Floating grinding device and method of steel jacket for side rolling resistant torsion bar device

A technology of anti-rolling torsion bar and steel sleeve, which is applied in the direction of grinding drive device, grinding machine tool parts, grinding/polishing equipment, etc. Small margin, damaged torsion arm and other problems, to achieve the effect of repairing the wavy floating of the outer diameter size, limited grinding contact force, and high grinding accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

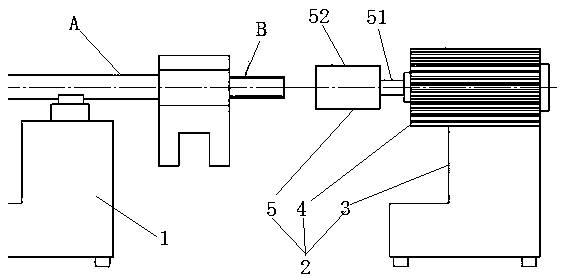

[0035] The following will be attached Figure 1~4 The present invention is further described with examples.

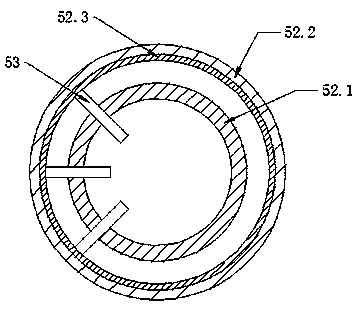

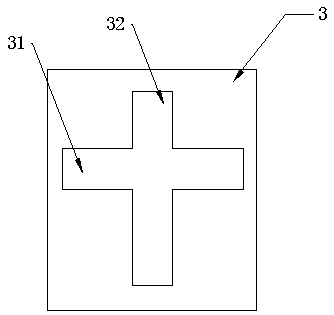

[0036] The steel sleeve floating grinding device for the anti-roll torsion bar device includes a support 1 horizontally supporting the torsion bar shaft A and a floating grinding assembly 2 for grinding the steel sleeve B on the torsion bar shaft A, and is characterized in that The floating grinding assembly 2 includes a motor base 3, a driving motor 4 mounted on the motor base 3 and capable of moving horizontally on the motor base 3, a circumferential grinding tool 5 coaxially installed on the rotating shaft of the driving motor 4, The central axis of the circumferential grinding tool 5 is at the same height as the central axis of the torsion bar shaft A, and the mobile drive motor 4 drives the circumferential grinding tool 5 to be set outside the steel sleeve B and coaxially aligned with the torsion bar shaft A. The grinding tool 5 is in elastic contact with the out...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com