Optical disk drive tray withdraw control method

A control method and a tray technology, which are applied in the directions of recording information storage, instruments, etc., can solve the problems such as the falling of the optical disc 30, the inability of the tray 20 to overcome the magnetic attraction force, and the inability to hold the optical disc 30.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

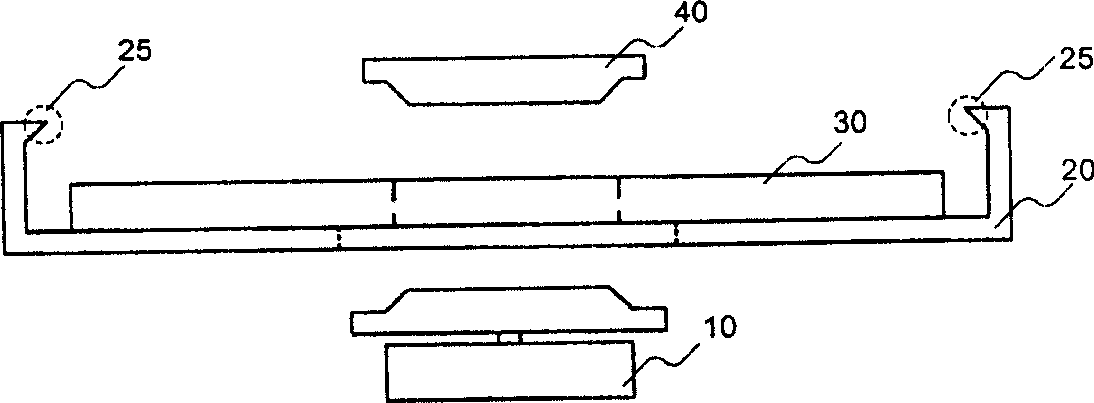

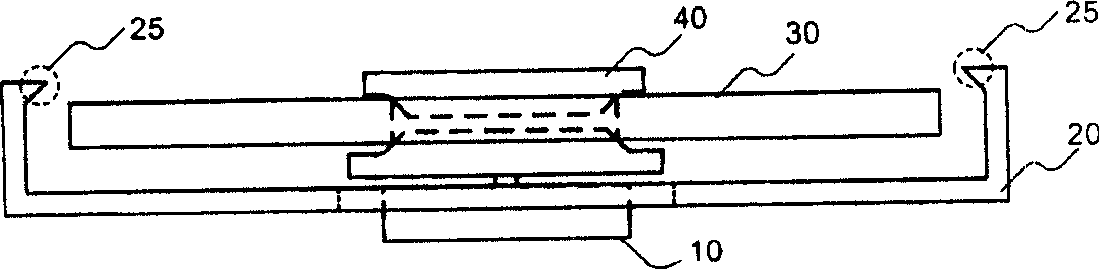

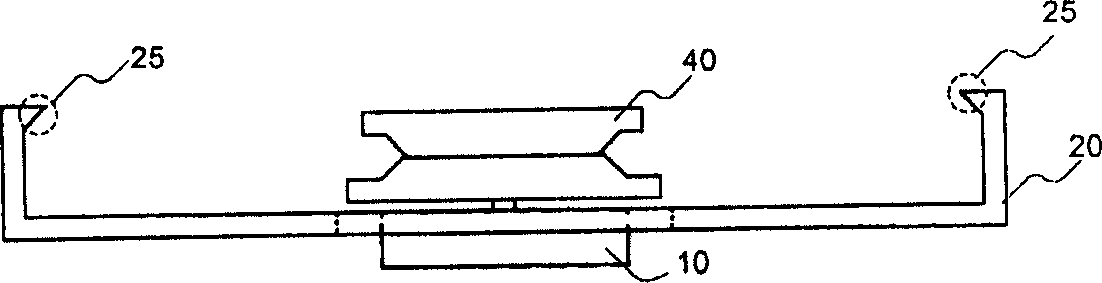

[0020] The present invention is an improvement on the situation that the optical disc 30 falls when the known vertically placed optical drive is unloaded. Please refer to Figure 2a and Figure 2b , which shows the waveform diagram of the ejection force of the tray of the optical drive of the present invention. Among them, the voltage (V) value represents the force applied to the pallet, and the higher the voltage, the greater the force.

[0021] Such as Figure 2a As shown in , it shows the tray ejection force waveform when an optical disc is placed in the optical drive of the present invention. When the optical drive places a disc and executes the eject operation, such as Figure 2a As shown, the exit force voltage of 6V is provided within the initial 20ms, and then the voltage of the exit force is changed to 3.4V until 200ms. The dotted line I displayed at 200ms means that the position of the tray is no longer affected by the attractive force of the permanent magnet at...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com