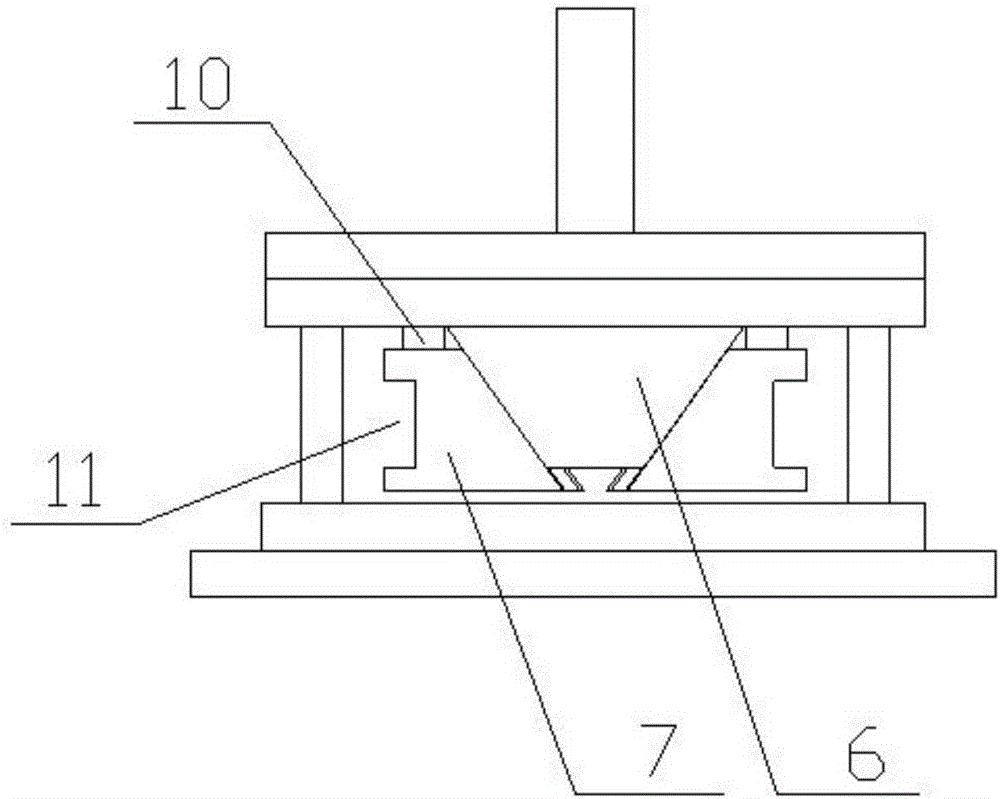

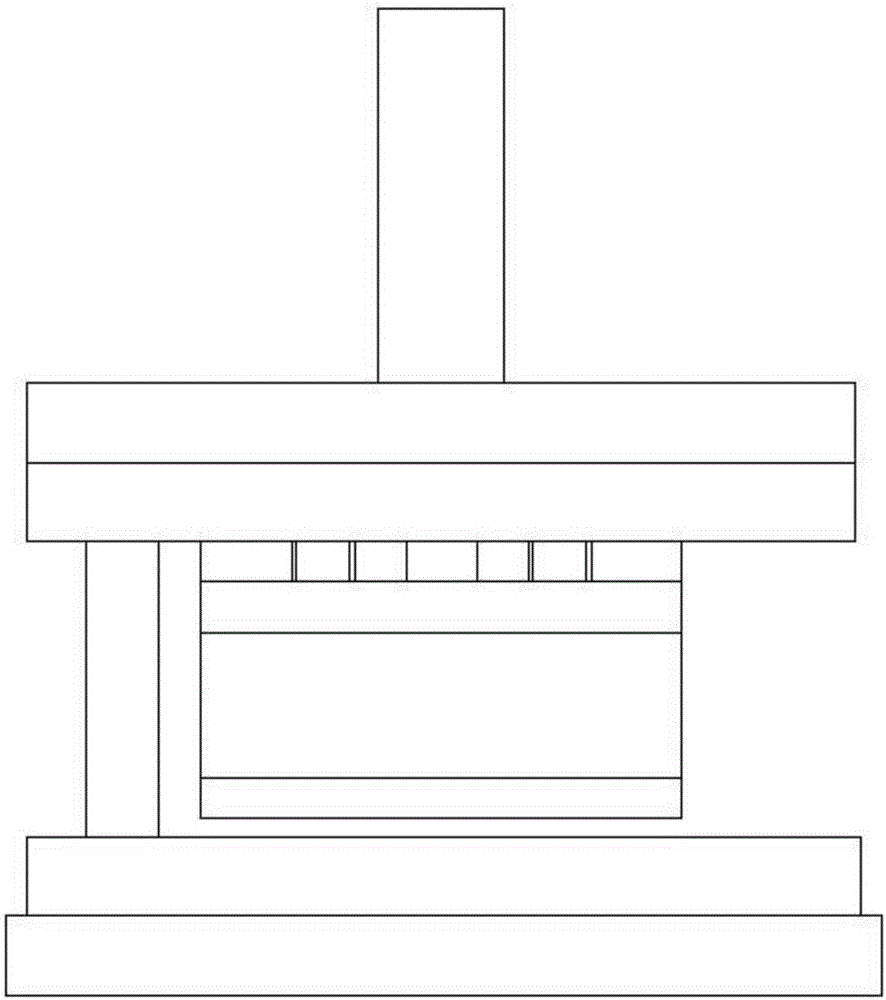

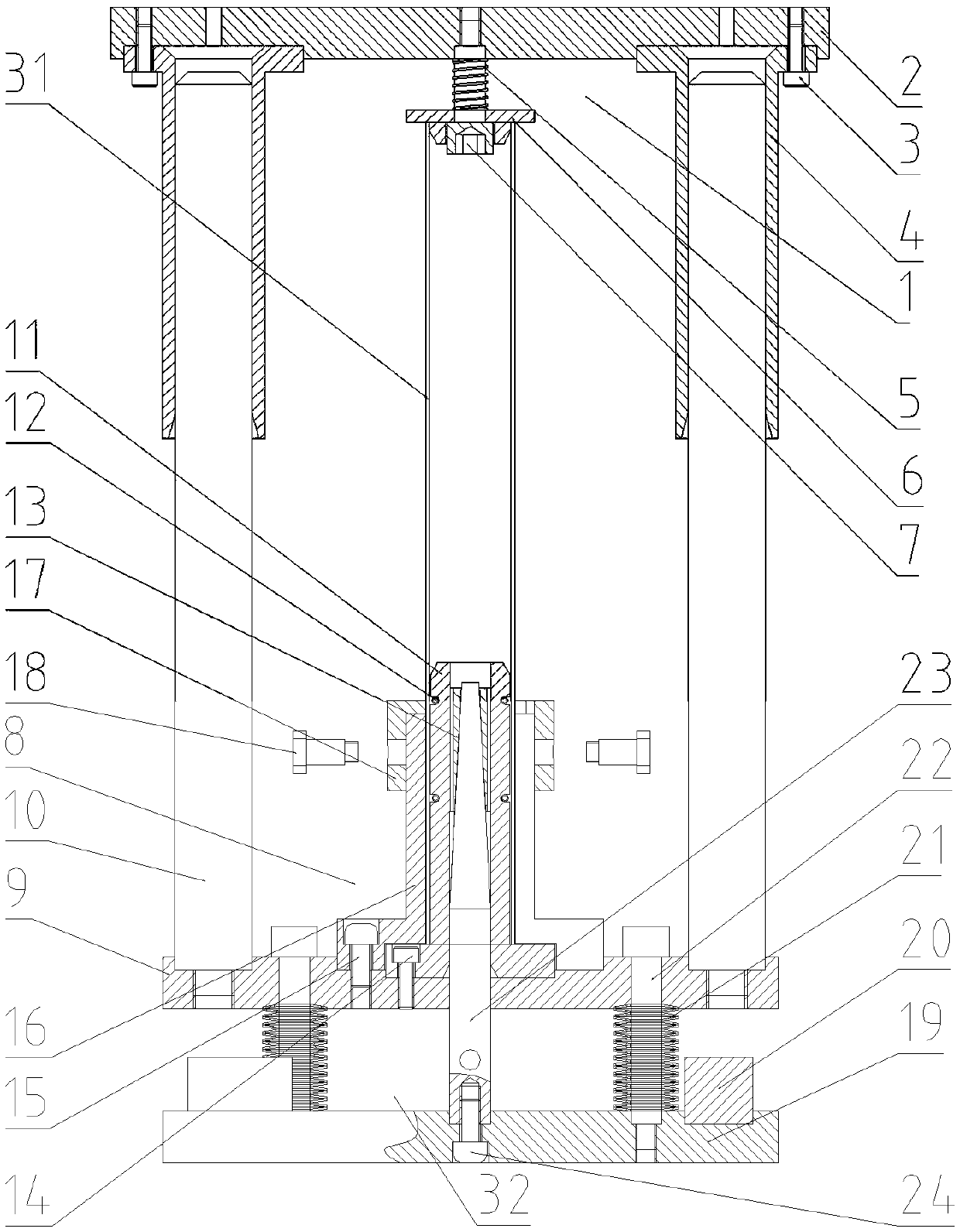

Vehicle shock absorber working cylinder expanding tool

PendingCN109985965AImprove machining accuracyQuality improvementShaping toolsVehicle componentsEngineeringIndustrial engineering

The invention relates to a vehicle shock absorber working cylinder expanding tool, which comprises an upper module, a lower module and a bottom module. The upper module is fixed to an upper jacking plate of a hydraulic machine, the bottom module is fixed to a workbench of the hydraulic machine, the bottom module is provided with an expanding rod with the conical top, and a male die seat is provided with a male die composed of three sections; through relative movement of the upper module, the lower module and the bottom module, the sectioned male die is jacked open through the conical expandingrod, and through matched using of a female die, a workpiece can be expanded to form the needed shape; and a to-be-machined working cylinder is automatically clamped, operation is easy, the time and labor are saved, and the machining quality is stable.

Owner:NANYANG XIJIAN AUTOMOBILE SHOCK ABSORBER

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com