Two-section angle pin

A two-stage, oblique pin technology, applied in the field of oblique pins, can solve problems such as the inability to demold the product and the trouble of mold design.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

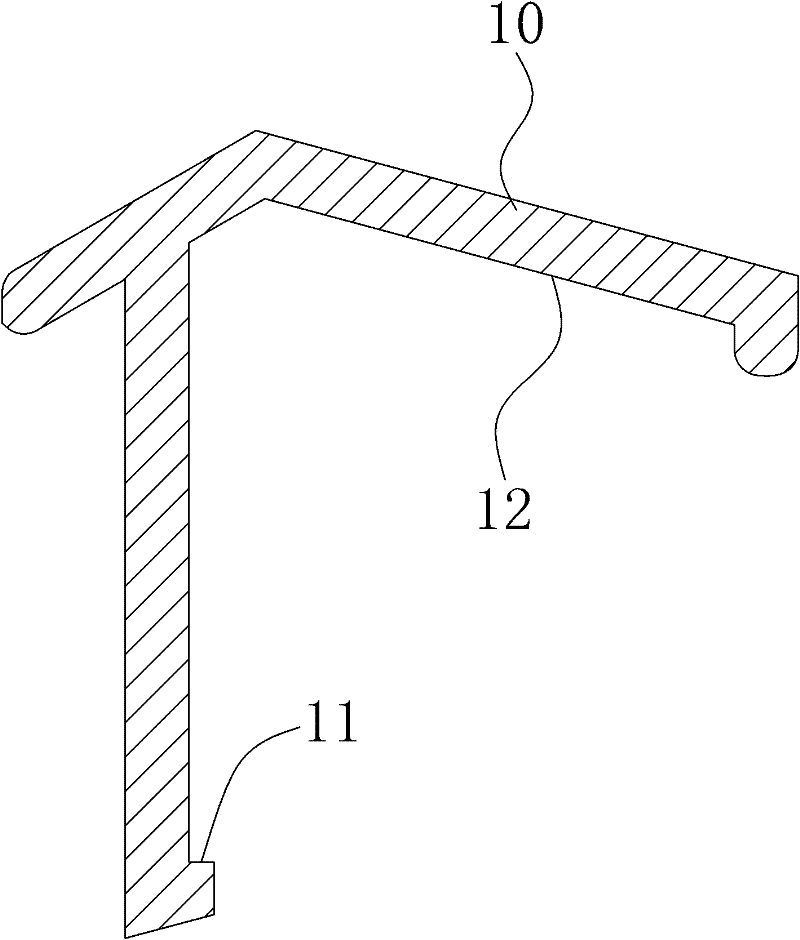

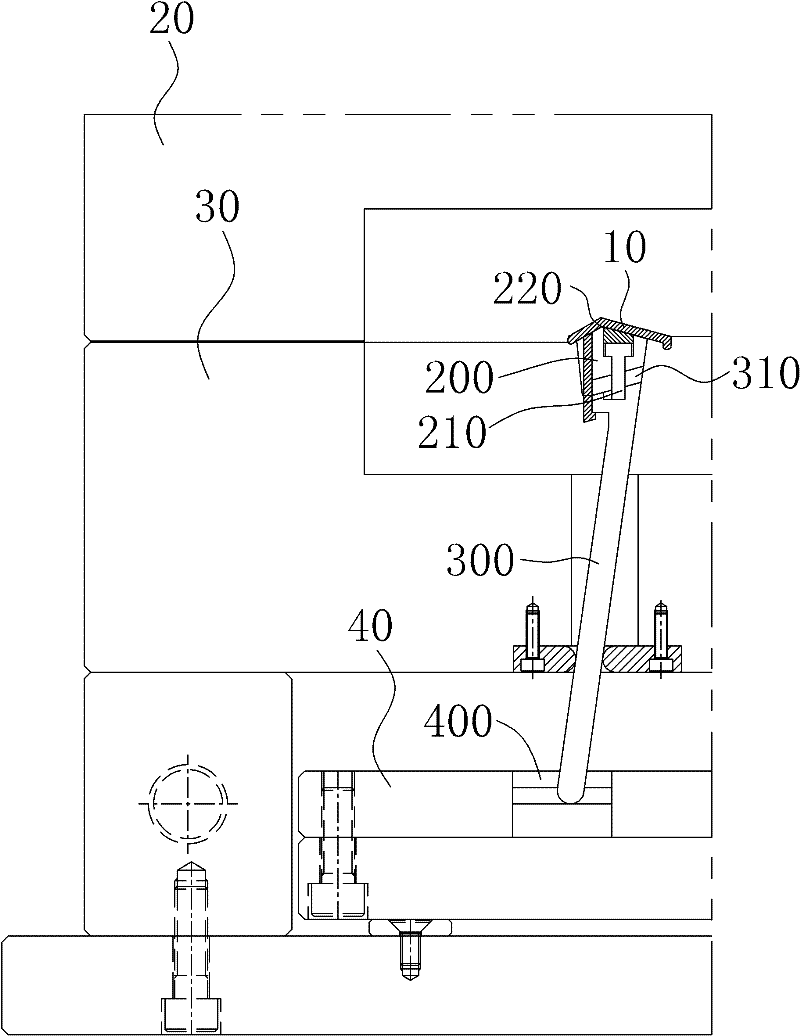

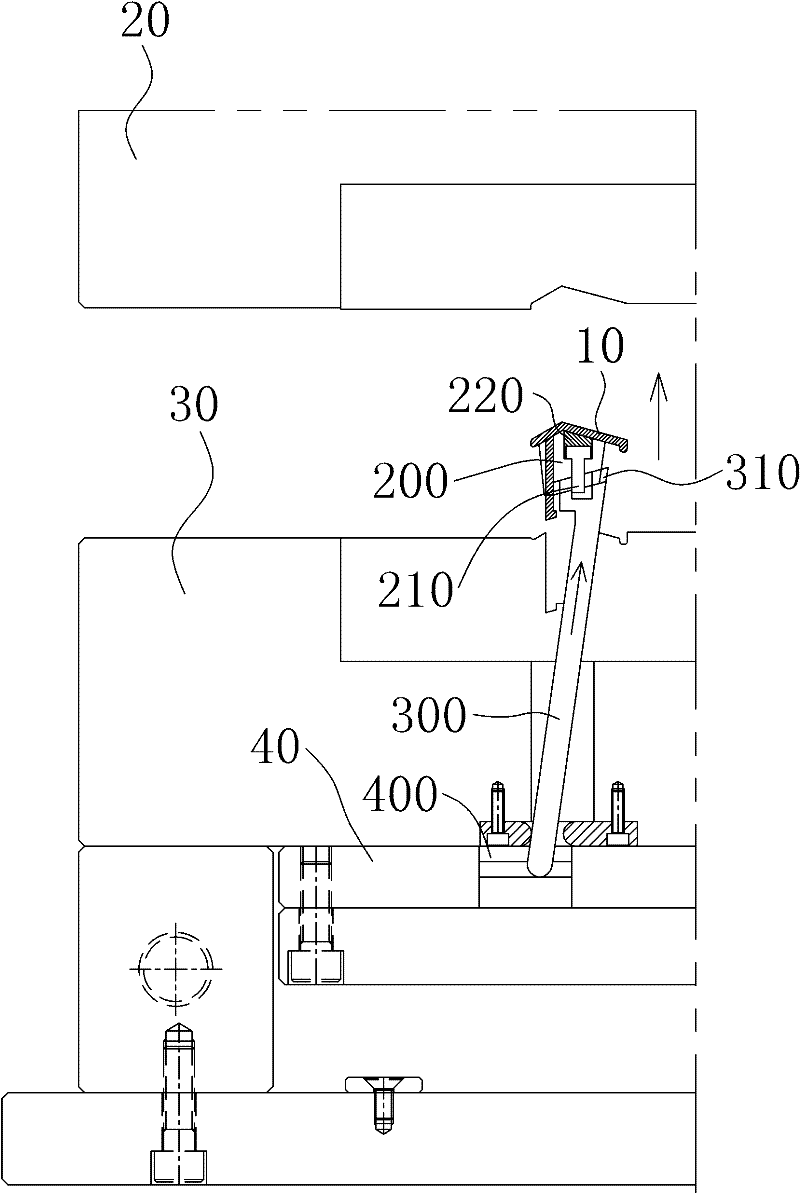

[0016] see figure 2 As shown, it depicts a schematic diagram of the mold clamping state of the two-stage oblique pin of the present invention. The two-stage oblique pin of the present invention is applied in a mold, and the two-stage oblique pin includes:

[0017] Slanted pin seat 400, which is located in the upper ejection plate 40 of the above-mentioned mould;

[0018] The first section of the oblique pin 300 has one end set on the above-mentioned oblique pin seat 400, and the other end is provided with a groove 310. In this embodiment, the groove 310 is a dovetail groove;

[0019] The second section of oblique pin 200, which is arranged on the above-mentioned first section of oblique pin 300, the second section of oblique pin 200 is provided with a stop pin 210, and one end of the stop pin 210 is arranged in the above-mentioned groove 310, and placed on the mold When the mold is closed, the stop pin 210 is in contact with one side of the groove 310 , and the second secti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com